Introduction

The company under analysis is Johnson and Johnson – a health and personal care product manufacturer. The firm’s mission statement can be found in its credo, which is a lengthy explanation of the firm’s mission. In the credo, the organization asserts that it gives precedence to the needs of its customers, who range from parents and their children to nurses, patients, and doctors.

Furthermore, it intends on maintaining a sufficient profit by new product development and superior production processes. The company’s vision can also be deduced from the credo, which is to meet customer needs by offering them an excellent experience.

At the same time, Johnson and Johnson (JnJ) also intends on meeting its communal responsibilities through environmental conservation and community support. It asserts that the company will take ownership of problems as soon as they arise.

The corporate structure in Johnson and Johnson is product–based. At the top, of the corporate structure is the company CEO; the Board of Directors supports him. After this level, the company has three key positions, which consist of consumer healthcare, medical devices, and diagnostics and pharmaceuticals.

Under consumer health care, one can find the following franchises: baby care, skin and hair care, topical care, women’s health, nutritional and over-the-counter medicines. Under the medical devices and diagnostics position, one can find Virco (a biotechnology firm dedicated to infectious disease management).

Ortho clinical diagnostics (test development), lifescan (diabetes products), and JnJ Vision care (contact lens manufacturer) are others. Ethicon-endo surgery (surgical devices), Ethicon (surgical stitches), DePuy (orthopedics products), Cordis (vascular disease technology), Animas (diabetes lifestyle care) and advanced sterilized products also fall in this group.

The third category of pharmaceuticals consists of dermatological, immunological, oncological, gastrointestinal, contraceptive, neurological, pain management and other categories of products, as well.

JnJ has a decentralized decision structure; consequently, all the components of the corporate structure are like franchises. As such, each franchise head has the capacity to make his or her own decisions in order to meet the needs of his or her customers (Johnson and Johnson, 2012).

Since each of the smaller franchises is part of a larger firm, that is; JnJ, then they also depend on decisions from members of the upper level of the corporate structure.

Executives decide on the creation of new business portfolios. They also make a number of strategic decisions such as green manufacture, resource allocation and crisis response. Alternatively, different segments of the organization transfer new marketing discoveries, manufacturing innovations, and technological breakthroughs to other segments.

This paper will focus on mass (manufacturing) customization of the Consumer health care products at Johnson and Johnson. It will summarize the principles behind manufacturing customization, the changes that Johnson and Johnson must make in order to introduce this concept and how to deal with interruptions and challenges during implementation.

The paper will be crucial to the success of the company because it will give it a source of competitive advantage. Some products sold in the ‘Consumer care’ section of the firm’s structure can be easily customized by clients.

Most of the clients may have preferences for certain features, scents and colors, so it makes sense if companies give them the right to select these attributes for themselves. It will highlight how other firms can use customization of production to create flexibility. This is a new trend that advocates for the shift from large scale production to consumer oriented production.

Discussion

Literature illustrates that manufacturing customization may seem contradictory at first (Duray, 2002). Mass manufacturing provides advantages which were the exact opposite of the crafted and personalized industry. Companies chose mass production in order to take advantage of the economies of scale so as to offer their products at low prices.

Small enterprises opted to remain as such in order to create unique and customized products. However, it is now possible to combine both these futures in operations management. Prominent organizations such as Dell, General Motors, Proctor and Gamble are at the forefront of this movement. It is because of these choices that such organizations have stayed ahead of the game.

Many firms have considered these alternatives because mass production has a number of impediments. First, it leaves room for superior product improvement. In mass production, most firms blanket consumer requirements in one large group; there is no mechanism for understanding individual customer needs.

However, customization of manufacturing allows companies to place customers at the center of product development. In mass production, product design occurs internally while manufacturing customization facilitates point of sale product design; it is no longer internal.

Product differentiation is time delimited in mass production, but the same is not true in mass customization. Here, only the customer’s ideas will be at the center of such a process. Therefore, the most significant advantage of mass customization is that it gives clients the satisfaction of consuming something that they partly created.

Review

Silveira et al. (2001) explain that organizations need to have a culture of knowledge sharing before mass customization can be implemented. Since this is already true in JnJ, then the company would be ideal for the solution. Effective customization can only be done well when the right technology and value chains exist. Companies need to take on the strategy when they have products that can be customized.

