Introduction

This report presents a discussion on aluminum casting alloys. The report describes the source of materials in the manufacture of aluminum alloys, the manufacturing process, and the economic importance of the product. The engineering properties that make aluminum casting alloys preferred are also discussed in the report.

Sources of aluminum casting alloy materials

Processed aluminum is lightweight and can easily be transported to different destinations. However, aluminum is extracted from various materials. The method of extraction determines the type and source of raw materials. Aluminum alloy materials are classified into two sources: primary and secondary logs (Lumley, 2010). Primary sources of raw materials for aluminum casting alloys are naturally-occurring compounds. On the other hand, secondary sources of aluminum, which is often used in recycling, include scrap metal and prime.

Aluminum occurs naturally in the form of bauxite. Therefore, bauxite provides the most common and largest source of raw materials for manufacturing virgin aluminum. Five nations are prolific producers of bauxite. They include Australia, Brazil, China, and Guinea. Currently, Australia is the largest producer of bauxite, yielding 250% more bauxite than its closest rival. Apart from the production of virgin aluminum, which is expensive both to produce and sell, aluminum can also be processed from recycled materials (Lumley, 2010). Recycling aluminum is the most cost-effective way of retrieving the metal from scrap.

With minimal differences in the structural make-up of the recycled and virgin aluminum, the high demand for the metal has been met through the recycling process. According to Azom.com (2014)), it takes 14,000 kWh to produce 1 ton of aluminum from bauxite whereas only 700 kWh are required to recycle the same amount of aluminum from scrap metal. Therefore, the energy consumption aspect and concerns about the environment justify the use of recycled aluminum.

Engineering properties that make Aluminium Preferred

Aluminum is one of the most used non-ferrous metal in industrial and domestic applications. Aluminum facilitates the construction industry, transport sector, mechanical and electrical engineering, and design (Lumley, 2010). The metal is unique, in its engineering properties, which makes it preferable for use in various applications. The following are among the common engineering properties of aluminum:

- Corrosion-resistant and durable – According to Higgins (2010), aluminum metal is very resistant to corrosion, which makes it durable than other metals. The thin oxide coating on aluminum provides protection from chemical decomposition.

- Good conductors – Aluminium is an excellent electrical and thermal conductor. This makes it a good thermo-conductor and thus better in heavy industrial use.

- Aluminum alloys often blend better with the base metal and exhibit the basic characteristics of aluminum. These alloys can be molded into many shapes and forms, and thus the multiplicity of application.

- Excellent recyclability – Aluminium has excellent recycling capability and can be recycled many times over.

- Aluminum casting alloys can be given an artificial oxide layer that is resistant to water, using the ELOXAL process (Timelli & Bonollo, 2013).

The engineering characteristics of aluminum, and the many applications through which the metal can be used made it recyclable since time immemorial. Aluminum parts and its alloys are highly recyclable because the metal is extremely well-suited for re-melting.

Production Process

The aluminum alloy casting process begins with the sourcing of raw materials from different suppliers. Aluminum naturally occurs in the form of bauxite, the primary raw material from which the metal is processed (Higgins, 2010).

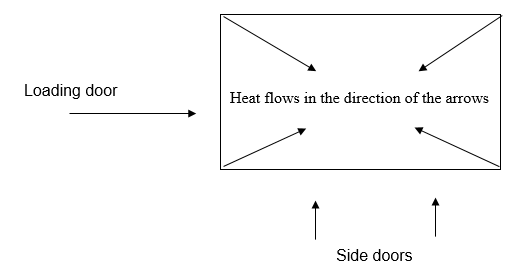

The raw material, bauxite, is prepared for production by the removal of impurities. A chemical process results in the production of alumina (aluminum oxide). The alumina is then mixed with sodium hydroxide solution, and passed through steady steam under high pressure to dissolve the aluminum oxide (Bonlalum.com, 2014). A blast furnace is used in this process. The casting equipment, through which the bauxite is passed consists of the pre-heat oven, the recuperator, front-end loader, and furnaces. The following diagram simplifies the process of purifying bauxite into alumina:

Impurities are filtered from the solution-form aluminum oxide through the process of filtration and filtration. The hot liquid solution is then allowed to cool, forming crystals of hydrated aluminum oxide.

The alumina crystals are then washed with water and dried in long rotary kilns (Higgins, 2010). The final clean and dry aluminum oxide is a very fine, crystalline compound that looks like sugar crystals. Aluminum is extracted from aluminum oxide through electrolysis. The alumina solution is electrolyzed in molten fluorides to make fine aluminum. The electrolysis process takes place in reduction pots, which are found in aluminum extraction plants.

Through electrolysis, high-quality final aluminum is produced. The reduction process reduces aluminum oxide to aluminum, eliminating the oxygen element from the oxide. It is interesting to note that alumina consists of an almost equal amount of oxygen as the aluminum component. This implies that one can extract one pound of pure aluminum from double the amount of alumina.

Production of aluminum alloys

The first step in alloy production is the addition of agents in recommended proportions into the furnace. The primary agents used in the preparation of aluminum cast alloys are scrape, prime, and hardeners, these consists of the charge (Bonlalum.com, 2014). These two elements are often pre-heated before being added to the furnace because of the explosion may occur if they contain moisture. The second stage is the degassing or fluxing stage. Degassing is the elimination of hydrogen elements from the molten metal (Higgins, 2010). Impure elements such as lithium, sodium, and alkaline are forced to precipitate.

Lastly, hardeners are added to the mixture to strengthen the resultant alloy. Before adding hardeners, samples are taken for spectrometer analysis (Timelli & Bonollo, 2013). The analysis evaluates element concentration in an alloy through comparative wavelength intensity analysis. Silicone and magnesium are added to the molten metal to act as hardeners.

Economic consideration

According to Aluminum.org (2014), the aluminum industry accounts for more than $150 billion of the US Gross Domestic Product (GDP). The industry has many economic impacts to any country involved in the production of aluminum. The following are the financial contributions of aluminum:

- Aluminum recycling produces significant value to the economy – apart from the increased value of production of virgin aluminum, recycling of the metal conserve energy by up to ninety percent savings.

- Job creation – In regions or nations where the manufacture of aluminum is evident, more job opportunities are created for the population. Primary manufacturing factories, smelting, and alloy production create numerous job opportunities for the population.

- Economic impact – the industry contributes towards the economic impact of the country by more than $60 billion. With suppliers and allied businesses, the overall contribution spills over $150 billion in economic impact (Aluminum.org, 2014).

Conclusion

This report has allowed us to discuss the subject of aluminum casting alloys. The report has established that aluminum casting alloys are better suited for use in many applications because of the positive characteristics of the metal. Recycling the metal is economically better than manufacturing virgin aluminum. There are many economic advantages of the metal, as discussed in this report.

References

Aluminum.org,. (2014). The Economic Impact of Aluminum: The Aluminum Association. Web.

Azom.com,. (2014). Aluminium – History, Sources, Properties, Forming and Products. Web.

Bonlalum.com,. (2014). Aluminum Casting Process – Casting Terminology. Web.

Higgins, R. A. (2010). Materials for engineers and technicians. London: Elsevier.

Lumley, R. (2010). Fundamentals of Aluminium Metallurgy (1st ed.). Burlington: Elsevier Science.

Timelli, G., & Bonollo, F. (2013). Quality mapping of aluminium alloy diecastings. Metallurgical Science and Tecnology, 26(1).