Executive Summary

Supply chain management is a very essential aspect in any organization irrespective of its size and should therefore be considered in the undertakings of an organization. This is because it determines the success or failure of the particular organization through its influence on efficiency, effectiveness, productivity, economy and profitability.

Toyota and Ford are different companies that are in the same industry (i.e. motor industry) but they both apply different supply chain management practices depending on what they deem appropriate and effective all aimed at achieving success in the companies.

Supply chain management is a practice that entails what a company engages in and the manner in which the activities are carried out in an effort to achieve the best. It is faced with various challenges and strategic planning is therefore necessary.

Introduction

Different organizations and companies have different management styles and practices depending on their specific objectives and goals and how they intend to achieve them.

Supply chain management entails the coordination of aspects (like resources for instance information, materials etc) as they move through the distribution channel, (I.e. from the suppliers to the manufacturers to the wholesalers to the retailers and finally to the consumer).

Supply chain management is a practice that involves the coordination and integration of the above within and among different companies with an aim of achieving efficiency, effectiveness, economy and profitability in the organization’s activities and practices. Companies should strive to establish and maintain an effective supply chain management system that reduces inventory under all circumstances.

A general supply chain management chain is composed of the finances flow which entails payment schedules, terms of credit and arrangement of title ownership and consignment, the information flow (which covers aspects like transmission of orders and updating the delivery status) and the product flow (which entails the movement of products and services from the suppliers all the way to the consumers) (Iver and Vasher 2009).

This paper looks into the supply chain management practices that are applied by the Toyota and Ford companies and the various aspects associated with the practices.

Describe And Critically Analyse The Supply Chain Management Practices Employed By Both Of These Companies.

Toyota is a motor company founded in 1937 with it’s headquarter in Japan and one of the world’s biggest automobile manufacturer in terms of production and also sales. The firm also takes on in producing robots and offering pecuniary services in addition to dealing with the manufacturing of vehicles. It is also well known for its production of environmentally friendly and technologically advanced cars.

Ford on the other hand is a motor company and an American multinational founded in 1903. It is ranked as the second biggest automobile and the world’s fifth largest in relation to the statistics of the 2010 vehicle sale.

Supply Chain Management Practices in Toyota

There are many benefits associated with an effective supply chain management system in any given company. Toyota Motor Company has been known for its performance advantages and this can all be accrued to the supply chain management practices that are employed in the company as they contribute collectively to the overall success of the company.

One of the strengths of Toyota Company is that it designs and manages its supply chain in a holistic manner and as a unit rather as a series of connected items which is very common in most companies.

The supply chain management in this company has helped it in the achievement of balance and efficiency through emphasizing on aspects like visibility, which advocates for maintenance of transparency in all the practices involved with an aim of allowing for continuous learning and improvement in the processes; velocity, which entails maintaining a steady flow for all the processes of the supply chain from suppliers to the consumers, variability which involves the management of any inconsistencies that may occur in an appropriate manner so as to reduce the cost and at the same time improve the quality of the processes, the products and services and variety of the products and services offered in relation to demand in the market and the operational efficiency (Iver and Vasher 2009).

The supply chain management system in Toyota aims at keeping the supply chain cost to a minimum while at the same time ensuring that the customers are well served with maximum satisfaction in regard to the quality of services offered and timely delivery.

The objective of the supply chain is to ensure that the right products are produced in the correct quantity at the correct cost, stored at the right place with the required conditions, and delivered to the correct clients at the correct t time.

The suppliers in the Toyota Company are organized into two functional tiers where the first tier suppliers are involved with the product development and hence liaise with the people involved in the development of the product in the company while the second tier suppliers are concerned with making of individual parts.

For effectiveness in the running of the processes, there is an enhanced cooperation and communication strategy between the first tier and the second tier suppliers and at times there is cross sharing of the personnel in the different departments.

The Toyota production system (TPS) is a very useful tool in the company and its practices and principles that include an extended supply chain which necessitates careful practices to ensure its efficiency. The supply chain is very complex with a lot of processes being joined together to form a unit.

The processes include; production of different parts at the supplier’s level, the transportation of the parts to the assembly plant of the manufacturer, the parts are then assembled to form complete vehicles; the vehicles are then distributed to the dealers from where they are finally delivered to the customers. The supply chain in Toyota is composed of operational and planning processes as well as physical processes (Borowski 2010).

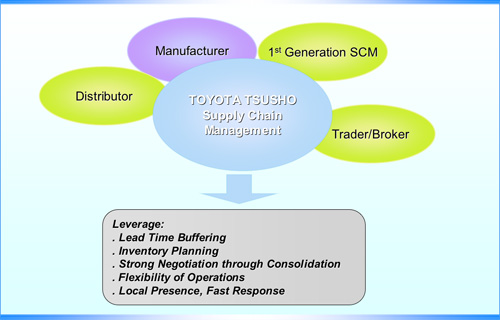

The above is the supply chain management at Toyota Tsusho. Web.

