Automatic Sprinkler Systems

- Automatic Sprinkler Systems are made to automatically extinguish fire using an approved fire fighting agent in building

- The systems consists of pipes with water in or below the ceilings of a building, with valves and sprinklers that allow water to flow automatically at certain temperature (Chen, Sharman, Rao, & Upadhyaya, 2008)

- It is a requirement for commercial business buildings over 4,000 square feet to have automatic sprinklers

- Automatic sprinklers must be maintained and inspected periodically to ensure that they are effective and up to their task

- Automatic sprinklers should be installed by professional to ensure compliance with Fire Prevention and Code Enforcement (NFPA, 2013)

- For compliance, the automatic sprinklers are periodically inspected by the municipality

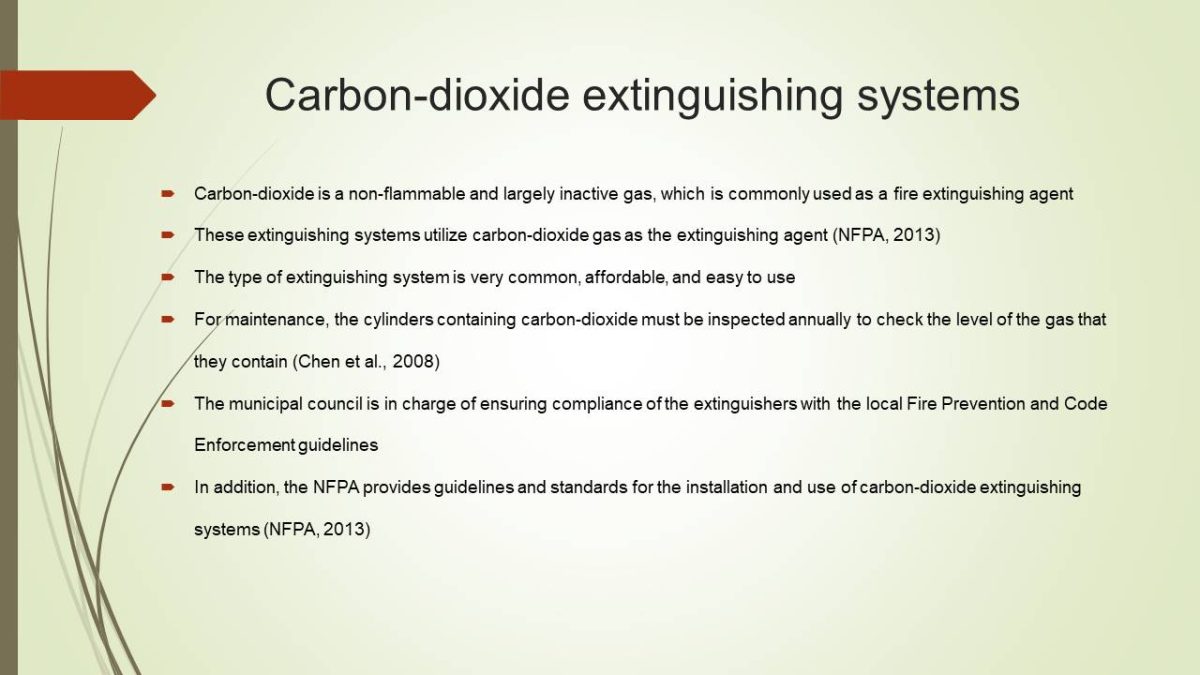

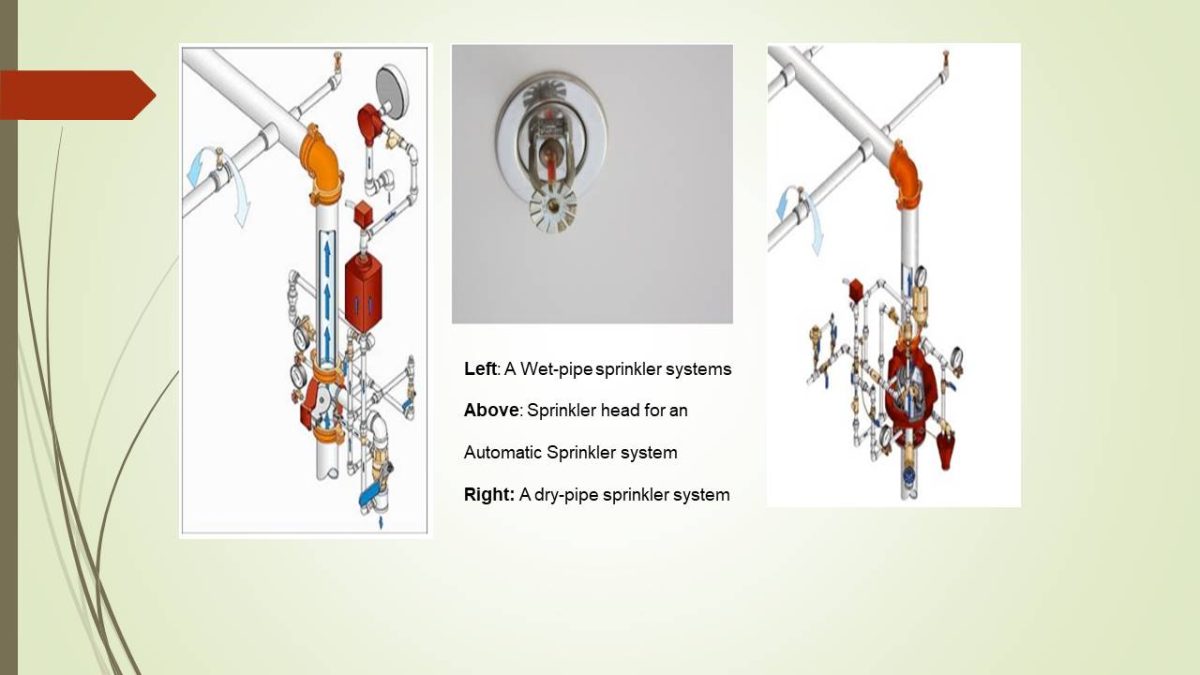

Wet-pipe Sprinkler Systems

- Wet-pipe Sprinkler Systems are the most common types of automatic structures for fire extinguishing in buildings

- Wet-pipe sprinkler systems, which contain water at all times, should only be installed in regions where they are not exposed to the risk of freezing (NFPA, 2013)

- Maintenance involves ensuring adequate water in the pipes and the supply tanks at all times

- Another important area of maintenance involves ensuring that the sprinkler and valves are working effectively and are able to launch upon detection of a fire

- The municipality’s fore department is in charge of making sure that the wet-pipe sprinkler systems are compliant (Chen et al., 2008)

- Compliance here includes confirming that the system uses approved valves and functional sprinklers

Dry-Pipe Sprinkler Systems

- Just like the name suggests, dry-pipe sprinkler systems are used in places with low temperature and where there is a risk of freezing

- They contain pressurized air, which is released out through the sprinkler to let water flow out (Chen et al., 2008)

