Science has never been as challenging as it is nowadays, with the opportunities that the recently developed technologies offer and the new discoveries that started tearing the very fabric of the existing scientific laws. However, when it comes to discussing the complexities of the modern science, one must admit that there is hardly as challenging and at the same time enthralling field as engineering design process.

Combining the elements of science and arts and demanding the skills in both spheres, engineering design process has been discussed rather actively over the past few years. Analyzing different viewpoints on the engineering design process will lead to redefining its place in the present-day engineering and redefine the actuality of the issues related to the engineering design process.

Schmidt takes a very responsible approach towards describing the specifics of the process. To be more exact, he splits the process into several steps, devoting one chapter to each. As the author explains, “The design process material is presented in a sequential format in Chapters 1 through 9” (Schmidt xxii).

In contrast to him, Haik and Tamer prefer defining the goals of the engineering design process, as well as offering the classification of the processes together with the related issues, such as the skills associated with engineering design, customer requirements, etc. Likewise, Budynas and Nisbet have chosen to describe the issues related to the analysis rather than offer a structured description of the steps that the process involves.

Indeed, according to the authors, the objectives are to “cover the basics of machine design, including the design process, engineering mechanics and materials, failure prevention under static and variable loading, and characteristics of the principal types of mechanical element” (Budynas and Nisbet xv).

Each author offers his/her own model of engineering design. Dieter offers a simplified iteration model (Dieter 6), though he explains that there is a variety of models, and each has its flaws: “There is no single universally acclaimed sequence of steps that leads to a workable de-sign” (Dieter 6).

Haik and Tamer offer four models that are supposed to be used in the engineering design process: a true model, an adequate model, a distorted model and a dissimilar model, while Budynas and Nisbet restrict their choice to the mathematical model, which means that they consider engineering design a process that involves a fixed number of steps..

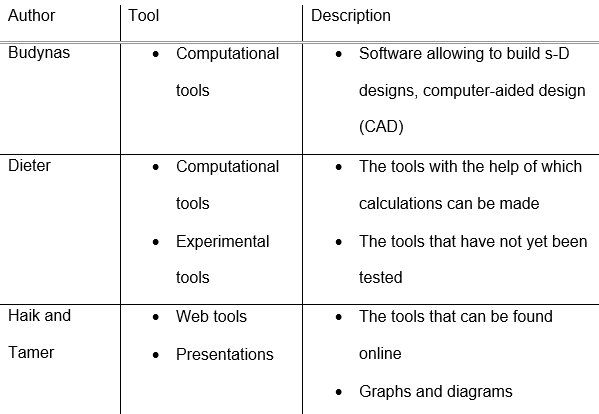

Table 1 The tools for engineering design process and their description

Therefore, it can be considered that, though engineering design is a very topical issue, there are still a number of problems related to the process of engineering design that need to be answered.

While the authors of the books discussed above offer a fairly clear picture of the process, it is obvious that certain elements of the given process are explained quite vaguely. However, with the current technological advances, it can be considered that the issues in engineering design process will be solved.

Works Cited

Budynas, Richard G. and Keith Nisbett. Shigley’s Mechanical Engineering Design. 9th ed. New York City, NY: McGraw-Hill Higher Education, 2011. E-book.

Dieter, George E. and Linda C. Schmidt. Engineering Design. 4th ed. New York City, NY: McGraw-Hill Higher Education, 2008. E-book.

Haik, Yousef and Tamer M. Shanin. Engineering Design Process. 2nd ed. Stamford, CN: Cengage Learning. 2011. E-book.