Introduction

Microbial communities are capable of self-organization and self-sustenance. When managed properly in accordance with the five principles of good management, they provide a number of benefits that include (Rittman 2006, 261):

- Detoxification of wastewater

- Capturing renewable resources such as energy and water

- Sensing pathogens in the environment

- Public protection against dangerous exposure to pathogens

The attached and suspended growth biological wastewater treatment processes: a Comparison

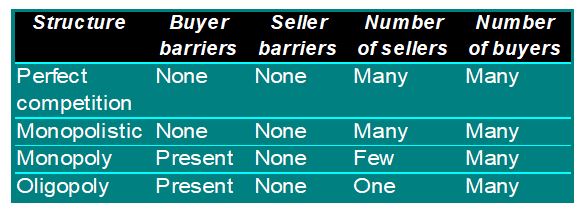

Attached and suspended growth biological wastewater treatment processes are classified under secondary wastewater treatment processes. They both rely on microorganisms for their operations. These microorganisms feed upon organic material in the waste for sustenance and reproduction. In addition, they create settleable solids from the nonsettleable ones (WEF 2008, 2-11). Both processes operate on the basis of two modes: in the presence of oxygen (aerobic) and in the absence of oxygen (anaerobic). Both processes are very efficient and effective in wastewater treatment processes but both processes are expensive in investment and operation.

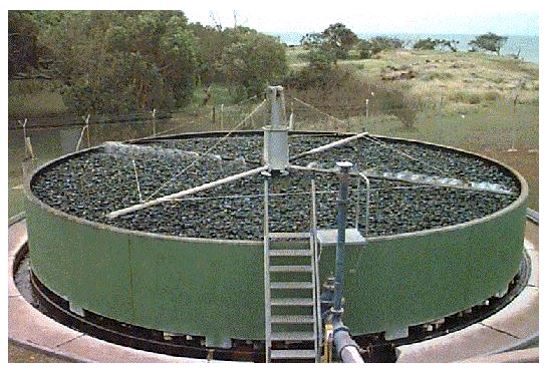

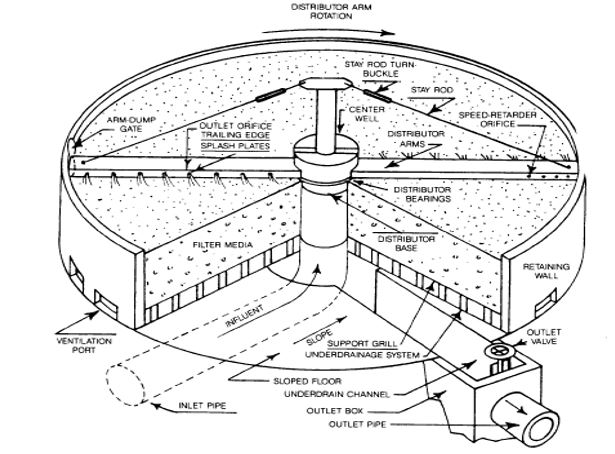

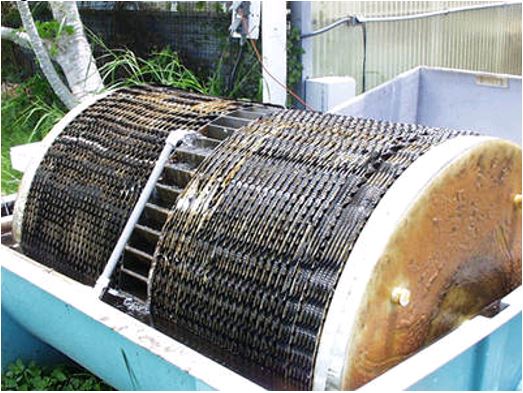

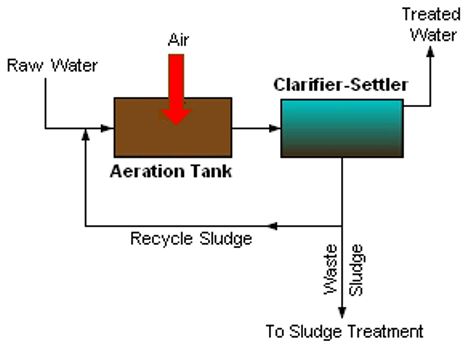

The microorganisms in suspended growth processes that are responsible for wastewater treatment are kept in liquid suspension through mixing and aeration to ensure that aerobic conditions are maintained. Continuous flow-activated sludge is the principal suspended process (Fig 4). While compared to the attached growth wastewater treatment processes, the attached process has a medium, for example rotating disks, fixed packing, or granular medium packing-which is utilized for the attachment of microorganisms and formation of a biofilm. This bio-film gets into contact with the microorganisms and the organic matter present is sequentially oxidized. The growth of the microorganisms is simultaneous with their sloughing from the surface of the medium. They are then removed by a solids separation device which is normally a filter and/or a gravity settling tank (Surampalli 2004).

