Introduction

The history of nutrition dates back a hundred years ago during ancient Greek times. However, scientific research on nutrition was recently done and the knowledge about different types of foods was deemed vital for good health. According to Beaudry (2005), nutrition is the scientific study of food and drinks and a process in which living organisms assimilate ingested foods for purposes of growth, development and maintenance. Nonetheless, it helps an organism in the process of replacing or nourishing the body cells. Currently, the market for fresh-cut fruits and vegetables is expanding in the entire world. Both developed and developing countries are demanding many products which are produced by food manufacturing companies (Gariepy, 2001). Unfortunately, in some countries, the very products are made through unfavorable conditions which may cause harm in consumption by consumers.

Due to the increasing demands for these types of products globally, there has been a dire need for research and increased efforts in rendering advanced techniques to ensure that fresh vegetables and fruits are produced (Davies,2005). Needless to say, good nutrition constitutes a healthy diet which is deemed necessary to sustain an individual. Lack of balanced nutrients usually leads to malnutrition which causes certain body malfunctions such as Kwashikor or marasmus (Farber, 2000). Good health is an outcome of nutrition hence, an individual is able to have a state of total mental, physical and social well-being without exposure to diseases.

MAP Technology

It was in 1979 that Modified Advanced Packaging (MAP) technology was commercially introduced (Zagory, 2000). According to Kader (2000), he argued that the increasing consumer demand for less processed and fresh foods was the sole reason why there was a need to implement a modified atmosphere for preserving the natural qualities of food products. MAP was initiated because there was an increasing need to expand the shelf life of fruits and vegetables through packaging and storing them in the surroundings with fewer oxygen capacities while increasing the volumes of carbon dioxide (Abeles, 2000).

MAP system ensures good packaging that protects fruits and vegetables from external harms such as infestations of pathogens or germs causing contamination and rotting (Gorris, 2002).

MAP technology was evaluated in the 40s to measure its capability to minimize the levels of oxygen to assist in the long-life thriving of fruit and vegetable (Brody, 2000). Notably, this system is capable of sustaining the storage of fresh fruits and vegetables, therefore, reducing undesirable or unwanted effects. Atmospheric components are a result of various aspects which involve permeability features of the particular package and the way plant material breath enters a certain package (Philips, 2006). The packaging surfaces should be penetrable, and the issues of temperature and water content in the air should follow some trends. Research studies have indicated that the modified atmosphere storage is one of the very best and most successful preservation mechanisms which are suitable for a range of various agricultural products and foods altogether (Hotchkiss, 2009).

Benefits to farmers

Without a doubt, grain farmers are benefiting from this kind of storage and are now embracing it compared to other forms of storage. It works well if the bins used to store the grains are made air-tight (Day, 2000). The bins which are used to store these grains need to be tightly sealed so that no air or contaminated materials penetrate through them. Modified atmosphere storage can be enhanced through the combination of interactive packaging which helps boost the control of oxygen in packages and therefore ensures that the stored products maintain levels of high quality (Goofings, 2005). Embedded gadgets in packaging materials control the storage duration and are capable of calculating reservation time for fruits and vegetables before they spoil (Kader, 2000).

Nowadays, Customers anticipate fresh vegetables and fruits to be produced and packaged all through the year. Therefore, modified atmosphere packaging has ensured a safe duration period over which these products will remain on the shelves (Church, 2004). This proves to be fundamental for consumers in locating fruits and vegetables which are safe for their health and that will be kept for a long period of time without rotting. Goofings (2005) cited that “When fruits and vegetables are undergoing biomedical and metabolic processes, they end up producing ethane which helps in ripening and the softening of the tissues.” However, if this is not closely monitored or controlled, it results in the reduction of shelf life.

