Background and Introductory Overview

Abu Dhabi National Oil Company (ADNOC) belongs to the leading oil production institutions in the Arabic world. This work outlines the successful strategies of the quality management, which have been introduced by the administrators of the business as well as verifies the marketing accomplishments of the company, which concern the introduction of the innovative high-quality car engine oil. The paper emphasizes the fundamental advantages and supremacy of the ADNOC products over the competitor firms and makes some suggestions as to the secrets of the firm’s success as well as emphasizes the positioning of the production on the global market.

Quality Management as a Prerequisite for Global Success

Environmental Protection in the Context of Oil Production

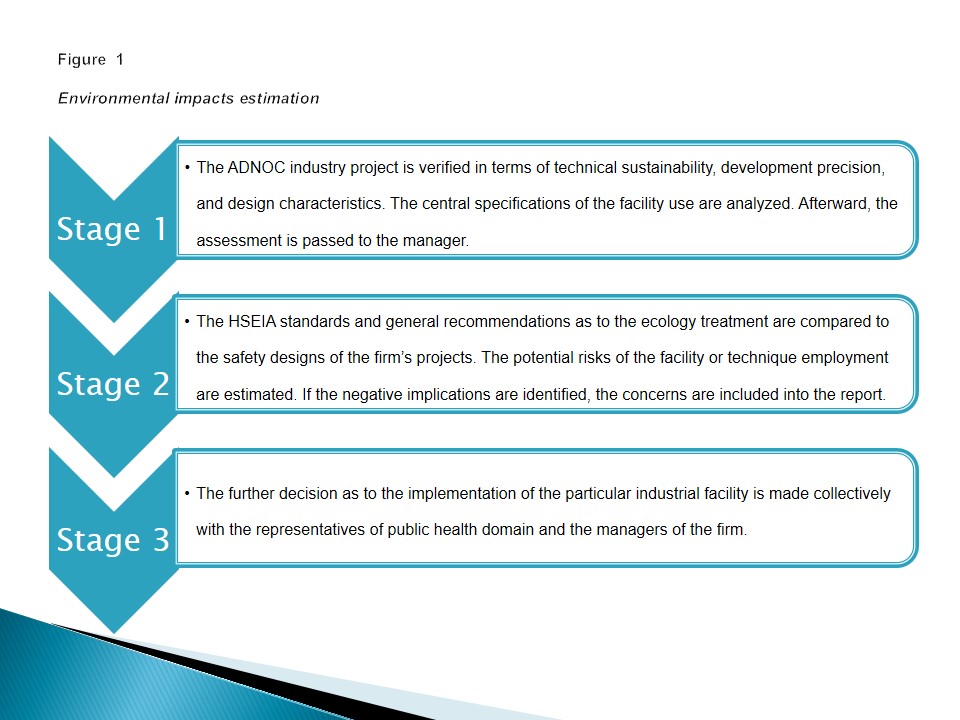

The primary issue, which ensures the world-wide success of the ADNOC products, concerns the values of the environmental protection. Thus, the business employs a consistent strategic planning, which targets the interrelations between the company values and nature safety. The staff includes a special health and safety consultant, who develops a three-stage assessment of the production implications, analyzes some statistic data that regards the quality of public health in the region as well as chemical and biological effects of the oil production mechanisms (see fig. 1). On the basis of the HSEIA assessment, the specialist makes some suggestions as to the technical changes in facilities or industrial methodologies (“Integrated Health, Safety, and Environmental Impact Assessment” par. 2).

- Stage 1. The ADNOC industry project is verified in terms of technical sustainability, development precision, and design characteristics. The central specifications of the facility use are analyzed. Afterward, the assessment is passed to the manager.

- Stage 2. The HSEIA standards and general recommendations as to the ecology treatment are compared to the safety designs of the firm’s projects. The potential risks of the facility or technique employment are estimated. If the negative implications are identified, the concerns are included into the report.

- Stage 3. The further decision as to the implementation of the particular industrial facility is made collectively with the representatives of public health domain and the managers of the firm.

