Introduction

Competitiveness is increasingly becoming a necessity for companies that want to excel in this competitive world. Most production companies have employed various mechanisms to enable them maximize their profitability.

However, this has become difficult as more competitors come into play, in effect, restricting such improvements on manufacturing cost reduction rather than on increasing the prices of finished products. Among the processes involved, is ensuring a proper facility layout, which is essential in providing high quality finished products at a lower production cost. Facility layout involves the physical arrangement of all elements required for production of goods.

When this is done, the processes involved takes less time, minimizing cost of production and hence enhancing quality of goods produced. This is essential in promoting efficiency and production cost reduction which is instrumental to the creation and sustenance of competitive edge. This paper will explore case study of a small medium industry to investigate the best facility layout using interactive WITNESS software (Roslin 412-421).

Company Background

The case study was done on Dinamika Pelumas Sdn., which manufactures solvent and lubricant. This company was started in 2007 and is categorized as a (SMI) small medium industry. The industry is located in Malaysia and manufactures various kinds of products; these include metal working fluids, oil for the compressors, gear, hydraulic and engines, which include marine types.

Other products include synthetic oil, automotive as well as industrial oil; they also manufacture greases which are essential in the automotive industry. Facility layout is very important in production; this is because it enables clear and concise planning to produce high quality products.

SMI industries such as Dinamika Pelumas produce various types of automotive products and they therefore require a proper layout facility to facilitate a progressive production. In this regard, the case study explores various ways through which the best facility layout would be chosen to improve production (Roslin 412-421).

Data Collection

The process of production is divided into two, the one which involves manufacturing and preparation of the lubricant, while the other process involves its filling and packaging. The company has an area of about 1081.5 square feet which is reserved for production. Facility layout involves arrangement of the equipment required for production in that area.

To achieve this, the equipment needs to be collected and placed in their designed positions. This equipment includes various machines, containers, worktables as well as tanks. The company redesigned their ways of production to the more effective (MTO) made-to-order method, in which products are produced on order. This helps in influencing the cycle of production process, which is closely aligned to the customer orders.

This is mainly done because of the small area of production which restricts storage of finished products for more than 24 hours after completing the process of manufacturing. These products are usually delivered straight to customers immediately after production (Roslin 412-421).

In laying out the flow pattern, three considerations can be followed. These include the need to minimize overall cost of implementing the flow pattern, desire to maximize direction of flow paths and the company’s endeavor to minimize length of flow path. These are aimed at mitigating on backtracking flow as well as stopping interruptions that may occur during process flows. The required kind of flow is that which allows effective pattern of flow path from initial point all the way to final station.

Due to inadequate space as well as limitations on the fix location of the two large oil base tanks which are near the big door (main door), two patterns or facility layout designs were employed. These were the Straight line flow as well as the U-shaped flow in the second and first halves of process respectively. In essence, design layout1 was U-shaped, while the design layout2 was S-shaped (Roslin 412-421).

Results and Discussion

The design layout which is proposed for this production line is one where facility layout is placed in accordance with the standardized sequence of activities, operations as well as production tasks.

The layout design also depends on the specific product types manufactured by the company. In this case, only one product is considered, and this is lubricant. The other special machines such the blending machine, induction sealing machine along with filling machine are arranged in a fixed lace that would match the specific processing requirements of the product.

Two facilitation layouts have been designed in accordance with the collected data. Difference is only encountered in the ground floor (First layer), while similarity is mainly in the second floor. The first design involves combination of U-shaped and Straight line flow pattern. The latter is utilized in the second half of the flow pattern while the former is used in the first half of the process. The figure 1 below shows equipment located in the production area (Roslin 412-421).

Fig. 1 Equipment located in the production area

Source: Roslin

Fig. 2 Precedence Diagram Solution using Longest Work-Element Time Rule.

Source: Roslin

Comparison of two Alternative Designs

By comparing the two layouts designs, it is found that the more preferable of the two is the U-shaped flow pattern. This is mainly because the length of flow path is shorter i.e. 37 ft. as compared to the other flow pattern, whose length is 46 ft. This is helpful in increasing the rate of production as it reduces the throughout time. Furthermore, U-shaped flow pattern provides a wider aisle space area than in the S-shaped design (2 ft.).

This extra space provides the company with space for material handling purposes. For instance, it can be used as a path for forklift. In choosing the best layout, prioritization matrix was used and the layout with the highest results chosen. This is a brainstorming exercise that puts in place requirements of the company as well as planers’ choice. U-shaped flow pattern scored 236 points, which was higher than that of Straight-line pattern which scored 200 points (Roslin 412-421).