Mechanism of MAP

The sole purpose of the modified atmosphere packaging is to minimize fruits and vegetable chances of rotting and further improve their shelf life (Church, 2004). This is done through the reduction of oxygen saturation, lowering of temperatures, and alternatively increasing the amount of carbon dioxide concentration (Beaudry, 2002). However, Carbon dioxide should not be supplied in large amounts since it leads to fruit and vegetable spoilage. The lowering of oxygen concentration with a corresponding increase in the carbon dioxide volumes leads to fruit and vegetable ripening (Davies, 2005).

Since fruits and vegetables are living substances, they undergo metabolism and other organic processes vital in sustaining their growth, while experiencing gradual biochemical changes (Farber, 2000). There is a great need for modifications in the surrounding conditions during storage for the fresh items since this helps in boosting their life span on the shelves. Due to inventions in modified advanced packaging, fruits and vegetables are capable of being preserved for long-life consumption (Goodburn, 2008).

MAP technology has helped experts of foods gain more skills and knowledge on the rising features of packaged fruits and vegetables. According to Kader (2000), Designing MAP systems entails taking into consideration various environmental factors like temperature, humidity and atmosphere details, biological and packaging technology factors. Thus, a membrane system that was deemed necessary for safeguarding the MAP system from Biochemical reactions with the atmosphere was invented (Hotchkiss, 2009).

The modified atmosphere packaging of the fruits and vegetables implies the mechanism of encapsulating the products inside a covered container made of polyvinylchloride. This process ensures that the presence of oxygen and carbon dioxide within the container is modified and is necessary for preservation. Nevertheless, it ensures that the metabolic process is minimized hence increasing the shelf lives of the produce (Gariepy, 2001).

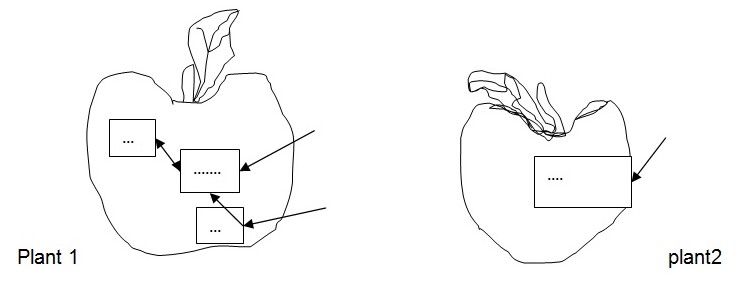

This is a diagrammatic representation of a modified atmosphere packaging system model which explains how two produces share a package (Goofings, 2008). According to the illustration, plant 1 is generated through the connection of three cells and the other plant 2, which is formed by one single cell sharing a package. The arrows in the diagram refer to the paths taken by small indivisible particles during diffusion. It can be seen from the diagrams that plant one is larger in size compared to plant two for the reasons that have been mentioned above.

The surrounding adjustments in the modified atmosphere packaging require that the breathing plant tissues and obstacles through which the respiration takes place are restricted. Reduction of oxygen supply with a corresponding increase in the carbon dioxide production generates a saturation deficit across the film leading to the movement of the gas in and out of the storage package (Abeles, 2002). The amount of both gases; the carbon dioxide and oxygen, which exist within a storage package, will depend on the interaction between the items, and the exchange of the very gases and the ease or difficulty in the movement of the gases in and out of the semi-permeable membrane (Brody, 2009).

To forecast the continuous and steady-state of oxygen concentration in the storage package a system that is taken in different temperatures and compares them to get a relative reading is invented (Church,2005). The model can now be used to make clear readings between the temperatures after checking the uptake of oxygen gas and its consumption through the film of the package and give a way of reducing and/or correcting any problems which may arise (Farber, 2000).

There are various crucial aspects that affect the shelf life taken by the agricultural products on the shelves which include the ripening, decaying, wilting, and darkening on the surfaces which were cut. MAP technology has helped in the reduction of such effects and that was the core reason why it was invented, to increase the shelf life (Day, 2000).

