- Introduction

- Design, Operation, and Application of the Surface Condenser

- Surface Condenser Installation

- Operating the Surface Condenser

- Maintenance of the Surface Condenser

- Effects of Air in a Condenser

- Design and Operation of Single and Two-Stage Air Ejectors

- Operation and Design Considerations for Condensate Extraction Pumps

- Conclusion

- Works Cited

Introduction

A steam condenser is a device or an appliance in which steam condenses and heat released by steam is absorbed by water (Rajput 4). According to Graham Corporation (3), a surface condenser is designed to ensure that a turbine can operate efficiently while at the same time allowing the condensation of steam to occur. Later, the condensed steam is fed back into the system to create a cool environment within the turbine. These activities are handled proficiently to reduce wastage of resources and guarantee reliable performance of the system.

This paper provides a discussion on condensers and other accessories contained within the steam turbine operation.

Design, Operation, and Application of the Surface Condenser

The design of the surface condenser is such that steam is made to get its way into the condenser system through an opening at the top section of the condenser system after which distribution takes place supported by the tubes internally laid within the steam turbine system. According to Stamper and Richard (3), the steam eventually gets condensed on coming into contact with tubes that are colder relative to the temperature of the steam. Due to the changes that occur during this process, a vacuity is created and maintained within the condenser for as long as no air exists within the condenser. The empty space in the condenser is constantly preserved with the help of a venting system designed to get rid of any air that finds its way into the condenser system. To ensure that the tubes inside the condenser do not heat up after encountering the hot steam, cold water is repetitively distributed through the system. The liquid that results from the condensation process, commonly referred to as the condensate is constantly dispensed with the help of condensate pumps and later released into the condensate system.

Ordinarily, the steam that gets into the condenser system has to be condensed fully. However, some air enters the system through leakages and other means and is not affected by the said condensation process. This air eventually combines with the steam and gets condensed in the process. The air cooling zone within the condenser system takes advantage of cold tubes to facilitate the cooling of air that mixes with water vapor. The expulsion of the waterlogged air is facilitated by venting paraphernalia such as air ejectors and ring pumps. In some cases, both tools may be utilized for maximum efficiency.

The whole idea of constantly getting rid of air from the condenser system is to ensure that at any particular time of operation, a desirable free space or vacuum is present within the system. Apparently the build up of air within the condenser can have a detrimental effect and reduce the effectiveness of the condenser system by causing the pressure to go up uncontrollably. To cut down on the amount of saturated air, Graham Corporation (4) suggests that the air should be cooled before being channeled into the venting apparatus. A poor cooling procedure may easily overwhelm the venting equipment and make it malfunction. It is also important to eliminate any openings that can lead to leakages and hence affect the operation of the condenser.

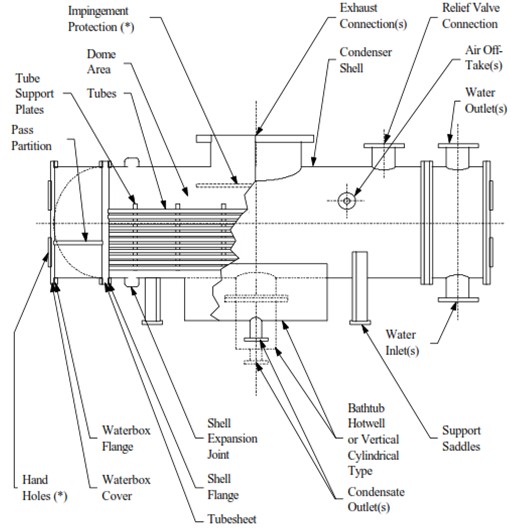

Figure 1 shows the structural design of the surface condenser. The system has steam inlet that acts as a draining point for the condenser. Impingement protection keeps the tubes safe from any form of damage. The condenser shell is provides the free space needed around the tubes. Besides the protection offered by the condenser shell, tube support plates are included in the design for additional fortification. The shell expansion joint is used to deal with tension as a result of the expansion experienced between the tubes and the shell. Tubes themselves contain water typically used in the cooling process. Further, they provide a separation between the condensing side and the cooling end of the condenser. Dome area is an open space over the tubes and facilitates the distribution of steam. The shell flange provides a point to fix the tube sheets to the shell air off-take provides a link to the venting apparatus of the condenser.