Suspended growth processes are mainly aerobic processes, which through the recycling of biological solids, are able to gain high concentrations of microorganisms. The microorganisms change biodegradable, organic wastewater constituents and particular inorganic segments into new cell masses and byproducts. The end results of this biodegradation process can be removed by gaseous settling, stripping, and related physical means.

Attached growth biological wastewater treatment processes employ the principle of organic matter removal, made possible due to the presence of microorganisms. The microorganisms involved in such processes are aerobic and therefore rely on oxygen for survival. Their survival also requires a filter media, which includes materials “like sand, plastic, gravel or peat to aid in the development of a film on the media through the recycling of dissolved organic material” (Massoud & Abrishamchi 2005).

Advantages and disadvantages of attached Growth processes

The attached growth biological wastewater treatment processes are advantageous because they have a high concentration of biomass that is active as a result of microorganism immobilization. In addition, there is evidence to support the claim that nitrification is minimally affected by low temperatures in attached bio-film processes when compared with conventional suspended-growth activated sludge systems (Delatolla et al., 2009).

As stated earlier on, attached growth wastewater treatment processes are governed by the principle of removal of organic matter from wastewater which is controlled mainly by aerobic microorganisms. There are two basic types of the attached growth processes as indicated below:

Trickling Filters

Rotating Biological Contactors

The most evident advantages of attached-growth biological processes include (Delatolla et al., 2008, 2009; Ramesh et al., 1999):

- Escalated concentrations of biomass in the reaction tank, which correspond to reduced wastage of biomass.

- Consortia of aerobic and anoxic metabolic activity in the same biomass ecosystem

- Lower sensitivity to toxicity effects as well as to other adverse circumstances

- Up-grading of existing systems at minimum cost

- Decrease of sludge-settling periods

The attached growth processes require lower energy, they are easy to maintain, have simple operations since operational adjustments are rare, recover favorably well from shock loads and are simple to operate (Metcalf & Eddy, 1991). They are better preferred with regard to “biochemical oxygen demand (BOG) removal, denitrification and nitrification” (Rittman 2006). Attached growth processes make use of the compact nature of technology largely as a result of the possibility of high loading rates that translate into decreased requirements of space during the construction or expansion of facilities on tight sites. The use of fixed biological films to contain microorganisms within the systems brings about stability within the systems. Most of the attached growth processes operate on relatively low energy.

The attached growth systems have got disadvantages as well. They require a large size of land for them to be operative. They function poorly in cold weather and are associated with odor problems. While compared with the suspended growth processes, the attached growth processes do not make proper use of influent carbon for denitrification purposes thus escalated costs due to external sources of carbon. There is minimal operator adjustment in response to changes with regard to loading conditions. These processes require much more capital when compared to suspended growth systems. They also have unfavorable shock load response attributed to fixed quantity of biomass by the biofilm media surface area.

Advantages and Disadvantages of Suspended Growth Processes

Suspended growth systems are otherwise known as conventional activated sludge as shown below in figure 4:

The suspended growth processes use several process modes that range from “conventional, contact stabilization, single sludge, extended aeration and sequencing batch, which are present for polishing effluents that are anaerobically treated” (EPA 2004). Suspended growth processes are ideal for “industrial plants, steam systems, heating and cooling systems, swimming pools, cooling tower systems and domestic water supplies” (Surampalli 2004).

The suspended-growth processes are operational in lesser space than the attached growth processes. However, compared with the attached growth process, suspended growth processes are not able to put up with radical changes in the quantity of biological material. In addition, they lack the capability to provide higher elimination rates for organic material and suspended soils (EPA 2004, 11-13). The suspended growth water systems do not have a high concentration of active biomass as a result of microorganism mobility. Low temperatures have not been found to have a minimal negative effect on nitrification as compared with attached bio-film growth systems.

