Introduction

This project management document is prepared in response to the recent bid that was won by BlueCrux Inc.. The project is to conceptualize, design, and manufacture a GPS chipset prototype to be used in mobile devices. Once the prototype is developed and approved the company expects to get orders for mass production of this chipsets. The market for these chipsets is expected to be huge because there is a trend in the market to provide location specific services, such as promotions and deals, to customers directly on their cell phones. To receive these location specific services cell phones need to have GPS capabilities, which will be possible by incorporating these GPS chipsets. This project is expected to add 20% additional revenue to the bottom line of the company over a period of 2 years.

Background

BlueCrux Inc. is a leading national chip-manufacturing company and has a strong background in designing and manufacturing chips for the electronic industry. The company has innovated, developed and manufactured several semiconductor based chipsets for its clients. The company usually responds to bids and uses its existing manufacturing infrastructure, process engineering expertise, organizational structure, and industry experience as its competitive advantage. The company uses a balanced matrix organizational structure, detailed in Figure 1 below. This organizational structure allows the company to focus on the strengths of its functional departments but also allows cross departmental interaction during projects with the project manager having sufficient authority (PMBOK – 4th Ed).

Shaded boxes represent staff reporting to PM for project related activities.

Strategic Alignment

The company has recently won a bid, issued by the customer through a RFP (Request for Proposal), to develop, design and manufacture a chip prototype that can be used in cell phones to provide it with GPS capabilities. After reviewing the RFP, that company determined that existing infrastructure can be leveraged to develop and produce the chip. Since the company is already in the business of manufacturing chipsets, the objectives of this RFP are consistent and strategically aligned with the business objectives of the company.

Project

During the RFP process, engineers have determined that this design is unique and needs to be specifically designed to meet customer requirements. As per the terms and conditions of the bid once the project is complete it will be handed over to the client for further testing. Since this bid is a temporary endeavour undertaken to create a unique product based on specific customer requirements, the company has decided to call this a project (PMBOK 4th Ed.). Upon successful discussions and signing of contract, the start date and end date will be negotiated and a project manager will be assigned to the project. The project sponsors, the Vice President (Sales) and Vice President (Engineering), has prepared and issued a project charter giving it higher visibility. The project charter includes the project description, name of the project manager, customer requirements, project justification, known stakeholders, and project deliverables.

Project Management

During the initiating process a Project manager (PM) was selected and assigned to the project. After going through the RFP, reviewing historical documents and project management processes, and discussing with experts, the PM has broken the project into the following four phases, namely, conceptualization, engineering, pre-production, and product testing.

The company has existing historical documents which have been used by the project manager to develop Integration Management processes. These processes tie the various phases of the project together and are used throughout the project. These processes include helping in creating the project charter, which includes the business need and project objectives. Scope management, developing a project management plan, directing and managing project execution, monitoring and controlling the project, integrated change control and closing the project are part of the Integration management plan (Mulcahy, 2005).

Identifying Stakeholders

Identifying stakeholders is a continuous process. However since stakeholders have maximum influence on project deliverables during the early part of the project (PMBOK-4Ed.), the PM has taken the time to identify as many stakeholders as possible, in an effort to manage their expectations. A partial list of stakeholders is their expectations are listed below:

Table 1: Stakeholders and their expectations

Scope Management Plan

During the planning process, using the project charter, the requirements document prepared during the RPF process, and the existing historical documents. The Project Management team has prepared a project scope baseline which includes project scope statement, Work breakdown statement (WBS).

Project scope statement

The scope of the project is to develop, design, and manufacture a GPS chipset prototype, which can be used in mobile devices. The development of the chipset will be based on the general and technical specifications provided by the customer. The specifications will include power consumption, size, and packaging requirements.

The scope does not include any subsequent changes to the specifications after the requirements have been finalized. All changes will be handled through the change management processes.

Work Breakdown Structure (WBS)

The PM with the help of the project team has created a WBS as detailed in Figure 2 below. The project/product is logically decomposed into several levels, with each level adding more details. The level 2 contains the main phases which makes up the entire project and is further decomposed into smaller and more manageable activities. Levels 3 and 4 add more details to the work that needs to be accomplished. These levels allow the functional managers to understand the level of work required to be done by their staff. Level 5 are at the lowest level and cannot be decomposed any further. These are called work packages and are realistically estimated and can be completed quickly. The shaded boxes in Figure 2 indicate the work packages, which will be executed as activities.

