There are three options available for the Ashburn project.

- Lease an existing box store.

- Open a store within the Ashburn Mall.

- Continue operations as normal with no new store.

An additional variable would be whether or not to conduct a feasibility survey before proceeding with the project.

- The cost of the survey is $20,000 and has a strong chance of being favorable.

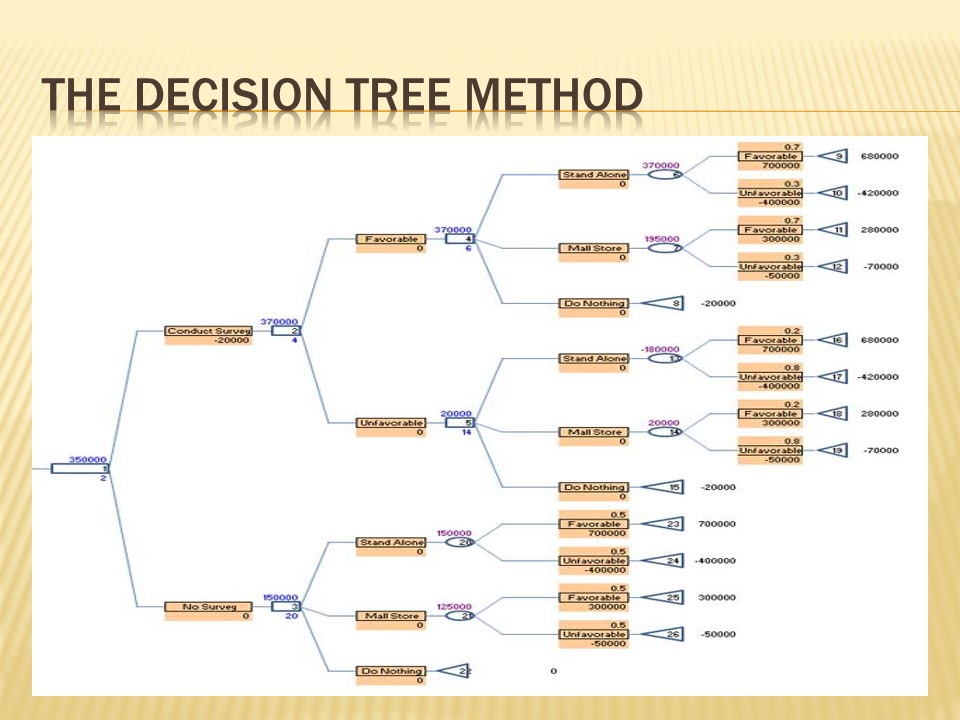

The Decision Tree Method

The choice to use the decision tree is based on it providing an easy to comprehend format by placing all decisions in a graphical layout. This allows for ease of explanation for the decisions, showing positive and negative variables and gives an almost instantaneous “cause and effect” evaluation of each potential decision. In addition to this, the concept of decision tree allows for comparison of elements of a concept which can be looked at concurrently and their importance, vitality and/or centrality to the decision under consideration can be made from their analysis and study (Yuan & Shaw,1995). It is in this regard that Yuan & Shaw (1995) surmise that decision tree method is one authentic decision making method that gives least chances of error, incompetence and poor judgment (Yuan & Shaw,1995, p. 127).

- Reasons to use the decision tree:

- Simple – Very easy to understand and interpret;

- Flexible – Can be adjusted to describe different situations;

- Replication – The results of a given situation can be replicated mathematically.

- Compatibility – This method is highly compatible with other analytical techniques.

- Decision trees consist of three (3) types of nodes:

- Decision Nodes – Commonly shown as squares;

- Chance Nodes – Commonly shown as circles;

- End Nodes – Commonly shown as triangles.

It is in this regard therefore that when the path with the highest potential is followed, it can clearly be seen that conducting the survey and selecting the stand alone store would be the most beneficial decision.

Shuzworld’s expansion recommendation

- Based on the decision tree, it is recommended that Shuzworld conduct the feasibility survey and proceed with the stand-alone “box” store.

- The potential from this method shows a high chance of a favorable market, and estimated returns of $350,000.00.

Factors of concern

Factors to consider for the location of a new store

- Accessibility.

- Cost of establishment.

Additional factors to consider would be:

- Transportation Costs.

- Communication Costs.

- Advertising and Promotion Costs.

