Abstract

Continuous advancement in the research for higher speed micro processors and power electronics has led to more focus on the performances of electrical machines, their roles in the industrial drives and a higher thirst for the determination of their parameters. Furthermore, ways and means of improving these parameters have not been ignored. This paper seeks to open the lid on the various types of electrical power machines, their modes of operation, parameter determination and relevant applications. Towards this, an insight analysis on the various and practical methods of protecting electrical machines from the effects of mechanical damages and electrical overloads will be focused. This paper therefore seeks to open up more knowledge to practicing engineers on machine design, protection, maintenance and choice.

Introduction

Much has been said within the engineering circles on the need to fully understand basic principles and functions of electrical machines with an aim of making proper and correct use of them. Okoro, Agu & Chinkuni (2006). describe the various electrical machines as “The Direct Current (D.C.) machine, the synchronous machine, and the induction machine.” In Electrical Engineering, squirrel cage induction machines have a number of advantages postulated by Okoro, Agu & Chinkuni (2006). as “lightness, simplicity, ruggedness, and robustness, less initial cost, higher torque-inertia ratio, capability of much higher speeds and ease of maintenance.” Its stays a tough competitor against D.C. machines because of its lower cost in the drives field. In comparison to the D.C. machine, its cost per KVA is in the ratio of 1:50 and possesses unique ability to exist and function normally under hostile electrical and mechanical conditions. However, induction machines also suffer from a number of limitations that in turn favor the use of D.C. machines. “In contrast to D.C. machines, their speed cannot be easily and effectively adjusted continuously over a wide range of operating conditions.” (Okoro, Agu & Chinkuni, 2006). In addition to that, the synchronous machine has the ability to effectively run and function over a very wide range of power factors. These involve conditions in the lagging and leading and as such are suitable to for operations that involve bulk power generation.

The difference in the mode of operation between these two machines is that in the induction machine, alternating current is relayed to the stator and induced in the rotor by the action of the transformer while the activity in the synchronous machine involve the supply of direct current to the rotor and a flow of Alternating Current (A.C.) in the stator. This research paper will discuss in depth the principles and basic features of various types of electric machines. Furthermore, it is common knowledge that for proper function of a machine, best knowledge on the maintenance, parameters, protections and electric machine applications must be fully understood. This paper will therefore not ignore these important aspects of normal machine operation.

Review, analysis and selection of an appropriate research methodology

The choice of the methodology approaches that have been selected and followed have been well explained and justified. The purpose of this research paper is to provide an analysis and to open the lid on the various types of electrical power machines, their modes of operations, parameter determination and relevant applications. “The scientific methodology of research was employed because it provides a systematic and organized series of steps that insures maximum objectivity and consistency in researching a problem” (Giancoli, 1988). “It also provides a shared basis of analysis and helps to promote reliability and validity (accuracy and consistency)” (Giancoli, 1988).

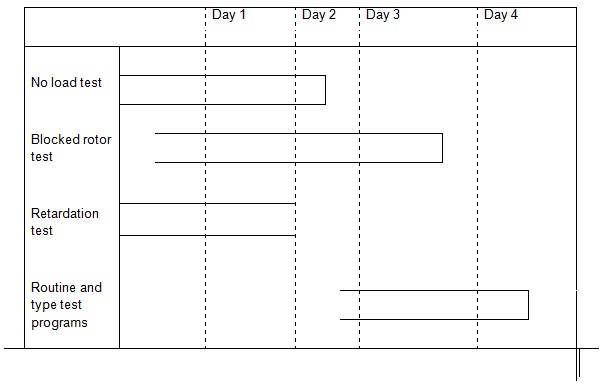

In this research paper, inductive research approach strategy was adopted. Here data was collected after practical analysis on the machine parameter determination that involves retardation test, blocked and rotor test. Theories are then developed after data analysis was carried out. The approach owes more to phenomenology as opposed to positivism research philosophy. Data for electrical machine and maintenance was collected after a routine and type test program. To effectively come up with accurate data on all these practical processes, a longitudinal time frame was applied. This involves the observation of the results for a period of time under different electrical, mechanical and environmental conditions.

Given the contextual framework of the research, case study research design was employed. Case study research design will be mainly qualitative (or more specifically interpretive qualitative) in nature. This will provide a deeper analysis on the more specific issues and address specific questions raised in the research. In the process of designing the research, the four dimensional framework suggested by Mouton (2001) was used. Within this framework, it was possible to classify the research into; empirical research, using predominantly primary data, where data is predominantly textual, and with, relatively low control. To effectively deal with error in this research, 5% margin of error was applied. The analytic strategy was adopted in the analysis of data as advocated for by Giancoli (1988). Basically, data generated was analyzed qualitatively. This involved an analysis of the observations generated from the research in depth. Information from the tabulated and non-tabulated results were analyzed in depth and the key themes identified and comparisons carried out among the various results obtained. This essentially formed the basis for making deductions about a given scientific research issue.

