Being such a risky profession, fire fighting requires the use of highly specialized gear that will enable the fire fighter to effectively deal with fire emergencies (Hasenmeier 1). It is therefore essential to provide fire fighters with well designed personal protective equipment so as to safeguard their lives. In the early days, firefighters had no choice but to fight fires with whatever they wore.

Today, however, it is easier and safer to deal with fire disasters thanks to successive technological advancements that have led to better quality personal protective equipment being made available for the fire fighters. The design of personal protective equipment worn by firefighters today is in so many ways different from what was used by the early firefighters (Hasenmeier 1).

According to Smith (1), the earlier gear used by fire fighters made it extremely difficult for them to get into burning structures to move victims to safety. The type of clothing used by earlier fire fighters offered poor protection from heat and flames and could not allow interior operations to be carried out effectively.

Using their daily unspecialized clothes, fire fighters could only fight the fires from the outside (Hasenmeier 1). The advent of modern personal protective equipment has, however, made it possible for the fighters to help people trapped in fire.

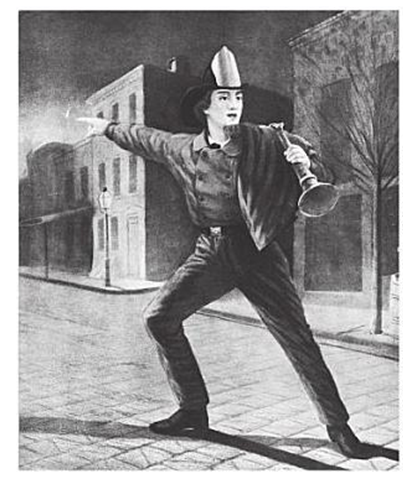

Although attempts were made to design uniforms to be worn by fire fighters, these were used mainly as a way to identify members of different fire fighting companies (Klinoff 77). Rather than being used when fighting fire, the uniforms were worn at parades and other forms of gathering.

The uniforms were well trimmed and had larger letters or numbers printed on the front of the shirt. In addition, the fire fighters would wear a thick leather belt with the company number on the buckle. The belt also provided a place to hang the fire fighters’ tools.

During the 1800s, standard uniforms were adopted by major companies and the larger numbers and letters were replaced by a badge identifying a member’s rank and his or her department. Figure 1 shows one of the old style uniforms used during firefighting (Klinoff 77).

This paper outlines how different personal protective equipment has evolved over the years. Specifically, the bunker gear, the fire fighter’s helmet, the self contained breathing apparatus as well as boots and gloves are discussed in the succeeding sections.

Bunker Gear

The clothing worn by a fire fighter is regarded as one of the most vital pieces of equipment that he or she must have (Smith 1). The bunker gear commonly refers to the coat and pant designed to help keep the wearer safe from dangers that are associated with fire fighting. Like other fire fighting equipment, the bunker gear has undergone an elaborate development process.

As has been argued by some people the bunker gear had its origins among the soldiers who fought in the World War I (Smith 1). As the methods of attacking fire became more aggressive, the fire fighter’s personal protective equipment had to keep up with the rapid change. Fire fighters started putting on long canvas coats together with boots that came up to the thighs to stay safe from falling embers.

Later, water barriers were added to the coat in an attempt to keep the fire fighter dry. Insulation was also added to protect the wearer from intense heat. As the quality of rubber improved, better fire fighter gear also became available. The use of rubber stickers worn over the woolen coats also added an extra layer of protection from heat and ensured that fire fighter remained dry (Smith 1).

Today’s bunker gear is a three component assembly designed to keep fire fighters from danger while at the same time maintaining comfort for the wearers (Smith 1). After the Second World War, standard setting bodies came into existence to ensure that the personal protective equipment were of acceptable standards It wasn’t until after World War II when standards for firefighter personal protective equipment were developed (Hasenmeier 1).

Many organizations were born to test the equipment and outline acceptable equipment standards. The pace setter in this undertaking was the National Fire Protection Association (NFPA), which still creates standards to be followed by designers of the personal protective equipment. To ensure conformity, the National Fire Protection Association described the design and maintenance standards for the bunker gear in 1971. To date, considerable research has been devoted to the development and testing of bunker gear (Smith 1).