The use of MAP to increase the shelf life of agricultural products as well as eliminate the darkening of cut surfaces can only apply to some plant species but fails in others (Beaudry, 2002). The quality of fresh products can be realized through effective monitoring and management of temperature with the help of modified atmosphere packaging (Goofings, 2005). MAP can minimize the rate at which products such as tomatoes ripen at extreme periods. In order to control the rate of decay, there is a need to reduce the number of organisms that are likely to cause decay (Hotchkiss, 2009). Examples of plants whose fruits do not undergo such decaying effects include the following: blackberries, raspberries, cherries, blueberries and strawberries. Nonetheless, they can successfully be stored under low concentrations of carbon dioxide (Kader, 2000). The method which can be used to improve and maintain the presence of carbon dioxide is increasing the production of the gas in the atmosphere (Goodburn, 2008).

Moreover, the plan depends on the continued process of respiration to eliminate the loss of carbon dioxide from the packaging materials something which is used commercially for several berry crops (Philips, 2009). In order to reduce cases of the cut surface being brown, a low supply or oxygen is used on those products or items which are lightly processed like the lettuce and salad mixtures. Processing and the use of atmosphere modification help reduce the development of cut browning in agricultural produce (Zagery, 2000). Consumers buying fresh vegetables often want to view the packaged product before acquiring them. Since MAP systems utilize plastic packages, they should be clear enough and free from condensed water. Films with anti-fog properties should be embraced to achieve the principle of visibility.

According to Beaudry, R.et al., (2002). Pores found in the films limit the functioning of the packages. This is due to the fact that the diffusion rates of the gases differ accordingly. Carbon dioxide diffuses at a higher rate compared to oxygen leading to low equilibrium levels hence, the pores that allow the movement of oxygen and exit of carbon dioxide should of similar sizes.

In addition, when designing a packaging material, there are various considerations that should be taken into consideration (Davies, 2005). In case of poor construction of modified atmosphere packaging, plant produce storage does not only get violated but also likely variations in the results of the surrounding environment will be generated (Goofings, 2005). The mode of packaging should be dealt with accordingly for the purpose of satisfying the consumers. Nonetheless, the control of temperature should be regulated to suit the products during their storage (Gorris, 2002).

For proper handling of produce, the packaging materials should be well built to ensure that heat transmission is well regulated so that extreme heat temperatures are not allowed to penetrate through the contents of the package (Abeles, 2002). Poor regulation of heat transmission causes increased chances of bacterial growth, especially those microorganisms responsible for food poisoning (Brody, 2009).

In addition to that, the growth of microorganisms leads to the reduced shelf life of packaged food products. The design and modeling of packages that will be used for the purposes of storage help enhance the understanding of the way the plants, packages and other various aspects in the surrounding can be useful in the storage process (Gariepy, 2001).

Before the invention of modified atmospheric packaging (MAP) technology, there were other techniques that were used in the past, for example, the controlled atmosphere storage used when water vessels such as ships would ferry fruits and vegetables (Beaudry, 2000). The containers contained very high levels of carbon dioxide in the rooms which helped to increase the life taken by the product on the shelf. A high concentration of carbon dioxide creates an unfavorable environment for bacterial growth (Philips, 2006). MAP constitutes an active packaging where some particular contents in the storage material are able to change and modify the existence and amount of gases during storage (Hotchkiss, 2009). Oxygen gas, for instance, is taken in by some absorbers contained in the storage material hence minimizing its existence and amount (Davies, 2005).

Another method of packaging was used as the vacuum packaging technique. This works in a way that the agricultural produce is placed on large rolls of aluminum foils or plastics after gas or air has been removed creating a vacuum. The absence of air inside the package creates an atmosphere free of microorganisms and is fit for food storage for a long since they tend to thrive well in presence of oxygen (Brody, 2009).

