Defining total quality management

- TQM emphasizes on the entire company quality management strategies

- TQM incorporates the entire commodities attributes and the physical characteristics capable of meeting the affirmed customer requirements.

- For ADNOC, TQM means designing and implementing corporate culture supporting continuous enhancement of the organization courses of action

- TQM implies acting appropriately to generate improved products and services which satisfy the needs of customers.

Total Quality Management refers to the combination of strategically designed management approaches of an organisation centred on quality and the comprehensive participation of all organisation members with an aim of providing long-term success (Deros et al., 2009). In fact, total quality management is the practice of managing the whole organization processes to achieve quality. For instance, total quality management entails the conformity to the requirements including continuous improvement, employee empowerment and quality circles.

Acting appropriately through Total Quality Management

TQM requires an organization to act appropriately. The clients needs can hardly be met without successful accomplishment and proper management of the available resources. Thus, TQM helps organizations to act perfectly in the first instance.

Synopsis of TQM

- TQM covers corporate processes that ensure the production of improved commodities

- The objectives of TQM are achieved by ensuring total customer satisfaction

- Customer satisfaction materializes from constant improvement of the organizational processes including the employees welfare and operations

- Given its significance, most organizations particularly those situated in the UAE have implemented TQM technique in its totality

- ADNOC is amongst the UAE corporations committed to the application of TQM in most business processes

Despite the implementation of TQM, the utilization of the TQM technique has remained shaky, undermined, and underutilised in several UAE corporations (Deros et al., 2009). However, TQM ensures systems improvement and the enhancement of the key stakeholders requirements including customers and suppliers. TQM aims at enhancing quality through doing the right thing.

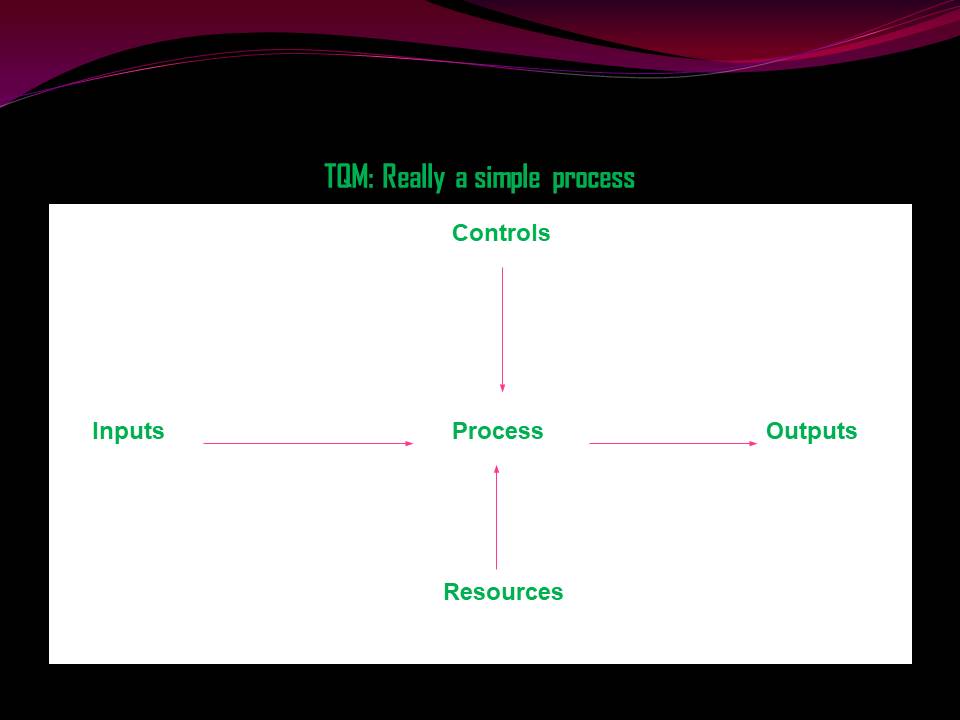

TQM: Really a simple process

From study literature on TQM, the approaches used in total quality management appear incorporate simple processes. Any organization that is deemed successful in implementing TQM has decisive such as inputs, resources, controls, and processes that generate the desired outputs. Such parameters make up TQM.