Commitment to Customers

The vision of the company on the production delivery is the second aspect of the quality management in ADNOC. Since, the company has a number of subsidiaries in the Arab countries, the management established a stable connection between the central administration of the firm and the individual industries. The workers of ESNAAD, which is the biggest ADNOC subsidiary report that annual meetings of the representatives, who compile the estimations of marketing rates as well as the customers’ reports on the services of the business, are held. At such conferences, the management discusses the achievements and shortcomings of production delivery and suggests the ways of the quality improvement. The administration primarily takes an orientation on the changes in the clients’ needs so that to meet the expectations of the ADNOC oil users. This strategy contributes to the stable development of the business and brings constant improvements to quality management (“ESNAAD: Company Profile” par. 3).

Service Optimization

The quality management improvement is conducted through the regular support of service optimization. The management of the ADNOC firm takes a direction on the maintenance of the optimal approaches to human resources treatment. For instance, the latest service introductions include the workplace orientation. Thus, the company takes care of the occupational injuries and diseases of the employees with the aim of ensuring safe work climate. Furthermore, the firm has recently embraced a new Health and Safety Environment (HSE) program, which provides the complex guidance for the workers, as well as their supervision, which targets the treatment of industrial facilities. Therefore, one should note that a human factor is a critical constituent part of any work procedure, which has to be taken into account by the administration (“Gulf Oil & Gas” par. 5).

Striving for Perfection: The Estimation of Car Engine Oil as a Basic Product of ADNOC

Voyager Silver

The best illustration of the company’s success is the illustration of the qualities of its production. The car engine oils, which are released by the ADNOC firm, find a strong favor among the customers throughout the world. Voyager Silver is an innovational oil that is based on gasoline and follows the semi-synthetic production design. The product is famous through its universal character. Thus, Voyager Silver may be used in both the conventional engines and the direct injection machinery. The experts recommend the use of the product in the standard passenger cars as well as the big trucks or vans (“ADNOC meets the needs of your machine” par. 7).

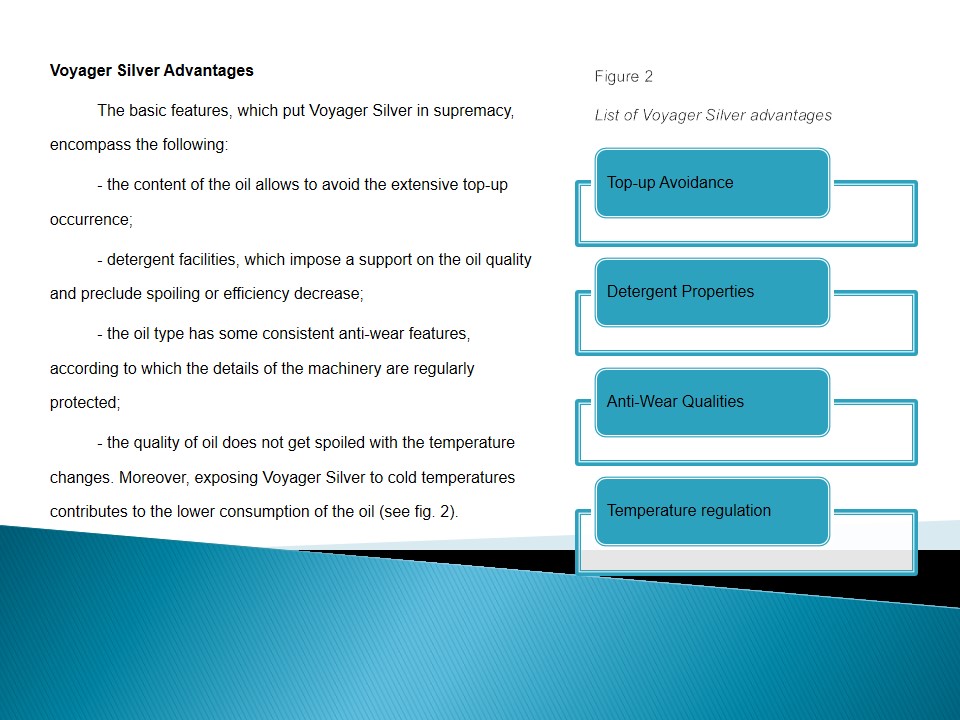

Voyager Silver Advantages

The basic features, which put Voyager Silver in supremacy, encompass the following:

- the content of the oil allows to avoid the extensive top-up occurrence;

- detergent facilities, which impose a support on the oil quality and preclude spoiling or efficiency decrease;

- the oil type has some consistent anti-wear features, according to which the details of the machinery are regularly protected;

- the quality of oil does not get spoiled with the temperature changes. Moreover, exposing Voyager Silver to cold temperatures contributes to the lower consumption of the oil (see fig. 2).

