Introduction

Cargo delivery system is generally regarded as one of the most important part of the entire supply chain strategy. As a rule, customer care relations should involve mutual satisfaction, cooperation, and trust, however, if delays in payments or cargo delivery is observed, trust credit is decreased essentially. Therefore, the drawbacks of the delivery and business performance system should have been subjected to changes. Therefore the entire system of cargo management was changed. The key reason of this change is associated with the fact that the new system will be able to get rid of the common problems, and improve the entire performance of the company.

Iron Triangle

Previously to analyzing the most important factor of company’s activity, the following consideration should be emphasized (Australian National Audit Service, 38):

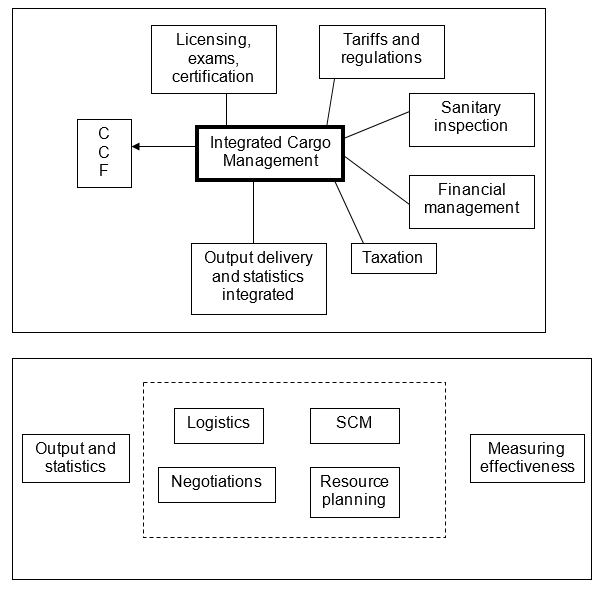

Customs’ business processes, legislative change, and the development of an integrated cargo system to replace Customs’ transaction processing systems. Included in the project were the Customs Connect Facility (CCF) and the Cargo Risk Assessment (CRA) system. The CCF is a communications and data transformation ‘gateway’ that allows external clients and internal users to transact with Customs’ business applications. The CRA system identifies and assesses potentially high risk cargo.

In the light of this fact, it should be emphasized that the main emphasis is made for the functionality of the product. In fact, this us regarded as one of the most important values of the marketing triangle, as proper quality and functionality level is the reasonable cause of the price. The costs are paid less attention, as there is no need to pay sufficient attention to the least problematic aspect of business performance. Schedule is regarded as a secondary aspect of company’s performance, and the new scheme is aimed at automatic improvement of the delivery schedule by improving the functionality of the product that will cause changes in the logistics.

The key reason why functionality was paid such an attention is based on the statement that there is a need to leave the audience satisfied: hence, if the product is delivered in time, and for low costs, but with poor quality, the customer will not be happy. And vice versa. Anyway, the customer expects to get a high quality product, and this principle was taken as the basis for the new system.

Project Analysis

Regardless of the fact that the project was created with maximum simplicity for the implementation, operation, and further restructuring, the most reasonable and important feature of the project is its reliability and effectiveness. Therefore, some moments could not be simplified. The simplest component of the system is CCF part. The most complicated part is the integrated cargo system with the declarations and reporting requirements. On the one hand, these elements are important for proper system performance, on the other hand, the absence of automated reporting systems creates barriers for in time cargo delivery.

Another complicated moment of the system is linked with licensing, as well as output delivery systems. While the former is important, the latter is not featured with an effective working scheme, and is associated with statistics collection. Considering the fact that statistical data is analyzed by bureau of statistics and the importance of the output system is doubted. For saving this element of the operative structure, the company will have to implement the improved, and the company will have to consider some principles of supply chain management for improving the existing scheme. As it is stated by Boone and Ram (405):

Strategic plans are drawn up with suppliers to support the manufacturing flow management process and the development of new products. In firms where operations extend globally, sourcing should be managed on a global basis. The desired outcome is a win-win relationship where both parties benefit, and a reduction in time required for the design cycle and product development. In addition, the purchasing function develops rapid communication systems, such as electronic data interchange (EDI) and Internet linkage to convey possible requirements more rapidly.

Therefore, it should be stated that the activities associated with the product sales, and delivery to customer require proper resource planning. Additionally, the key elements of the cargo delivery involve logistics principles, as well as negotiation skills for communicating with consumers.

The definition of the requirements for the project was associated with the necessity to improve the cargo management principles, as well as increase the reliability of customer care strategy. Therefore, it was impossible to violate the basic principles of CRM construction, as the project dependability on stakeholders is rather significant. In the light of this fact, the understanding of the requirements is associated with the values of the proper cargo management, reporting, customer care, and certification of the cargo. These principles define the effectiveness of the entire management, and if one of these points is lacking, it may break the entire management chain.

Since, it was impossible to define the entire set of requirements, the system is based on the generally accepted rules. Additionally, it may be divided into four main components that are needed for all round focus, and proper arrangement of the problem. These are: customer focus, operational focus, support focus, custom rules focus. Each component involves sets of attributed problems, and each should be resolved by the corresponding department, and each is attributed to a specifically defined block of the CRM scheme. However, demands, rules, strategies, and business environment are changing constantly, hence, it is impossible to define all the sets in advance. (Thomas and Mackey, 145)

Considering the complexity of the dependence, the customs had an option to develop a more iterative approach. This means that the cargo management principles should involve the key elements of the cargo management planning. This will require managing cargo more effectively, and with application of logistics, supply chain, asset, and procurement management approaches. Hence, the iterative approach will be regarded as a part of the cargo management process, however, customs had to resort to strict measures for stimulating the development of the present system. In the light of this fact, it should be emphasized that the actual importance of the cargo management is defined by its effectiveness on each particular market, and in accordance with the research by Wang (28):

Experts found a strong relationship from the largest arcs of supplier and customer integration to market share and profitability. Taking advantage of supplier capabilities and emphasizing a long-term supply chain perspective in cargo management can be correlated with firm performance. As logistics competency becomes a more critical factor in creating and maintaining competitive advantage, cargo management measurement becomes increasingly important.

Model Diagram

Model diagram demonstrates the modified operational scheme of the cargo management re-engineering process. Therefore, the integrated management principles involve all the necessary components for effective management of the product flow and customer relations, and some blocks are united for improving the ergonomics of the scheme.

Risk Management

Works Cited

Australian National Audit Service. Customs’ Cargo Management Re-engineering Project. The Auditor – General. Audit Report No.24 2007. Performance Audit.

Boone, Tonya, and Ram Ganeshan, eds. New Directions in Supply-Chain Management: Technology, Strategy, and Implementation. New York: AMACOM, 2002.

Thomas, Michael F., and James Mackey. “Supply Chain Management: Monitoring Strategic Partnering Contracts with Activity-based Measures.” Management Accounting Quarterly 8.1 (2006): 145.

Wang, Mark Y. D. Accelerated Logistics: Streamlining the Army’s Supply Chain. Santa Monica, CA: Rand, 2000.