When determining the productivity of the production process at Frito, one of the main approaches that would be appropriate is compare output against the cost of production. The primary goal of this unit, as it tries to increase its productivity, is to lower the cost as it increases the output. The goal can be achieved by eliminating wastes and maximising on its human and capital resources. The company can also determine its productivity by establishing the amount of products processes per unit time. The lesser time it takes to process a product, the greater the productivity of the firm becomes. As a company, which boasts of delivering fresh products to its customers, it should reduce the time that it takes to process its food products.

FEEDO and many other firms in this industry, face immense pressure to reduce their environmental footprints from various sources. One of the main sources of pressure is customers. As shown in the case study, customers are becoming increasingly concerned about climate change. They want to participate in ensuring that local manufacturers reduce pollution as much as possible. The only way of achieving this goal is to shun brands known to produce excess greenhouse gases. As such, FEEDO has immense pressure from the market to reduce environmental pollution.

FEEDO has embraced various strategies to reduce environmental pollution to become a green manufacturer. One such way is to use renewable energy instead of using fossil fuel. The company is using solar and biogas energies to help protect the environment. It is also planning to increase the production of renewable energy to avoid relying on the energy from the national grid. In its offices and production plants, the firm is maximising the use of natural light. Recycling and re-use of water and by-products of the company is another way of embracing green production. Currently, only 3.5% of the company’s wastes go to landfill.

FEEDO must find ways of increasing its productivity in the market for it to achieve a competitive edge over its rivals in the local and regional market. The company can develop the quality of its products through value addition. It should understand the specific needs of its clients and then develop innovative ways of achieving them. A thorough inspection of all products in the entire value chain may help to identify and eliminate defaults that may compromise on the quality of the products.

The company also needs to be flexible in its operations. Changes in tastes and preferences in the market should be reflected in the production and marketing strategies of the firm. Taking employees through regular training and involving them in decision-making processes may help enhance the flexibility of the firm. It is also necessary to find ways of lowering the cost of production. That goal can be achieved by eliminating wastes and maximising the use of the company’s resources. The management should strive to embrace productive practices by embracing emerging technologies and maintaining a team of highly skilled employees.

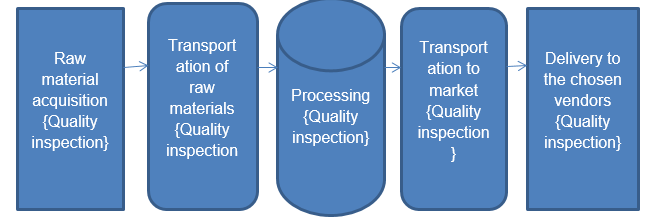

One of FEEDO’s popular products in the market is Ruffles potato chips. The process of preparing this product, as shown in figure 1 below, starts with the acquisition of fresh potatoes from the firm. The raw material must be inspected for quality before being transported to the firm. Once it is delivered to the firm, the next step is to process it (washing, peeling, crisping, frying, cooling and packaging) into a final product. The next process is the transportation of the product to the market before being finally delivered to the carefully chosen vendors.

As shown in figure 1 above, every stage in the production process should be subjected to quality inspection as a way of improving the value offered to the customer. Other than the analysis of the quality, the firm should also try to analyse any other factor that may impede the production process and determine ways of overcoming them.

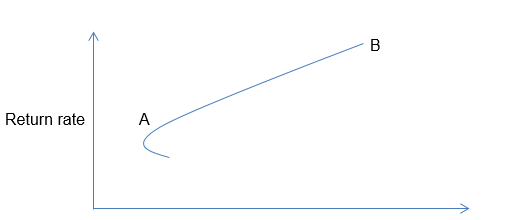

The efficient frontier concept helps a firm in making informed investment decisions. The goal is always to ensure that risk taken is as low as possible while at the same time trying to maximise rate of returns. Low-risk investments (Point A) often yield low investments while high-risk investments (Point B) often yield high rates of return as shown in figure 2 below.

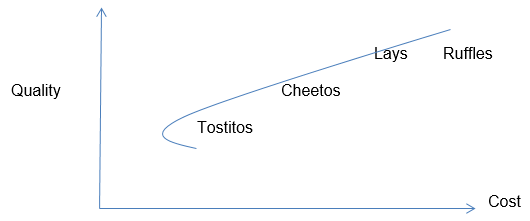

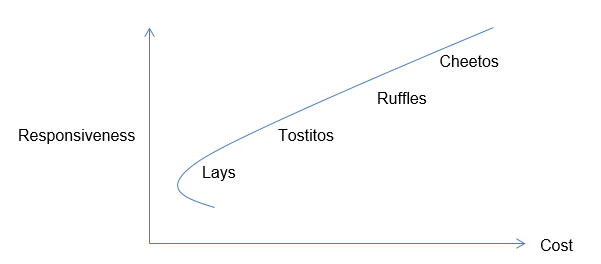

Lay’s, Tostitos, Cheetos and Ruffles are some of the dominant firms in the region responsible for the production of chips. Each of these firms uses the concept of efficient frontier differently to achieve their goals. Lays and Ruffles emphasise on quality over cost to meet customers’ needs. As shown in figure 3 below, it costs them more, but they are keen on offering the best value to their customers.

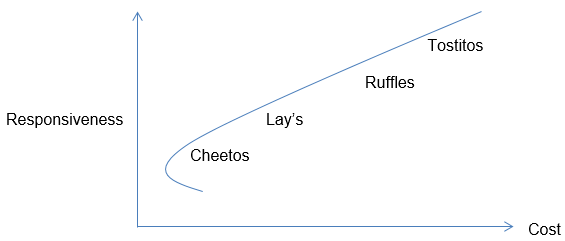

Cheetos on the other hand is keen on being responsive to customer needs while at the same time lowering the production cost, as shown in figure 4.

Tostitos value flexibility in its operations as a way of improving efficiency in production without increasing the cost, as shown in figure 5.