Helmet

The helmet is the most well known equipment for protecting the fire fighter’s head. As a product of necessity, its design has evolved over the years with different many designs ranging from cloth and felt hats to leather, metal, fiberglass, and plastic being tried out. The traditional shape of the helmet was created with a short brim on the front and a long brim on the back to keep embers and hot water from going down the back of the fire fighter’s neck.

The shield was mounted on the front with the company number and the fire fighter’s name. Its rib shaped structure was designed specifically to provide rigidity. The improved helmet design became especially important as interior fire attacks became more prevalent. Figure 2 shows a collection of fire helmets (Klinoff 77).

According to Hasenmeier (1), Jacobus Turck is credited with the invention of the first helmet that took place in the 1730s. Jacobus’ design of the helmet was made out of leather and had a high crown with a wide brim (Hasenmeier 1). Later, Matthew DuBois modified the helmet’s design by putting wire to the brim so as to offer resistance to moisture and heat (Smith 1). Later in the year 1836, Henry T. Gratacap designed a helmet that in many ways was very similar to the type of helmet used by fire fighters today.

This design was a dome shaped leather structure with a front shield and a brim that rolled to a long back tail. As designers continued to improve the design of the helmet, the leather was strengthened further by adding ridges on the inside of the helmet. It later emerged that the helmet could be made even stronger by ensuring that numerous ridges were made available on the helmet.

Just like with the bunker gear, helmet designers also experimented with quite a number of materials. Eventually, leather prevailed as the preferred choice of material for the helmet into the 20th century. At one point, aluminum was used but because of its strong ability to draw heat and electricity, the outcome was quite dangerous. Its use was therefore abandoned at once. With the improved helmet design, it became possible to protect the fire fighter’s head from dangerous falling substances (Hasenmeier 1).

Today, helmets are made in such a way that the fire fighter is well protected from water, heat, as well as from falling objects. It also offers very good protection to the neck although the eyes are still exposed to danger (Smith 1). The helmets are made using different colors that help to identify the fire fighter’s rank. With different members using different colors, it also became easy to identify the fire fighters.

As the helmet designs kept improving, the presence of numerous organizations in the sector helped to ensure that the quality was not compromised at all. Higher standards therefore became available in the market. Acceptable standards required the helmets to have an improved outer layer to protect the fire fighter from the effect of very high temperatures of heat.

Self Contained Breathing Apparatus (SCBA)

In the early days of fire fighting history, respiratory protection for use by the fire fighters was quite minimal. It is alleged that fire fighters had to grow beards as a mechanism of protecting themselves. During a fire rescue operation, they would soak the beards in water, bite them and breathe through them so as to stay safe in an area filled with smoke.

Although the beards served pretty well as air filters, they could not completely protect the fire fighters as they would still get choked by the by-products from the fire (Smith 1). In some cases, the fire fighters would wrap wet rags around their faces to ensure that they do not get affected by smoke and ash generated by the fire.

The next improvement that came was the canister or gas mask, which protected the fire fighters from smoke particles. Unfortunately, the canister also did nothing to protect the fire fighters from the effects of toxic fire gases and low oxygen concentrations. In the year 1825, an Italian scientist Known as Giovanni Aldini made an attempt to develop a mask that would make it possible for the fire fighters to receive a good supply of fresh air and also protected them from heat (Smith 1).

The idea of the mask generated a great interest among designers to start making more reliable devices. Sometime later, a miner named John Roberts invented a filter mask that became quite popular and was extensively used in Europe and the United States. Around the same time, designers came up with different types of helmets that were fitted with a hose supply the wearers with fresh air (Smith 1).

Because of the many hazards that fire fighters were still being exposed to, there was need to design personal protective equipment that would better protect the wearers. This led to the discovery of the self contained breathing apparatus (SCBA) which is today used on almost all fire incidents to guarantee the safety of the fire fighters. The self contained breathing apparatus is considered as one of the most vital pieces of equipment used by fire fighters (Williams 1).