Efforts to ensure that MAP achieves fresh and quality products are being made (Gariepy, 2001). High use of oxygen in food preservation reduces the flavor of the products hence disrupting the nutritional value of the product. MAP uses high concentrations of carbon dioxide other than oxygen (Kader, 2000). In addition, the MAP system has an added advantage in that it is uniquely coated and highly proofed. Therefore, it prevents damages caused by fire, water, or corrosion making it possible for fruits and vegetables to be consumed without causing harm such as food poisoning. In fact, some of the coatings contain substances that act as carriers of sensitive elements that improve the quality and safety of the products (Gorris, 2000).

Freshly cut agricultural products have been recommended as the best, and are acceptable and also convenient to be consumed by customers (Goofings, 2005). Readymade Produce that has already been sorted and packaged reduces the time needed in preparation for the consumers since all the work has been done what only remains is to consume it. The availability of these types of products in institutions, schools, business places, bus stops and working areas, allows the clients to have access to firsthand healthy food. Consumption of fresh and well-preserved food products helps in fighting diseases associated with poor sanitation and food handling (Beaudry, 2000).

The management of packaged fruits and vegetables has been modified and improved to appreciate standards. This is due to the fact that the key reason of preservation through modern techniques including modified atmosphere packaging (MAP), extended to the provision of quality products and not prolonged shelf life only.

Modified advanced packaging or storage plays an important role in conserving the environment which is also an agent of quality nutrition (Farber, 2000). Fruits and vegetables that are well packed are wholly consumed by the consumers therefore there have been no reports or issues related to land pollution. Moreover, it helps in the reduction of labor needed for produces which are prepared at home locally together with their waste disposals. Waste material is generated when peels from vegetables and fruits are carelessly dumped. As the demand to reduce consumption of unhealthy food snacks continues, people have opted for freshly cut fruits and vegetables that are healthy. Therefore, more food industries have opted to use the modified advanced packaging (Davies, 2005)

Modification of bag sizes has to be done to meet the different package sizes of the food products. The fact that products of the same category need to be packaged in different packages, appropriate films utilized in the modified atmosphere packaging (MAP) systems have to be established.

Impact of MAP on food

The life span or the shelf life of perishable foods like fruits and vegetables is dependent on normal gases present in the air by two important aspects which are the chemical impacts of the environment like oxygen and the expansion of air destroying tiny living things (Beaudry, 2002). All these factors bring about alterations in the smell, color, texture and flavor of the food substance in the storage media. These effects will reduce the shelf life of the stored products (Brody, 2009). Thorough exploration and research have been conducted for use in the achievement of fresh and quality fruits and vegetables. (Day, 2000).

That is why MAP uses high concentrations of carbon dioxide other than oxygen (Beaudry, 2000). In addition, the MAP system has an added advantage because it uses coatings that can be consumed by humans and are not dangerous for human health. In addition, it acts as a carrier of sensitive elements that improve the quality and safety of the products (Hotchkiss, 2009). Freshly obtained products have become recommended as the most convenient way of delivering ready consumable products (Gariepy, 2001). Products that have already been washed and packaged reduce the preservation time for the consumers since all the work has been done and the only remaining task is to consume the product (Gorris, 2000).

According to plasse (2005), “modifying the atmosphere inside fresh produce packaging to provide lowered levels of oxygen and elevated levels of carbon dioxide is beneficial. It can reduce the rate of respiration, reduce ethylene production as well as tissue ripening and softening, alleviate physiological disorders and chilling injury and decrease the rate of chlorophyll degradation and biosynthesis of carotenoids and anthomycins while at the same time it can maintain the nutritional value. The effect of decreased oxygen and increased carbon dioxide levels on senescence and ripening process are additive and can also be synergistic.”

