Introduction

Masafi is a fast growing company in the UAE and holds the position of one of the top FMCG brands with reference to all its innovative products. The growing range of products by the company, which has been recognized for its bottled mineral water production in the Middle East and across Gulf for about 35 years, has contributed to its vision to become an absolute FMCG Company (Masafi, n.d.).

Plant purpose and product range

Masafi was established in 1976 in the Gulf as a pure natural mineral water company. Since then, it has evolved as a leading brand in this field and has made recognition in the business community by offering world-class products with highest quality and freshness (Masafi Mineral Water Co. LLC, 2013).

The product offerings by the company can be seen below:

Mineral Water

It offers mineral water of varied sizes like from 4-gallon to1.5 L, 1L, 500ml, 330 ml, 200 ml and 100ml (Masafi marketing audit presentation, 2012).

Masafi Mineral Water Range

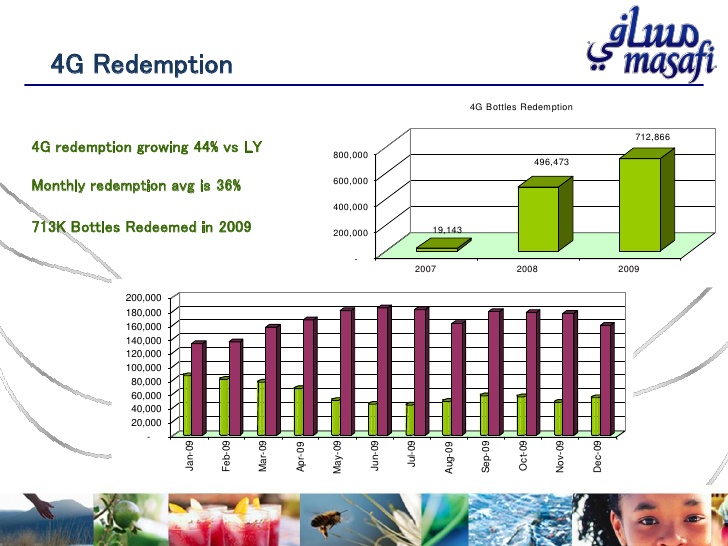

The redemption of 4Liter Gallon

Gourmet potato chips

It supplies potato chips flavored with “sea salt, sweet chili, our cheese and Laneh and Zaatar” (Masafi marketing audit presentation, 2012, p.9).

Facial Tissues: Masafi has launched tissues in various colors and fragrances. Besides this, there is a wide range of tissues for children and for cars.

Juices

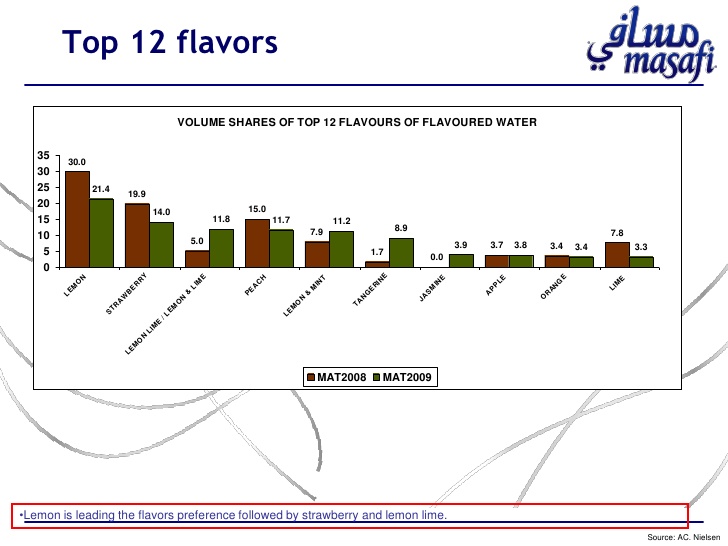

Masafi juice is available in 14 flavors. The hot fill technology is used to pack these juices. The top 12 flavors are rated in the following chart.

Flavored Mineral Water

Mineral water is also available with different fruit flavors like peach, lemon, mint etc. (Masafi Flavoured Water garners 65.6% market share in the non carbonated flavoured water segment within six months of launch, 2007).

Premium Basmati Rice

Recently Masafi has launched its new range of basmati rice.

Equipment used

Masafi sources the production equipments from global industry leaders, especially from Germany (Krones Machines). Engle machine is used for designing caps that produces46000caps/hour. Netstal machine is used for PET Rasin. Sidel machine is used for the production of bottles that produces 18000 mineral water bottles/hour, 40000 bottles of 1.5 Liters and 10000 bottle/hour for containing juice. Krones machines are used for filling water and Kettner is used for making boxes.

There are three sheds of production in Masafi. These are juice production and finished goods, gallon and raw material, PET and sixteen underground wells. The company makes sure that the entire short term as well as long-term equipment is available with convenience. Regular maintenance of machines is done as a preventive measure (Masafi presentation for Central Europe, 2010).

Machine rate 17103 B/H

40 mould/40000 B/H.5 Liter

Japan 330 ml moulds.

