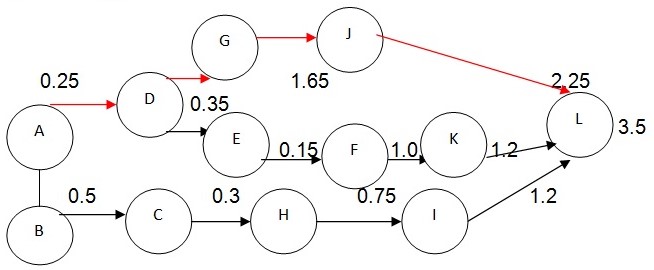

The major issue that Wood faces in the discussed case is the need to speed up the process of goods delivery to customer, because the current lead time that it takes to provide the customer with the goods after the order is placed is too long. To identify the elements of the order processing path that consume excessive time and thus to cut time required for completing tasks associated with those elements, it is necessary to design a PERT chart first (Langford, 2006, p. 215).

Thus, Figure 1 reveals that the critical path, i. e. the way to deliver the goods to customers that takes the largest amount of time, includes tasks A, D, G, J, and L, and amounts to 8 days in total (highlighted in red in PERT Chart). At the same time, the two remaining ways tale the least amount of time, i. e. each way requires 6.45 days to be completed.

Drawing from this, to reduce the time of goods delivery it is necessary to first of all consider the chances for reducing the time required for the most time-consuming tasks. In particular, Wood should examine tasks L, J, and G before others. These tasks require the largest amounts of time in the delivery process, and reduction of this time can considerably change the total time involved in the process. Another reason to consider namely those three tasks is that they cannot be commenced until all other tasks are completed, and the company should have enough time to make them more time-effective, while other tasks are in progress.

At the same time, the idea of technological advance that can reduce the time required for task H from 0.75 day to 0.03 day is worth considering. The implementation of the “Star Wars – Robotic” order picker is a rather interesting idea for Wood, as it will allow reducing the time required for one of the least time-consuming delivery ways and making it 5.73 days instead of 6.45 days.

Further on, if Wood has an alternative of either increasing expenses for faster transportation or for other improvements, the former point should be considered as the better for the company. Task L, i. e. transportation, is the most-time consuming task in the process (3.5 days), and reduction of this time, if the cost of such a reduction is not in question, will improve the delivery process considerably. If at least 1 day reduction is achieved, the least time-consuming way will require only 4.73 days, which is almost twice as little as the critical path of goods delivery requires (Johnson et al., 2007, p. 196).

Accordingly, Wood might want to compensate the additional transportation costs by reducing costs and increasing time consumption in other tasks. The most fitting alternatives for such reduction are tasks E, A, and C, as they currently require the least time among all tasks. The increase of their processing time distributed equally among the activities is unlikely to seriously affect the total delivery time, while the costs saved on these tasks might help reduce transportation time.

So, it is obvious that the current delivery process adopted in Wood’s requires too much time to be completed, but there are logistics initiatives that can help reduce this time and improve the effectiveness of the company’s work in the period between order reception and goods delivery.

References

Johnson, James et al. Contemporary logistics. Prentice Hall, 2007. Print.

Langford, John. Logistics: principles and applications. McGraw-Hill Professional, 2006. Print.