Advantages of MAP

The availability of these types of products in institutions, schools, business places, bus stops and in offices or working places allow the consumers to have healthy food, in the long run, to assist in improving people’s health (Philips, 2006). This type of strategy assists in the minimization of the rising rates of illnesses like obesity and cancer. There is also a minimized number or cases of retail wastes as well as conservation of the environment since most of the products have already been peeled (Zagery, 2000). High nutrition values and qualities are retained because the products are washed and cleaned before they are cut or peeled. There is also enhanced display and clarity in the way the products are viewed (Parry, 2000). The products are always fresh in that there are no reports of dirt and lack of flavor as a result of product drip due to the fact that there are stackable hygienic packs and well-sealed storages (Farber, 2000).

Chemical preservatives are less useful in this structure. Given that there is a good packaging mode, there is a corresponding increase in the shelf life and as a result, there is reduced or minimized costs incurred during the transportation of the products for delivery to respective consumers (Abeles, 2002). The processes of packaging and storing products are done in one place which ensures that control is also centralized (Goofings, 2005). Another advantage is that production, packaging or storage costs are minimized due to the efficiency that comes with it (Church, 2005).

Disadvantages of MAP

As much as there are advantages, there are also demerits. Setting up the MAP machinery is quite costly and a lot of money is used to purchase equipment that is used in the packaging of the products (Philips, 2006). Purchasing and maintaining the gases is also a great deal. Another type of cost incurred includes the acquiring of analytical tools which are used to ensure that there exists an accurate amount of gas concentration in the packaging materials (Beaudry, 2000). The fact that there are increased capacities of packing materials will result in the affecting of the modes of transportation and also room or space for displaying the products (Farber, 2000). If one makes the mistake of opening the package before it is sold, then it is deemed to go bad automatically since it will have been exposed. There is a likelihood of the products being invaded by pathogens as a result of failure to observe the temperature regulation (Goodburn, 2008).

Most consumers nowadays are anticipating fresh fruit and vegetables products which can take a long in their shelves and that have or posses’ good and nutritious factors and high quality and also safety (Philips, 2006).

Modified atmosphere packaging or MAP system has helped greatly the researcher with numerous expertise, skills and knowledge on the rising features of packaged fruits and vegetables (Davies, 2005). There was also a need to introduce a membrane system that secures the MAP system from reactions against biochemical (Brody, 2009). The designing of MAP systems is not a very easy or simple thing. It entails taking into consideration various environmental factors like temperature, humidity and atmosphere details, biological and packaging technology factors (Goodburn, 2008).

The life span or the shelf life of perishable foods like fruits, vegetables and others is only directed to the existence of the normal gas or air by two important aspects which are the chemical impacts of the environment like oxygen and the expansion of air-related or airborne destroying tiny living things (Zagery,2000). All these factors bring about alterations in the smell, color, texture or the feeling and the flavor of the food substance in the storage media. These effects will reduce the shelf life of the stored products (Hotchkiss, 2009).

The modified atmosphere packaging of the fruits and vegetables implies the mechanism of encapsulating the products inside a covered container made of polyvinylchloride so as to ensure that the oxygen and carbon dioxide presence within are modified to suit the preservation requirements which will minimize the metabolic processes hence increasing the life span or shelf lives of the products (Gariepy, 2001).

The environmental changes made in the modified atmosphere packaging require that the process of respiration of plant tissues and obstacles through which the respiration takes place is hindered (Church, 2004). The lowering of oxygen supply with a corresponding increase in the carbon dioxide production which comes up as a result of tissue breathing or respiration generates a saturation deficit across the film which gives a push for easy movement of the gas in and out of the storage package (Davies, 2005).

Produce storage has been on the rise in past years due to the production of sufficient materials for the latter (Philips, 2006). The knowledge and skills on how the seals on the packages are less, incidences of gas emissions have occurred and the printing has also provided for attractions for the consumers (Goodburn, 2008).

There has been advancement in the gradual expansion of commodity shelf life which meets the long-distance travel aims for the deployment of the products. This has helped enhance the distribution of the product (Abeles, 2002). The keeping of the quality of the products is achieved through the lowering of the rate or degree of respiration, browning cuts, decays and fruit softening and withering (Gorris, 2002).