Accessibility – this involves how convenient a location of the business for Shuzworld is to its potential customers. When Shuzworld is located as a stand alone, it is much closer to the town center as compared to when located at mall store. By way of comparison, the mall store would potentially attract more customers who may not otherwise shop at Shuzworld due to the inclusion of anchor stores within the mall.

Cost of establishment – this involves the amount of money and resources needed to establish the business. When the Shuzworld store is established as a stand alone location, the initial costs will be higher due to the requirement of additional signage and advertising unlike the mall store which will already have an established group of shoppers meaning less initial capital is needed for advertising and signage.

Transportation Costs – this factor is imperative for the success of the business as it caters for the costs that will be incurred during the transportation of the company’s cargo, personnel, raw materials and products to its stores or manufacturing sites. These costs have to be maintained at an all time low as far as possible to ensure maximization of profitability.

Communication Costs – all correspondence within the company in terms of calls, mails, internet usage (etc) is the other factor that has to be considered. There should be effective communication channels since it is only through this that corporate objectives and company vision can be properly conveyed to its personnel so as they work towards their realization. It has been surmised that poor communication is the recipe of definite failure in company operations.

Advertising and Promotion costs – these are the costs that go into popularization of the company within its market niche. In many companies, these costs are usually among the highest costs since promotional activities are very costly. In the same breathe, these costs cannot be done away with as they are the anchor upon the company’s market share dangles upon. They should be well assessed and strategies to ensure that they are at a minimum explored especially when the business is still in its formative stages.

Project Techniques

- Critical Path Method.

- Communications (Scope of Work).

- Job Costing.

- Activity Costing.

Critical Path Method – this is a project management tool that schedules project activities in a manner that presents a greater capacity to follow through them properly with minimal chances of error. This technique has great capacity of positively affecting the construction plan since it will help reduce waste and increase productivity of the project. This can be seen in its three core elements of operation shown below (Milosevic, 2003):

- It lists all the activities necessary for completing the project that are usually categorized within a work breakdown structure.

- It indicates the time duration that each of the listed activities is estimated to take for it to be completed.

- It lists the dependencies between the activities.

Communications – this method conveys relevant information of the work to the people working on the project so that all are aware of what is required of them. Communication methods sort of encompasses everything since there is literally nothing that can be done to fruition without communication. The specific area that this method ensures productivity of the project and minimizes wastage of time and resources is in its conveyance of information regarding the scope of work involved in the project so that proper planning and preparation is done (Milosevic, 2003).

Job Costing – this method estimates the general costs that will be incurred during the project. This is imperative for proper planning and preparation of the budget of the project. The most dreadful thing for a project that is underway is a situation where it runs out of money before completion. Job costing is a technique that ensures that there is proper financial and cost planning to ensure that the project sees light of day.

Activity Costing – like job costing, activity costing estimates the cost that each activity of the project is likely to incur. This then gives an idea of how much the entire project may incur which corporately help in the preparation of the project budget and consequently, ensures well planned and conducted project. It is among the best tools of project management whose absence almost guarantees project failure and whose inclusion promises better results in preparedness and project success in its productivity (Milosevic, 2003).