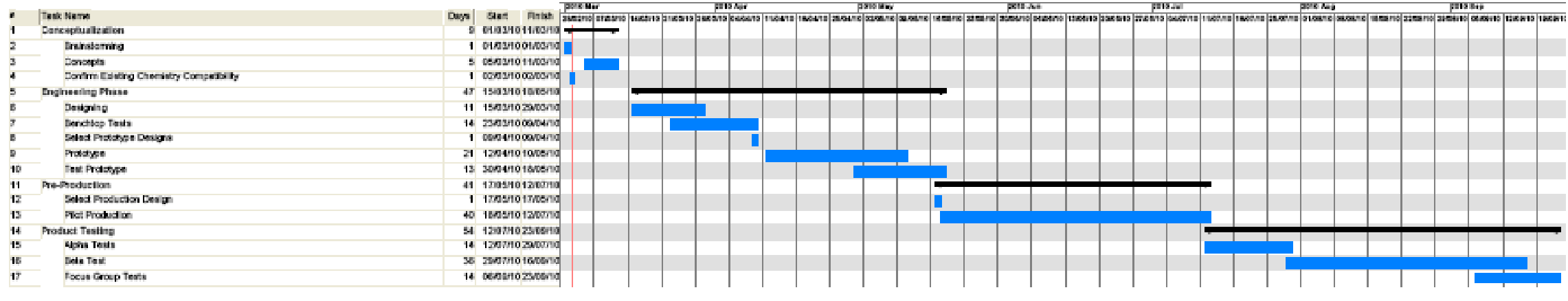

Schedule Management Plan

The schedule management plan establishes a schedule baseline against which the schedule will be measured during the monitoring and control process. The work package identified during the WBS planning is executed as a single or set of activities, which is very specific and can be estimated, measured, and monitored. The PM and the team have estimated the duration of each activity which is listed below in Table 2.

Table 2: Activity Definition

Schedule Constraints

A two schedule constraints have been identified.

- The project has coincided with an emergency leave of an engineer who is an expert in developing architecture for this specific chipset. Architecture/block diagrams have to be completed before he leaves on vacation and the PM has requested the engineer to complete the architecture before his leave. Also in case of an emergency, the PM has requested for permission to contact the engineer while away.

- The vendor selection must be completed before the production of the pilot. The PM has put plans in place to prevent these schedule constrains from delaying the project. The PM has contacted the Director – Supply chain and requested for a list of vendors who specialize in producing packaging for these chipsets. The engineering team will develop specifications for packaging which will be provided to the supply chain and contracting departments so contracts can be drafted.

Milestones

As per the contract negotiated by the management with the customer, the customer will be billed upon completion of milestones. The PM, the project team, and the customer have decided on the following milestones.

- Architecture document – This document will be completed after the completion of the conceptualization phase. The document will be reviewed by the customer before proceeding to the next phase.

- Engineering Design Document – The document is completed after the completion of the Engineering phase.

- Procurement document and Prototype Document – These documents are completed after selecting the vendor and the end of Pre-Production phase.

- Test report – This milestone marks the end of the Product Testing phase and the project. This document will be sent to the customer for review to ensure the prototype meets specifications are stated in the datasheet.

Network Diagram

Based on the list of activities listed in Table 2 above, a network diagram is created as shown below in Figure 3. The Activity On Arrow (AOA) is used to develop the network diagram with arrows representing activities and nodes representing dependencies.

Most of the dependencies are mandatory dependencies because it is inherent in the nature of the project. From the network diagram, there are two paths which are detailed in the table below. The critical path of the project is 123.

As mentioned above, the organization uses industry best practices to manage projects and has established PM processes and procedures. SPI index is used to track projects schedule on a continual basis and the current SPI is 1.1, which indicates the project schedule is on track. The Gantt chart, Figure 4 in the appendix, describes the activity list, start and end date.