The company overview and TQM

- Abu Dhabi National OIL Company is amongst the reputed companies in the global oil industry

- The company reports constant business achievements emerging from quality management practices

- ADNOC is successful given its emphasis on TQM practices in all the undertaken business processes

- ADNOC TQM focuses on constant improvement of its products, services, customers, suppliers and employees

Over the years, ADNOC has increased its production and manufacturing efforts towards achieving a greater competitive market share to become the world’s leading oil producing companies. It dominates the marketing, shipping, and production paradigms (ADNOC, 2013). TQM has enabled the company to increase its production capacity, gain significant market share and become the world leading corporation in the oils and shipping industry.

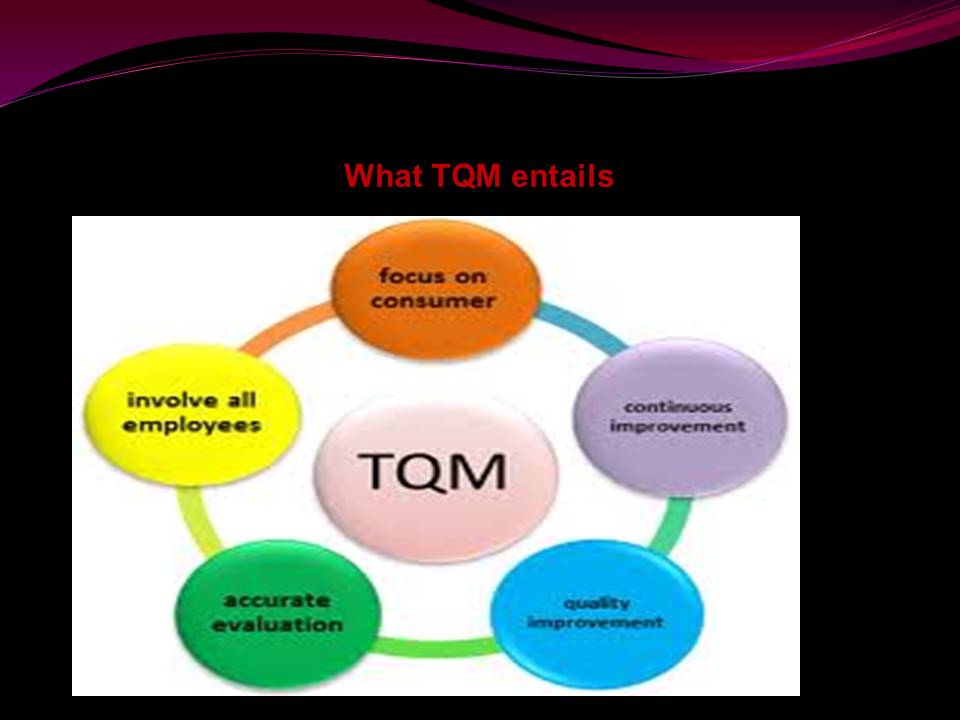

What TQM entails

TQM entails various focal points. Successful corporations such as ADNOC include quality management, continuous improvement, customer focus, inclusion of every worker, and accurate evaluation in their TQM strategies. All these measures such companies to the their stakeholders obligations.

ADNOC’s executive commitment to TQM

- Executive commitment to the implementation of TQM is amongst the principles leading to the success of an organization

- ADNOC management ensures that TQM objectives are implemented via motivation, leadership, proper planning and continuous innovations

- The executive ensures that they fully contributed towards participate in the attainment of the company mission, vision, objectives and goals

- ADNOC has emphasized on excellence in the business processes through initiating the Sheikh Khalifa Excellence Award (SKEA)

- SKEA enhances the company capabilities to increase its competitive advantage and encourage continued existence, success and growth.

Total Quality Management can hardly be achievable by only setting organisational goals, objectives, mission and vision statements without actively participating in their follow up through actions (Al-Shobaki et al., 2010). As such, ADNOC has excellent schemes intended to promote the understanding and awareness of TQM practices that ensure enhanced performance.