List of Voyager Silver advantages:

- Top-up Avoidance.

- Detergent Properties.

- Anti-Wear Qualities.

- Temperature regulation.

Voyager Gold

The properties of Voyager Gold car engine serve as the representation of the ADNOC’s environment-related quality management policies. The type of oil fully relies on the synthetic resources and does not pose any threat to ecology and human heath. The product is particularly applicable to the high-quality turbo machinery such as recreational vehicles, trucks, and vans. Moreover, Voyager Gold is the top oil in the race machines since it has the quality to lubricate the effects of Gasoline and Diesel use.

Voyager Gold Benefits

The use of Voyager Gold provides a range of advantages:

- the oil type protects the machinery from weather conditions as well as is resistant to corrosion and soot;

- the product maintains a stable emission control;

- the use of Voyager Gold is optimal for fast driving, for the circulation of oil is extremely quick;

- the oil is not vulnerable to oxidation and is susceptible to thermal control.

- the content of the oil ensures the prevention of metal contacts (see fig. 3).

Voyager Gold advantages:

- Corrosion and Soot Resistance;

- Emission Control;

- Optimal Circulation;

- Oxidation and Temperature Control;

- Metal Contacting Prevention.

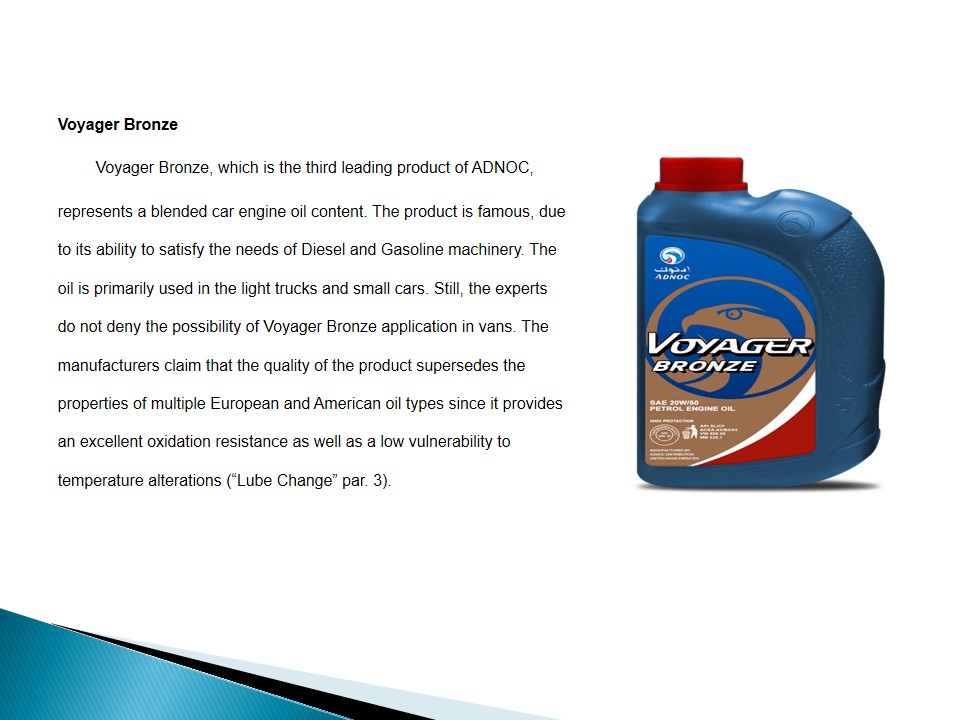

Voyager Bronze

Voyager Bronze, which is the third leading product of ADNOC, represents a blended car engine oil content. The product is famous, due to its ability to satisfy the needs of Diesel and Gasoline machinery. The oil is primarily used in the light trucks and small cars. Still, the experts do not deny the possibility of Voyager Bronze application in vans. The manufacturers claim that the quality of the product supersedes the properties of multiple European and American oil types since it provides an excellent oxidation resistance as well as a low vulnerability to temperature alterations (“Lube Change” par. 3).

