Introduction

The Carrefour Group is a multinational retail corporation with headquarters in France. It is among the top global leaders within the hypermarket sector with approximately 1,452 stores. The company has an interest in regions such as Europe, South America, Asia, and North Africa. Among the notable products retailed by the company are convenience stores, warehouse clubs, hypermarkets, discount stores, and supermarkets. The current operating income of the company is €2.347 billion with total equity of €10.2347 billion. At present, the company has more than 381,277 employees. This paper will review different aspects of operations management about the Carrefour Company.

Work process

The operations model in Carrefour’s operations management supervises the reaction rate and screens all production processes from product creation to distribution channel. The model helps with following costs and effectiveness of the operational channels, such as apparatus and human resources, besides the utilization of these channels in the most cost-effective way. Also, it tracks externality and internality variables that are subject to the speed of execution such as productivity within a specific period, the reaction by the client, and the nature of item discharged into the production process. These factors apply to cost, productivity, dependability, and quality in the entire operations process (Teece 156). In particular, the Carrefour Company has set up an effective operation administration display that balances the variables to create a flowing transition from production to distribution in the most effective manner. The Carrefour Company has a proficient production model, which is unique in tracking the productivity process from procuring goods from suppliers to distributing the goods to different stores and eventually selling to customers.

The above capacities are joined at the central planning point which envelops costing, velocity, quality, adaptability, and reliability to make a smooth ceaseless operation model that works like PC starting with one section then onto the next. The Carrefour Company is aligned with the human resource department, finance department, marketing department, operations department, and supply chain department. The operations administration arrangement of the Carrefour Company incorporates the aspects of proactive planning, systematic development, strategic implementation, and consistency in disclosure (Andrea 27). The procedure is supported by process maps, status reports, production activities, human resource use, and quality in the output over a definite duration of time.

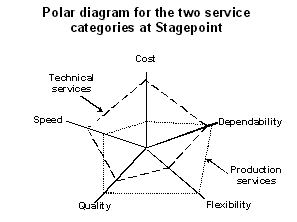

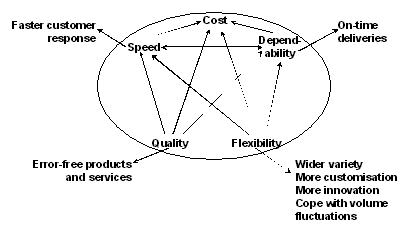

Essentially, the operations administration frameworks at the Carrefour Company incorporate part of cost, constancy, pace, quality, and adaptability. These variables determine the strength or weaknesses of the operations module at the company. These aspects are attainable through quality conveyance, continuous expansion, and innovativeness through the company’s research and development division (Teece 143). Specifically, these variables are part of the systems and apparatuses, which are vital in the specialty of operations administration at the company as summarized in appendix 1 and appendix 2. For instance, a specialized procedure of comprehension in the operations at the company includes operations administration, its application, and assessment criteria (Bowman 5).

The aspect of speed manager response rate monitors utilization throughout the production and marketing process as the primary inputs. Speed assists in tracking costs and efficiency of labor productivity tools such as machinery, human labor, and optimal use of these aspects at a minimal cost. Besides, it tracks externality and internality variables that are dependent on the speed of performance such as efficiency in the period between production and delivery, the response by the customer, and the quality of product released into the market (Koren 405).

Despite having this efficient operations management system, the company has not fully established a mechanism of monitoring progress at the micro-level, and majorly depends on macro auditing in decision making. Notwithstanding having this proficient operations administration framework, the Carrefour organization has not completely settled a competent strategy for observing production efficiency at a macro level. At present, the company largely depends on macro production tracking tools that cannot pinpoint inefficiencies within each unit of production design. As a result, the company has struggled with consequences on poor decision making, dynamics in the production, and imbalances between different factors of production (Smithson 161).

Business productivity reflects the ideal usage of distributed variables in the creation of products at the most cost-effective module. From the above refection, it is clear that the Carrefour organization should integrate the Flexible Monitoring System (FMS) to balance the quality variables that determine the magnitude of production sustainability in the short run and long run (Koren 403). Despite lower rates of return beneath the projection, the general impact of adopting the FMS is that the company will have advantages that will exceed its restrictions. For example, when the FMS is completely embraced as proposed, the company will be in a position to manage expenses from production and logistics management (Smithson 164).