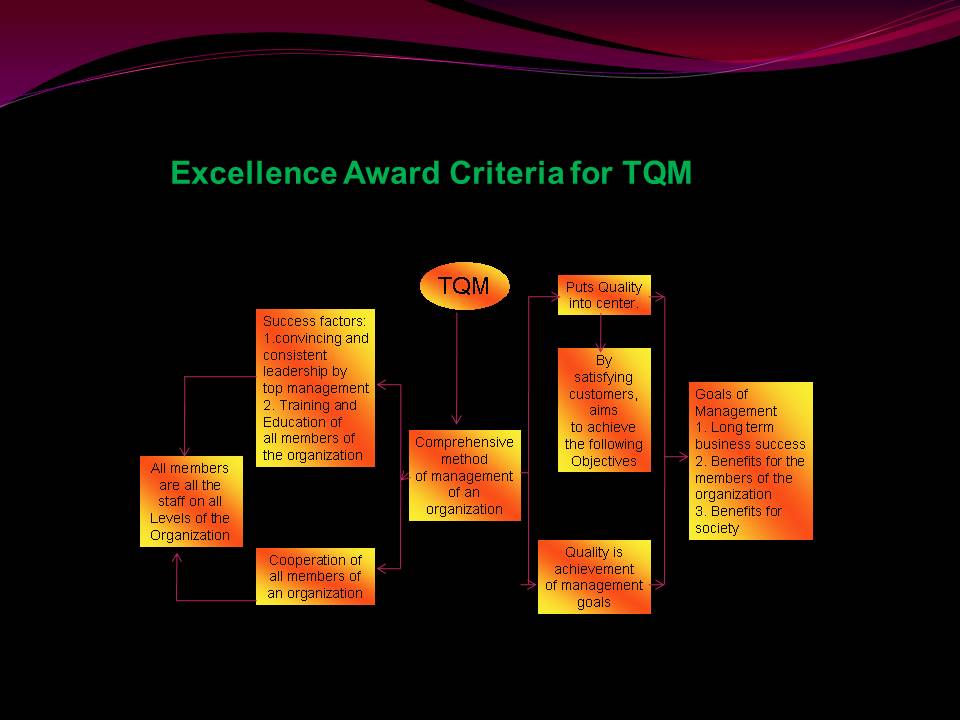

Excellence Award Criteria for TQM

The excellence award criteria for TQM highlights the requisite elements needed when implementing TQM. For instance, the criteria highlights the success factors such as apt leadership and training, the involvement and cooperation of all members, as well as comprehensive management methods. Besides, according to the method, it is important to put quality first through satisfying the clients, and realizing the management goals.

The company focus on customer satisfaction

- To successfully implement TQM, companies focus on practices that satisfy customer needs

- ADNOC has instituted measures that encourage trust and reliability

- The company integrates customer services, the quest to improve and achieve customer satisfaction

- ADNOC integrates processes that ensure the continuous improvement of commodities aimed at satisfying clients needs

- The company responds promptly to the customer claims, enacts customer compensation policies and diligently respond to customer complaints

TQM may typically imply total business focus towards meeting and exceeding customer’s needs and expectations by considering their innermost interests (Deros et al., 2009). ADNOC ensures the customers’ needs are met through improving the quality of products and services that in turn have increased its competitiveness in the market.