Nutrient Removal

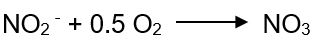

Wastewater is rich in high levels of nitrogenous and phosphoric nutrients. “The excessive release of nitrogenous and phosphoric nutrients into a water body, known as eutrophication fosters overgrowth of cyanobacteria and algae” (Sedlak, 1991). Removal of nitrogen is achieved through nitrification. Nitrification entails biological oxidation where nitrogen is oxidized to ammonia and subsequently to nitrate.

here oxidation of ammonia-nitrogen to nitrite-nitrogen takes place with the help of the Nitrosomonas bacteria (Surampalli 2004).

oxidation of nitrite-nitrogen to nitrate-nitrogen by the nitrobacter take place.

Denitrification follows nitrification and it entails a reduction of nitrate to nitrogen gas. This gas is released into the atmosphere. Some biological nutrient removal (BNR) processes utilize suspended growth processes while others make use of the attached growth processes (Sedlak, 1991).

Nitrification can be biologically attained by using either attached or suspended growth processes. However, suspended growth is the most common. The principle reasons that make suspended growth processes to be ideal are

- Nitrification can be conveniently integrated to fit within the design of the aerobic reactor

- The process is easy to operate

The flow-through in suspended growth processes as indicated below is also ideal for nitrification but requires adjustments in aeration configurations, solids retention time, aeration equipment design and operating mode.

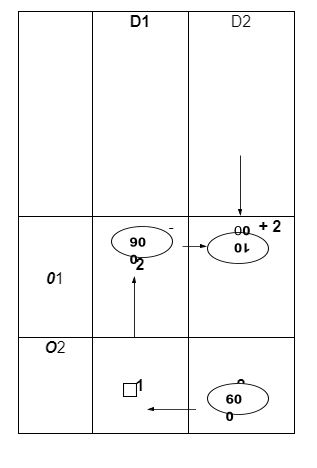

There are various biological nutrient removal (BNR) process configurations that vary depending on the nutrients to be removes. There are BNR systems that remove the total nitrogen only, other remove the total phosphorus only while others remove both nutrients. The appropriateness of any configuration used depends on the operator’s experience, effluent and influent equality and the already existing treatment process. BNR systems meant to remove the total nitrogen should have an aerobic zone that supports nitrification and an anoxic zone for denitrification purpose.

BNR systems designed to remove phosphorus should have an anaerobic zone that is free of dissolved nitrate and oxygen. In most cases, sand or some other kind of media filtration is used as a polishing step towards the removal of particulate matter when minimal concentrations of total nitrogen and phosphorus are required. Filtration of san can be combined with attached growth denitrification filters to make a further reduction of soluble nitrates and effluent nitrogen levels (WEF and ASCE/EWRI, 2006).Proper operation and control of BNR systems is essential if they are to achieve the desired impact with regard to low nitrogen and phosphorus effluent concentration. Temperature, pH, recycle loads, dissolved oxygen and filamentous have been shown to affect the system’s performance thus, the need to clearly understand how these factors affect the system before hand. Nitrification and denitrification rates are directly proportional to temperature. If there is an increase in temperature, the rates of nitrification and denitrification will also rise. The effect of temperature on phosphorus removal has not been articulately comprehended but, slow phosphorus removal reaction rates are realized in temperatures beyond 30 degrees centigrade (Jeyanayagam, 2005).

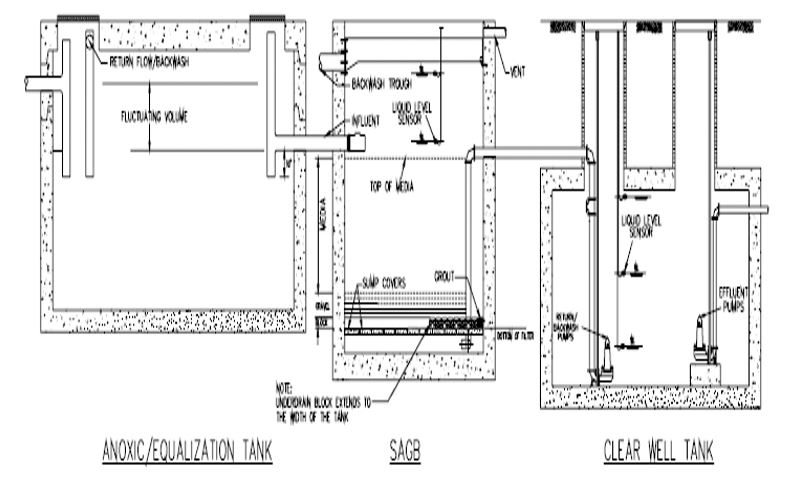

Submerged Attached Growth Bioreactor (SAGB)