MAP is a technique that has been utilized by large firms to maintain the distribution of fresh-cut food products as well as quality fruits. In order for these firms to sustain their business ventures, they have adopted the modified atmosphere packaging where the levels of oxygen and carbon dioxide gases are controlled to minimize the growth of microorganisms. In presence of high levels of oxygen, microorganisms multiply fast using fruits and vegetables as a source of energy. On the other hand, increased carbon dioxide content reduces the activity of these microorganisms. For carbon dioxide gas to work well, then the temperature should be controlled (Dixon, 2002).

Food goes bad due to exposure to substances like oxygen and other contaminants which may make it go bad hence reducing the life span that will be taken in the shelves (Church, 2005). MAP is a methodology or technique which helps in slowing or stopping such contacts through the use of natural ways to prolong freshness (Day, 2000). The acts of managing gases and temperatures during the storage and distribution of a fresh product or perishable fruits or vegetables can help greatly to improve the life duration of the packaged food products (Gariepy, 2001). In some countries, there are no periods when there is experienced a lack of fruits in the market. This is because of the presence of the MAP which ensures that these fruits and vegetables are stored well to stay for longer seasons (Hotchkiss, 2009). In other nations, which have not embraced this kind of technology, during seasons when the fruits are not ready to produce or simply off season, that means that the products are not found in the market by the consumers who by then need them dearly (Abeles, 2002). When these MAP stored foods are stored in very cool rooms which have low oxygen, they tend to slow the rate at which they ripen.

MAP not only extends shelf life but also improves quality (Goodburn, 2008). It entails the variations of the levels of gases in the storage materials to decrease the natural spoilage of the products. For various foods to go bad there must be a catalyzing factor which is oxygen (Beaudry, 2000). Oxygen allows the thriving of the bacteria which need this gas or molds and other reactions which need oxygen (Beaudry, 2002). The major types of gases used in the MAP comprise of carbon dioxide, oxygen and nitrogen (Farber, 2000). Carbon dioxide gas tends to be used to discourage the ability of bacteria and other reactions to grow or thrive since it instills low temperatures which are not favorable for bacterial growth (Davies, 2005).

In addition, Oxygen gas helps in protecting fruits and vegetables from being destroyed. Since it also allows the browning of cut surfaces it must be kept away from any food contacts (Goofings, 2005). Nevertheless, Nitrogen is used to help in the elimination and/or filtering of oxygen hence preventing food spoilage (Gorris, 2002).

MAP has created gaps for research to be done to ensure that more advanced and rapid methods able to attain the best atmospheric conditions suitable for good packaging are accomplished. These gaps include factors causing reduction of flavor in MAP systems, ways of increasing taste as well as improving the quality of fresh fruits and vegetables. In cases of improper handling of the Modified Atmosphere Packaging (MAP), undesired effects come into being (Mullan, 2002). Such effects may occur due to irreconcilable film length as well as poor temperature control. The two factors may cause “anaerobic respiration with an accumulation of acetaldehyde, ethanol, ethyl acetate and lactic acid, all of the fermentation, contributing to the development of off-odors, flavors and disuse deterioratio.” (Gorris, 2002). In order for suppliers utilizing the MAP systems to successfully distribute quality products, they should ensure that the proper procedures of handling the packaging system are followed.

According to Zagory (2000), packing foods in a modified atmosphere can offer extended shelf life and improved product presentation in a convenient container, making the product more attractive to the retail consumer. However, MAP cannot improve the quality of a poor food product. It is therefore essential that the food is of the highest quality prior to packing in order to optimize the benefits of modifying the pack atmosphere.”

Conclusion

Food preservation is a crucial practice in our generation today. During the medieval ages, people used to preserve their food using crude means such as salting or drying. As much as it would help it did not guarantee long shelf life periods. Modern technology such as refrigeration has helped curb issues related to food spoilage and wastage.