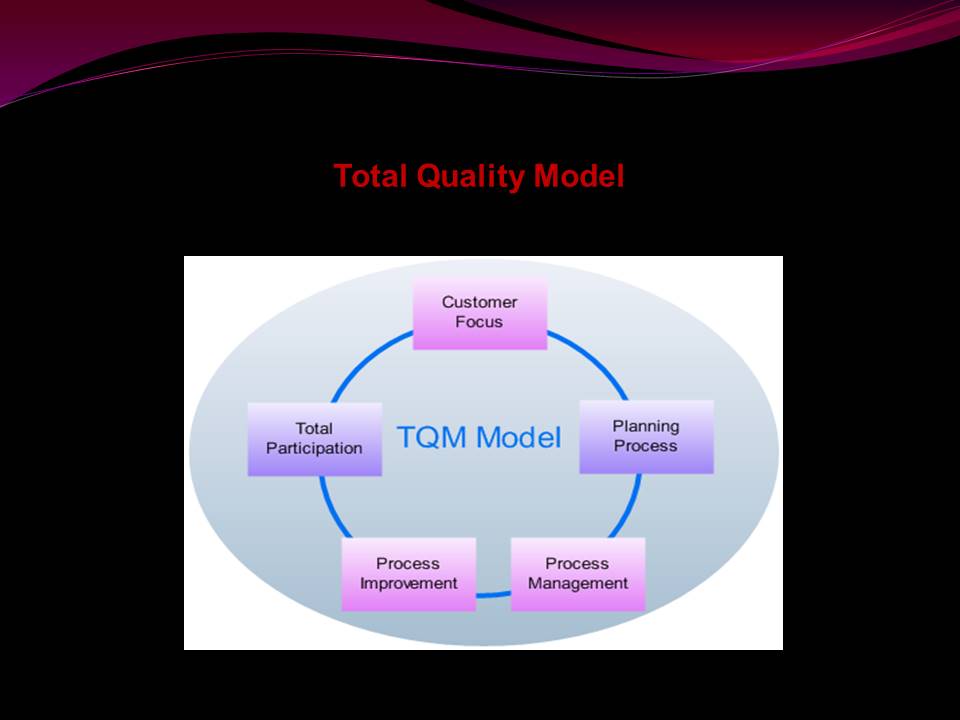

Total Quality Model

Basically, TQM is intended to increase and accomplish the clients satisfaction. Any total quality management model necessitates process management, process improvement, planning processes, total participation, and focusing on the needs of the customers.

The company quality planning and culture

- Corporations establish cultures that enhance quality of business processes

- ADNOC plans and performs quality attainment practices that enhance business performance

- Planning involves appropriate preparation and guidance in attaining goals

- ADNOC staffs are trained and guided on the principles concerned with quality attainment culture

- Quality is paramount at ADNOC and the company has quality assurance departments to ensure quality production

For TQM implementation to remain successful, strategies towards achieving quality planning and having the culture towards quality accomplishment is paramount. Corporate managers and employers must remain intrinsically driven to enhance and maintain quality through strategic planning schemes, which involve training workers on principles concerning quality achievement and quality culture (Shahin, 2011).

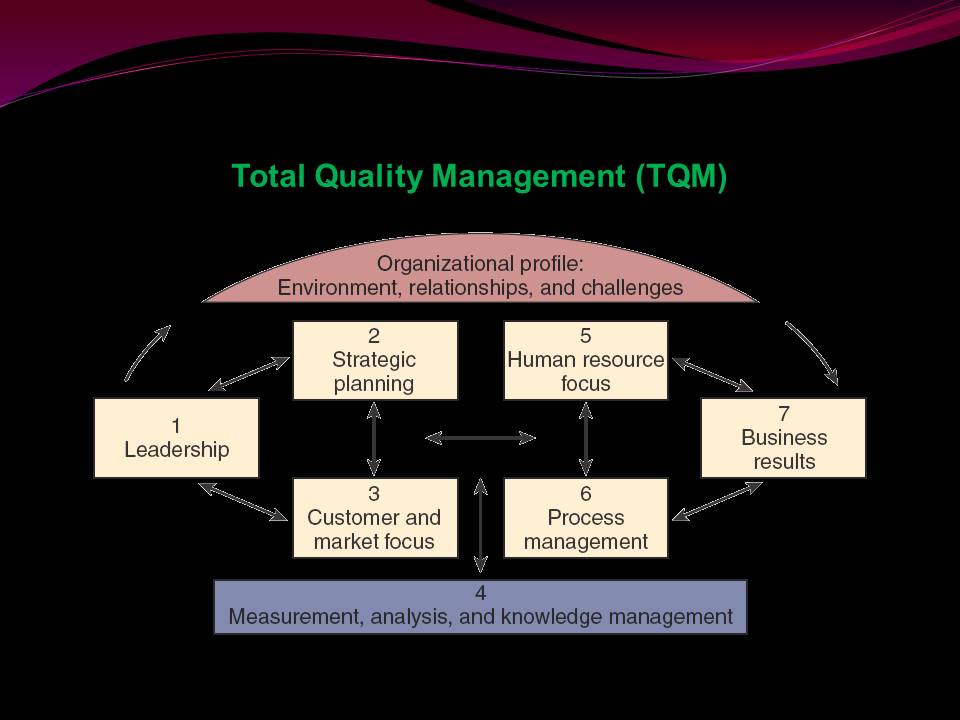

Total Quality Management (TQM)

Total quality management integrates leadership, strategic planning, workforce, business results, client and market focus as well as process management. In fact, TQM entails the organizational profile including the environment, challenges and relationships. However, successful management of TQM requires measurement, analysis, and the management of knowledge management.

