Company description

Dubal is a major manufacturer and supplier of aluminum products. The company’s mission is to be the leading company in global aluminum production. The company also aims to lead in marketing of aluminum products by the year 2020.

The company is perceived to be a major supplier of alloy products to the automotive industry. Moreover, the company also supplies billet, foundry alloys to construction, electronics and aerospace industries.

The company is also renowned for producing water products through thermal desalination. The company’s major markets are located globally, with China, Europe, North America and Middle East being major market destinations.

Description of operations

Aluminum smelting

This is the initial aluminium production process that involves extraction of aluminium from its oxide (Davis 1). This procedure takes place in stages, where bauxite is turned into Alumina and then through an aluminium smelter where it is eventually turned into aluminium.

Raw material handling

The company procures high quality materials from various parts of the world. The company sources raw materials like alumina, aluminium fluoride and calcined petroleum coke from Australia, India and the United States respectively.

Sourced imports pass through Jebel Ali Port. This is because the company has storage facilities for its raw materials at the port. Moreover, the company import raw materials in bulk and later transport the materials to the manufacturing plant by road tankers.

Carbon anode manufacturing

This is an on-site manufacturing process. The carbon anodes are necessary for the electrolysis process used in aluminum reduction process (Kvande & Haupin 29). Apparently, the company has the capacity to produce more than 380,000 carbon anodes annually.

Casting operations

This is the final process of making aluminium. It entails casting molten aluminum and alloying the same with magnesium, silicon and manganese. Casting is important in adding metal properties like corrosion resistance and strength (Kaufman & Rooy 1). The company’s annual casting capacity is 1.2 million tonnes of aluminium.

Supply chains decisions

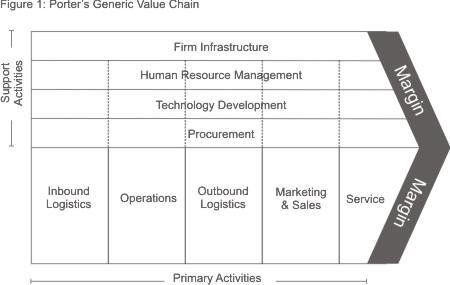

Dubal’s supply chain takes the format of a typical Porter’s value chain.

Inbound logistics

Procured materials from Australia, India, and the United States pass through Jebel Ali Port, where the company has storage facilities. The presence of storage facilities at the port is critical for constant supplies, storage and transportation of materials.

Operations

Main operations inside the company’s manufacturing plant include aluminium manufacturing processes. Operation managers make critical decisions on the quantity and quality of products manufactured.

Outbound logistics

Operation managers are required to decide the mode of transportation in delivering products and services. Decision on company transport, outsourced transport is critical. Decisions on distribution channels and delivery locations to the company’s outlets across the world are also critical.

Marketing and sales

Marketing and sales initiatives are globally focused. Operation managers insist on manufacturing products that are environmentally sensitive.

The company uses the aspect of quality as a marketing strategy in generating demand for its products. In addition, the inclusion of competitive prices for its products and services in relation to competitors has been integral in generating sales.

Service

The company treasures its relationship with the customers. In this respect, constant communication with existing customers has been an organizational culture. Moreover, the company offers value-additional services to the customer who want consultation on aluminium products and services.

Procurement

This is a supporting activity for the company’s supply chain primary activities. Operation managers make outsourcing decisions based on suppliers and vendors convenience, reliability and prices.

Human resource management

Human resource personnel are recruited on merits of skills and competence. To ensure that human resource is competent enough, the human resource manager motivates, organizes frequent training and conducts performance appraisal on staff members.

Technological development

The company uses information communication systems, in harnessing its operations. Operation managers have resorted to using Material Resource Planning (MRP) and Enterprise Resource Planning (ERP) software in making critical decisions on resource planning and allocations.

Another form of information technology used is Computer Aided Designs (CAD) for purposes of manufacturing and mass production.

Infrastructure

Operation managers need to determine the organizational structure of the company. This means that critical support systems like accounting, procurement, transport, administration, marketing, legislative and general management are required.

Organizational support systems are critical in harnessing the flow of information and operations within the organization.

Operational decisions

Human resources and job design

This operation decision requires identification of skills required to produce the company’s products and services. In this respect, decision on the job design and requirement is integral before recruitment of personnel. The recruitment process of human resource is also necessary to consider.

This is because a flawed recruitment process may negatively affect the productivity of the organization. A decision on how to make the working environment favorable to the employee is necessary after hiring the employee.

This means that the working environment should not pose health risks to the employees. Moreover, a metal manufacturing environment is highly hazardous and requires the use of protective gear while working. This should be provided to all employees.

This is critical in ensuring that manufacturing of products and services achieves quality goals. Wages and salaries allocated to employees should be reasonable in relation to the amount or level of job assigned (Rynes & Gerhart 16).

An operation decision to decide the expected productivity from employees is crucial. In this respect, employee performance appraisal is necessary to determine whether employees are delivering to their expectations (Bowen & Ostroff 217).

This is the only way the company can remain highly productive and competitive among other industrial players.

Productivity

Productivity can be measured by finding the average output of the company’s workers (Bloom & Van Reneen 1362). This requires a unit of measurement. In this respect, the company can use units of products produced as a unit of measurement.

In general, productivity will be determined by total units produced in relation to input used. Input is always represented as the amount of labor used.

In a manufacturing company like Dubal, outputs are considered as workers-hours required in manufacturing a single unit product.

In order to determine the production cost of a single product unit and hours required of the same, total paid hours in a month are divided by the number of units produced in the same month.

Productivity can be increased through constant monitoring of operations and employees (Johnson & Peter 208). A technological strategy like the use of email monitoring is necessary in evaluating employees’ attendance to responsibilities.

In this case, employees are to submit daily or weekly reports on work performance. Eliminating distractions such as unnecessary meetings and watching television is also necessary. Another way to increase productivity is delegation of duties or outsourcing operations (Young & Johanna 141).

Making a list of activities that require priority is essential. This makes it easier for the operation manager to arrange required tools of work and amount of workforce required in completing a job.

Works Cited

Bloom, Nicholas and Van Reenen, John. Measuring and explaining management practices across firms and countries. The Quarterly Journal of Economics 122.4 (2007): 1351-1408. Print.

Bowen, E., David and Ostroff, Cheri. Understanding HRM–firm performance linkages: The role of the “strength” of the HRM system. Academy of management review 29.2 (2004): 203-221. Print.

Davis, R., Joseph. Corrosion of aluminum and aluminum alloys. Arizona: ASM International, 1999. Print.

Johnston, Robert and Peter Jones. Service productivity: towards understanding the relationship between operational and customer productivity. International Journal of Productivity and Performance Management 53.3 (2004): 201-213. Print.

Kaufman, J., Gilbert and Rooy L., Elwin. Aluminum alloy castings: properties, processes and applications. Arizona: ASM International, 2004. Print.

Kvande, Halvor and Haupin, Warren. Inert anodes for AI smelters: Energy balances and environmental impact. Jom 53.5 (2001): 29-33. Print.

Rynes, L., Sara and Gerhart A., Barry. Compensation in organizations. New Jersey: Jossey-Bass, 2000. Print.

Young, Suzanne and Macneil, Johanna. When performance fails to meet expectations: managers’ objectives for outsourcing. The Economic and Labor Relations Review 11.1 (2000): 136-168. Print.