WITNESS Simulation

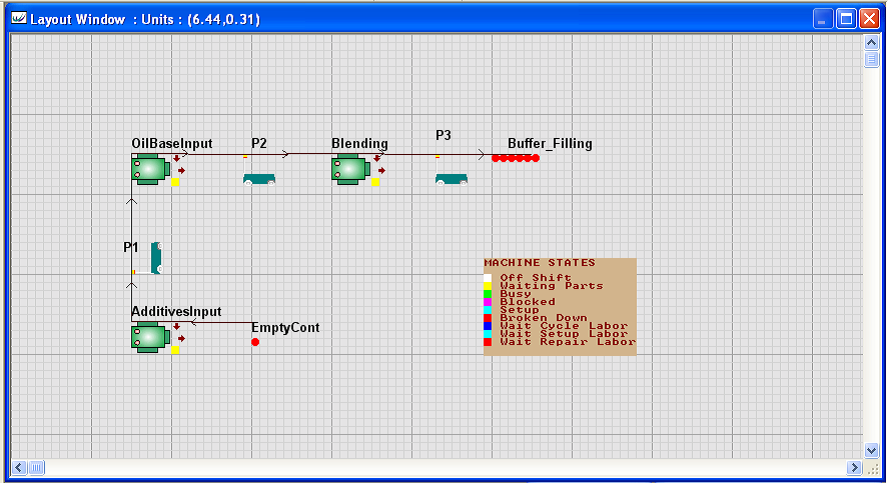

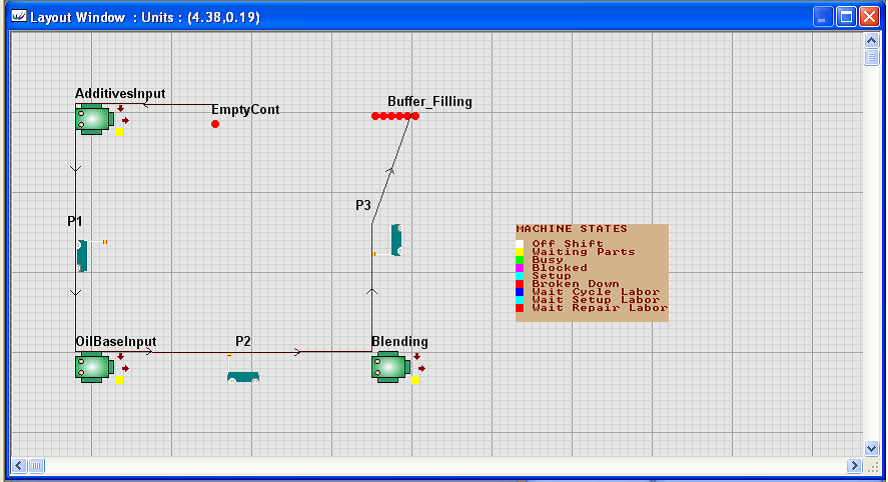

This is simulation software employed in determining line efficiency of the designed layout. It is built on WITNESS window and is also based on arrangement of workstations in the new layout design. The model balancing is according to CMOM along with manual calculations. The U-shaped model and S-shaped models are as shown in the figures 3 and 4 below (Roslin 412-421).

U-shaped flow pattern design for the first half of the process as shown in the WITNESS window

Source: Roslin

S-shaped flow pattern design for the first half of the process as shown in the WITNESS window

Source: Roslin

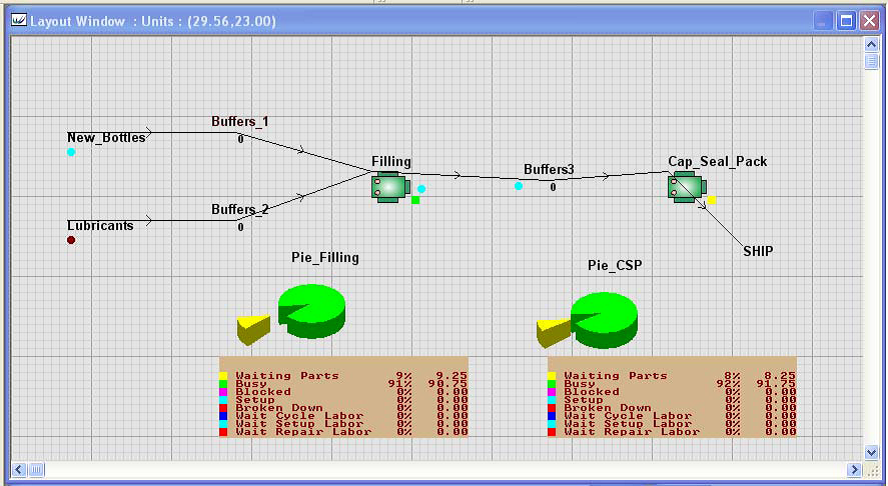

Fig. 5 shows a Straight Line flow pattern as shown in the WITNESS window

Source: Roslin

Simulation Results

The simulation results show that the line of efficiency of U-shaped pattern is better than that of S-shaped pattern. This is well portrayed in the Idle and Busy percentage score in which U-shaped flow scores higher. In addition, the overall path travelled by the U-shaped pattern is less than that of S-shaped pattern (Roslin 412-421).

Conclusion and Recommendation

The study was aimed at establishing the best facility layout model for the lubricant manufacturing company. WITNESS software was utilized in analyzing as well as simulating the model build. This model build was structured in accordance with the two new alternatives for flow pattern layout.

These layouts were U-shaped and S-shaped flow pattern. The solutions resulted in a higher score for U-shaped flow pattern as compared to the S-shaped flow pattern. U-shaped flow pattern is therefore the best design layout and should be chosen by the company for implementation in their production line (Roslin 412-421). This is because it will enhance their production rate as well as reduce the throughout time.

Work Cited

Roslin, Eida. “A Study on Facility Layout in Manufacturing Production Line Using WITNESS”. APIEMS 2008 Proceedings of The 9th Asia Pacific Industrial Engineering & Management Systems Conference. 2008. Print.