Hip Anatomy

The hip anatomy refers to the structures which make up the hip. “The hip contains various parts. These include bones and joints, which are our major concern, ligaments, tendons, muscles, nerves, the bursae, and blood vessels, which shall be discussed in this section.”

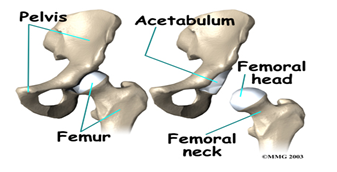

The hip is an example of a ball and socket joint. The most notable structures in a hip are the bones and joints. The bones are made up of the femur and the pelvis. “The head of the femur interlocks the acetabulum that is located besides the pelvis”.

However, wear and tear might occur around the joints, causing chronic pains. This wear and tear might be as a result of accidents, and or due to excessive walking, leading to a condition known as osteoarthritis. This involves replacing the damaged cartilage and bone of the hip joint with artificial ones.

This kind of a process is carried out in two different ways: the cemented prosthesis and the uncemented prosthesis. The uncemented prosthesis is whereby the implants are made with special coatings which allow the bone to grow on to the implant. This is crucial since it aids in the integration of the implant into the body.

This is actually achieved through designing implants which are porous. On the contrary, cemented prosthesis involves the use cement to attach the implant to the bone. The merits of carrying out an artificial joint hip replacement are: helping in movement of the person, doing away with the chronic pain at the joints and also to reduce the tear and wear at the joint. However, a good thing has never lacked shortcomings.

The hip is bound to undergo some dislocations, which are caused by the fact that implants are always smaller than the original joint, something which makes the ball to come out of the socket (BoneSmart). It might also lead to blood clots, a condition known as thrombophlebitis and also the patient might fall victim of some infections.

Artificial Joint Hip Replacement

In the past, traditional materials were being used to replace worn out hip joints. However, these prosthetics were subjected to a lot of wear and tear and were therefore not effective. This necessitated the development of modern materials, which would be more wear resistant and last longer. The implant materials to be used ought to have certain mechanical properties in order to be effective.

They are supposed to be wear and tear resistant, hard, strong, with good corrosion resistance and considerable levels of stiffness. Very high stiffness in materials can result in weight shielding, which cause eventual fracture of the implants. Other factors such as biocompatibility and degradation of the biomaterials also play a key role in influencing their performance.

In view of these properties, metals, ceramics, and polymers are the most used materials in the making of implants for artificial hip joints. The table shows below some of the mechanical properties of the most frequent used materials in this modern world.

Metals have good fracture resistance and are stong enough to be used in making of hip joints. However, they have very high stiffness, which, as indicated earlier on, leads to weight shielding. “Steel is an alloy of iron, nickel,chromium and molybdenum”. An implant made from it lasts much longer since it is highly resistant to corrosion. This means that it does not degrade in the body easily.

Steel has relatively high stiffness levels and it can be shaped easily, meaning reduced cost of production. On the other hand, nickel, which is contained in steel, might be of a problem to some people who are allergic to it. The other metal which is used to make implants in place of steel is the Freeman cobalt-chromium.

This is an alloy composed of cobalt, molybdenum and chromium(27-30% Cr, 5-7% Mo, rest Co). “The freeman cobalt-chromium is used by patients who are allergic to nickel since it does not contain the latter”.

Materials Selection

Titanium implant is yet another metal which is used in making artificial hip joints. “A titanium implant has a stiffness of less than half that of stainless steel or cobalt chrome, which therefore reduces the effects of weight shielding. Its constituents give it excellent corrosion resistance, but it does suffer from relatively low fracture toughness and poor wear properties…”.

Titanium is special since it permits the use of finely polished wear resistant metal heads, which boosts its wear resistance. Polymethylmethacylate (PMMA) is one of the polymers which are most frequently used as grouting material. Its main limitation is that when used, there is always some release of heat to the neighboring bone, causing cell death.

Cement might also cower, leading to toxic monomers being emancipated into the bloodstream. Zirconia (zirconium oxide) ceramic has found continued use in making of Zirconium Ceramic Femoral Head.

“It is highly valued due to its mean surface roughness, being very hard and highly resistant to scratching and wear”. “Hydroxyapatite is made up of calcium phosphate, which makes it biocompatible. For this reason, it is, in absence of bone cement, used to coat implants”.

Current Trends

In the current times, the most favored type of implants hybrid ones. This is whereby different type of materials is combined in order to achieve the desired mechanical properties. This goes a long way in assuring the longevity of the implant. Some of these hybrid implants are discussed below.

Metal ball (made up of cobalt chrome molybdenum) and Polyethylene liners have gained popularity over the years among the surgeons due to its good performance and durability. Polyethylene is capable of achieving stability in the body while the surgical operation is still underway and it’s also less expensive. The wear rate which is 0.1millimeters each year is a bit low and therefore it’s a better implant.

Ceramic ball and polyethylene liner is another implant which is widely used. The wear rate is about 0.05 millimeters per year. The other hybrid implant is the metal ball and metal liner. They have very much reduced wear rate and the amount of bone lose is minimal. Of all the implants, these offer the largest ball heads, which means greater stability and therefore the risk of dislocation is highly reduced.

Some of the feared aspects are that the metal’s soluble ions might dissolve into the body, being accompanied by some harmful effects. Ceramic ball and ceramic liner implants are the hardest and lowest in terms of wear rate (about 0.0001millimeters per year) but are more expensive than the other implants.

Conclusion

In conclusion, various materials can be used in making artificial hip joints and this majorly rely on the biocompatibility of the material, its mechanical properties, and its level of degradation while in the body.

Bibliography

Cluett, J., Hip Replacment Implant Options, 2008. Web.

Drijber, FLIP & J. B. Finlay, Proc Instn Mech. Engrs—Part H: J Eng Med, vol. 204, no.H4, 1990, pp. 253- 258.

Malik, H., Advanced Hip Replacement, 2010. Web.

Orthogate, Hip Patient Education, Artificial Hip Dislocation Precautions, 2000-2007. Web.

Queen Mary, Department of Materials: Materials Selection for Total Hip Replacement, 2010. Web.

ScienceDaily, ‘Cementless Hip Implants Are Durable For At Least 20 Years,’ Number of stories in archives, vol. 93, 2009, p. 728. Web.

Turner, I., Why Study Materials?, UK Centre for Materials Education, 2008-2010. Web.

William, D. C., Materials Science and Engineering: an introduction Wiley, 3rd edn, John Wiley & sons, New York, 2008.