Even though the value of the Carrefour venture is lower than often anticipated, the FMS will make it reasonable since it manages the element of costs in managing operations by ensuring that optimal productivity is achieved at the least possible cost (Bowman 6). Also, the part of productivity as a consequence of FMS will push the generation logistics management towards manageability over a long period. Fundamentally, the prompt adjustment of the proposed FMS will contribute towards supportability in the part of cost, reliability, velocity, quality, and adaptability of the current operations management module (Teece 145). In particular, the increased productivity at the least cost will give room for the development of different products without expanding the physical production utilities. More space means more products being created inside the same production lines. Because of expanded yield, the Carrefour business will grow as the organization becomes more attractive for the investors (Koren 409).

Since the end goal is to accomplish quality operations administration, the current performance management matrix should be occasionally moved up to track the various working operations models such as proportion examination in operation administration, which is perfect in proactive management of the entire performance matrix in the short term and long term production activities. These variables are achievable through quality assurance, production expansion, and inventiveness as part of the performance management (Bowman 7). The modification of performance management variables as a strategy is fundamental in the specialty of operations administration at the Carrefour Company (Koren 405). Notwithstanding, having proficient operations administration framework will enable the Carrefour Company to completely track the component of checking advancement at miniaturized scale beside the large scale production cycle across different divisions within France and beyond (Teece 153).

Product and service design

The organization has assorted food products and keeps on growing new product lines that satisfy the demand of customers. Case in point, the convenience store, warehouse club, hypermarket, discount store, and supermarket products have been rolled out by the company to tap the global market. The products are exhibited as having high quality and value. The diverse production ability has positioned the company as a global leader in different retail businesses across the globe.

Quality management issues

Exploring the operations administration arrangement of the Carrefour Company is vital to considerably arranging and realizing quality management, which works by reducing expenditure through planning and managing the production budget. The Carrefour organization has an ideal quality management strategy to balance the cost against output as part of its primary generator of competitive advantage. To accomplish this, the current cost management frameworks are intermittently moved up to present numerous working channels, for example, quality affirmation in operation administration that is good at tracking progress in the short term and long term (Bowman 8).

The business model of the Carrefour Company is managed like a corporation with different interests in retail products. The business is managed as divisions, which work as partitioned branches that are managed from a central point. This has improved the company’s rating in the global business market in balancing competing interests in different divisions. The company has a simple logistic plan in getting credit from banks due to its large capital structure (Andrea 25). Because of the balanced and stable financial management framework, the Carrefour Company has remained extremely aggressive and feasible in terms of its business sector extension procedures.

The technique for reviewing the performance management variables at the Carrefour Company is adjusted to correspond to quality assurance strategies across the departments such as logistics, human resource, production, research and development, and supply chain. To guarantee success in performance management, the quality administrators at the Carrefour have adjusted both the performance trackers and complete production cycles across different divisions as independent entities (Teece 134). As a result, the quality management strategies that guarantee long term commitments are satisfied in the production cycle in each division (Andrea 22). This is conceivable because this model of operations administration framework takes into consideration the operations process aggressiveness as it manages the superfluous overhead expenses from waste and underutilization of production inputs (Koren 403).

Capacity planning

The abilities displayed by the Carrefour Company presents yet another part of its general process management, as far as procedure and limit are concerned. The organization runs a dynamic corporation that is divided into different food, beverages, and nutritional additives that are retailed in convenience stores, warehouse clubs, hypermarkets, discount stores, and supermarkets. These structures frame a portion of generation lines for distinctive process management. The decision approach at the Carrefour is marked by a consultative structure characterized by endorsements originating from the top managerial staff comprising of capable and experienced managers. The organization depends vigorously on operations administration in choice-making (Andrea 24). For instance, the proposed expansion in the Indian market in the year 2017 was supported by comprehensive market research (Carrefour Group par. 6).

The capacity planning systems at the Carrefour incorporate planning, development, implementation, and discovery. Reflectively, the process captures a process map, compliance requirements, review structure, and resources employed within a specified period in business. Since capacity planning is properly balanced at Carrefour, the system has remained efficient due to consultative decision science, which ensures that the sustainability of the manufacturing process is guaranteed. For instance, there is a performance tracking system which monitors the costs of running the production and supply chain process, the time it takes to complete each production schedule, and the general flow of activities from one unit to another (Carrefour Group par. 6). The above aspects have guaranteed effective and sustainable capacity planning to ensure that the manufacturing process meets the basic operation efficiency matrix.