Type of Production:

In Masafi, water is a continuous flow production as it has three lines. Juice is a batch production since it has only one line.

Primary or secondary manufacturing

Mineral water is their primary manufacturing and bottle caps and juices are the secondary manufacturing. Other producer products are HDP, PET- Rasin, juice concentration, labels, and boxes. Preforms are made from PET-resin that comes from Saudi and Hakiston.

Organization and Manufacturing

Plant Organization and Set up

Masafi water is collected from the mountain where it appears in the cracks of the rockface. It is now collected with the use of many pipes and funnels bound for the nearby bottling plant. Sixteen powerful pumps complete the filtration and bottling process. Water is collected in the wells located below the mountain. From here the water is pumped out for the process of filtration. The water resource and production manager, Pankag Naik describes the procedure that a firmly controlled filtering system carries water through the filters and 0.03-micro-filters in a cooled state.

Then the bottles are planted on a conveyer belt with their necks dangling and carried to the filling room where they are positioned below a high-pressure jet. A 500 ml bottle is filled within 3 seconds. Now the caps are put on the bottles and they are lined for labeling and then are boxed. The whole procedure takes place automatically. People are there only to supervise the work (Harnan, 2010).

Design and Packaging

Mineral Water: Mineral water is packed in the PET (Poly Ethylene Terephthalete) and no additives are used while packing. It is microbiologically safe and healthy and produced with 23% less plastic (Masafi marketing audit presentation, 2012).

Juices: In the packing of juices, the hot-fill technology is used.

To embellish this new Masafi line, cartoons like Toto the Turtle, Hoofy the Zebra etc that were earlier featured on the mineral water packs for kids are printed on the labels. (Food and drink innovation network report, 2006).

Gourmet Chips: The gourmet chips are packed with Thermal Air Process.

Tissues: The packaging and designing of tissues does not include any harmful chemicals or avoids the use of any type of bleach (Masafi marketing audit presentation, 2012).

For making tissues, paper is taken from other companies in a bulk. Then it is cut into shape, pressurized in double layer through machines, and lastly packed in the boxes.

Flavored Mineral Water

“The flavor is first filled at 85 degree centigrade into a bottle and the air is removed with vacuum. The bottle is then capped so it does not need to contain preservatives” (Masafi Flavored Water garners 65.6% market share in the non carbonated flavoured water segment within six months of launch, 2007,Para5).

Bottles and caps for packaging

For making bottles, PET resin is put into a tank with an oven at 260° C to shape the bottle. Then blue color is added to the mineral water bottle only. Now, the bottles are put into the molds and 40 bar air is pushed inside the bottle to expand it in the mold perfectly.

Bottle caps are made of High Density Polyethylene (HDP). HDP is melted at 220° C and then injected into the molds. 46000 caps are manufactured per hour in Masafi. The HDP and the color are of food grade quality.

Production Planning

In Masafi, the production planning depends on the forecasts and budgets set for the particular product. Besides this, it depends on the demands of the products (Masafi presentation for Central Europe, 2010). Orders are taken every Thursday. Orders from other companies like ADNOC are received on Thursday. Line 3 has a continuous production for 6 days and Line 2 is scheduled for 5 days.

Dispatch and Delivery

After packaging, the boxes of water are kept in the warehouse for two days and then dispatched to different states of Gulf on trucks. The local deliveries are made in 3-4 days after packaging (Harnan, 2010).

- Inventory/Stores: The Masafi products have different outlets categories:

- Key Accounts: A class outlets include Large Supermarkets.

- Direct Distribution: B and c class outlets include groceries, mini markets, and supermarkets

- Vending Machines: vending machines in schools, parks, malls and mosques

- HORECA: Hotels

- Prestigious Outlets: Coffee shops and non-F& B retail outlets

- 4 Gallon: Homes & Offices

Sales and Marketing

Masafi has been successfully maintaining its market leadership in the mineral water sector in the UAE with 40% share and has the maximum per capital consumption of mineral water in the world. Approximately 30% Masafi products are exported to various countries of the world (Masafi Flavoured Water garners 65.6% market share in the non carbonated flavoured water segment within six months of launch, 2007).

The CEO of Masafi, Ashraf Abushady said that their 3P bottom line approach has contributed to the outstanding performance of the company. The 3P bottom line strategy refers to Profit, People, and Planet. This strategy focuses on the financial bottom line (profits) along with the commitment of the company to meet the requirements, tastes, and liking of the consumers (people). The company also emphasizes on the need to protect the environment (planet) (Masafi profit spurts 36% in ’08 , records 35% year-on-year growth to touch AED378 million, Launch of Masafi Gourmet, innovative products caps exciting year,2009).

According to A C Neilsen, “the Masafi mineral water shared the highest equity index ever, while Masafi Tissues achieved UAE market leadership in July 08 and the company also achieved 27.8 per cent share in the market for its Flavored Water range (Masafi profit spurts 36% in ’08, records 35% year-on-year growth to touch AED378 million, Launch of Masafi Gourmet, innovative products caps exciting year, 2009 Para8).