Employee involvement, training and empowerment

- Employee involvement, training, and empowerment are imperative when designing, and implementing TQM

- Employee commitment incorporates involvement and participation

- Empowerment and motivation enable workers to communicate, corporate, and be effectively and professionally responsible

- Companies should prioritize training as a TQM principle to handle organizational changes

- ADNOC supports workers training on quality measures, improves knowledge, skills, and attitudes of staffs

The department of HRM is responsible for nurturing and developing employee skills for corporate success (Bahri et al., 2012). To win the willingness and corporation of employees in achieving TQM goals, the company might take initiative of motivating and empowering workers for them to be intrinsically and extrinsically responsible. Lack of awareness on the objectivity of TQM generates difficulty in comprehending TQM as a significant strategy.

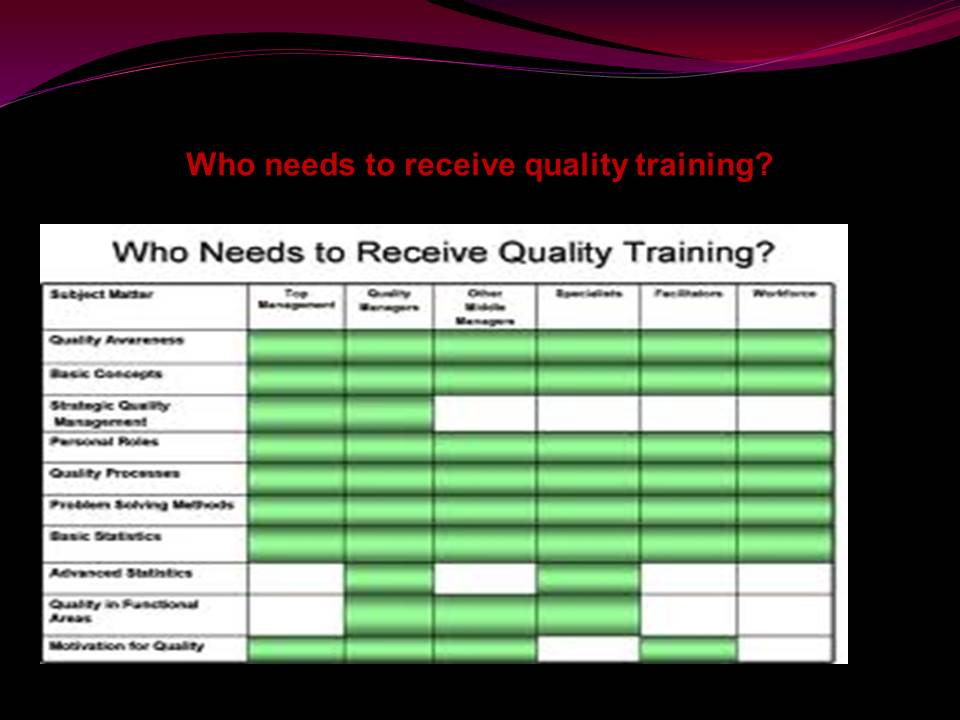

Who needs to receive quality training?

According to TQM, quality training is supposed to be given to the top management, quality manager, other middle managers, specialists, facilitators, and workforce. The training should incorporate quality awareness, strategic quality management, procurement practices, and advanced statistics training. Besides, the basic concepts of TQM, and motivation should be given to the workforce to help in the implementation of the TQM.

Unity of purpose, cooperation and teamwork

- TQM implementation depends on unanimity, organizational corporation, and teamwork principles

- The aspect of unity in purpose is imperative when implementing TQM

- Cooperation and teamwork illustrate the success in TQM implementation in most organizations

- ADNOC promotes unity of purpose, cooperation, and teamwork via TQM

- ADNOC management develops performance improvement programs to overcome ADNOC challenges and create opportunities

To encourage functional departmental teamwork, introduction of multilevel discipline, enhancing monitoring of department, and recognition of ADNOC were the main objectives of performance improvement programs. The directors believe that success power rests on team work that remain self motivated to competently undertake organizational duties since ADNOC promotes cohesive approaches in achieving teamwork (Deros et al., 2009).

