The six-sigma technique as applied by DUCAB Company

The six-sigma methodology is a structured procedure for change management that leads to the improvement of activities. It entails approaches of Define-Measure-Analyse-Design-Verify (DMADV) (Linderman 2006). The DUCAB Manufacturing Company is well known for its cable material manufacturing in the UAE region.

The company has been implementing the six-sigma technique in its change management and process. A six-sigma model is a system that is comprehensively used by most management to ensure sustainability and maximisation of operations.

The primary aim of using the six-sigma model is to ensure the improvement of manufacturing quality for consumer satisfaction and reduction of the overall production costs. It also ensures that a company gains a competitive advantage in the market.

The Phases of the Implementation of the six-Sigma Technique in DUCAB

The DUCAB Company implements the six-sigma technique mainly in two phases. The first phase involves the training of the techniques and procedures that are required for the ‘black belts’. Another activity that is carried out in this phase is project improvement that can combine several projects at the same time.

The definition of the project activities and identification of goals are also accomplished. The need for change is explained to the staff.

Phase 2 involves the controlling and maintenance of the improvement levels that have been achieved in the first phase. Training is also done in details to ensure accuracy and quality improvement (Linderman 2006).

The DUCAB Company’s management has ensured a twelve-stage procedure of the six-sigma approaches to ensure efficient implementation of the technique.

The first stage is the development and composition of various teams of five or seven competent employees (Linderman 2006).

The selected teams are trained in the second stage to master the Deming Circle of development methods, analysis procedures, and relevant tools that are required. The analysis tools are used for gathering information and bringing about solutions to any change issues that arise.

The third stage is the identification of an opportunity for improvement. The opportunities are identified by determining the customer needs and preferences. Upon identification of such needs, the management ensures that the customer expectations are exceeded to ensure a repeat business.

The fourth stage entails gathering information on the process that is to be accomplished. The company ensures that it establishes particular metrics to be used for obtaining the baseline information on the performance of the process and problem identification.

Next is the analysis stage. It clearly identifies the cause of an issue. The causes are then confirmed statistically to provide concrete evidences for the changes to be effected.

In the sixth stage, the problems are brainstormed in details after which solutions are executed in the next stage. From the several solutions and interventions, the management ensures that a best option is adopted through efficient leadership practices and change guidelines.

In stage nine, the management determines the suitable mechanisms and procedures for implementing the best option for change. If such option is applicable, the employees are trained thoroughly to ensure its effective implementation. The solution procedures are executed and documented for future reference.

A follow-up is also done to ensure the sustainability of the process. To ensure that the company delivers products of greater value to customers, the value chain is organised critically in manner that underpins the implementation process.

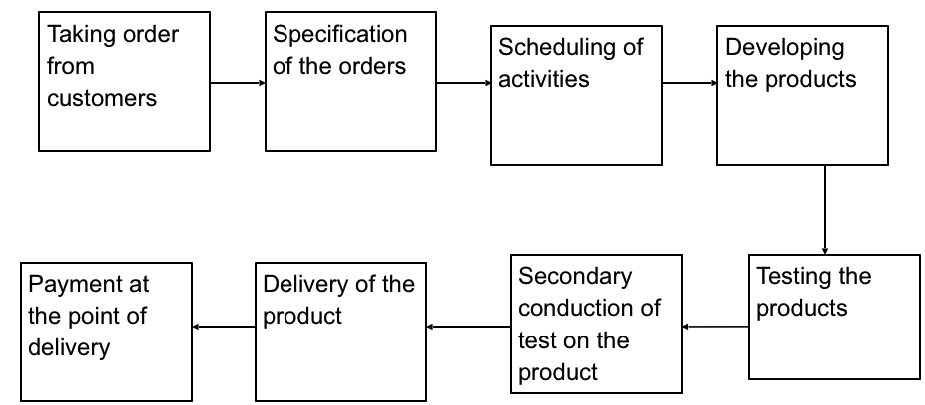

Figure 1: The Company’s Value Chain

The figure clear depicts that the process involved in the production and service delivery is longer and cumbersome. As a result, a straight process that is easier to handle is required to manage the company’s value chain efficiently.