- Hence, a delay is witnessed from the time the fire is detected and the period when the sprinkler becomes effective

- The delay means that a fire can grow bigger than would be the case with the wet-pipe

- Thus, the system requires more sprinkler heads per square feet

- Maintenance involves ensuring that the sprinkler system does not freeze and that water is available at all times

- One of the compliance areas involves ensuring that the delay from fire detection to when water comes through the sprinkler is less than 60 seconds (NFPA, 2013).

Pre-action Sprinkler Systems

- Pre-action sprinkler systems contain pressurized air and water, which are released only when a detectable fire arises

- These sprinkler systems are used in areas that do not allow one to have pipes full of water, especially in areas containing highly valuable resources that can be damaged by water (NFPA, 2013)

- Water is only released when the smoke detector or fire alarm goes off

- The maintenance of the system prevents water discharge in case of false alarm

- The city’s fire department offers guidelines on the approved sprinkler systems and valves for pre-action sprinkler system (Chen et al., 2008)

- The guidelines are important in ensuring compliance with the municipal’s Fire Prevention and Code Enforcement

Deluge Sprinkler Systems

- A deluge sprinkler system is majorly used in special cases of industrial risks

- It is similar to the pre-action sprinkler system, although it is only activated when there is certainly of fire after a fire alarm or a smoke detector goes off

- The system is useful in areas where the hazard is severe, for instance, in industrial areas where flammable liquid can easily spread over a large area causing serious damage (NFPA, 2013).

- The system has a combination of valves, which open to ensure all the water in the pipes is drained in the event of a fire

- Maintenance involves ensuring adequate water in the event of a fire in highly hazardous areas (NFPA, 2013).

- For compliance, strict Fire Prevention and Code Enforcement must be followed by organizations

