The Just in Time (JIT), Toyota Productions System (TPS) and lean operations are some of the production systems used by different companies to improve operations and eliminate wastes.

Main Purpose of JIT, TPS and LEAN Operations

Operations and production improvements are mainly carried out to eliminate wastes, remove variability and improve throughput.

Eliminate wastes: Most of the production systems focus on waste reduction. The main types of wastes that should be reduced include overproduction, transportation, Queues, inventory, movement of people, over processing and production of defective products.

Variability: variability refers to the deviation from the normal process. This results to production of products within the set limits. The main sources of variability include poor production process, inaccurate and incomplete drawings and not understanding the customers demand.

Throughput: this is the total time required to complete the production process. It is the time required to change raw materials to complete products.

Just in Time Method

The just in time principle entails the continuous improvement of the production process. JIT focus on reducing inventory and throughput. It is widely used to improve operations. The materials arrive where they are needed and when they are needed. This drives out wastes and delays, reduces variability, improves throughput and reduces cost associated with excess inventory.

JIT aims at minimizing the distance between long production lines, improving employee communication, increasing flexibility and reducing space and inventory. JIT is also used to improve quality through the use of statistical process control, empowering employees, use of failsafe methods and providing immediate customer feedback.

Toyota Production System (TPS)

This Toyota production system emphasizes on continuous improvement, respect for people and the use of standard work practices. Continuous improvement entails building an organizational culture and a value system that stresses the need for process improvement. Respect for people involves empowering employees and training them so as to make improvements. The use of standard work practices involves defining the works completely in terms of content, sequence, timing and outcome.

Lean Operations

Lean production focuses on the customer. The customer’s wants are indentified and used to improve the production process. The main lean production techniques include;

- The use of JIT to eliminate inventory

- Employee training

- Space reduction

- Educating suppliers and forming partnership with them

- Eliminating services that don’t add value

Mutual Insurance Company of Iowa

The main attributes that the claims processing department will have include

- There will be no unprocessed claims as claims arrive and they are immediately processed

- Improved communication

- Use of computers to process claims

- Reduction of distance and processes that the claims have to go through

- Reduction of unnecessary employees

- Reduction of activities that don’t add value

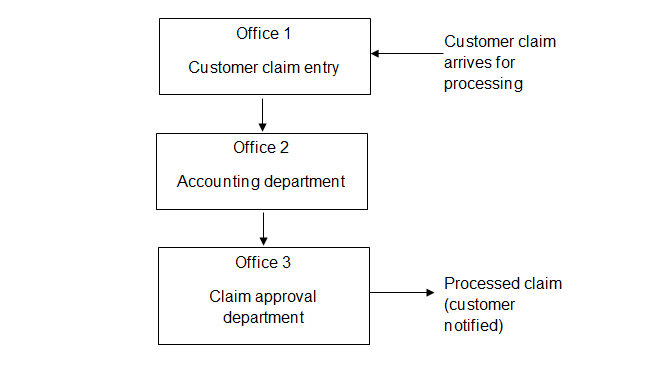

The restructured cell layout for claim processing

Figure 1: claims processing department layout

Assumptions about personnel and equipment

- The workers have been trained on new data entry techniques

- There will be new computers and equipments to help process the claims fast

Benefits of JIT to IOWA Company

- Reduce the time taken to process claims

- Ensure customers are satisfied with the company

- Reduce the number of legal suits the company faces

- Reduce the number of redundant employees

- Increase profits

- Reduce cost associated with handling unprocessed claims