Problems and Weaknesses exhibited using the Six-Sigma Technique in the DUCAB Company

Inadequate Technical Capacities

The technical capacities that are implemented in the six-sigma technique are not up-to-date; hence, the strategy is seen as ineffective to execute change management successfully.

This situation perceived in terms of the wastages that are incurred during training and delivery of products among others. Most researchers also attest that more time is spent in processes that bear insignificant profits.

Employee Reliance on Reward System

A gap is exhibited in the six-sigma methodology whereby employees’ motivation and promotion are done based on their hard work. The employees are motivated to work extra hard to meet their targets.

A problem of misunderstanding the six-sigma concept can arise amongst the employees. Some employees fail to deliver quality outcomes; hence, their promotion chances diminish (Linderman et al. 2006).

Lack of Innovation

The six-sigma methodology is viewed as simply a repackaging of the obvious quality management (QM) methods. This process normally leaves most managers in a dilemma. Upon failure to adopt the six-sigma model, the company risks losing the opportunity to gain more benefits and market shares.

On the other side, if the six-sigma method is not considered in the QM technique, there will be absence of new practices that should be implemented by the DUCAB Company to improve the change processes and systems (Näslund 2008).

Addressing the Gaps that exist in the Six-Sigma Methodology

Most managers need to understand the various techniques and procedures that are entailed in the six-sigma methodology deeply. Change management and processes need two major constructive decisions to be in place.

The first decision entails what is supposed to be done while the second encompasses what should be carried out (Näslund 2008). The report outlines three crucial assumptions that should be implemented in the QM and change management processes.

The first approach to the six-sigma model is that the methodology should be treated as a control program that has a wider base. The system is far greater than the mere traditional approaches of QM where the internal teams are used to solve daily problems within a department that solve single problems at a time.

The methodology embraces the overhaul change of the entire process that covers productivity, communication, external services, and staff involvement.

The second approach should be the combination of the six-sigma methodology with other approaches such as lean six-sigma and/or lean manufacturing techniques. The processes will ensure the effective reduction of wastages in terms of time and other resources.

The combination also brings about improvement in the various processes (Arnheiter & Maleyeff 2005). Many companies currently embrace the lean six-sigma approach to change management to ensure continuous improvement.

Managers should further understand the interactions that exist between the six-sigma methodology and other techniques with a view of ensuring excellence (Davison & Al-Shaghan 2007). Lastly, the methodology should be viewed as an approach to change management rather than the traditional approach to QM.

This viewpoint can help managers ensure improved ways of its implementation and analysis of the necessities for change management processes (Zu, Fredendall, & Douglas 2008).

Although the company uses twelve stages to implement the six-sigma methodology efficiently, a proper four-step summary should be embraced as explained below.

Creation of Awareness and Desire for Change

The company should also offer training to the employees. The management should clearly define the objectives of the training and reasons for such changes. It should further clarify the competencies that are required for the success of the change (Peppard 1995).

To manage this stage effectively, the DUCAB Company should ensure the availability of an adequate budget and time for the implementation of the change process. Furthermore, the management should ensure that enough resources such as finance and human resources are in place (Zu, Fredendall, & Douglas 2008).

Development of Skills

The company must constantly manage the training of employees to ensure learning processes in seminars, on-job training, and issuance of tutorials among others (Zu, Fredendall, & Douglas 2008).

Embracing Practices in the Premise

Offering theoretical knowledge about the procedures and practices for change is not enough. Therefore, the company has to embrace practical techniques in the change processes. The management should also encourage the management and training of people in the usage of information technology among others (Anupindi 2006).

Reinforcement of change competencies within the group teams

The DUCAB Company management should practice motivational leadership. The employees should be rewarded through recognition of their actions and valuable contributions towards change management (Al Sharif 2011).