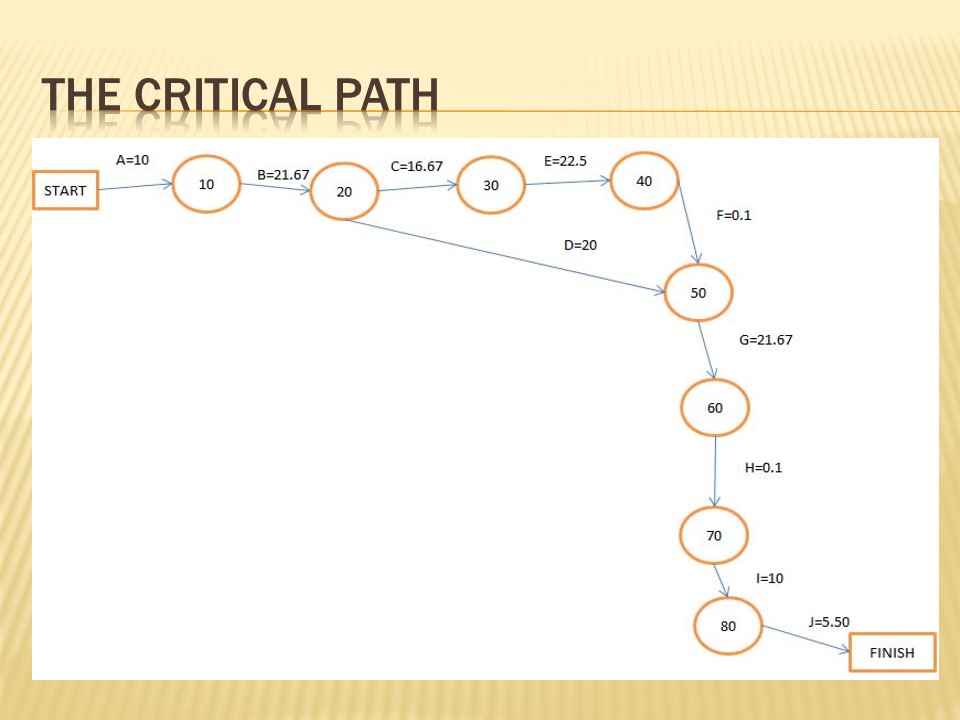

The Critical Path

The Critical Path Method (CPM) helps with determining the timeline for a project, while at the same time planning which events need to be completed first to complete the entire project. In the case of this particular scenario, the time to complete the project is estimated at 108.2 days.

The Critical Path Analyses are presented using simple circle and arrow diagrams. Circles designate events within the project, such as the start and finish of tasks. The number shown in the left hand half of the circle allows you to identify each one easily. Circles are sometimes known as nodes (Kelley, 2003). An arrow running between two event circles shows the activity needed to complete that task. Arrows are also sometimes called arcs. The chart shows a completion time of 108.2 days.

There are two cardinal reasons that support the use of Critical Path Method for this project which also are two of its greatest advantage. These are flexibility and capacity for expansion. Critical Path Method currently has been expanded to allow the use of resources related to each activity in a process called resource leveling and activity-based resource assignments (Kelley, 2003). This expansion allows for more relevant details to be covered for project activities thereby making the technique very effective. The other reason why CPM is important and appropriate for this project is its flexibility. The structure of CPM analysis has the capacity of measuring the variance from the original schedule that may be caused by any given change and also gives provision for adjusting or ameliorating such impact caused (Kelley, 2003). This allows for flexibility where changes impacting a project can be isolated and adjusted accordingly without compromising the integrity of the entire project.

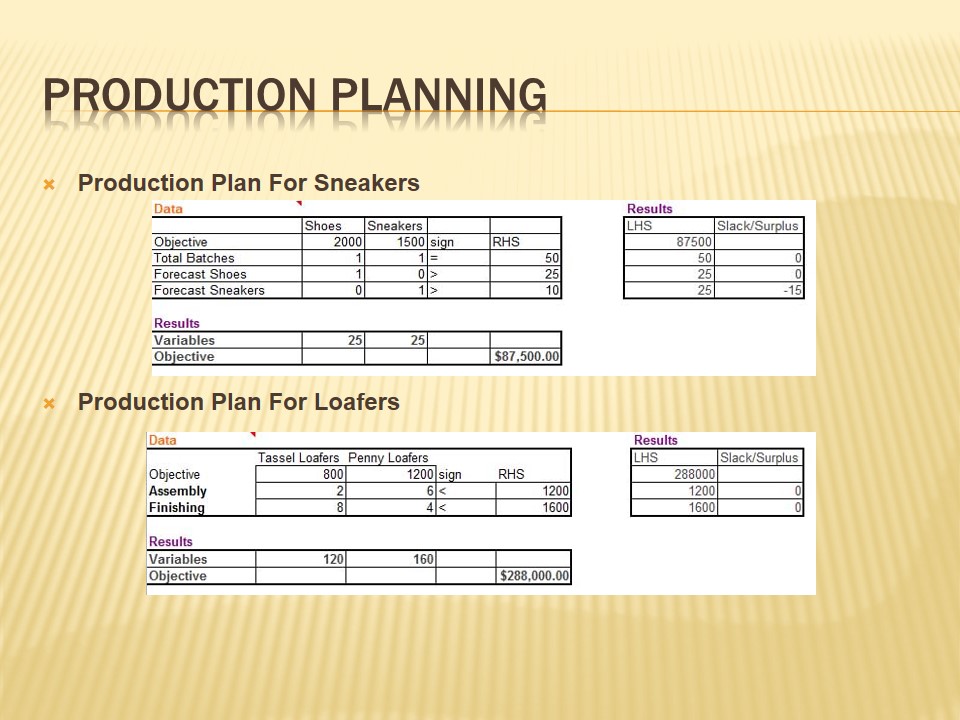

Production Planning

- Production Plan For Sneakers.

