Introduction

The key competitive dimensions that drive sales for Timbuk2’s custom messenger bag are customization options, quality, durability, comfort, convenience, and value. Customers may personalize their bag with a multitude of options ranging from size and color to lines, logos, compartments, and straps (Timbuk2, 2023). Timbuk2 is known for its high quality and durable bags that provide comfort and convenience for its users. The company strives to provide excellent value for its consumers, offering reasonable prices for its bags.

Discussion

It is true that the competitive priorities for the new laptop bags sourced in China are different from those for the custom messenger bags. The key competitive dimensions for the laptop bags are cost, quality, convenience, and value. The primary goal for the laptop bags is to provide the best possible features and quality at the lowest possible price. As the laptop bags are sourced from China, the cost is lower, allowing Timbuk2 to provide purchasers with an excellent value. Additionally, the laptop bags are made with convenience in mind, allowing buyers to order their bags quickly and easily with a few clicks of the mouse.

The volume or pace of production, the degree of labor expertise required, the level of automation, and the number of raw materials and finished goods inventory on the assembly line in San Francisco and China are all notably different. The San Francisco enterprise is committed to creating exact, handmade messenger bags for each customer, regardless of volume or rate of production. This needs a degree of personalization and care for detail that a Chinese assembly line producing fresh San Francisco-made items is unlikely to be able to match. The rate of manufacturing in China is certainly higher than in San Francisco due to the lack of personalization. The necessary expertise and worker skill levels are expected to vary between San Francisco and China. Employees at the San Francisco location must be very talented and skilled in the design and construction of tailored messenger bags. This necessitates a level of ingenuity and attention to detail that are not typical of China. Chinese laborers are likely less qualified and experienced because they are creating innovative products designed in San Francisco.

The San Francisco Company is probably more automated because it creates personalized messenger bags based on the desires of the individual client. This requires an accuracy and precision that are likely beyond the capabilities of human labor. The Chinese assembly line appears to be less automated since it is producing whole new products that were made in San Francisco. The inventory of finished goods and raw materials is anticipated to decrease since the San Francisco Company creates personalized messenger bags to exact specifications. The Chinese assembly line is probably going to have a bigger stock of raw materials and completed goods while they are making new products in San Francisco.

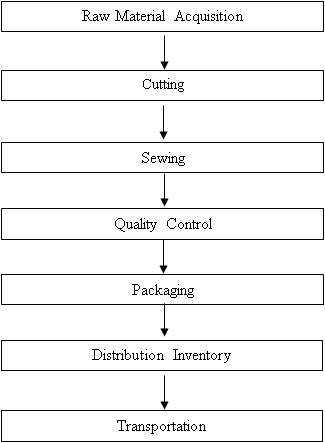

Supply Chain for Products from China

Steps in Manufacturing Process

Conclusion

The craftsmanship and material quality of the items made in China should be taken into account by Timbuk2. The business runs the danger of losing the loyalty of its customers if the quality is subpar. Timbuk2 should take both the delivery time and the cost of shipping from China to the buyer into account. If the price is too high or the delivery time is long, clients could be less likely to purchase from Timbuk2. The expense of the labor employed to make the bags should be taken into consideration by Timbuk2. The business ought to make sure that the employees in China are treated with respect and paid a reasonable salary.

Reference

Timbuk2. (2023). Timbuk2 bags: Backpacks, messenger bags, custom bags. Timbuk2. Web.