Impacts of the Changes that should be made in the Six-Sigma Methodology

The processes implemented by the DUCAB Company in embracing change management by use of the six sigma methodology is cumbersome and leads to time wastages. Integrating lean manufacturing into the lean six-sigma approach will ensure the reduction of lead-time in the process of change management (Laguna 2004).

This situation ensures an improvement in cash flows and time of delivery. It also reduces wastage of resources (Al Sharif 2011).

In the processing companies, for instance, the lean manufacturing techniques ensures reduction of set-up time that ensures running of small batches, changes that are more and frequent as well as improvement of maintenance of the various appliances in the entity (Al Sharif 2011).

The six-sigma methodology should also be implemented with the Plan-Do-Check-Act (PDCA) cycle to ensure a thorough check on QM technique.

Lean manufacturing is majorly based on the speed, efficiency reduction of delivery and waste reduction while six sigma methodologies is based on continuous improvement and effectiveness. Combining the two approaches leads to improved performance of an organisation (Al Sharif 2011).

Lean manufacturing also ensures a closure of gaps that exist between strategies laid down and performance. This situation brings about improved performance. The combination also minimises variations in processes and techniques and ensures that value addition is factored in the process of production (Al Sharif 2011).

Factors that the management of DUCAB Company must consider in ensuring sustainability of the changes include continuous support by the top leadership from top to down levels, resource dedication, giving incentives, taking advantage of the nature of the premise that suits the six sigma methodology, quality in training, and proper alignment of projects (Al Sharif 2011).

The Key Performance Indicators of Six-Sigma Methodology and Lean Manufacturing

The DUCAB company is mainly manufacturing cables to the consumers thus its main KPI for the various processes it implements includes the efficiency of the processes, the resource allocation, effective methods of handling complaints, cost reduction, cycle time, and the overall quality outputs to the consumers among others (Al Sharif 2011).

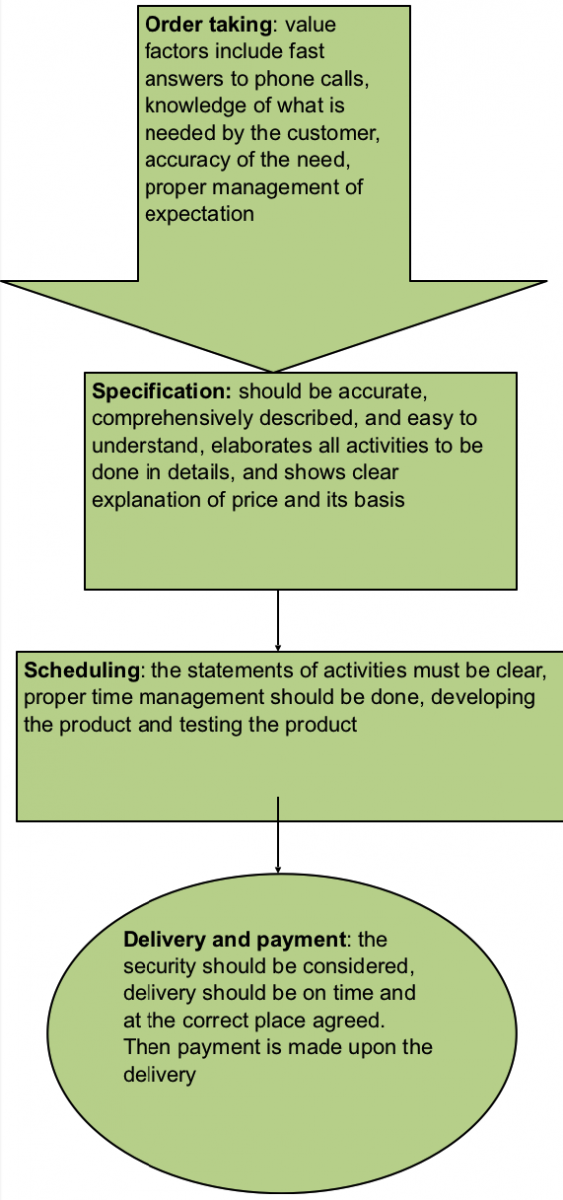

The recommended value chain that should be implemented mainly composes of four main stages that include order-taking, specification, scheduling of activities, delivery, and payment (see figure 2 below).