Supply Chain Management Practices in Ford

Ford Company utilizes a supply chain model which involves development of the product, obtaining parts from a variety of suppliers; the goods are then manufactured and then sent to the potential customers through various distribution channels.

The supplier chain network in Ford is rather complex and in most instances, suppliers are identified depending on individual cost consideration rather than total supply chain cost as is the case in the Toyota Company.

The supplier networks are managed by a purchasing department that is separate and independent from the product development while the distribution channel is composed of independent agents who interact with the potential customers and finally deliver their orders through the distribution channel.

Ford company enters into long term agreements with the identified strategic suppliers which serves as an important tool for enhancing transparency, communication and a partnership attitude which keep the parties involved on their toes as they aim at achieving the best.

It allows for accountability and responsibility among those involved in the supply chain. This allows for compliance and supplier development through reduction of the supply base and development of strong and transparent networks with a fewer number of suppliers for a long period of time.

The purchasing business strategy or model employed in the ford company is the aligned business framework (ABF) which has agreements which govern the business practices and activities in a way that future collaboration is enhanced for instance in terms of payment of various costs, data transparency and extended sourcing. This allows for increased volume of business with the specific suppliers that have been identified.

The accords of the associated trade structure also act as a guide to the supplier associates and uphold “bigger responsibility” and guarantee appropriate working conditions and effectual (environmental management) systems in all the progressions in the chain.

ABF has proved to be a very useful tool in the Ford’s supply chain management as it increases profitability, allows for creativity and innovation and also reduces the probability of operational and reputation problems through the utilization of a strong management system that ensures productivity and sustainability.

It also allows the company to manage the human rights and the environment in an in depth, collaborative and appropriate manner. It has also strengthened the company’s working relationships with the suppliers locally and even on a global basis and provided a means for the alignment of the working conditions and the environmental management in a way that conflicts do not arise.

This alignment in return enhances the supply base and allows for the achievement of the company’s objectives (Parker 2006).

The above picture depicts the wireless tracking in Ford’s supply chain. Web.

Are They Involved In Strategic Alliances With Major Trading Partners?

Toyota and Ford companies are involved with major trading partners as they consider it a positive act towards strengthening their efforts and increasing productivity and profitability through unity. Toyota Company has alliances with numerous partners for instance Tesla and Toyota seal electric car alliance where some practices and services are shared between the two companies.

Tesla delivers prototypes electric vehicles to Toyota after they entered into agreements to work together towards the development of vehicles with no emissions. The alliance is aimed at helping the two companies presently and even in the future (Business Green 2010).

Toyota Tsusho Corporation is also another alliance where there is a business alliance agreement with Thai sugar manufacturer. The alliance is aimed at maintaining a well balanced profit structure where the Toyota Company will be able to expand its business operations by engaging in non automotive practices for instance those that are food related (Nexis 2010).

Ford has also entered into partnership with other companies for instance the collaboration of the Ford performance racing partners with Trading post group which is a classified advertising business company for a period of two years to the end of the year 2012 with an aim of making the practices of both companies better through combined efforts (Bhatt 2010).

What Strategies Do They Apply To Procurement And Outsourcing?

Procurement entails the process of obtaining commodities and services. It involves preparation, processing of an order to the receipt and endorsement of the invoice for payment purposes. Outsourcing on the other hand entails contracting some of the company’s activities usually the non-core ones with an aim of saving on tome personnel, money and even facilities for the sake of the core activities that lead to competitive advantage.

There are a range of approaches that are employed in the procurement and outsourcing practice in both companies (i.e. Toyota and Ford). The procurement activities and practices in both companies are usually based on engaging in fair business practices as a way through which cordial relationships and mutual benefits can be achieved.

Toyota is occupied in a wide range of trade activities in diverse fields and is for that reason involved with the procurement of parts, equipments and even materials and amenities from the diverse businesses from the suppliers positioned in different parts of the globe. The company requires that the suppliers provide high quality products at a relatively low cost at the right time.

Along with the above, the company also works together with them to enhance environmental conservation and also meet other societal needs. The procurement policy ensures fair competition, amicable relationships that lead to mutual benefit and based on mutual trust, dealing with environmentally friendly products, localization of business as well as the strict following of the company’s rules and regulations.

Outsourcing at the Ford Company is only undertaken where the practices involved are deemed to make long term strategic benefits or where it is really necessary. It for instance outsources components, IT services as well as engineering services from India (Parker 2006).

What Challenges And Risks Do They Face Internationally? How Does Each Attempt To Overcome These Challenges?

Just as any other company, Toyota and Ford are faced with some challenges and risks both locally and globally in carrying out their practices and activities and each deals with them differently according to the specific challenge and the solutions they deem effective.

