Learning Curve Concept

There are many ways on how to define, analyze, and improve the current business environment. Each new project is an attempt to understand how and why a product or a service should be produced (Heldman, 2011) and consider the importance of such factors like time, cost, and performance of the project. The connection between the quality of the work and time that is necessary to complete the required portion of work is evident and cannot be neglected.

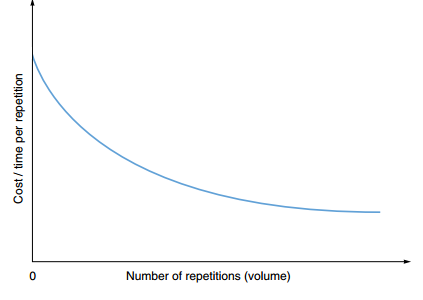

That is why it is very important to measure the profitability of a project and clarify how to improve the project if necessary. For example, it is possible to use learning curves as the main tool used by the people involved in the current project (the production of T-shirts with a special label on them). Learning curves are various graphic representations of the repetitive functions of the project activities within the frames it is possible to reduce time, resources, and money. Learning curves may have a significant implication for all project activities. Therefore, it is not enough to comprehend the basics of their occurrence in a project but pays more attention to the effects the learning curves can produce.

The concept of learning curves can be explained on the basis of several principles. For example, it is evident that each time a manager performs a task, he/she spends less time in comparison to the last time the same task was performed. Besides, the amount of the required improvements can decrease considerably, with more units being produced (Kerzner, 2013). With the help of the learning curve, it is possible to define how to decrease time if the task is performed over and over again in a proper way.

Cumulative Average Curve

A learning curve demonstrates the relation of the cumulative average time and the cumulative units produced in the project. Nussbaum and Mislick (2015) explain the cumulative average curve as the average cost of production quantity. To understand if the curve may be valid to the current project, it is necessary to define the repetitive (similar) activities mentioned in the trade-off analysis. There are six main stages identified: the identification of project conflicts, objectives, environment, and alternatives, the choice of the best alternative, and the creation of a new plan on the basis of the improvements.

Each step is unique. Still, it touches upon the same project. It is hard to predict that the increased number of repetitions can decrease the number of cost and time on the completion of the same work. At the same time, the production of a T-shirt, its promotion, and selling is the project that is full of repetitions: the same people may be involved, the same services should be offered, the same goals have to be achieved. That is why the average level of time and cost spent on the production of T-shirts and the organization of the work can be reduced considerably.

For example, the current project lasts for one year (12 months). It is necessary to control the relations with suppliers, promoters, developers, and sellers every month. The first month is the most difficult period because a number of new ideas should be offered, many decisions should be made, and certain discoveries and obstacles can be expected. Within a short period of time, a kind of model to work on the project can be developed and followed. It means that a cumulative average curve can help to define the possibilities of time and cost-saving.

This table shows that the project under analysis has rather successful indicators to be improved. The period of 12 months and the leverage curve of 90% is a good solution for the organization to rely on. The cumulative average curve can be created on the basis of the information offered in the first and third columns of the table.

Follow-On Orders

Follow-on orders and any possible continuations of the products are considered to be the extensions of the chosen curve. It is necessary to determine the cumulative average and unit curves and understand if the development of follow-on orders is possible. The unit curve introduces the hours/costs that are necessary for particular units of production (Kerzner, 2013). The cumulative average is the dependence between the number of units and the total cumulative hours spent on the production of the project. The differences between the final stages of the main project and the outcomes of the follow-on orders are evident and should be considered. It is wrong to believe that the outcomes achieved in the main project should be expected in the follow-on order. There are a number of factors that can predetermine the quality and success of the work discussed.

Manufacturing Breaks

The evaluation of manufacturing breaks should also be organized in the project so that the managers could identify the possible improvements within a short period of time. A manufacturing break is the period of time between the completion of an order and the commencement of a follow-on order or the restart of the main unit (Kerzner, 2013). This period cannot be ignored as it means that the manufacturing process is interrupted, and a certain cost should be paid for such kind of interruption. This period may last from one day to several months, and the length of the period determines the financial aspects of the whole project. In other words, any manufacturing break can affect the aspects of the cost and time of the project. The managers should realize that the time used for this kind of break becomes as significant as the time spent on the manufacturing process itself.

There are five main factors that may be influenced by the manufacturing break in the project under consideration. First, the break can touch upon the personnel. People may lose momentum when repetition helps to save cost and time. People simply forget about the necessity to use the same skills to achieve the best results in a short period of time. Second, supervisory learning undergoes several changes. The managers should make more efforts to achieve the already gained quality of supervising because of the break they have to experience. The continuity of productivity is the third area that is challenged because of the break. The relationship between different sectors of the manufacturing process worsens. These kinds of losses are hard to overcome.

The methods should also be revised after the manufacturing break. Finally, the positive aspect of this break is the possibility to think about new tools and ideas on how to improve the work and achieve better results. The comparison of the already achieved goals, current opportunities, and expectations should be organized to clarify if there is a chance to promote changes with a minimum of losses.

Effects of the Learning Curve Concept

In general, learning curves are very helpful to any organization. The main effects of this concept are connected with the possibility of analyzing time and predict it for future tasks. This curve also helps managers to comprehend how to succeed in planning, budgeting, predicting risks, controlling the activities, and making decisions. The development of the curve proves that it is never too late or too ashamed to learn and gain some new knowledge about old things. The success of the project is not about the solution to the challenges but about the ability to decide on the priorities and make sure to do everything well (Kalina, 2011). The estimation of cost can also be improved by means of learning curves.

In general, learning curves have a possibility to express the effects of possible improvements of the chosen project. Managers are able to develop special estimations and find methods that can justify the development of the chosen project. As a rule, the expectations of the project are based on the skills and knowledge gained by the managers. Besides, the development of learning curves helps to underline the importance of corporate culture and knowledge. In spite of the fact that some problems may take place during the development of the learning curve, the results and effects of this kind of work are effective in regard to future projects.

References

Heldman, K. (2011). Project management jumpstart. Hoboken, NJ: John Wiley & Sons.

Kalina, P. (2011). Mother of all learning curves. The Sydney Morning Herald. Web.

Kerzner, H. (2013). Project management: a systems approach to planning, scheduling, and controlling. New York City, NY: John Wiley & Sons, Inc.

Nussbaum, D.A. & Mislick, G.K. (2015). Cost estimation: Methods and tools. Hoboken, NJ: John Wiley & Sons.