The removal of inorganic nutrients has been of great importance following the severe effects of eutrophication on water resources. The submerged attached growth bioreactor (SAGB) is a biological nutrient removal process used in the removal of nitrogen from waste water. The SAGB is associated with two advantages, namely (Grady et al., 1999):

- Small volume requirement

- Removal of downstream clarification

Unlike other attached biological process and the suspended processes, the SAGB permits an escalated biomass concentration that leads to a short hydraulic retention time hence; a significantly decreased reactor volume. The SAGB also contains a fine media that allows separation of solids through physical filtration. There are different configurations of SAGB that have largely contributed to the advanced comprehension of these systems. This is very vital in achieving the second principle of good management which is the ability to develop and apply more tools in understanding microbial communities. A combination of nitrification and aerobic oxidation of organic are perceived as one operational unit during the complete removal of nitrogen from wastewater while denitrification is considered to be another separate unit (Andersen et al., 1995; Holbrook et al., 1998). The oxidation process entails following electrons thereby achieving the third principle of good management with regard to waste water treatment.

A pilot study by Pedros and Dobie (4608-4615) has been used to demonstrate how the SAGB process is adapted for nitrogen removal. A biological aerated filter which is a type of SAGB was set in series and positioned downstream of a denitrification unit. It indicated a recirculation of “300% inflow from the filter back to the denitrification unit eliminating nitrogen and organics to desired levels” (Yoshinobu et al., 1997). There was a single biological aerated filter that had a separate anoxic zone within the reactor. This was used for the combined removal of nitrogen and organics (Rogalla & Bourbigot, 1990). The use of single-units to accomplish the removal of organics and nitrogen is an innovative process variation.

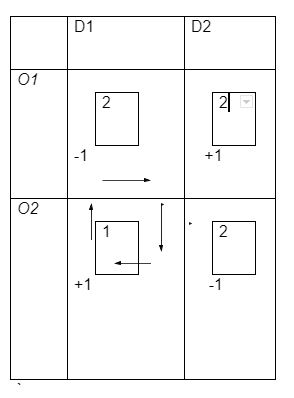

As indicated in figure 5 below, the SAGB process consists of one anoxic/equalization tank, a clear well and a SAGB. It operated in the same way as a sequencing batch reactor where water is cycled back and forth via the filter. There is an intermittent aeration of the filter to help achieve both the aerobic and anoxic environments. Both environments are very imperative for the process. The aerobic environment is required for the oxidation of organics and nitrification while the anoxic environment is important for denitrification. The SAGB system offers low visibility as all tanks are underground. It also provides compact footprint and effectively removes nutrients from the wastewater. The system experiences minimal effect from cold air temperatures.

Influent wastewater gets into the system through the anoxic /equalization tank. It has sludge storage and settling zones that serve as primary clarifiers before the SAGB. Wastewater flows by gravity from the anoxic tank into the SAGB. Hydrostatic pressure from different liquid levels acts as the forward driving force with regard to the forward flow of the wastewater. This action of making use of generated energy is with regard to the first principle of good management in wastewater treatment processes.

The reactor is made up of: “an underdrain, support gravel, filters media and a backwash trough” (Pedros & Dobie 2006). The underdrain at the bottom of the reactor is an important component of the reactor as it offers support to the media. It also allows an equal evenly distribution of water and air throughout the reactor. The delivery of air and water to the bottom of the reactor occurs simultaneously or separately through individual pathways. The design of the SAGB enhances this (Pedros & Dobie, 2006).

The SAGB is in an alternation operative mode between down-flow and up-flow. The up-flow mode is achieved by a pumping mechanism from the clear well, back up via the filter. The very same path via the reactor that occurs in the forward flow cycle is followed. Prevention of backflow into the anoxic/ equalization is achieved by the check valve positioned in the influent line of the reactor. The reactor is filled with the flow that overflows into the return flow/backwash trough and through gravity, it flows back to the front of the equalization/anoxic tank. The recycled flow containing nitrates mixes with incoming raw influent containing organic carbon. When the pump shuts off, the recycled flow adopts a forward flow once more.