Consumer products are the best because they add value at the point of consumption. Products must possess alterable feature, as well. Before a company takes on this practice, it must ensure that the market is ready for mass customization. Other organizations like Proctor and Gamble are already doing it, so this is the right time to implement it.

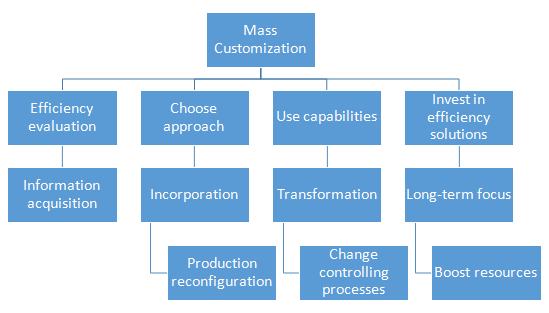

In order for Johnson and Johnson to implement this process effectively, it must start with an evaluation of its efficiency. Since the company will only provide customization for one product portfolio, then it needs to look at its level of efficiency. The organization ought to know the supply changes, the stock changes and other operational management issues that require improvement.

This will prevent the organization from repeating the same mistakes in the new customization program. After an analysis, JnJ will need to decide on its approach. Mass customization may take many forms. Sometimes it may be done partly by involving customers in only some parts of production, or it may involve getting their input in different parts of the production process.

Once the business has a clear approach, then it must use its existing capabilities. Some of the tasks that workers carry out in the corporation already are under great improvement. The fourth step before implementation of mass customization is to invest in solutions that would increase efficiency especially since the firm will introduce a batch-like process to the mix.

This company ought to perceive this process holistically rather than as a function of operations management alone (Zilber and Nohara, 2009). However, this will not be very difficult for JnJ because the organization’s corporate strategy is already in tandem with this approach.

The company has a deep commitment to its clients’ needs, so placing them at the centre of their operational decisions, as in mass customization, will not contradict this approach.

Prior to implementation, the initiators must win the support of the rest of the Consumer care department. Unless there is a clear understanding of the relationship between mass customization and tangible returns, then the rest of the company will not implement it whole heartedly.

Implementation should commence with the acquisition phase. Here, the client will give information about his desired product. The company must find a way of tying this information with all facets of its operations. It must trace the exact areas that can lead to a different outcome, then start working on it.

After the acquisition of knowledge, the business must then incorporate the external information into its internal processes so as to create value. Here, the company will effectively place the client at the centre of the manufacturing process. Incorporation precedes transformation, which entails changing the company designs and routines so as to combine the new consumer-based knowledge with the former one.

After transformation has occurred, the JnJ must develop a long-term orientation towards mass customization. It must keep soliciting information and taking it through the above mentioned processes. Shown below is a chart that will guide JnJ through mass customization.

Key:

Level 2: preparation for the implementation of mass customization at JnJ

Level 3: Implementation of mass customization at JnJ

Level 4: post implementation processes in mass customization at JnJ

To boost outcomes or results from mass customization, the company needs to have additional equipments, stock and human resources in order to handle variations inherent in such a system. This may occur as a result of irregular changes in product mixes or alterations in product diversification.

One may, therefore, assert that flexibility in volume capability, customer delivery, manufacturing processes and product mix can only be improved by stepping up these resources during mass customization.

In addition to ample resources, the company needs to reconfigure it production plans readily owing to the rapid changes in demand. Lastly, the company will need to implement network controls during mass customization. It is quite difficult for the organization to use a fixed method of control in such a strategy, so it should be willing to alter this.

Conclusion

The literature illustrated that mass customization is a new source of competitive advantage. However for success to occur, companies must understand their capacities and processes. The market needs to be ready and the nature of products should be customizable; JnJ fits this description perfectly. Implementation should start with acquisition then information, transformation and long term advantage.

JnJ should consider thus approach for its Customer care products because those ones can be easily customized. The organization will need to revamp its resources, its product configuration and its control mechanisms so as to achieve tangible results from mass customization.

References

Duray, R. (2002). Mass customization origins: mass or custom manufacturing? International Journal of Operations and Production Management 22(3), 314-328.

Johnson and Johnson (2012). J&J Management approach. Web.

Silveira, G., Borenstein, D. & Fogliatto, F. (2001). Mass customization: Literature review and research directions. International Journal of production Economics 72(1), 1-13.

Zilber, S. & Nohara, J. (2009). Mass customization and strategic benefits: A case study in Brazil. The Electronic Journal on Information Systems in Developing Countries 36(5), 1-26.