Introduction

As it is, the system keeps tabs on inventory sales and orders placed by clients via the web. The store itself doubles as the warehouse for this system. All in-store purchases are immediately reflected in the inventory tracking system with a manual update. The online store’s automated system handles the entire process from placing an order to receiving the product, including any necessary follow-up with the clientele.

The process begins with a customer placing an order, which is processed after it is placed online by sending a charge to the fulfillment center (Kabadurmus et al., 2022). A feedback loop is created when a purchase is sent from an e-commerce platform to a fulfillment center. In the warehouse, a worker tracks the item and any others that might have been part of the order using an internal system. The cycle is closed when an item is taken from storage and delivered to the fulfillment center.

The warehouse staff member updates the stock system after sending the order to the fulfillment center. Expected customers in the future can use the online shop system to see if a product they want is in stock (Kabadurmus et al., 2022). When the order is processed, there is another unintentional loop in the system when the order is transferred from inventory to the fulfillment center. As soon as the order is ready in the fulfillment center, the shipping order is made, and the box is prepared for transport. Once the order is labeled and wrapped, and sent out for delivery. When a new order came through, the process began again. Customer service and ongoing assistance that continues even after a sale have been completed ensures happy customers and shows the company cares about them from the very beginning of a transaction to its very end.

Recommendation

I think the system may benefit from an upgraded inventory tracking mechanism, so I propose updating the current system. Another piece of advice is that the business acquires shipment monitoring software. As far as I can tell, the only way to ensure that inventory is always accurate is to connect the point-of-sale system to the warehouse store directly. Because of this, the warehouse manager no longer needs to enter sales data into the store’s database manually. Cin7 is a cloud-based record-tracking application that would be useful for the organization in keeping track of warehouse stock, orders, and retail and online deals. That way, the inventory system, and online platform can keep a complete and correct tally. We should expect a more streamlined and productive business because of these adjustments. In this situation, a feedback loop exists.

The current system shows alignments of discrepancies. Employees at the company share a single computer used for everything from managing inventories to keeping tabs on packages in transit. When multiple, diverse employees work toward the same goal for various consumers, delays are inevitable (De Vass, Shee, & Miah, 2021). When one worker is waiting for another to finish their work so they can search the inventory of a commodity for a retail store, everyone else must wait. Customers may become frustrated with the current system since inventory levels are not updated promptly. Companies risk losing clients for inferior reasons if they fail to update their inventories promptly, which prevents customers from obtaining products that are advertised as being in stock but are out of stock. Jobs need to be reorganized and rethought to maximize productivity in the workplace.

Maintenance of a system’s effectiveness. Further, I propose that more computers be purchased so that all the business’s systems may function more efficiently. By incorporating additional computers into the network, we can speed up the rate at which work gets done and, in turn, update the stock system. According to De Vass et al. (2021), warehouse workers may need to split into three groups, each with their own set of computers but working in tandem to manage the warehouse’s current infrastructure. The first group will oversee updating orders that have been culled from online and offline outlets, tracking down products based on consumer purchases, and scouring stockrooms.

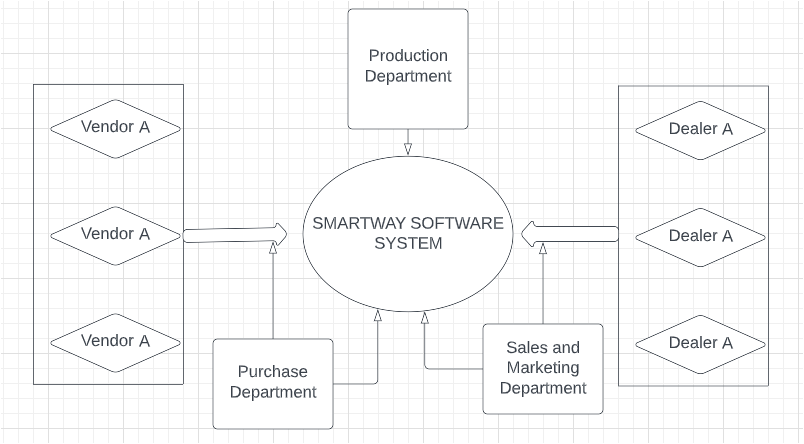

The three departments that make up Lost Pine Outfitter’s SCM are outlined below. With specialized legacy software being used by each division, information must be manually transferred from one system to another, making the workflow slow and cumbersome and requiring a lot of employee time. While the sales and marketing departments oversee keeping an eye on the dealers, production oversees the manufacturing process. In addition, managing suppliers is the responsibility of the purchasing division.

Considering the preceding, I propose that Lost Pine Outfitters adopt integrated SCM software to streamline its business operations and take advantage of the technical improvements provided by the Integrated Software solution. Below, I have outlined some of Smartway SCM’s most prominent objectives;

- Fully automated to eliminate human error.

- Better service for employees and consumers is assured, and at least four person-hours will be saved by eliminating duplication of effort.

- It is easier to work together, which improves coordination

- Handoffs across departments are now transparent and automatic

- The increased profitability of the business is a direct result of the cost-effective solution.

- The Current Workflow is Simplified.

Modeling

In the following Visio diagrams, I have attempted to visually represent the SmartWay SCM workflow as shown in Figure 1 below;

Conclusion

The ability to recognize problems inside an existing system is a major benefit of system thinking in a business setting. I could examine the challenges thanks to my use of System thinking. I proposed alternatives to help the business update its system. The corporation will be better able to keep track of its stock levels if it maintains a steady schedule of software updates and makes that software available to all its employees. Users of this system, including stores and e-commerce sites, will have access to accurate stock information. Compared to doing things manually, this will save time and allow management to concentrate on other aspects of the firm. By implementing the SmartWay mentioned above SCM, Lost Pines Outfitters’ operating workflow will be technologically improved from the existing individual legacy systems, and real-time analytics will be guaranteed at a minimum cost.

References

De Vass, T., Shee, H., & Miah, S. J. (2021). Iot in supply chain management: a narrative on retail sector sustainability. International Journal of Logistics Research and Applications, 24(6), 605-624. Web.

Kabadurmus, O., Kayikci, Y., Demir, S., & Koc, B. (2022). During outbreaks, a data-driven decision support system with smart packaging in grocery store supply chains. Socio-Economic Planning Sciences, 101417. Web.