Project Cost Management

Project cost management plan was prepared which includes estimating, budgeting, and costing (Mulcahy, 2005). In the previous sections, the project was decomposed into work packages. Cost estimation for the project is completed by analyzing the project scope, WBS, network diagram, existing historical documents, and other organizational process documents. Existing historical documents were used to identify costs for known risks, human resources costs and project management costs. Since the company has already completed projects similar to this before, expert judgement was used to determine vendor costs and quality costs as compared to other mathematical techniques such as three-point estimating.

To budget for the project, the cost of each work package was determined by calculating the cost to complete each activity associated to the work package. Other costs such as management reserve, contingency costs, project costs were added up to develop a cost budget. The allocated budget for this project was $250K. Table below details the cost per activity, including contingency and management costs. The cost of materials is estimated to be $10,500.

Table 3: Cost Estimate

To control costs, the PM has decided to use the Earned Value Technique to measure variances on a continual basis. This technique will allow the PM to integrate cost, time, and scope to forecast future dates and costs (Mulcahy, 2005). The budget has taken into account contingency reserves to provide for known risks and additional management reserves to cover for unknown risks.

Cost Constraints

The cost management plan includes contingency and management reserves to offset any variance in costs during the project. The PM has identified two constraints for the project

- The cost of materials is estimated to be $10,500. This value is determined based on invoices of preferred vendor. Depending on the vendor selected the price of materials may increase. $4,000 is reserved for block diagram development and designing in case an engineer is unavailable. Since funds for material are required later in the project, the PM has planned to use these funds to offset increase in material costs, in case it is still available.

- Manufacturing costs are estimated to be $70,000 based on 40 days of work. This information is largely based on information available from historical documents. Cost management plan includes $4,000 for contingency in case of increase in manufacturing costs. Further a $10,000 is reserved under management expenses to offset increase in manufacturing costs.

Quality Management

Three issues relating to the quality of the GSM chip have been identified. Two of these are generic, which means they are applicable to most chip manufacturing processes. Fabrication problems can cause problems in a finished semiconductor chip and needs to be detected during the prototyping. During a new product development process, analog testing is crucial to ensure chip parameters and functional performance of the chip meets the customer specifications. The third issue is the quality of packaging. The vendor of choice has some labour relation issues and the quality of material available from the alternate vendor needs to be verified.

To achieve overall quality and reliability of the new chip, quality control department is independent of manufacturing and process engineering. The Quality management plan has taken into account the above mentioned challenges, quality requirements negotiated with the customer, and existing internal quality assurance and quality control policies. The plan is to have quality audits throughout the process to detect issues early in the project and reduce cost or rework.

Risk Management

Changes in Process technology causes increase in manufacturing costs and this directly affects the ROI of the company. This is a risk that has been identified during the planning process. News reports indicate that the preferred vendor is engaged in labour disputes and there are concerns about their ability to meet delivery of packaging material for the chips. If the preferred vendor is unable to meet their contractual obligations, new contracts will have to be drafted for alternate vendors and their ability to meet these requirements will have to be determined. The timing of the project coincides with the spring break and some key employees who have scheduled vacation several months ago will be on leave.

These are the known risks specific to the project that were identified early during the planning of the project. Besides these several known risks there are other inherent risks in the process engineering and manufacturing process that have been identified from existing historical documents. These risks are documented in a separate document called the risk register. The risk register contains all known risks and are categorized and high, medium, and low risks based on their impact to the project and the company. The risk register also contains potential responses and root cause of the risks.

Conclusion

In conclusion, the project management plan has incorporated several industry best practices and industry approved project management methodologies. BlueCrux has many years experience in designing and manufacturing chips (IC) and have substantial documentation to be used for the current project. As seen in the network diagram in Figure 3, there are only two paths and since there are no convergence points, the project overall is less risky. SPI and CP indexes are used to measure schedule and cost performance continually to manage variance.

References

Mulcahy, R. (2005), The PMP Exam, 5th edition, RMC Publications Inc.

PMBOK-4th Edition (2008) – A Guide to the Project Management Body of Knowledge, Project Management Institute Inc. (PMI), PA, USA