The pressure release connection is used to ensure that the condenser is not subjected to unbearable pressure. The Hot-well offers some form of storage for the condensate while condensate outlets provide links to condensate pumps. Support saddles are used as a base for the condenser to rest on. Tube sheets are used to keep the tubes firm in the system as well to offer separation for the steam and the cooling substance on the other end. The water box shielded using a water box cover creates a channel for smooth water circulation within the condenser system. Water box flanges are used to affix the water box to the tube sheet or to the water box cover. The function of pass partitions is to split the water channels based on the needed number of tube passes. The water inlet and the water outlet are connections for the cooling water supply and return. Finally, hand holes are used for examining the tube sheets and tube ends.

Mechanically, the tubes in the surface condenser usually extend to penetrate the tubes structurally located at the two extreme ends of the condenser. To ensure that no deflection is experienced within the system and that no damage occurs to any of the tubes, support is guaranteed using strategically placed support plates. The support plates ensure that the tubes are firmly placed within the system to avoid any damage resulting from vigorous activities undertaken by the system.

Surface Condenser Installation

Before proceeding with the installation of the condenser system, it is necessary to thoroughly inspect the system including all the associated paraphernalia. According to Graham Corporation (9), there are two important things to note during the installation of the surface condenser.

First, the installer should ensure that the distance needed to link the outlet for the vapor to the venting tool is kept at a minimum. This apparently allows for effective control of the pressure drop.

The second consideration has to do with the removal of the condensate. Based on best practice, the installer should ensure that the condensate drain system can accommodate the correct amount of pressure required to maintain a desirable performance.

Operating the Surface Condenser

Ludwig (211) provides a sequence of steps to ensure a successful operation of the surface condenser. First, all the vent valves in the system must be in place and fully operational. It is then important to check and ensure that valves attached to the water box are well placed to get rid of air from within the condenser. Next, valves inside the condenser have to be opened in order to facilitate a smooth circulation of water while ensuring that the water boxes are constantly filled with water. The water in the hot-well should then be checked to ensure that it roughly somewhere around the middle. In case the condensate is used as the coolant, its valves should be left open. The situation is, however, different when cold water is used for cooling purposes. Once all the above directions have been taken into account as expected, the condensate pump can then be started followed by the vacuum venting apparatus. Finally, the steam turbine is started once a desirable free space is realized.

Maintenance of the Surface Condenser

Regarding maintenance, the condenser should be inspected consistently to ensure absence of leakages. Glands must be tightened whenever leakages are detected in the system. On a quarterly basis, plates should be checked and replacements recommended where necessary. Finally, the tubes have to be examined on a yearly basis and any deposits detected on them must be carefully removed. If the condition is compelling, the tubes should be replaced all together (Graham Corporation 19).

Effects of Air in a Condenser

Generally, continuous accumulation of air within the condenser will drastically interfere with the available free space needed for effective operation of the system. If not properly checked, too much air in the condenser will make it malfunction as a result of increased pressure. Rajput (925) identifies the following four effects of air leakage in a condenser.

First, it leads to lower thermal efficiency which consequently hinders effective operation of the condenser system. The leaked air in the condenser results in increased back pressure on the prime mover which means that there is loss of heat drop and consequently the thermal efficiency of the steam power plant is drastically reduced.

Secondly, leaked air in the condenser leads to an increased requirement of the cooling water. The leaked air lowers the partial pressure of steam which means a lowered saturation temperature of steam. As the temperature saturation of the steam continues to go lower, its latent heat increases. An increased amount of cooling water to provide increased latent heat in the condenser will thus be required.