Since all technological advances in nutritional practices encompass quality assurance procedures, Modified Atmosphere Packaging is not an exception. Quality control in MAP systems includes package testing and measurements of gas levels. In order to achieve the distribution of safe and fresh fruits and vegetables, then quality checks should be done more often.

References

Abeles, F. (2002). Ethylene in Plant Biology, 2nd ed. California, CA: Acad. Press.

Beaudry, R. (2000). Responses of horticultural commodities to low oxygen: limits to the expanded use of modified atmosphere packaging, Hort Technology Journal, 10, 491-500.

Beaudry, R. (2005). Effect of O2 and CO2 partial pressure on selected phenomena affecting fruit and vegetable quality. Postharvest Biology Technology journal, 15, 293-303.

Beaudry, R. et al., (2002). Modified-atmosphere packaging of blueberry fruit: Effect of temperature on package O2 and CO2, Journal of American Soc. Hort. Sci., 117, 436-441.

Brody, A. (2009). Controlled/Modified Atmosphere/Vacuum Packaging of Meat, Controlled/Modified Atmosphere/Vacuum Packaging of Foods, ed Brody A. Trumbull, CT: Food and Nutrition Press.

Church, J. (2005). Modified Atmosphere Packaging Technology, A Review of Science Food Agric., 67, 143-152.

Church, N. (2004). Developments in Modified-Atmosphere Packaging and Related Technologies, Trends in Food Science & Tech., 5, 345-352.

Daniels, J. (2004). A Review of Effects of CO2 on Microbial Growth and Food Quality, Food Protection, 48, 32-537.

Davies, A. (2005). Advances in Modified-Atmosphere Packaging, New Methods of Food Preservation. Glasgow: Blackie.

Day, B. (2000). Extension of Shelf -Life of Chilled Food, European Food and Drink Review, 4, 47.

Dixon, M. (2002). The Inhibition by CO2 of the Growth and Metabolism of Microorganisms, Journal of Application of Bacteriols, 67, 109-136.

Farber, J. (2000). Microbiological Aspects of Modified-Atmosphere Packaging Technology, A Review, Journal of Food Protection, Vol.54, No.1, pp.58-70.

Gariepy, Y. (2001). Long term storage of cabbages, celery and leeks under controlled atmosphere. New Jersey: Agricultural and food research center.

Goffings, G. (2005). Modified atmosphere packaging of freshly cut fruits and vegetables. London: Oxford Press.

Goodburn, K.(2008). Modified Atmosphere Packaging: A Technology Guide. New Yolk, NY: Leatherhead Food.

Gorris, L.(2002). Modified Atmosphere and Vacuum Packaging to Extend the Shelf Life of Respiring Food Products, Hort Technology, 2 (3), pp. 303-309.

Hotchkiss, J. (2009). Microbiological Hazards of Controlled / Modified Atmosphere Food Packaging, Journal of Assoc. Food Drugs Office. 53 (3) 41-49.

Kader, A. (2000). Modified Atmosphere Packaging of Fruits and Vegetables, Critical Review on Food Science Nutrition, 28 (1) 1-30.

Mullan, W.M.A. (2002). Dairy Science and Food Technology-science and technology of modified atmosphere packaging. Web.

Parry, R.T., (2000). Principles and Applications of Modified Atmosphere Packaging of Food. Glasgow, UK: Blackie.

Phillips, C. (2006). Review: Modified Atmosphere Packaging and Its Effects on the Microbiological Quality and Safety of Produce, International Journal of Food Science and Technology, 31, 463-479.

Plasse, J. (2005). Long term storage of cabbages, celery and leeks under controlled atmosphere. London: Prentice Hall.

Zagory, D. (2000). Modified atmosphere packaging of fresh produce, Food Technology Journal, 42 (9), 70-77.