Introduction and Background

Headquartered in Boston, MA, GE is a giant digital industrial conglomerate dealing in a wide a range of products and services spanning from aircraft engines and parts, medical imaging, financing and power generation to industrial products, and oil and gas production (Reuters, 2019). It has more than half a dozen segments and is indicated to have been reaching out to customers in over 180 countries worldwide by the close of 2016 (Reuters, 2019).

GE is currently producing on a lean Six Sigma product development process. The Six Sigma was a strategy CEO Jack Welch introduced between 1981 and 2001 in order to measure and analyze internal performance and reduce defects to the margins of 3.4 per 1,000,000 (General electric, n.d.).

This strategy eliminated a lot of internal bureaucracies and enhanced performance and efficiency. Under CEO Jeff Immelt between 2001 and 2017, GE took a swipe towards lean unrelated diversification and digitization. The GE Capital exit plan announced in 2017 under the 2016 Annual Report (Lohr, 2017) is ostensibly a move towards an even leaner diversification in a commercial-market focused strategy. The removal of GE Capital from its portfolio implies that GE eliminates its focus on consumer-based markets and can now channel all its efforts into diversifying products for its commercial consumers of power infrastructure and technology.

Main Objectives

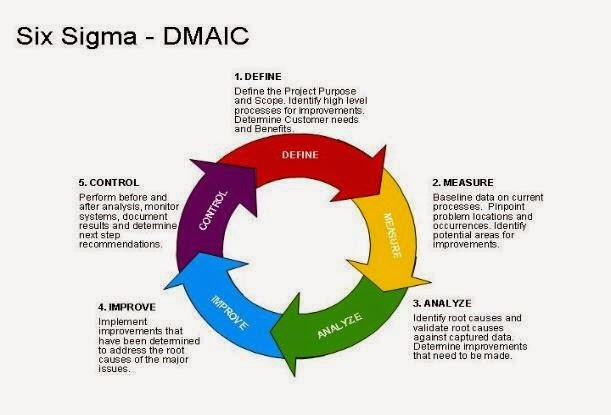

The Design for Six Sigma (DFSS) is the systematic methodology that utilizes tools, training, and measurements to give GE the ability to design processes and goods that align with the customers’ expectations. The DFSS also ensures that the goods and processes are within Six Sigma quality standards (General Electric, n.d.). The Define, Measure, Analyze, Improve, and Control (DMAIC) is a production process for GE that ensures continued improvement (General Electric, n.d.).

The DMAIC is not just systematic; it is equally scientific and fact-based. It is a closed-loop process and thus eradicates unproductive steps, emphasizes new measurements, and utilizes technology to initiate development. The DMAIC process is versatile and is transferrable to new products that GE may intend to produce. The versatility of the DMAIC process at GE arises from the adaptability of the products to the production process. In order to take advantage of the human resource and other resources in the developing world, GE has outsourced manufacturing plants as well as Research and Development (R&D) to these countries.

The recent developments and policy changes in China and India have encouraged great foreign direct investments by giant multinationals of GE’s threshold, and GE has moved into these markets to capitalize on that (Mullock, 2016). The reasoning behind these moves has been to remain cost-effective in pursuit of global expansion.

Figure 1 below shows a summarized process map for how GE produces its products.

At GE, the business-level strategies involved are in three-fold: focused low-cost, focused integration, as well as integrated low-cost and differentiation strategies (Kobayashi-Solomon, 2014). The focus for GE’s businesses in the many industries the corporation operates is on providing power and technologies to the aging industrialized world (Kobayashi-Solomon, 2014) primarily through digitization and to provide the budding developing world with the requite infrastructure and power (Kobayashi-Solomon, 2014). Therefore, the Define and Improve sections of the process map are the areas of process improvement for GE.

Conclusion

GE is a highly innovative and a diversified conglomerate and is both a make-to-order and an engineer-to-order type of a producer. The focus of GE’s business-level strategies is on who its customers are, what they need, and how GE should satisfy the need of these customers. Most of GE’s customers are commercial who will need highly differentiated products and services rather than individual consumers (Kobayashi-Solomon, 2014) and therefore GE focuses on producing products and services that are more commercially-oriented than they are consumer-oriented. The need to focus on the emerging markets in the developing world makes it necessary to incorporated focused low-cost into the focused differentiation because of the limited capital power in these markets.

References

Best Business Tips. (2018). Benefits of the lean six sigma methodology. Web.

General Electric. (n.d.). What is six sigma? The roadmap to customer impact. Web.

Kobayashi-Solomon, E. (2014). General Electric’s business strategy (pp. 1-6). Advisor Perspectives, Inc. Web.

Lohr, S. (2017). G.E.’s new strategy: Less is more. The New York Times. Web.

Mullock, H. (2016). Impact of globalization on General Electric (GE) policies. Web.

Reuters. (2019). Company profile: General Electric Co. (GE.N). Web.