- Production Plan For Loafers.

Linear programming is a tool, or set of tools widely used to calculate an optimal solution when presented with a finite set of resources. It allows for you to reach optimal output while keeping your input levels at a lower point, meaning reduced costs and increased profits (). These two are the main reasons that make this tool greatly recommendable for such a project as this. The following computational illustrations show the convenience of using this tool in further explaining why it was preferred for the project.

For the sneakers and shoes, the objective is to produce a total of 50 batches of shoes and sneakers, minimizing production costs.

Using the linear programming tool, let Y batches of sneakers and X batches of shoes be produced.

Min Z = 2000X + 1500Y (Cost per batch $2,000.00 for shoes (X) + $1,500.00 for sneakers (Y)).

Subject to:

- X+Y= 50 (50 batches of shoes and sneakers);

- X ≥ 25, Y≥10 (A minimum of 25 batches of shoes and 10 batches of sneakers).

To minimize costs and meet production goals, you arrive at 25 batches of shoes and 25 batches of sneakers with a minimum production cost of $87,500.00

For the loafers, the objective is to produce the optimal number of tassel loafers and penny loafers to maximize profits.

Maximize Z = 800X+1200Y (Profit of $800 per batch of tassel loafers (X) + profit of $1,200.00 per batch of penny loafers (Y)).

Subject to:

- 2X+ 6Y≤ 1200 (2 hours assembly time for tassel loafers (X) + 6 hours of assembly time for penny loafers (Y) with a maximum allowed time of 1,200 hours);

- 8X+ 4Y≤ 1600 (8 hours of finishing time for tassel loafers (X) + 4 hours of finishing time for penny loafers (Y) with a maximum allowed time of 1,600 hours);

- X ≥ 50 and Y≥100 (Minimum production level for tassel loafers (X) is 50 batches, minimum production level for penny loafers (Y) is 100 batches).

Therefore, the optimal solution is to produce 120 units of tassel loafers and 160 units of penny loafers with a maximum profit of $288,000.00.

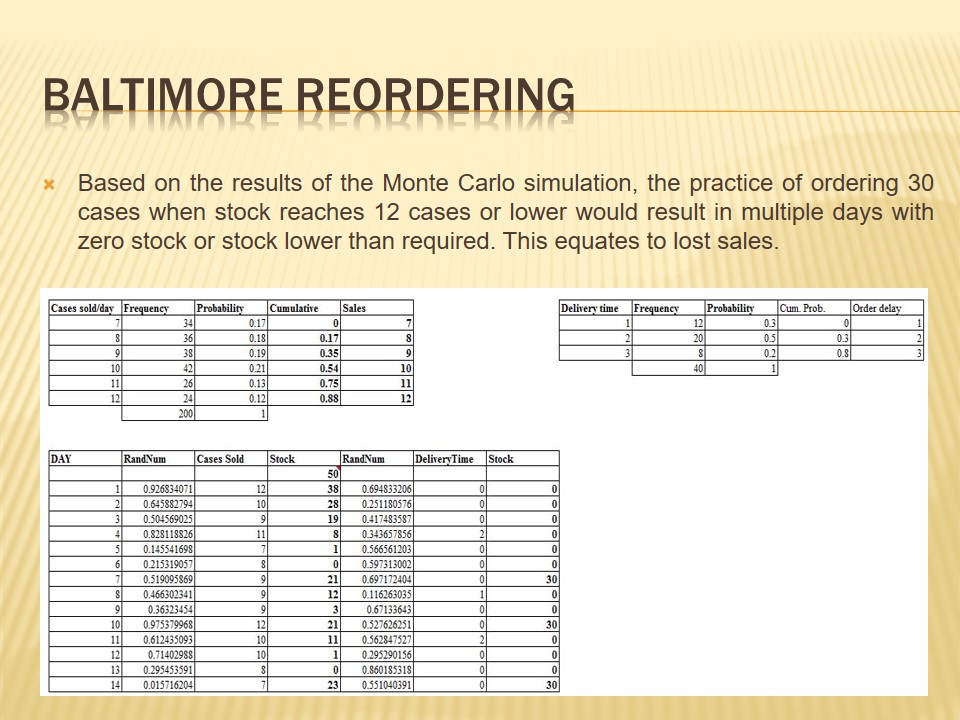

Baltimore reordering

Based on the results of the Monte Carlo simulation, the practice of ordering 30 cases when stock reaches 12 cases or lower would result in multiple days with zero stock or stock lower than required. This equates to lost sales.