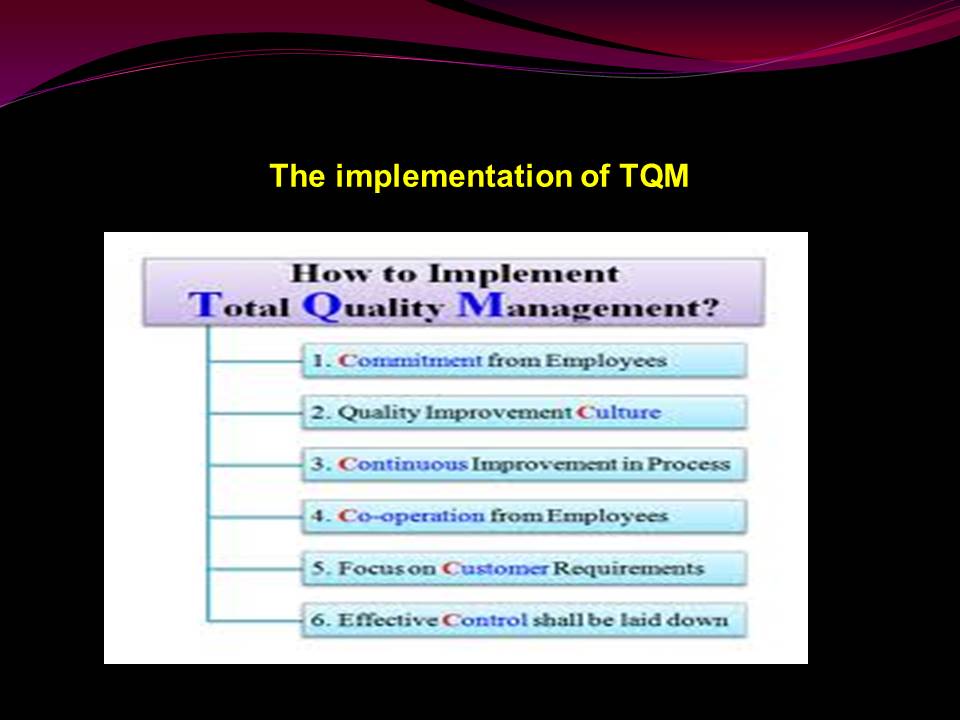

The implementation of TQM

The implementation of TQM requires the commitment from the workers, focusing on the requirement of the customers, laying down effective control, workforce cooperation, quality improvement culture, as well as continuous process improvement.

Paradigm of shift: Corporate cultural change and TQM

Total Quality Management

- Externally focuses on client with open and free communication

- Empowering employees and prevention

- Incessant improvement, supportive associations and problem solving starts at the roots

Conventional Approach

- Internally focuses on the regulation with hindrances to communication

- Employees manipulation and control

- Seeking for stability via adversarial associations and members allocated blames

There has been a paradigm shift in the traditional approach to quality management to the current TQM strategy. Various components that constituted the customary approach varied significantly with the advent of the TQM. In the context of ADNOC, the company has encourages continuous progression, and relationships that are inclined to support TQM activities. To realize this, the company empowers its workforce and encourage them to avoid shifting blames but rather tackle every problem from the root cause. Besides, ADNOC concentrates on delivering commodities that satisfy the clients needs through facilitating free and undeviating communication between the company staffs and the clients.

Implementation resources

- TQM implementation can hardly be realized with deficient resources

- The availability of resources enable TQM to increase market competence, productivity, and profitability

- Financial and human resources are imperative during TQM implementation

- ADNOC is the most developed and financially stable organization in UAE

- ADNOC has designed diverse financial support projects to assist in the implementation of TQM

Lack of the implementation resources like financial and human resources lead to failure of TQM implementation. ADNOC successfully implements its TQM projects given that the company has sufficient resources. Apart from the financial and human resources, ADNOC empowers and motivates its workers to communicate, corporate, and be effectively and professionally responsible.