To achieve quality capacity planning in manufacturing, the forms of production system monitoring at the Carrefour are periodically upgraded to introduce multiple operating system models, which are compatible with tracking and analysis the flexibility, optimality, and cost-effectiveness of the manufacturing process. The capacity planning systems at the Carrefour include the aspects of cost, dependability, speed, quality, and flexibility (Carrefour Group par. 6). These variables are achievable through value delivery, value addition, and creativity in the planning for the right capacity. High standard operations management system acts as the engine that supports implementers of business strategy to comprehensively verify rationale for supporting current, predicted, and actual results for every step upon introduction of a functional system in the production schedule. Fortunately, the Carrefour has strategies on the ground to track the decision science, optimal operations, and cost-effectiveness to ensure that the production process is profitable and sustainable.

Forecasting techniques

Utilization of all the essential capabilities has empowered the Carrefour Company to manage its position as a global leader in the aggressive business sector. Thus, the company is a central cause of a business that has kept on grasping quality operations administration in terms of steady organizational communication culture, proficiency, and ideal asset use in delivering food products to customers across the globe (Koren 403). The corporate methodology proposed by the administration of the Carrefour Company is to guarantee long term production capacities.

For the execution of the methodology, the administration has been proactive in equalizing both the transient and long term goals as part of the decision matrix. This fete is achieved by making arrangements for assets in innovation, preceded with the development of the new product through continuous research, and directing different experts to distinguish market demands by different segments of customers. It is evident that appropriate coordinating of delicate aptitudes, for example, group building, authoritative viability, initiative, choice-making, critical thinking, imagination, adaptability, and group building is well integrated into the management aspect of the company’s operations matrix (Teece 138).

Through enhanced flow in the production schedule, the Carrefour organization is set to quickly and considerably pick up from the unwavering quality perspective when contrasted with its rivals. Since customers will have the capacity to get their request inside of a shorter time, the organization stands to gain from consumer loyalty and referrals (Bowman 7). Since the length of time of conveyance has diminished by around 33% of its past rate following the integration of six sigma system, the organization is equipped to profit from economies of scale because of expanded ability to create and disseminate within a short time will guarantee increased productivity for different product lines currently being produced by the Carrefour Company (Andrea 27).

Layout and facilities planning

The Carrefour Company divisions are situated in strategic regions in France and different parts of the world. Since the business targets different clients, the company is known for its extensive hyper-store facilities that retail different product lines. This translates into expanded production volume across the globe (Carrefour Group par. 6). The Carrefour divisions are connected with dynamic and efficient organization environment through the state of art production facilities and employee recreational centers. This strategy has empowered the Carrefour Company to emerge as a vivacious domain for employees, who are motivated by the ideal work environment. As indicated on the company website, Carrefour has a healthy work environment that encourages employee innovativeness and creativity (Carrefour Group par. 6).

The maintenance approach adopted by the Carrefour Company is comprehensive of the exploratory perspectives, for example, the specialized procedure of comprehension of the operations and legitimate utilization of measurable devices. These devices are basic in checking and dealing with the logistics behind the business capacities in different facilities. These variables are legitimately adjusted as demonstrated in the productivity of the business, in terms of store size across the globe.

Conclusion

From the above research, it is apparent that the value creation model cannot align cost-effectiveness when logistics of operation are aligned to a single operational system. For instance, lack of strong control systems and poor benchmarking approach will compromise the organizational strategy of cost reduction, customer satisfaction, and reduction of risks when the supply chain management function is managed from different units. In the case of Carrefour, the operations management models are well balanced. However, the company should adopt the IFM system to improve on efficiency tracking. Besides, the IFM system will ensure that the operations management channel at the company is streamlined and efficient to support the short-term and long-term production needs.

Works Cited

Andrea, Arnaldo. “Understanding how Formal and Informal Communication affect Purchasing, Manufacturing and Logistics Integration.” Advances in Management 4.7 (2011): 22-32. Print.

Bowman, Singh. “Corporate Restructuring: Reconfiguring the Firm.” Strategic Management Journal 1.4 (2003): 5–14. Print.

Carrefour Group. Operations Management. 2016. Web.

Koren, Caren. “Manufacturing Capacity Planning Strategies.” Manufacturing Technology 58.3 (2014): 403–406. Print.

Smithson, Samuel. “Analysing Information Systems Evaluation: Another Look at an Old Problem.” European Journal of Information Systems, 7.3 (2008): 158-174. Print.

Teece, David. “Business Models, Business Strategy, and Innovation.”Long Range Planning 43.1 (2010): 172-194. Print.

Appendices

Appendix 1: Operation Management Model at Carrefour

Appendix 2: Actual Representation of the Operation Model