Technological development affects virtually any sphere of human activities today and those who make use of it obtain advantages on their way to success. In business, new services are constantly created that make operation faster, easier, and more effective; businesses that fail to adopt technological advancements face the risk of falling behind.

Even in small businesses, such as operating a small clothing store, the standards are changing due to the introduction of management systems. It is hard to operate such a store if the inventory needs to be managed manually. The owner will face numerous problems: how many items should be purchased and stocked? When will they be sold out? What is the best time for ordering new items? What are the expenses associated with storing items? What orders should be made to optimize the delivery and flow of sales?

One of the ways to answer these and other inventory management questions is to keep records, such as spreadsheets. However, there are multiple issues with such documentation: data is quickly outdated, mistakes are probable, and there is no connection between such records and other systems (e.g. payment systems) (Chang, 2016). This is why a better solution for a business is an automated inventory management system that will collect appropriate data, perform all the necessary calculations, and generate reports that will enable better decision-making for the business.

An inventory management system is a type of software that processes inventory tasks and provides such information as sales prediction and purchase plans based on the dynamics of business operation and the resources the business possesses (e.g. storage capacity). The benefits of using such systems are evident: improved logistics, usage of space, purchase schedule, and demand addressing. A major consideration, however, it the budget: what is needed in this case is a low-cost inventory management system.

When choosing or building an inventory management system, one should consider three main aspects: features, cost, and efficiency (Trujillo, 2015). There is a variety of services in the market, and it is necessary to ensure that the system’s features are adequate, i.e. neither excessive nor insufficient. Second, a tight budget does not necessarily mean a poor system: there are solutions marketed for free for certain trial periods, and their use can help the business save some money for further purchase of the system for a longer period. Finally, it is important to calculate how efficient the system will be before buying it. For example, it should be calculated how much the additional equipment will cost, and how much time will be needed to adopt the system and learn to use it effectively.

Apart from the software itself, additional equipment may be needed. A 2D barcode scanner is the first consideration. However, with a small budget, a less expensive option can be considered: there are mobile solutions that allow using smartphones as barcode scanners, and such a solution may be sufficient for a small store. To make use of a barcode-based inventory system, the business will also need a barcode printer. The main considerations in choosing a barcode printer include workplace conditions, quality of printing, and necessary print volume.

If it is not planned to print many labels, and the high quality of them is not crucial, a regular thermal printer will suffice; it can easily function under the conditions of a clothing store, too. To collect data, the business may need such hardware as a mobile computer to assist the operation of the inventory management system. Some additional pieces of equipment may be required to connect the system to existing electronic services, such as the payment system, in case it is planned to adjust such connections.

If it is planned to purchase one of the inventory management solutions currently available in the market, the cost of the system will consist of the cost of software and the cost of the equipment described in the previous paragraph. What should also be counted toward expenses is the time needed to install software and hardware and to learn how to use them properly.

However, if it is planned to build inventory management systems, the expenses will include the cost of software development, i.e. development specialists will need to be hired. For the small store, it is not recommended to opt for this solution because available inventory management systems will fully meet the needs of the business; custom solutions are for more advanced businesses that have complicated operation, want to adjust their inventory management systems to it, and can afford software development services.

If it opts for an existing inventory management system, the ongoing maintenance will include updating the software and paying for a particular subscription plan; conditions vary among providers. If a barcode scanner is not purchased, hardware maintenance will mainly consist of operating the barcode printer, which requires regular supplies. This maintenance is easy to schedule and implement; it is not expected that, with the recommended low-cost inventory management system plan, maintenance will be an important issue. The operation of the system (e.g. inputting data and applying barcode labels) is not considered part of the necessary maintenance.

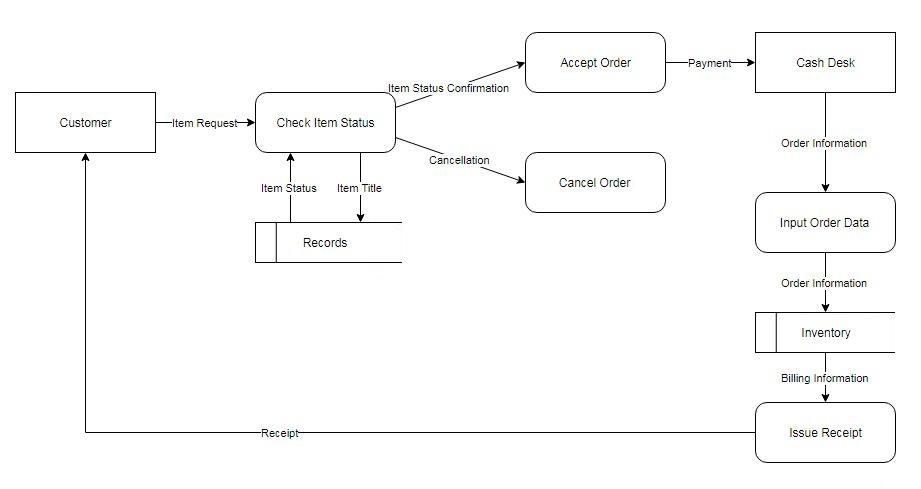

The workflow of the system will depend on the complexity of functions and the scope of integration. The main principle, however, is coordinating data and actions among customers, the store, the inventory, and the database (Ting & Tsang, 2012). The general workflow is shown in Figure 1.

As the workflow shows, the proposed system will check the requested items’ status in the records, approve payments, the track sold items, update the inventory information, and process billing. This way, it will be able to control the inventory; additional data processing services will generate reports on inventory management that will contain such information as stocking advising and sales dynamics. It is expected that, with this workflow, the system will make the store’s inventory management more effective.

References

Chang, J. F. (2016). Business process management systems: Strategy and implementation. Boca Raton, FL: Auerbach Publications.

Ting, S. L., & Tsang, A. H. (2012). Design of an RFID-based inventory control and management system: A case study. The West Indian Journal of Engineering, 34(1), 70-79.

Trujillo, P. (2015). How to build the right inventory management system. Web.