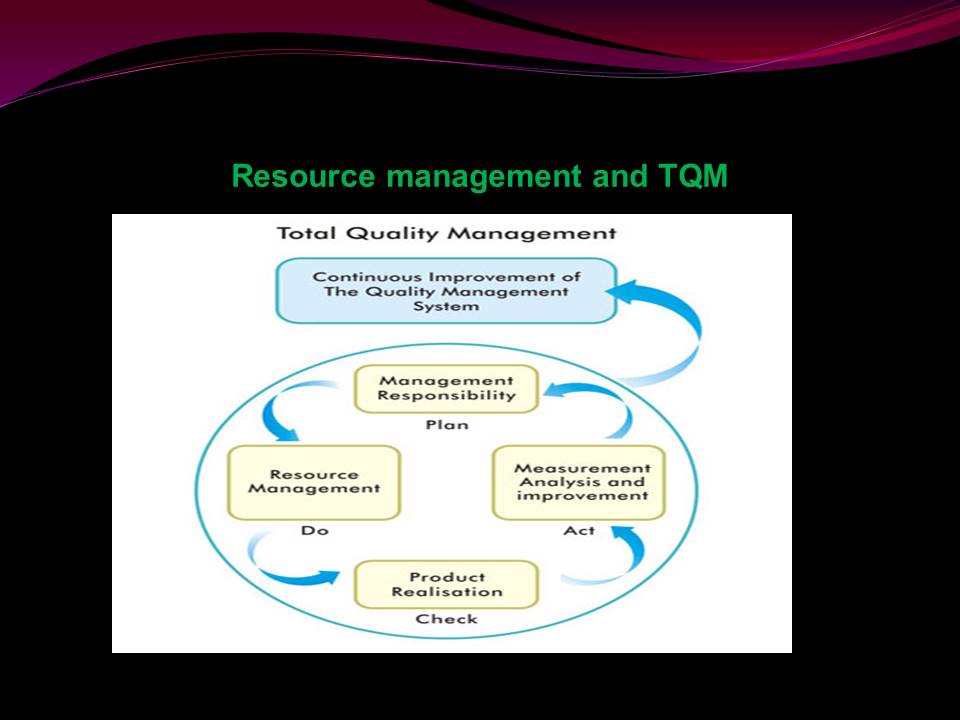

Resource management and TQM

Given that enough resources are needed during TQM implementation, TQM requires its systems to be continuously improved through management responsibility, product realization, and resources management. These call for proper planning, action, assessment, and doing.

Conclusion

- TQM is the most anticipated quality based initiative in the present world

- Organization must employ many principles and concepts to successfully implement TQM

- TQM is successful with resources, cooperation and teamwork, training, empowering, employee involvement, and executive commitment

- The adoption of TQM strategies explain why ADNOC is dominant in the UAE transportation, oil and refinery paradigms

From companies reports and study literature, the advent of TQM has helped many organizations to amicably address quality issues. However, for successful implementation of TQM, various theoretical constructs and measures must be incorporated. These include, rewarding staffs, training, discipline, as well as integrating the management and workforce commitments.

References

ADNOC (2013). About ADNOC: Abu Dhabi National Oil Company (ADNOC). Web.

Al-Shobaki, D., Fouad, H. & Al-Bashir, A. (2010). The implementation of total quality management (TQM) for the banking sector in Jordan. Jordan Journal of Mechanical and Industrial Engineering, 4(2), 304-313.

Bahri, S., Hamzah, D. & Yusuf, R. M. (2012). Implementation of total quality management and its effect on organisational performance of manufacturing industries through organisational culture in South Sulawesi, Indonesia. Journal of Business and Management, 5(1), 10-24.

Deros, B., Rahman, M., Ghani, J., Wahab, D., Hashim, M. & Khamis, K. (2009). Role of senior management in TQM implementation in Malaysian small and medium enterprises. Journal -The Institution of Engineers, Malaysia, 72(3), 15-20.

Shahin, A. & Dabestani, R. (2011). A feasibility study of the implementation of total quality management based on soft factor. Journal of industrial engineering and management, 4(2), 258-280.