Introduction

MTO is a common choice for providing customers with the products strictly according to their specifications. It is beneficial for achieving higher levels of customer satisfaction with the finished product. Within the context of this research, custom-built homes will be the main focus. The rationale for making this choice is the fact that they are usually constructed based on the features desired by the customer and after making an order.

Custom-built homes are designed and constructed according to the specific instructions of a particular customer and based on the specificities of a particular location. They are created to maximally satisfy the needs of a person who orders one, including layout, financial resources, and size. This product is provided by both private and state-owned companies operating in the construction industry.

Value Chain

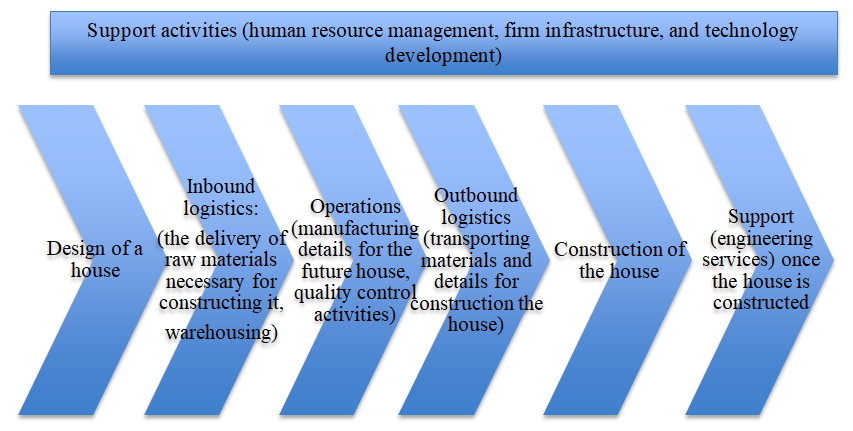

Value chain consists of primary and support activities (Kelly et al. 309). There are two classes of primary activities: inbound (supplying raw materials) and outbound (logistics, processing raw materials, design, construction, and support once the house in constructed). As for support activities, they involve firm infrastructure (guaranteeing safety in the workplace, assuring that a company creates the requested product regardless of the desired location, etc.), human resource management (workers with an adequate level of skills and knowledge), and development of technologies (using innovative technologies for completing projects). Detailed information is presented in Figure 1 below.

Capacity

Capacity planning is critical for guaranteeing that the construction company corresponds with the initial design and contract requirements. From this perspective, it is essential to pay special attention to such aspects, as the thorough planning of all processes (breaking the construction process into clear and easy-to-control stages), arranging and checking deliveries of raw materials and any other resources necessary for the timely completion of the project, and allocating necessary human resources (Sears et al. 17).

In this case, it is paramount to point to the fact that planning procedures should be made keeping in mind any undesirable changes in the process, including delays in delivery, weather conditions, specificities of the location of the future house, and human factor. Therefore, keeping it in mind, 100% is a maximum capacity. Still, it is critical to recognize the fact that achieving it is complicated and close to impossible. In this way, capacity utilization is planned at 85%. It will prove that allocated resources are used at almost maximum possible effectiveness, including delays, human factor, resource wastes, and weather conditions.

Production Process

The process of producing custom-built homes includes several distinct and interrelated stages. The first one is designing a house according to customer’s specification as well as specific features of its future location. The second one is confirming this design with the customer. The third stage is determining resources necessary for constructing the house, including the identification of needed raw materials and details that can be produced or ordered before the beginning of the construction process.

The fourth stage is the construction process itself. The fifth stage is putting the house into operation – letting the customer use it. At the same time, it is critical to note that all stages should be accompanied with strict quality control measures, especially when it comes to deploying technologies and human resources, in order to satisfy the customer’s needs and desires to the maximum possible extent (Walker 142).

Production Planning and Control

In addition to identifying production stages, it is essential to pay special attention to planning them. This process is commonly referred to as microplanning because all details are determined based on the peculiarities of the project and resources needed for completing it (Sears et al. 143). In the case of custom-built housing, it is critical to focus on such aspects of planning as schedules of workers and workloads. When determining them, it is essential to lay stress on infrastructure because it may either hasten or slow the construction process down (Sears et al. 148).

That being said, the shortest stage is design because it does not require the involvement of numerous designers and is less time-consuming compared to the construction process. Construction itself is the longest stage that is as well broken down into particular steps with their own timeframes. As for control, it is essential to develop particular standards (for instance, safety, construction, adhering to schedules and workloads, etc.) and conduct timely checks to assure that the project will be completed in time (Sears et al. 154).

Material Resource Planning

Resource planning stands for appropriate allocation of resources, budgeting, estimating costs, and controlling the use of resources (Nicholas and Steyn 12). Here, it is imperative to point to the fact that all resources needed for constructing the house are determined based on the specificities of the design. The needed resources usually involve inventory, raw materials, and equipment necessary for completing the project. Special attention should be paid to supply chain management. In this case, it is critical to assure that trusted suppliers are cooperated with, so there are no delays in delivering needed materials. The same is true for cooperating with contractors and transporting companies to assure that work is completed in time and wastes are eliminated when needed (Sears et al. 211).

Conclusion

Constructing custom-built homes is a common example of MTO products in the construction industries. Based on the specificities of the projects – the criticality of adhering to design features and customer preferences – it is essential to guarantee that all of them are properly planned. Therefore, this report has presented the most significant planning aspect to focus on when working on a construction project.

Works Cited

Kelly, John, et al. Value Management of Construction Projects. 2nd ed., Wiley Blackwell, 2015.

Nicholas, John M., and Herman Steyn. Project Management for Engineering, Business, and Technology. 4th ed., Routledge, 2012.

Sears, S. Keoki, et al. Construction Project Management: A Practical Guide to Field Construction Management. 6th ed., Wiley Blackwell, 2015.

Walker, Anthony. Project Management in Construction, 6th ed., Wiley Blackwell, 2015.