The use of a Monte Carlo simulation allows for random variables to be generated through the use of random numbers in effort to map a process or procedure. In the case of this scenario, it will randomize the sales per day as well as the reorder times in effort to simulate stock levels over a prolonged time to estimate a reorder point and quantity.

The scenario is assuming that the store starts with an initial 50 cases of product.

The first column of the simulation table represents the day. The simulation is run for 100 days.

Column 2 is a random number calculated for each day. This random number is used to calculate the number of sales per day.

The third column will show the number of cases sold for the day. To determine the number of cases sold per day, you would use the calculations below:

Using the chart at the top left, under the heading cumulative, you will see the variables that are used in calculating the number of cases sold per day. For example, if the random number R is such that 0 ≤ R < 0.17, the cases sold is 7. If the random number R is such that 0.17 ≤ R < 0.35, the cases sold is 8. If the random number R is such that 0.35 ≤ R < 0.54, the cases sold is 9. If the random number R is such that 0.54 ≤ R < 0.75, the cases sold is 10. If the random number R is such that 0.75 ≤ R < 0.88, the cases sold is 11. If the random number R is such that 0.88 ≤ R < 1, the cases sold is 12.

Column 4 subtracts the number of cases sold and adds the number of stock received. Again, due to the variable missing from the scenario, the initial stock level is based on 50 cases.

If the remaining stock reduces to 12 or less we have to order for a quantity of 30; however, there is a delay in inventory arrival. Due to this, column 5 is a random number generated for the calculation of inventory arrival time.

Observing the chart at the top right, under the heading cum. prob., you will see the variables that are used in calculating the arrival time of orders. For example, if the random number R1 is such that 0≤ R1 < 0.30, the order delay is 1 day. If the random number R1 is such that 0.3 ≤ R1 < 0.80, the order delay is 2 days. If the random number R1 is such that 0.8 ≤ R1 < 1, the order delay is 3 days. This delivery time is calculated in column 6 using the simulated random numbers.

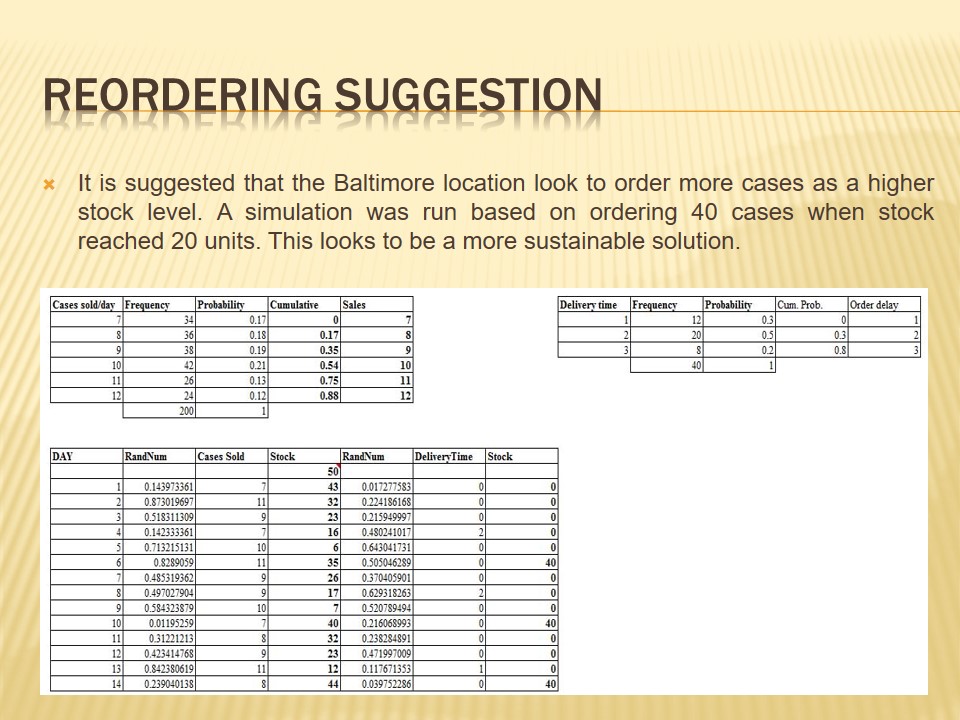

Reordering Suggestion

It is suggested that the Baltimore location look to order more cases as a higher stock level. A simulation was run based on ordering 40 cases when stock reached 20 units. This looks to be a more sustainable solution.