Major resistance that can be encountered

Rigidity of the Technique

The six-sigma methodology clings on the rigid processes that contradict skills, innovation, and creativity that are achieved due to technological advancements (Clifford 2001). A combination of both the manufacturing and six-sigma methodology can be difficult.

Issues that pertain to production, studies, and other solutions and approaches cannot be factored in the six-sigma methodology because of its rigid nature. Most managers only have a tendency of rebranding products and outsourcing projects for improvements.

Accounting for such practices can be clumsy (Clifford 2001). Executing the lean manufacturing technique will ensure flexibility. However, the employees will need thorough training in the application of the technique (Harmon 2007).

Resistance to Change by Employees

Most employees who are fond of the six-sigma methodology are trained inadequately. This state of affairs leads to difficulty in controlling such employees to ensure that they are dedicated to the full task. The accomplishment of the objectives is sometimes lengthy and intricate (Linderman 2006; Tan 2007).

To manage such a problem efficiently, proper training that is frequent should be done to the employees to learn the lean manufacturing approach. Employees’ engagement should also be enhanced through proper motivation (Hammer 1995).

Conclusion

Proper change management requires pertinent understanding of the goal of change and methodologies that are executed for its implementation. The procedure for implementing the given technique should also be properly understood to avoid loss.

It is clearly indicated that the DUCAB Company uses the six-sigma methodology to manage organisational change efficiently. Management dilemmas have been reported to arise due to the misunderstanding of the concept as a traditional QM technique.

The six-sigma technique should be treated as a methodology that should only be applied to change management of every unit of the organisation. Further, the technique should be combined with other change management approaches such as the lean manufacturing methodology for its efficient application.

However, the management must consider the key performance indicators (KPIs) of the processes to ensure the realisation of customer satisfaction and improved overall productivity.

References

Al Sharif, A 2011, Exploring the critical factors of the successful implementation of Six Sigma approach: a case study of Ducab, UAE’, Doctoral dissertation, Bournemouth University, vol. 1 no. 1, pp. 1-236.

Anupindi, R 2006, Managing Business Process Flows: Principles of Operations Management, Prentice Hall, Upper Saddle River.

Arnheiter, E & Maleyeff, J 2005, ‘The integration of lean management and Six Sigma’, The TQM magazine, vol. 17 no. 1, pp.5-18.

Clifford, L 2001, ‘Why you can safely ignore Six Sigma’, Fortune, vol. 143 no. 2, pp.140.

Davison, L & Al-Shaghana, K 2007, ‘The link between Six Sigma and quality culture: An empirical study’, Total Quality Management & Business Excellence, vol. 18 no. 3, pp.249-265.

Hammer, M 1995, The Reengineering Revolution: The Handbook, HarperCollins, New York, NY.

Harmon, P 2007, Business Process Change: A Guide for Business Managers and BPM and Six Sigma Professionals, Elsevier, New York, NY.

Lean, Six Sigma and Lean Sigma: fads or real process improvement methods?’, Business Process Management Journal, vol. 14 no. 3, pp. 269-287.

Laguna, M 2004, Business Process Modelling, Simulation, and Design, Pearson, London.

Linderman, K, Schroeder, R & Choo, A 2006, ‘Six Sigma: the role of goals in improvement teams’, Journal of Operations Management, vol. 24 no. 6, pp.779-790.

Näslund, D 2008, ‘Lean, six sigma and lean sigma: fads or real process

Peppard, J 1995, The Essence of Business Reengineering, Prentice Hall, Upper Saddle River.

Tan, A 2007, Business Process Reengineering, Prentice Hall, Upper Saddle River.

Zu, X, Fredendall, L & Douglas, T 2008, ‘The evolving theory of quality management: the role of Six Sigma’, Journal of operations Management, vol. 26 no. 5, pp.630-650.