The SCBA provides fire fighters with a good supply of breathing air that makes it possible for fire fighters to get into burning buildings that often will be charged with smoke and super heated gases. When using the self contained breathing apparatus, fire fighters would be able to get to core of the fire much faster. This apparatus made it possible for them to perform rescue, ventilation, suppression, salvage, and overhaul functions without breathing in toxic smoke and gases (Williams 1).

When the self contained breathing apparatus was invented and adapted to fire fighting use, the ability to perform interior attack was greatly enhanced. The fire fighters no longer had to back off from the fire to take a blow to fill their lungs with fresh air (Klinoff 78).

Because the nozzle of the self contained breathing apparatus draws air alongside the fire stream, one method used by the fire fighters to get fresh air in a smoky building was to place their faces by the nozzle. The use of the self contained breathing apparatus also helped to drastically reduce the number of fire fighters suffering from cancer caused by being exposed to toxic gases and soot from the fires. Figure 3 shows the modern self contained breathing apparatus (Klinoff 78).

Today, the self contained breathing apparatus is an indispensable piece of fire fighting gear providing important protection for the fire fighter’s lungs, respiratory tract, eyes, and face (Smith 1).

Its tank weighs roughly 30 pounds and has the ability to hold up to 30 minutes of air. Normally, the breathing apparatus is worn on the fire fighter’s back and then connected to an airtight mask that nicely fits on to the fire fighter’s face (Smith 1).

As with other types of personal protective equipment, the self contained breathing apparatus has evolved and improved in a number of ways over the years (Williams 9). The use of lightweight steel, aluminum, and fiberglass wrap, has resulted in decreased weight of SCBA tanks and increased air volume. Advances in design, such as the positive pressure mask, anti-fog lenses, low air warning devices, and others, have helped to make self contained breathing apparatus safer and more effective for fire fighters to use (William 9).

While most people would agree that the use of self contained breathing apparatus aids significantly in the effective performance of fire fighting duties, it is not without its drawbacks and limitations (Williams 1). One problem associated with the use of the self contained breathing apparatus is the limited duration of the air supply to the fire fighters. This can be a major concern when fighting fires in large industrial complexes and in high rise buildings.

There is often the potential for the air supply to become depleted prior to the fire fighters retreating to smoke free areas where the self contained breathing apparatus can be removed and the air bottle changed. A second problem is the limited air flow through the regulator. Under heavy work loads, such as rescue maneuvers, stair climbing with equipment, and forcible entry, the rate of air flow from the regulator has the potential to limit the physical performance of fire fighters (Williams 1).

The total quality management principle of continuous improvement suggests that in order to deliver the best possible service to the customers, fire service managers should be constantly looking for ways to improve performance (Williams 10). The recognition of some of the limiting aspects of the self contained breathing apparatus clearly indicates that there is a need to search for better or improved techniques and equipment in order to facilitate maximal performance (William 10).

Boots

Because of the nature of their job, fire fighters have to step on hot and sharp objects. Boots are therefore very critical to the life of a fire fighter as they play a big role in protecting the fire fighter from serious dangers that can be caused by the hot and sharp objects (Smith 1).

Boots also protect fire fighters from falling objects that can easily trapping and hurting their feet. The boots used by earlier fire fighters were made out of rubber and would not even reach the knee height. These boots had to eventually be replaced with knee length boots that apart from being safer protected the fire fighters from fire underneath them.

Improvements in the quality of rubber further made it possible for designers to come up with better quality boots which ensured that the wearer’s feet were always kept dry. The National Fire Protection Association (NFPA) finally set standards for boots and required designers to make boots using strong leather or rubber material. They also had to be have hard soled and able to withstand dangerous environments (Smith 1).

Gloves

Fire fighters also used gloves that helped to protect their hands from heat and sharp objects (Smith 1). The gloves would also be used to protect the fire fighters any time they used hoses, ropes or other powerful equipment that could damage their hands. In the early days, fire fighters were forced to use improvised gloves whenever they had to deal with fire disasters. Over the years, however, the quality of the gloves improved greatly and today, one can find reliable designs made using powerful heat resistant material known as Kevlar.