Voyager Bronze Assets

Despite the Voyager Bronze is not claimed to be the ecology-friendly type of oil, it still has its considerable advantages and can be improved with the reference to HSE policy. The benefits of the product are the following:

- the oil reveals low dependency on the seasonal changes, for it is suitable for any temperature regimes;

- Voyager Bronzer supports viscosity grade;

- the product is highly resistant to sludge and it is, therefore, optimal for the winter use;

- the deposit formation is not a threat for the particular engine if it drives on Voyager Bronze oil (see fig. 4).

Properties of Voyager Bronze:

- Temperature Resistance.

- Viscosity Grade.

- Winter Use.

- Deposit Formation.

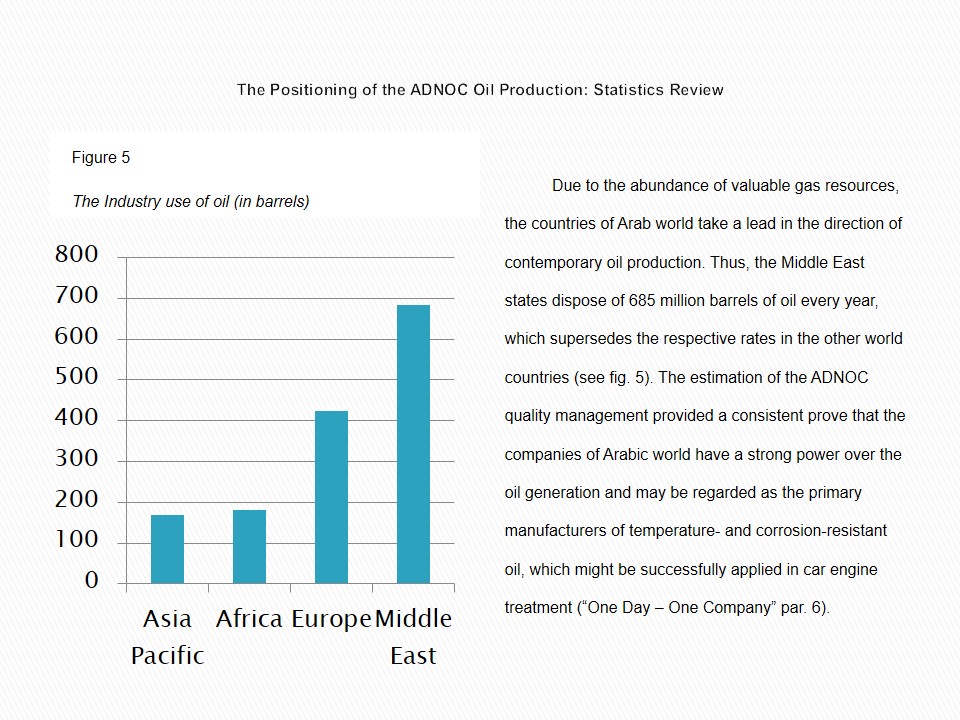

The Positioning of the ADNOC Oil Production: Statistics Review

Due to the abundance of valuable gas resources, the countries of Arab world take a lead in the direction of contemporary oil production. Thus, the Middle East states dispose of 685 million barrels of oil every year, which supersedes the respective rates in the other world countries (see fig. 5). The estimation of the ADNOC quality management provided a consistent prove that the companies of Arabic world have a strong power over the oil generation and may be regarded as the primary manufacturers of temperature- and corrosion-resistant oil, which might be successfully applied in car engine treatment (“One Day – One Company” par. 6).

Works Cited

ADNOC meets the needs of your machine 2015. Web.

ESNAAD: Company Profile 2013. Web.

Gulf Oil & Gas 2013. Web.

Integrated Health, Safety, and Environmental Impact Assessment 2015. Web.

Lube Change 2011. Web.

One Day – One Company 2014. Web.