Third, leaked air in the condenser leads to reduced heat transfer. Typically, air has poor thermal conductivity. As a result, the leaked air eventually reduces the rate of heat transfer from the vapor, and consequently this requires the surface of the tubes of a surface condenser to be increased for a given condenser capacity.

Finally, leaked air in the condenser will lead to corrosion. Ostensibly, the presence of air in the condenser increases the corrosive action and this ends up reducing the life of the tubes and other parts within the condenser. It is thus imperative to ensure that every necessary precaution is taken to safeguard the condenser and give it a long life.

Design and Operation of Single and Two-Stage Air Ejectors

Ejectors may be single or multi-stage. In a single stage ejector, the steam outlet from the ejector is either exhausted to the atmosphere or on top of water within the condenser. As noted by Ludwig (346), this installation makes it possible for the steam condensate to be re-used in the condensation process. However, single stage units are usually not used where compression ratios or ratio of absolute discharge to suction pressures, are greater than three. Seemingly, this type of pressure increase for low pressure steam is usually uneconomical when the final discharge pressure exceeds one-third of the high pressure steam. These units are normally limited to single stage installations based on steam economy. The two stage ejectors are designed with barometric surface type condensers. Typically, the discharge of the steam from the condenser is made possible by an existing second stage jet. In some instances, however, the steam is condensed in the after condenser and, essentially, only non condensable fluids end up leaving the vent of the after condenser.

Operation and Design Considerations for Condensate Extraction Pumps

This section provides a description of the operating conditions and corresponding design considerations for condensate extraction pumps. Given that condensate extraction pumps are made to be used in very harsh environments, their design involves the use of a very strong steel substance that is meant to give them a long life. A drum is also affixed to the pump to offer additional support. A major function of the condenser extraction pumps is to ensure a smooth flow of the coolant fluid and other types of fluids in the condenser. As such, the design of the condensate extraction pump includes an electric motor that facilitates mobility within the condenser.

The direct contact heater is supplied with condensate from the condensate pumps together with condensate drains from steam piping and various heaters. The condensate is sprayed into the steam atmosphere at the top of the heater along with any drains returned, and the heated water is pumped a long in turn from a bottom suction by the main pumps.

Since the feeder pumps which take suctions from the direct contact heater, pump water that is almost saturated, the heater must normally be located 30 to 50 feet above the pumps in order to provide enough positive suction head to prevent the feed pumps from having a tendency to flash when inevitable pressure fluctuations occur in the heater during unexpected changes (Stamper and Richard 24). Consequently, the heater must be well located in the boiler room casing, or special feed booster pumps designed to operate with a low suction head must be provided. The main pumps are quite vital and very hard to maintain, and as a result, they can very easily be damaged when the condenser malfunctions. The pumps are usually located in the lower level in order to achieve maximum net positive suction effect.

According to Massoud (877), it is important to employ the appropriate condensate pumps and condensate booster pumps in coming up with the design head and the flow rate. The same principle applies to other types pumps used within the condenser such as the main feed water pump and the feed water heater pump.

Conclusion

This paper has presented a discussion on various aspects of the surface condenser. Its design, installation, operation, and maintenance have elaborated been explained. Other issues regarding the surface condenser considered in the paper include effects of air leakage on a condenser, the workings of single stage and two stage air ejectors, and operation and design considerations for condensate extraction pumps.

Works Cited

Graham Corporation. Surface Condenser: Operation, Maintenance and Installation Manual, Batavia, NY: Graham Corporation, n.d., Print.

Ludwig, Ernest. Applied Process Design for Chemical and Petrochemical Plants, Woburn, MA: Gulf Professional Publishing, 1995. Print.

Massoud, Mahmoud. Engineering Thermofluids: Thermodynamics, Fluid Mechanics, and Heat Transfer, College Park, MD: Springer, 2005. Print.

Rajput, Rao. Thermal Engineering, New Delhi, India: Laxmi Publications, 2010. Print.

Stamper, Eugene and Richard Koral. Handbook of Air Conditioning, Heating, and Ventilating, New York: Industrial Press Inc., 1979. Print.