Aerobic and anoxic conditions are achieved within the biofilm after process air is supplied at intermittent periods through the underdrain at the bottom of the reactor and does not depend on the return flow cycles. A typical aeration sequence takes 3 minutes when the process blower is on and 15 minutes when the blower is off. Cyclical forward and reverse flow of the wastewater stream, are very important aspects of the SAGB. This is because they help to achieve the hydraulic retention time. Intermittent aeration of the filter also helps to achieve this and also creates the required aerobic and anoxic conditions necessary for the achievement of desired levels of biological nitrogen removal (Pedros & Dobie, 2006).

Production of Methane

Up-flow Anaerobic Sludge Treatment Process (UASB)

The UASB reactor is a form of technology that has been adapted to produce methane during the treatment of wastewater. It uses an anaerobic process simultaneous to the formation of a blanket of granular sludge seen to suspend in the tank. An example of such an anaerobic digestion plant in Germany is illustrated in figure 6 below. Anaerobic micro-organisms act on wastewater as it flows upwards through the suspended blanket. There are various factors that come into play for the suspension of the blanket to occur. There is the “upward movement of wastewater alongside the settling action of gravity, which with the help of flocculants enables suspension of the blanket” (Khopkar, 2004). It is suggested that the blanket matures after a period of three months.

The formation of small sludge granules that have got their surface covered in bacterial aggregates begins. The absence of an enhancement from the support matrix leads to the creation of a selective environment by the flow condition. Microorganisms capable of attaching to each other are favored by this kind of environment as it supports their survival and proliferation. Biogas with high methane content is produced as a by-product. It can be tapped and utilized as a source of energy in generating electricity. This process requires adequate monitoring to make sure that the sludge blanket is not washed out hence, is maintained. Loss of the sludge blanket would make the process lose its desired effect. During the generation of electricity, heat is produced. Reheating of the digestion tanks is made possible by the reuse of generated heat (Khopkar, 2004).

Khopkar (2004) has indicated two main anaerobic bacteria involved in this anaerobic process, namely:

- Acetic acid-forming bacteria are known as acetogenins.

- Methane-forming bacteria are known as methanogens.

The bacteria feed on the initial feedstock from where they obtain their nutrients. This feedstock undergoes varying processes during which it is changed to immediate molecules, namely: “hydrogen, sugars, and acetic acid before the final conversion to biogas” (Khopkar, 2004). Anaerobic systems operate in the absence of oxygen. This is made possible by physical containment of the process in sealed tanks. As a result, gaseous oxygen is not permitted to get into the systems. The input material is comprised of components (inorganic oxides or organic material) that act as the main source of oxygen for the anaerobes. The process of obtaining oxygen from the organic material within the initial material leads to the formation of “aldehydes, organic acids, alcohols, and carbon dioxide as the intermediate end-products” (Khopkar, 2004). The conversion of the intermediate end-products to final end-products that include: carbon dioxide, methane, and traces of hydrogen sulfide, is governed by the presence of methanogens. Methanogenic bacteria are responsible for the conversion of chemical energy, present in the initial material, to methane (Massoud & Abrishamchi 2005).

The anaerobic digestion process takes place in four stages (Khopkar, 2004):

- Hydrolysis

- Acidogenesis

- Acetogenesis

- Methanogenesis

Large organic polymers, which are constituents of biomass, ought to be broken down into smaller constituents that will increase the surface area to volume ratio. This enables anaerobic bacteria to access the energy potential of the material in use. The breakdown of the large polymers and dissolution of the minuscule molecules is called hydrolysis. Acetate and hydrogen are the products of hydrolysis in the first phase and can be utilized by the methanogens as they are in the intermediate forms. However, volatile fatty acids-VFAs (longer than acetate) need to be catabolized that can be readily used by the methanogens. Elements from the first phase are further broken down by acidogenic or fermentative bacteria during acidogenesis (second phase). Alongside the production of VFAs, “carbon dioxide, ammonia, hydrogen sulfide, and related by-products are also produced” (Khopkar, 2004). This second stage in the production of methane (acidogenesis) is likened to the souring of milk.

Acetogenesis continues and it entails the further breakdown of simple molecules created in the acidogenesis stage by acetogens. The main products of acetogenesis are “acetic acid, carbon dioxide, and hydrogen” (Khopkar, 2004). This stage is followed by methanogenesis (the final stage in the production of methane), where methane alongside water and carbon dioxide is produced. This comes by when methanogens act on all the intermediate products produced in the preceding stages. Methagonesis is sensitive to both acidic and basic conditions. Therefore, a pH of 6.5 to 8 is desirable. The residue (indigestible material) that cannot be fed on by the microbes together with the dead bacteria remains, make up the digestate (Khopkar, 2004).