The existence of many players in the glove design industry compelled designers to ensure that they only produced gloves of higher quality and better standards. The National Fire Protection Association also recommends the use of high quality gloves that must protect the firefighters from dangerous substances such as flames, liquids, vapor, and heat as well as sharp objects (Smith 1).

Other Types of Personal Protective Equipment

In spite of all the advancements in fire fighting technology, a lot more still has to be done to guarantee the complete safety of fire fighters. On various occasions, fire fighters trapped in structures would easily be overcome by heat or smoke from a fire despite wearing most of the protective gear. As a matter of fact, many fire fighters have suffered serious injuries or lost their lives after being exposed to toxic materials (Smith 1).

According to Smith, the injuries or deaths happened because fire fighters often lacked a means of alerting colleagues of their need for help (1). To address this problem, personal alert safety system devices were made in such a way that they could signal for assistance through an alarm system.

As soon as danger was detected, these devices would come to the aid of the struggling fire fighter by either sensing movement or lack of it. An alarm signal would then be activated if lack of motion exceeded specified time limits. Through the loud alarm signal that was generated, colleagues on the ground would be alerted that a fire fighter was out of action.

The rescuers would then be guided to where the incapacitated fire fighter was located and he or she would be rescued (Smith 1). Although the current National Fire Protection Association only requires that the personal alert safety system devices be fitted with a motion detector, some manufacturers have gone ahead to incorporate other useful features to make it more effective (Smith 1).

According to Hasenmeier, steady progress in the design of personal protective equipment was realized during after the World Wars (1). Some of the developments include the long rubber trench coats, elongated rubber boots, as well as the traditional fire helmet.

The extended rubber boots used by the fire fighters were often known as three quarter boots and these covered the fire fighter’s leg up to somewhere above knee (Hasenmeier 1). Other useful personal protective clothing worn by the fire fighters for their own safety include goggles, leather hoods, nose clamps and a whistle.

Conclusion

Major strides have been made in the evolution of the fire fighters’ gear with the National Fire Protection Association setting the acceptable standards as well as the requirements for the personal protective equipment. Today, all the clothing worn by the fire fighters must be certified by the NFPA to ensure that they conform to the correct standards (Smith 1).

Because of such advancements, the fire fighters of today are much safer than those of who lived and operated in the past decades whenever they are confronted with a roaring inferno or even a small blaze.

While in the past people would helplessly watch as fire destroyed lives and property, this is no longer the case as the art of fire fighting has greatly been simplified by the use of sophisticated technology. For many people, there is no single equipment that is more important than the gear used to secure the lives of the fire fighters (Smith 1).

As new materials are invented and new standards set, the fire fighting gear will continue to evolve further and hopefully, be able to guarantee total safety of the fire fighters. Allegedly, a new suit known as the bunker gear ensemble is under way and will soon find its way to the market.

This new design is meant to offer a barrier incase that fire fighter encounters biological or chemical hazards while on the job. The point is to design a bunker gear that can protect the fire fighter from all types of hazards. With such technological advancements occurring all over, it is presumed that the future of the fire fighting industry will have the best personal protection wear.

According to Smith, future standards of the bunker gear as well as the self contained breathing apparatus will include improved features such as increased thermal performance to deal with hot burning materials, heat sensors placed in various spots within the bunker gear to and global positioning systems (1).

Fire disasters have been around for ages and will continue to be witnessed. Considering that the lives of the fire fighters are very important, fire managers should stop at nothing to arrive at the best technology that will guarantee complete safety of the fire fighters.

Works Cited

Hasenmeier, Paul. The History of Firefighter Personal Protective Equipment. Tulsa, OK: PennWell Corporation. 2011. Web.

Klinoff, Robert. Introduction to Fire Protection. Clifton Park, NY: Cengage Learning, 2011. Print.

Smith, Rachael. The Evolution of Firefighters Personal Protective Equipment. Lansing, MI: Firefighternation. 2011. Web.

Williams, Bernard E. The Effects of Oxygen Enriched Air on Firefighter Job Performance. Alberta, CA: National Fire Academy. 1998. Web.