Introduction

The Emirates National Oil Company (ENOC) is a huge energy production corporation that is based in Dubai. The corporation was established in the early 1990s under the control of the Dubai administration. The Jebel Ali Processing Plant whose operations are mainly in Dubai runs the ENOC Processing Company, which is one of the corporation’s subsidiaries.

As stipulated in the company’s vision, ENOC concentrates mainly on gas and oil production. The company has at least 20 branches that rely on orders from the main company’s management department. With these highlights, this report shows how the energy factory has made enormous growth towards attaining its objectives, assignment, and dream of serving clients from all over the world.

Operations at ENOC

ENOC’s main operations involve supply, trading, and processing of oil and oil-related products such as gas. These operations contribute towards the organization’s progress since they enable it to concentrate on profits from the mid-stream and downstream resources (ENOC Supply, Trading and Processing par.1). The activities help in supporting the company’s value-added business propositions.

The segments are also critical in facilitating other operations of the organization, including gas distribution and retail-based fuel trading. They also facilitate the company’s interactions at the international arena and the major players in the international oil markets to develop sustainable growth opportunities. Through supply trading and processes, ENOC identifies and establishes strategies for targeting new markets.

Role of Operations at ENOC

ENOC’s top management, which plays the role of implementing the company’s proposed activities, decides on the requisite strategies that the organization needs to adopt to ensure that it meets the demands of the emerging market trends to guarantee sufficient and timely response to the strategies that are adopted by competitors. This management role is evident in the company’s mission of gaining sustainable development in the effort to maximize its profitability.

The objective is to meet the growing energy needs of the people of Dubai while at the same time having up to date technologies to use in the implementation of the organization’s practices. Hence, it can achieve excellent performance via giving customers the best services that exceed their expectations in terms of quality and service delivery (ENOC ENOC Vision par.3).

Additionally, the company aims to gain and maintain industry standards that address issues that touch on environment conservation, health, and safety while at the same time bringing and retaining top talent employees. ENOC’s operations strategies establish different activities, which when precisely followed, lead to the attainment of the corporation’s vision, goals, objectives, and mission.

At ENOC, its supply, trading, and process activities constitute the main drivers that ensure that ENOC remains a market leader through people in the oil industry. Indeed, the company’s employees are in continuous contact with the market, associates in the oil business, and customers. People collect information from these stakeholders to guarantee consistent value addition to ENOC’s business.

Support is required at all ENOC’s business levels from different departments in a bid to realize the operations function of implementing strategies that drive the company forward. Through the support function, ENOC acquires data that relates to market trends, including strengths and limitations of the players.

This information helps the implementer to develop strategies for countering the competitors. Hence, the three operations functions iterate. For example, upon the implementation of success strategies at ENOC, people monitor their results by providing feedback to the top management to facilitate the development of new or reviewed company’s STP strategies.

The Four-Stage Model of Operations Contribution

Various factors enhance organizational growth. Such factors include cost effectiveness and the development of operational strategies that respond to the emerging market needs. Such strategies should also be effective in helping an organization to gain a competitive advantage so that it can withstand competitive forces both in the short and long run (Johnson, Scholes, and Whittington 41).

At ENOC, effective management of its operations is critical in enhancing competitive advantage. The operations section plays the role of implementing growth and success strategies. Besides supporting the operations by availing the required resources, the operations department also oversees the continued running of the company’s projects.

These functions may be represented in a four-stage model that demonstrates how the operations contribute to the success of an organization. In stage 1, an organization endeavors to identify and correct its worst operational challenges. In this stage, the organization is impartial from within. However, problems hold it back in the industry.

Stage 2 entails the attempts to adopt best practices in the industry to become equally competitive just like the competitors. At this stage, an organization is externally neutral. Operations function of implementing becomes important in linking stage 1 and stage 2. At ENOC, this stage involves the identification and implementation of a change to ensure sustainability of the STP and the replenishment of the overall process.

The implementer role of operations guarantees dependability, operationalization of business strategies, and the explanation of various practicalities of ENOC’S business. Stage 3 encompasses the linking of operation with strategies. This process is linked to stage 2 by the supporting role of operations so that an organization becomes not only distinguishable in its industry of operation but also internally supportive.

The supportive role contributes to the operations by ensuring its appropriateness, increasing the simplicity of understanding the strategies, and/or making vital decisions. In stage 4, an organization acquires operations competitive advantage to redefine its industry anticipations.

The driving roles of the operations processes link it to stage 3 so that it becomes externally supportive. The driving function of the operations ensures innovativeness, fastens strategies, and guarantees the development of ENOC’s long-term goals. As the company progresses from stage 1 to 4, the upgraded operations increase the company’s capabilities and strategic impact on the energy market.

Role of Operations in driving Organizational Competitive Advantage

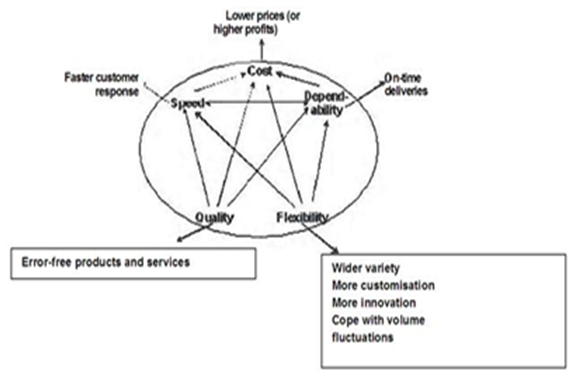

The company’s operations function provides a competitive advantage through its key objectives that include eminence, momentum, reliability, suppleness, and cost competitiveness. These aspects have diverse meanings in deferent organizations.