Figure 7 below shows a summary of the processes involved in the production of methane from wastewater

This process of methane production makes use of principles of good management in wastewater management. There is the reuse of heat and biogas generated during the process hence meeting the principle of aiming for big benefits.

Conclusion

Currently, it has been found that the combination of both the attached and suspended to form the hybrid reactors has more benefits than the use of each process on a separate level. The main adopted configuration is the incorporation of biofilm within the activated sludge system. The hybrid system is characterized by the growth of biofilm on a stable or portable carrier. This kind of combination brings about efficiency in substrate removal even at low temperatures. Stability and sludge properties of the hybrid reactors are improved. They have been created to bring about a high rate in chemical oxygen demand (COD) removal and upgrade COD removal plants to nutrient removal.

References

Andersen, K., Bundgaard, E., Andersen, V., Hong, S., & Heist, J., 1995. Nutrient Removal in Fixed-Film Systems. Water Environment Federation, 68th Annual Conference & Exposition, 1, 581-590.

Asano, T., 2007. Water Reuse: Issues, Technologies and Applications. New York: Metcalf & Eddy, Inc.

Delatolla, R., Berk, D., & Tufenkji, N., 2008. Rapid and reliable quantification of biofilm weight and nitrogen content of biofilm attached to polystyrene beads. Water Research, 42, 3082–3088.

Delatolla, R., Tufenkji, N., Comeau, Y., Lamarre, D., Gadbois, A., & Berk, D., 2009. In situ characterization of nitrifying biofilm: minimizing biomass loss and preserving perspective. Water Research, 43, 1775–1787.

EPA, 2004. Primer for Municipal Wastewater Treatment Systems. EPA 832-R-04- 001. Washington, DC.

Grady, C., Daigger G., & Lim, H., 1999. Biological Wastewater Treatment. 2nd ed. New York: Marcel Dekker, Inc.

Holbrook, R., Hong, S., Heise, S. & Andersen, V., 1998. Pilot and Full-Scale Experience with Nutrient Removal in a Fixed Film System. Water Environment Federation, 71st Annual Conference & Exposition, 1, 737-774.

Jeyanayagam, S., 2005. True Confessions of the Biological Nutrient Removal Process. Florida Water Resources Journal.

Khopkar, S., 2004. Environmental Pollution Monitoring and Control. New Age International

Massoud, T., & Abrishamchi, A., 2005. Integrated Approach to Water and Wastewater Management for Tehran, Iran, Water Conservation, Reuse, and Recycling: Proceedings of the Iranian-American Workshop, National Academies Press.

Metcalf and Eddy, Inc., 1991.Wastewater Engineering: Treatment, Disposal, and Reuse, 3rd ed. New York, NY: McGraw-Hill, Inc.

Pedros, P., & Dobie, W., 2006. A Submerged Attached Growth Bioreactor for Decentralized Wastewater Treatment. Rockland: F. R. Mahony & Associates Inc. (pp. 4608-4615)

Ramesh, M., Shankar, K., Mohan, C., & Varghese, T., 1999. Comparison of three plant substrates for enhancing carp growth through bacterial biofilm. Aquacultural Engineering 19, 119–131.

Rittman, B., 2006. Microbial Ecology to Manage Processes in Environmental Biotechnology. Trends in Biotechnology, 24 (6), 261-266.

Rogalla, F. & Bourbigot, M., 1990. New Developments in Complete Nitrogen Removal With Biological Aerated Filters. Wat. Sci. Tech., 22 (2), 273-280.

Sedlak, R., Ed. 1991. Phosphorus and Nitrogen Removal from Municipal Wastewater: Principles and Practice. 2nd ed. Florida: Lewis Publishers.

Surampalli, R., 2004. Advances in water and wastewater treatment. Virginia: American Society of Civil Engineers. (pp 117-132).

Water Environment Federation (WEF) and American Society of Civil Engineers ASCE)/Environmental and Water Resources Institute (EWRI), 2006. Biological Nutrient Removal (BNR) Operation in Wastewater Treatment Plants. New York: McGraw Hill.

Water Environment Federation (WEF), 2008. Operation of Municipal Wastewater Treatment Plants. 6th ed. New York: Water Environment Federation.

Yoshinobu, T., Takashi, N., Masumi, I., & Morio, H., 1997. Feasibility Study on Nitrogen Removal Process by Biological Aerated Filter. Water Environment Federation, 70th Annual Conference & Exposition, 1, 641-652.