Descriptive statistics were then carried out. These involved the calculation of the mean values, the standard deviations and standard errors. Analysis of variance (ANOVA) was then conducted as a test of significance on the sizes, winding resistances and leakage reactances. Percentages representations were then computed. Data was then presented using text, tabular and semi tabular presentation methods. For all the above analysis, the level of significance was set at degree of error at.5. This section has clearly and explicitly discussed the methodology adopted in the research. Here, the research design, data collection methods and data collection procedures have been clearly stipulated. In the next chapter, the research findings generated will be provided and a discussion of the key findings highlighted.

A Gantt chart detailing research plans and approach

From the engineer’s point of view, the major questions being asked are what type of machine is best suited to be used in a particular job? What remains behind the knowledge in making use of the correct machine for a particular? How best should a machine be maintained for optimum performance and maximum output? These are the questions this section will seek to answer by reviewing the literature on basic principles and functions of electrical machines. “Electrical machines and faults can impose unacceptable conditions and protective devices are therefore provided to quickly disconnect the machine from grid and protect it from damages related to overloads.” (Okoro, Agu & Chinkuni, 2006). To make effective use of a machine, the need to fully understand its mechanical and electrical conditions are paramount. The identified risk factors associated with lack of knowledge in the understanding of machine conditions are supported by literature presented in prior studies. “It is necessary to determine the winding resistances and reactances as well as the mechanical properties of the machine in order to evaluate its performance under steady and dynamic conditions” (Giancoli, 1988).

A literature review

“The primary purpose of the literature review is to define or develop the research question while also identifying an appropriate method of data collection.” (Giancoli, 1988). This step must incorporate the gradual literal analysis of the paper to the results. A detailed review of literature that addresses the basis for the study and the gaps not addressed in research that the authors seek to fill by conducting this study is presented. The authors first present prior studies that identify the need to understand the basic principles and functions of electrical machines to make correct and informed choices on their usage.

The gaps in literature necessitating the study are also pointed out by other authors. “Generally, when deciding on a particular type of machine, this should take into consideration the actual conditions in mind.” (Giancoli, 1988). Knowledge on the machine operation conditions aid in the reduction of unscheduled down time and high costs of repair. “Temperature dependent devices must be protected from excessive winding heating due to overload, increased ambient temperature, impaired cooling, intermittent operation, high switching frequency and phase failure” (Giancoli, 1988).. “Such machine operation statistics are indispensable in large machines with thermally critical factor” (Giancoli, 1988). Through this review of literature, the authors have clearly presented the study problem on which the study is based, the absence of adequate research on the area of research hence indicating the need for their study and the prior research interventions that explain their focus on a different aspect of attempts to solve the problem of incorrect machine type application in most spheres of engineering field. Through the review of literature, the authors have modeled a conceptual framework that is relevant to their study, though not fully tested.

Specification of a hypothesis, research objectives and assumptions for development of a subsequent research-based conference paper

“Findings indicate that lack of adequate knowledge on machine type and performance can lead to higher repair costs.” (Okoro, Agu & Chinkuni, 2006). The findings are related back to the purpose of the study. The results suggested “a careful look at the basic features and principles of operation of electric machines, determination of machine parameters, basic protections, maintenance, and electric machine applications are the basics of leveraging down manufacturing costs.” (Okoro, Agu & Chinkuni, 2006). This statement of findings relates these findings to the purpose statement made to guide the study. The authors do not explain the unexpected findings but a review of literature is presented to give an indication to the possible explanations for the findings.

In conclusion, I suggest the areas where future research is needed to better explain these findings. I therefore relate the implications of the findings to the engineering profession clearly as follows…..the need to understand the correct type of machine through an analysis of the electrical and mechanical properties of its components is best explored. The paper is envisaged to serve as a platform for future research works on the proposed areas that need further analysis. Furthermore, future conference paper presentations are expected to provide more platforms for in-depth presentations of more findings on the same.

References

Giancoli, D.C. 1988. Physics for Scientists and Engineers. Prentice-Hall: Princeton, NJ.

Okoro, O.I., M.U. Agu, and E. Chinkuni. 2006. Basic Principles and Functions of Electrical Machines. Pacific Journal of Science and Technology. 7(1):45-52.