Using the same calculations as previously noted regarding the simulation and changing the variables to a reorder point of 20 units and order quantity of 40 units, we see a more profitable and optimized order process. There is consistently enough inventory to cover all daily sales.

Human Resources strategy

- Hire the Best.

- Retain The best.

- Lead Effectively.

- Engage Employees.

- Develop and Implement a Human Resources Strategy.

- Hire the Best: the cardinal rule here is to hire those who can make the most contribution to your bottom line. Identify the positions in your organizations which most impact the bottom line and hire the best people who can achieve results in these positions. This will require that you adopt a recruitment strategy to attract the best. Today this includes employer branding to ensure your company is constantly marketed as a great place to work (Johnson, n.d).

- Retain the Best: this strategy recommends holding on the personnel that are most experienced and most productive in what they do as much as possible. This can be achieved by revamping HR strategies, such as compensation and training programs, remunerations allowances, reward schemes, support the attraction and retention of the best employees to entice such personnel into remaining within the company (Johnson, n.d).

- Lead Effectively: it is imperative to polish up on your own leadership skills and ensure your senior team does the same. Important leadership skills are basic – honest, competent, motivational (positive), and visionary.

- Engage Employees: this is best captured in the slogan “An engaged employee is a productive employee”. Most people want to work at a job at which they feel they have some control and can make a contribution; at a company where they know what is going on; with inspiring credible leaders; where they receive feedback on what they are doing well and how they can improve; and in an environment of trust (Johnson, n.d).

- Developing and Implementing A Human Resources Strategy: it should be strived to develop and implement a Human Resources Strategy that is in line with your business objectives; a strategy that embraces a goal of productivity improvement. People are the one asset with unlimited potential that leaders can directly influence to impact productivity (Johnson, n.d).

Reducing Waste

- Six Sigma.

- TQM.

- Kaizen.

Six Sigma – this is a business management strategy that seeks to improve the quality of process outputs. This improvement is done by identifying then removing of the causes of defects or errors and minimizing variability in manufacturing and business process (Emiliani, Stec, Grasso & Stodder, 2007, p. 121). This technique reduces wastage and maximizes productivity by creating special infrastructure of people within a corporation and ensures that each sigma project that is carried out follows a defined series of steps that come full with quantified financial targets like profit increase or cost reduction (Emiliani, Stec, Grasso & Stodder, 2007).

Total Quality Management (TQM) – TQM works on the surmise that the quality of processes and products is the sole responsibility of all the people who are involved in the creation, usage and offering of the products of services in that given organization (Emiliani, Stec, Grasso & Stodder, 2007). Productivity is increased and wastage reduced by TQM through its insistence capitalization on the involvement of workforce, management, customers, and suppliers in the hope of meeting and exceeding consumer expectations. This makes this technique all inclusive and effective for project management.

Kaizen – this is Japanese concept that focuses on continuous improvement of processes especially in manufacturing, supporting business processes, engineering and management (Emiliani, Stec, Grasso & Stodder, 2007). It eliminates waste by improving standardized activities and processes and this is best explained by its five key elements of principle operation which greatly improve productivity:

- Improvement morale;

- Personal discipline;

- Teamwork;

- Quality circles;

- Suggestions for improvement.

References

Emiliani, B., Stec, D., Grasso, L., & Stodder, J. (2007). Better Thinking, Better Results: Case Study and Analysis of an Enterprise-Wide Lean Transformation (2e. edn.). Kensington, CT, US: The CLBM, LLC.

Johnson. M. (n.d). Harvard Business Review. Web.

Kelley, J. (2003). Critical Path Planning and Scheduling: Mathematical Basis. Operations Research, 9(3), 61-78.

Milosevic, D.Z. (2003). Project Management Tool Box: Tools and Techniques for the Practicing Project Manager. New York: Wiley.

Yuan, Y., and Shaw, M.J. (1995). Induction of Fuzzy Decision Trees. Fuzzy Sets and Systems, 69(12), 125-139.