The meaning of Quality, Speed, Dependability, Flexibility, and Cost at ENOC

Through an effectively planned production process, workers are given an opportunity to concentrate on tasks that add value to their respective organizations. Such tasks need to add eminence and momentum while at the same time guaranteeing steadfastness, suppleness, and the achievement of a cost advantage in an organization. At ENOC, quality refers to the stakeholders’ conformity to the established specifications.

Such specifications are established to ensure that the consumer does not complain about the different products that are offered for sale by the organization. At the operations level, quality ensures that few or no mistakes are made in the supply, trading, and processing stages. The goal is to not only save on costs but also increase dependability and response time (speed).

In this context, Hansen and Birkinshaw assert, “If an operation is continually correcting mistakes, it finds it difficult to respond quickly to customers’ requests” (89). This claim suggests that quality influences the other four parameters that determine an organizations’ operations performance.

In terms of the company’s external operations, speed denotes the lapse between the time when a customer makes a request for products and the period when he or she receives it from ENOC’s premises. In the context of ENOC’s internal business affairs, speed relates to its cost-reduction strategies.

For example, speed in the supply of raw materials (crude oil) has the effect of reducing the necessity for holding high inventories. The goal is to reduce the associated risks. Therefore, it cuts down the cost that is associated with for insurance, material handling, and storage.

Dependability refers to the degree to which a product will be available in the market when a customer needs it. At ENOC, flexibility implies the capacity to change operations in some given ways to reduce response duration to save time, money, and/or increase dependability.

Cost refers to any expense that ENOC incurs in its operations. Costs can be quantified in terms of money or time that is lost in the process of engaging in unnecessary activities or delays during service delivery. In some situations, some costs, including the value of a lost customer or poorly motivated employees, are hard to quantify.

Competitive Advantage

All organizations focus on retaining and attracting new customers via building competitive advantage. As Bertscherk and Kaiser confirm, competitive advantage refers to “the advantage that a company gains over competitors by offering consumers’ greater value, either by means of lowering prices or by providing greater benefits and services that justify higher prices” (398).

Consequently, a strategy for enhancing competitive advantage at ENOC needs to have the perspective of cost attached to it. Indeed, quality, dependability, flexibility, and speed have features of cost in their internal impacts on ENOCs operations. Figure 1 shows this relationship.

By focusing on cost as the source of competitive advantage, ENOC can improve its productivity by heightening its customer dependability, service quality, flexibility, and order delivery speed. Concentrating on tasks that are capable of adding value to the quality of ENOC’s operations has the effect of reducing the prices of its products. The company eliminates costs that do not lead to value addition in the production of every unit by the company.

In the effort to save on costs that are associated with the implementation of new process designs, small-scale testing of designs before they are implemented on a large scale leads to immense cost reduction. This move has the effect of saving the company millions of dollars due to the failure of large-scale or full-size new model or a breakdown in the operations routes.

Therefore, the company requires fewer sales to break even so that it can afford to offer its products at low prices. Through the emphasis on building competitive advantage around costs, flexibility reduces the response time. Hence, it saves money (Chase, Jacobs, and Aquilano 51).

It also increases dependability so that ENOC can acquire a higher reputation for its products. An attempt to increase dependability may lead to increased efficiency, which implies that ENOC’s operations are executed at high speed.

Conclusion

After facing various operational challenges, ENOC has considered several mechanisms for inducing organizational change in the effort to gain a competitive advantage in its industry of operation. An organizational framework for change involves a review of the organizational structure (Hansen and Birkinshaw 89). The review should improve the organizational needs.

ENOC has been encountering various organizational challenges, which prompt the putting in place of various organizational changes to enhance its performance. Consequently, the operations management needs to take up extra roles. The personnel in the operations management needs to propose and seek approval for various innovative strategies for reducing operational costs.

In case of ENOC’s supplies, issues such as the successful execution of innovative outsourcing services, the determination of the criteria for setting priorities, and the establishment of mechanisms for resolving various customer disputes and other service units are necessary. More participation of stakeholders in the evaluation and making of recommendations for new process development is critical for ENOC’s continued success.

The implementing function should continue to guarantee the achievement of the organization’s vision. Therefore, it is critical to utilize KPI performance standards to review the performance of operations’ implementers. ENOC should emulate and benchmark from the Toyota Company in its costs reduction strategies.

In fact, operations management scholars such as Johnson, Scholes, and Whittington believe that Toyota’s operations strategies can form a significant yardstick (98). Toyota Company’s processes revolve around five facets. They include the development of a production system that is unique to Toyota, investments in re-engineering, high emphasis on quality and superior technology, production of hybrid vehicles, high concerns on employee welfare-related costs, and building a motivated workforce through the adoption of various employee satisfaction strategies.

Although each of these facets is incredible in business success strategies, ENOC should recognize that a production system can affect the overall direct costs of production in such a way that the final products may be offered to the market at exorbitant prices. Such outcome may in turn influence ENOC’s sales volume, profitability, and competitive advantage.

Works Cited

Bertscherk, Immanuel, and Anderson Kaiser. “Productivity Effects of Organizational Change: Microeconometric Evidence.” Management Science 50.3(2004):394-404. Print.

Chase, Richard, Robert Jacobs, and Nicholus Aquilano. Operations Management for Competitive Advantage. New York, NY: McGraw-Hill, 2007. Print.

ENOC. ENOC Vision and Mission Statement, 2012. Web.

ENOC. Supply, Trading and Processing, 2015. Web.

Hansen, Michael, and James Birkinshaw. “The Innovation, Value Chain.” Harvard Business Review 85.6 (2007): 87-98. Print.

Johnson, Gerry, Kevan Scholes, and Richard Whittington. Exploring Corporate Strategy. Harlow: Prentice Hall, 2005, Print.