Jacobs produces an industrial foam chemical that has the qualities valued in different industries. Thus, Calopeia’s manufacturers of air conditioner retrofit kits are interested in buying Jacobs’ chemicals. Jacobs’ operations are discussed with the focus on the network including a factory and a warehouse in Calopeia.

Problem Identification

Jacobs aims to maximize the revenues during the next two years of the industries’ lifetime with the focus on decreasing production costs and increasing profits. In addition, it is necessary to address the problem of the lost demand. Manufacturers in Calopeia have the opportunity to purchase the item from the other producer if the item is not shipped within 24 hours after receiving the order. It is possible to resolve the problem with adding capacity to the factory, changing the order quantity, controlling ROP, and changing the shipping method.

Demand

Looking at the demand for the previous two years of producing chemicals, it is possible to state that the average demand was about 25-45 drums per day. Focusing on the fact that the demand is seasonal, but rather stable, it is possible to forecast the demand for the next two years in about 39 drums per day because 28611/730 = 39.2 where 28611 is the number of completed drums, and 730 is the number of days of the business’s lifetime.

The Cost Differential between Truck and Mail

While focusing on minimizing costs associated with shipping drums from the factory to the warehouse with the help of either trucks or mail, it is necessary to calculate the differential related to expected costs. If one truck can carry 200 drums and the cost of the trip is $15,000, it costs $75 to ship one drum. In comparison, it costs $150 to mail one drum. This number doubles the costs of using trucks. Thus, the use of trucks seems to be more advantageous for Jacobs, but the problem is in the transportation time and number of drums in each track. It is important to adjust the schedule and control completing trucks while focusing on avoiding the lost demand. The solution is to use mail when the number of drums is 100 items or less than 100 items.

Order Quantity

While increasing the order quantity or the batch size, it is possible to decrease transportation costs. Chaining the order quantity from 150 to 200 on Day 730, it is possible to achieve cost savings in production. Thus, Jacobs regularly produces about 190 batches (28,600/150). The cost without the number of drums x$1000 is 190 (batches) x $1500 (price per batch) = $285,000.

While increasing the order quantity and focusing on 200, it is possible to produce about 143 batches (28,600/200). As a result, it is possible to save about $70,500 because (190-143) x $1500 = $70,500. Increasing the batch size to 400 on Day 1,055, it is possible to save more than $105,000 because the production costs will be two times less. To produce batches including 400 items is a more cost saving strategy because production costs become twice less, and transportation costs also decrease because of the opportunity to make fewer trips to the warehouse.

Capacity

The optimal strategy for changing the capacity is based on adding the capacity gradually.

Timeline:

- Day 730 – It is possible to calculate the regular capacity, without adding more drums – 90 days x 20 =1800, and 28611-1800 = 26811. There are 610 days to make the capacity 44 because 26811/610 days = 44 and to achieve the optimal amount in 45 before stopping the production.

- Day 731 – It is necessary to change the capacity, and make it 40 drums per day.

- Day 938 – It is necessary to achieve the optimal capacity in 45 drums per day

Capacity in 45 drums addresses the company’s focus on maximizing profits because increasing capacity, Jacobs receives the opportunity to accept more orders, and to reduce production and transportation costs. Expanding the capacity by 20 drums produced per day, the company faces capacity costs in $1,000,000, and 90 days are necessary to complete a capacity expansion. However, focusing on savings in production and transportation costs, it is possible to add capacity on Day 938 instead of 822 in order to balance the production schedule and costs. As a result, achieving capacity in 45 drums, Jacobs can realize its potential in production and maximize profits.

Summary Table of Recommendations

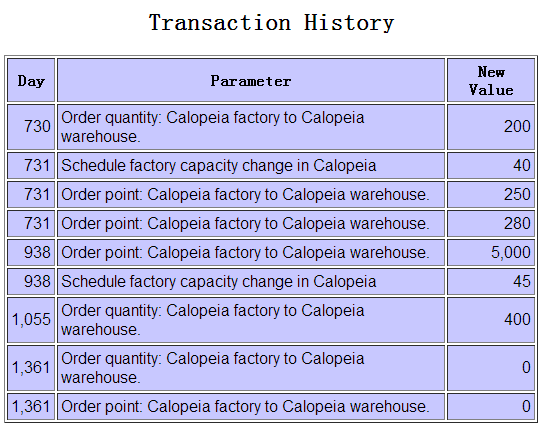

Appendix 1. Transaction History