Masafi uses different communicative measures to reach its consumers. These may include producing billboards , posters, truck ads, neckties for water bottles, fridge magnets, stands, display tent cards, danglers, ads on chillers, vending machines and creative displays such as a bus display for kids packs and more (Masafi marketing audit presentation, 2012).

Maintenance

Every Friday the Masafi bottling plant is closed for weekly cleaning. The necessary repairing and changing of parts is done on Friday. In the Masafi water plant ozone, O3 is used every six hours to kill bacteria from the drinking water. Ozone water filters come in three types

- 0.65 Filter for dust and particles

- 0.2 Filter for micro bacteria

- Ozone Filter to clean the bottles from bacteria

The filtration process takes 7 hours and only then, the water is suitable for drinking. (Due to the strong smell of O3 water cannot be used be consumed before 7 hours. After 6 hours O3 breaks into O and O2). The pumps are changed every six months and parts like bearings are changed in one year.

Health and safety including risk management

Masafi has a robust Research and Development department that is constantly involved in discovering measures to reinforce the high quality of products created by the company. Internal auditing and customer survey programs, food safety programs, regular assessment of the suppliers and distributors and departmental and customer surveys are conducted for feedback (Masafi marketing audit presentation, 2012).

New Installation, inspection, testing and commissioning

The testing is done and certified by the significant authorities of the industry. The company is associated with International Bottled Water Association (IBWA) and Asia Bottled Water Authority (ABWA). NSF International, U.S.A does the testing of the mineral water produced by Masafi Company and on behalf of IBWA conducts surprise audits annually (Masafi Mineral Water Co. LLC, 2013).

They install new hygienic machines. The new workers are trained by HSE. Environment Management System:

It has produced eco-friendly water bottles as a gesture to protect and safeguard the environment (Masafi marketing audit presentation, 2012).

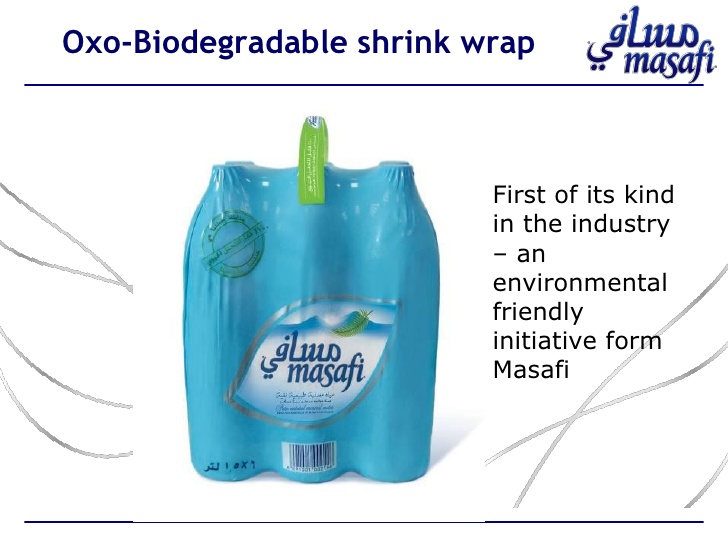

A new oxo – biodegradable technology is incorporated in making the wrappers and handles. The plant manager of Masafi plant, Mohammed Usman said, “We have introduced oxo-biodegradable shrink wraps and handles for our 1.5 liter bottle; a first of its kind initiative in the industry for this region to protect the environment” (Lukwaro, 2010, Para 1).

Oxo-Biodegradable Shrink Wrap

The company has introduced the Masafi Carbon Action Plan in 2008, which measures and decreases the carbon releases to the environment. It has also launched the corporate recycling service to trim down the impact of plastic bottles on the environment. Masafi has been endowed with the ‘Environmental Contribution of the Year’ gratitude at second Annual Middle East Business Achievement Awards 2008 in this connection (Masafi profit spurts 36% in ’08 , records 35% year-on-year growth to touch AED378 million, Launch of Masafi Gourmet, innovative products caps exciting year,2009).

Conclusion

Masafi bottled mineral water has already acquired the top position in the UAE market. The company is making constant efforts to position itself as a top FMCG brand. Through its excellent innovative production line and strong marketing strategies, it is spreading its business enterprises in the global market.

Masafi’s contribution to the environment preservation and its commitment to gain profit through providing health benefits and consumer satisfaction to people is praiseworthy.

Works Cited

Food and drink innovation network report 2006. Web.

Harnan, Eugine, “Masafi from the source to market.” The National. 2010. Web.

Lukwaro, Gureni, “Masafi introduces plastic that degrades in two years.” The National. 2010. Web.

Masafi n.d. Web.

Masafi marketing audit presentation 2012. Web.

Masafi mineral water co. llc 2013. Web.

Masafi flavoured water garners 65.6% market share in the non-carbonated flavoured water segment within six months of launch 2007. Web.

Masafi presentation for Central Europe 2010. Web.

Masafi profit spurts 36% in ’08 , records 35% year-on-year growth to touch AED378 million, Launch of Masafi Gourmet, innovative products caps exciting year 2009. Web.