There are a number of local business establishments which are characterized by a properly chosen JIT (just-in-time) philosophy and helpful approaches to manufacturing planning and obligatory control (Vollmann et al., 2005). Each industry develops considerably taking into account customers’ demands, expectations, and interests; and one of the most successful industries is considered to be the food one.

Modern business environment undergoes numerous changes day by day, this is why each establishment has to take particular steps in order to grow and gain prosperity required. McDonald’s is the fast food business establishment chosen for the analysis in this paper.

This company is one of the most successful examples of how JIT philosophy turns out to be helpful to organize services, satisfy customers, and create products in accordance with customers’ expectations.

The essence of JIT philosophy is all about minimizing waste that is possible during the process of manufacturing in order to “subdivide waste into time, energy, material, and errors” (Vollmann et al., 2005, p. 301).

The success of JIT is possible in case service operations remain repetitive, qualitative, and innovative. In other words, JIT philosophy that is used by the representatives of McDonald’s establishment has to involve all types of manufacturing-like operations and services.

For this organization, it is not enough to demonstrate the quality of services and products in one particular place and time but promote this quality in broader meaning: for example, “in order to ensure process quality, it industrialized the service delivery system so that all workers would be able to provide the same eating experience around the world” (Lai & Cheng, 2009, p. 16).

To make use of JIT philosophy properly and succeed in the chosen business, it is very important to identify what McDonald’s’ customers may expect from this establishment. Martin (2008) admits that “satisfaction is based on expectations” (p. 75). What McDonald’s’ visitors may expect is a high quality of food, fast services of good quality, and comfortable environment.

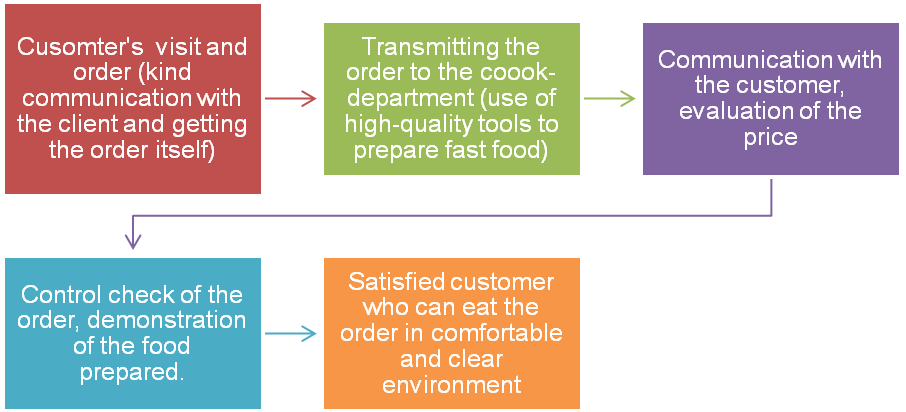

The evaluation of the production process steps helps to define strong and weak sides of McDonald’s. First, this company aims at providing the best quality of food at lower prices within a short period of time. It means that the main steps of the production process should be getting the order from the customer, transmitting information to the other department, using the best technologies to prepare necessary food fast, proper communication with customer, and satisfaction of customer’s need by providing the order.

The process of how the production is introduced to the customer looks like this:

The main point about this flowchart is the presence of standardized and non-standardized process steps which may influence the quality of service and its speed. High quality of services and fast speed provided are the major advantages of McDonald’s company. This is why to support the chosen way of service, it is very important to define standardized production and try to improve its quality as frequent as possible.

The organization under consideration makes use of standard production like hamburgers, cheeseburgers, or fish burgers (innovation). The customer who comes to this fast food organization is already aware about the variety of possibilities, this is why less time is spend to make a choice and to prepare the order. As for some non-standardized process steps, they are connected to the quality of food that may be required by the customer.

The effectiveness of the process that is demonstrated by McDonald’s is evident indeed. First of all, many people are eager to visit this establishment all the time. It means that they are satisfied with the services and the quality of food and that they have already done their choice and they are satisfied with it. As for my personal opinion about the effectiveness of the process and services presented, I think that McDonald’s is one of the most successful and caring organizations in regards to their customers.

They try to present fast services; they pay attention to each customer; and they work for people to save people’s time and efforts. The idea to create McDrive is another powerful attempt that helps to attract more customers and demonstrate that good and fast services are still possible and available for people. To improve the process, several ways may be used.

One of the most evident problems in many countries is connected to lack of places for customers. Very often, when people make orders and get their fast food ready, they are deprived of the opportunity to find a free table to enjoy the meal. This is why to attract more attention, it is possible to enlarge establishments and give people more space. In this case, all customers may come to this fast-food restaurant and be sure to get an order quickly and find a free space to have a rest.

In general, the quality of service in McDonalds is good indeed. People know what to expect from this establishment; they can even evaluate how much time they should spend at this restaurant; and what is more important they know that prices are stable there, and their costs may be evaluated beforehand.

Reference List

Lai, K & Cheng, C.E. (2009). Just-In-Time Logistics. Farnham: Gower Publishing Limited.

Martin, N. (2008). Habit: The 95% of Behavior Marketers Ignore. Saddle River: Pearson Education.

Vollmann, T.E., Berry, W.L., Whybark, D.C., & Jacobs, F.R. (2005). Manufacturing Planning and Control for Supply Chain Management. New York: McGraw Company.