Introduction

Laser-Induced Breakdown Spectroscopy (LIBS) is widely used as an analytical method for the qualitative study of materials. It is based on focusing a laser pulse on the surface of the material under study, whereby the material is heated and plasmaized within a fraction of a second. In fact, the LIBS device has a two-pulse characteristic: the first laser pulse ablates the detachment of matter from the substance and the accompanying heating, and the subsequent second pulse is aimed at additional excitation of the plasma through the transfer of electrons to external valence orbitals. After the laser pulses are applied, the plasma with the excited atoms cools, which causes the electrons to be transferred to their former states; the energy released creates radiation, which is recorded by the detector and constructs a spectrogram. Each element in the Periodic System has unique transition energy of electrons, which allows LIBS to be used as a method of individual identification of substances in a material.

Discussion

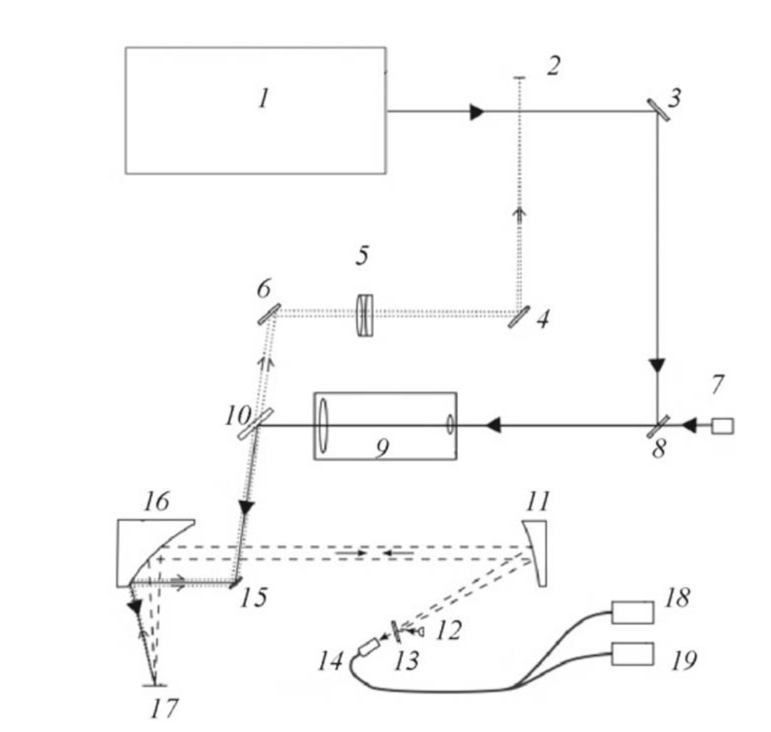

The basic principle of the LIBS spectrometer described above is based on the integrated optical circuit shown in Fig. 1. A two-pulse laser signal is applied from the laser 1, and along with the system of mirrors creating parallel-collinear beams, it reaches the object 17, whose radiation is recorded by the input sensor in the LIBS spectrometer 14. Laser unit 1 is equipped with two laser sources pumped by semiconductor diode arrays, a solution used to increase the overall stability of the system and the lifetime of the spectrometer. The laser pulse comes from source 1 and travels according to the optical path shown in Figure 1. Notably, the circuit uses parabolic mirrors 11 and 16 to focus the plane waves to form a focal spot. The beam hits the paraboloid 16 by reflecting off the mirror 15, generally located at an angle of 45° relative to the optical axis of the incident light. It is known that the size of the focal spot is the determining characteristic for specific plasma formation and excitation. For this reason, it is necessary that the laser beams emanate from the paraboloid at a strictly defined angle: for mirror 16, the angle is 90°, whereas, for mirror 11, it is 30°. A five-fold telescope 9 is also included in the setup to reduce the divergence of the laser beam coming from mirror 8. The need to minimize divergence is motivated by the desire to regulate the size of the optical spot. The focused laser beam converges at the inlet 14 to the spectrometer, where it is detected and analyzed by polychromatic spectrometers 18 and 19.

The analyzed object is mounted on the movable flat surface 17. The movable mechanism is realized along the vertical axis and allows controlling the focal distance to provide the best resolution of the spectral image. The laser beam focused on the object is reflected coaxially and spreads to the paraboloid mirror 16, from where it is reflected to the mirror 11. As can be seen from Fig. 1, the light reflected from the paraboloid 11 is brought together in the optical sensor 14. It can be seen that a small rotating mirror 13 and a green diode 12 are installed in front of the entrance to the optical fiber system of the spectrometer 14.

Conclusion

The installation of such a system is intended to provide additional illumination of the object surface, thus minimizing spectral imaging errors; however, if necessary, installations 12 and 13 are removed from the optical circuitry. The optical signal fed to the polychromators 18 and 19 is analyzed using CCD array detectors. The data are analyzed using the built-in LAEMS software.

Reference

Voropay, E. S., Gulis, I. M., Tarasau, D. S., Ermalitskaia, K. F., Samtsov, M. P., Radko, A.

E.,… & Kirsanov, A. A. (2021). Laser atomic emission spectrometer with achromatic optical system. Journal of Applied Spectroscopy, 88(3), 603-609.