Some of the challenges encountered by the Toyota and Ford companies collectively include the risks associated with outsourcing for instance lower quality of product and services, less control due to involvement of different parties where chances of less responsibilities and accountability may arise and worst still longer lead times for instance the popular recent issue of Toyota’s product recall.

Employment practices, handling of the workers in terms of rights and the working conditions are issues of concern at Toyota. The company has taken measures to ensure that the workers’ needs are catered for so that the working conditions are conducive. The company has also established some industrial ties with trade unions at various operations worldwide.

It has also allowed the workers to form unions through which they can voice their grievances. One of the challenges of Ford is the credit market risks for instance market risk, residual risk, credit risk, and liquidity risk. These problems are handled uniquely in relation to their specific contribution to the company’s overall international risk (Ferrari 2009).

Compare How These Organisations Are Incorporating Sustainable (Green) Strategies in Their Supply Chains

The environment is a very important aspect in our daily lives and should therefore be considered in all activities that are undertaken by either individuals, groups or even companies. The manufacturing industry in which Toyota and Ford companies fall are responsible for a great percentage of emissions which cause pollution which is dangerous to individuals for instance the depletion of the ozone layer due to green house gas effect.

This threatens people’s lives in the present time and also for the generations to come and it is therefore necessary for the industries to indulge in environmental friendly operations throughout the supply chain to avoid damaging the environment in any way (Sovereign 2011).

Toyota and Ford companies have engaged in different strategies that are aimed at ensuring a sustainable environment for instance, Ford has a plan of surveying a representative number of suppliers to gauge the energy used and the green house gas emissions in an effort to reduce carbon emissions in the company and the automotive industry at large.

The data collected will be used as a basis for establishing a carbon management strategy for the supply base. The strategy is aimed at ensuring collaboration and sharing of processes and practices which can result into a considerable emissions reduction and in a way help in attaining the future regulatory requirements.

The carbon disclosure (project supply chain program) is also another scheme in which Ford Company is taking part and is working hand in hand with the (automotive) industry action group in coming up with guidelines which can be used to gauge the purveyor emissions.

Most of the Ford’s dealers are now insightful on the emission matter, for instance, Johnson Controls has an evaluation system (which allows the business to gauge its supply base sustainability). Ford aims at reducing green house gases by 30 percent by the year 2030.

It is also the believe of the Toyota company that it should bring a change in the world through nurturing a sustainable society by taking care of the environment by undertaking environmental friendly operations. This has been made possible through collaboration with philanthropy, the suppliers, the government and other bodies towards maintaining a mobile society that is environment friendly.

Toyota has been involved in various programs that aim at educating and mobilizing people to manage the environment well for their benefit for instance the Together Green program that funds projects aimed at conserving the environment, undertakes training for environmental leaders and also offer opportunities for people to volunteer and work towards conserving the environment.

It has also been involved with the government to harmonize fuel efficiency and regulate green house gas emissions.

Its collaboration with business partners for example the dealers and suppliers also help in conserving the environment through the provision of the green supplier guidelines which encourage the partners to work towards meeting the environmental expectations and more so get involved in the Toyota’s programs that have been designed to cater for the environment (Urlaub 2011).

Conclusion

It is evident that supply chain management is a very essential tool in any given organization as it helps in the maximization of added value while at the same time helping in the reduction of the total cost.

Just like information and communication technology, supply chain management has become a tool through which organizations can achieve a competitive advantage and be able to secure a place both locally and even in the global market.

It has however been deemed important in manufacturing companies like Toyota and Ford as it aids in the timely delivery of products at a competitive cost without compromising the quality.

Supply chain management is also a practice that has allowed many organizations to survive through restructuring their operations in a manner that they are able to focus on the core competencies of the organization and outsource other services to enhance its productivity while saving on time and cost through specialization.

An effective supply chain management in an organization also help a firm in strategic decision making in regard to the partners to be involved with resources utilization as well as the manpower in addition to market positioning.

Reference List

Bhatt, R. 2010. Ford Performance Racing partners with Trading Post. Web.

Borowski, A. 2010. Report on the Toyota Company. Germany, Grin Verlag.

Business green, 2010. Tesla and Toyota Seal Electric Car Alliance. Web.

Ferrari, B. 2009. Toyota’s Evolving Challenges- A Sure Global Survivor. Web.

Iver, A. Seshadri, S. and Vasher, R. 2009.Toyota Supply Chain Management: A Strategic Approach to the Principles of Toyota’s Renowned System. USA, McGraw-Hill Professional.

Nexis, L. 2010. Toyota Tsusho Corporation – Business Alliance Agreement with Thai Sugar Manufacturer. Web.

Parker, S. 2006. Ford Motor Company to Outsource to India. Web.

Sovereign, R. 2011. Importance of Supply Chain Management in Modern Businesses. Web.

Urlaub, J. 2011. Managing Risk with Sustainable Supply Chain Management. Web.