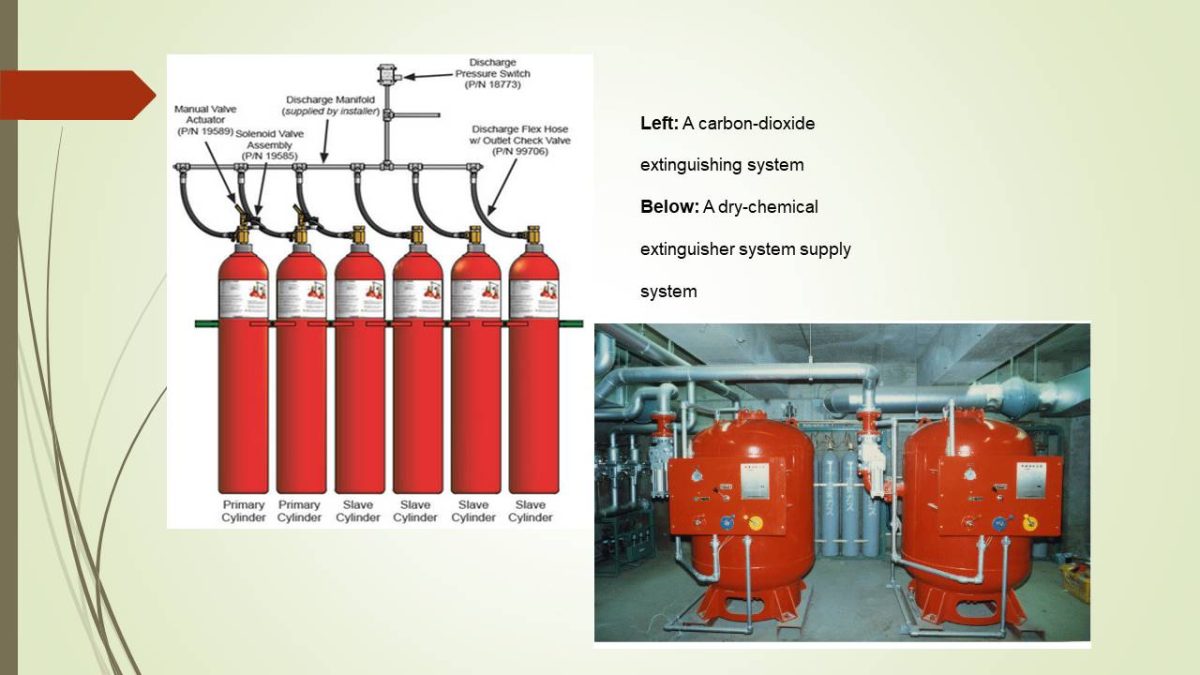

Dry-Chemical Extinguishing Systems

- This extinguishing systems constitute small particles mainly potassium bicarbonate, sodium bicarbonate, mono-ammonium phosphate, and urea-based potassium bicarbonate (NFPA, 2013)

- The systems work by interrupting the chain reaction sequence, as well as through heat absorption effects

- They are useful in industrial setting where there are highly hazardous and valuable resources that can be destroyed by water based extinguishers

- Maintenance ensures the systems are functioning and that dry chemicals necessary for the fire fighting role are adequate (Chen et al., 2008)

- The implementation of the system must be in compliance with the municipal council’s Fire Prevention and Code Enforcement

- The system must comply with the National Fire Protection Association (NFPA) guidelines and standards, which include NFPA 17 and NFPA 33 (NFPA, 2013)

Wet-Chemical Extinguishing Systems

- Wet-chemical extinguishing systems use wet chemicals to extinguish fires, especially in commercial areas (Chen et al., 2008)

- They are effective in cooking areas where the chemicals react with fire and oil to form foam, which prevents reheating and re-ignition of fire

- The wet-chemical in these extinguishing systems is mainly a potassium carbonate-based solution (NFPA, 2013)

- The maintenance of such extinguishers is bestowed on individual organization in collaboration with the municipal council

- The use of the wet-chemical extinguishing system must adhere to the local Fire Prevention and Code Enforcement

- Further, it must adhere to the guidelines of NFPA 17A (NFPA, 2013)

Clean-Agent Extinguishing Systems (Halogenated Agents)

- lean –agent extinguishing systems are important in high-value resource centers that contain resources such as telecommunication equipment and data storage system (NFPA, 2013)

- The clean agents are ideal for such locations since they are non-conductive and easily vaporize without damaging electrical equipment

- The clean agents include halogenated agents and innate gases, which do not affect the environment (Chen et al., 2008)

- They have very strict compliance guidelines and standards contained in the NFPA 2001 (NFPA, 2013)

- The systems are subject to inspection by the National Fire Prevention Association

- The local municipal fire department also ensures compliance of the system with the NFPA and local guidelines

Carbon-dioxide extinguishing systems

- Carbon-dioxide is a non-flammable and largely inactive gas, which is commonly used as a fire extinguishing agent

- These extinguishing systems utilize carbon-dioxide gas as the extinguishing agent (NFPA, 2013)

- The type of extinguishing system is very common, affordable, and easy to use

- For maintenance, the cylinders containing carbon-dioxide must be inspected annually to check the level of the gas that they contain (Chen et al., 2008)

- The municipal council is in charge of ensuring compliance of the extinguishers with the local Fire Prevention and Code Enforcement guidelines

- In addition, the NFPA provides guidelines and standards for the installation and use of carbon-dioxide extinguishing systems (NFPA, 2013)

The Economic Impact of this Code Adoption

- The implementation of the Fire Prevention and Code Enforcement will have financial implications on the municipal council and the involved organizations

- Firstly, the implementation of the code will involve training for organizations to guarantee compliance (Chen et al., 2008)

- Secondly, for compliance, the metropolitan council will have to employ more officers to oversee compliance in the municipal’s jurisdiction

- Organizations will incur costs when upgrading or adopting new systems that meet the municipal’s guidelines (Chen et al., 2008)

- In terms of economic advantage, the new codes will guarantee fewer destructive fires in the targeted areas, thus saving the organizations money in case of fires

- It will be an advantage to the municipal fire department since the fires to fight will be fewer, thus saving the council money

Reference List

Chen, R., Sharman, R., Rao, H. R., & Upadhyaya, S. J. (2008). Coordination in emergency response management. Communications of the ACM, 51(5), 66-73.

NFPA. (2013). 13-Standard for the Installation of Sprinkler Systems.Web.