Abstract

Premier Bakeries is one the leading companies in production of bread, cakes, biscuits and other bakery products. However, the company uses old production systems. New companies that use modern technology threaten the Premier Bakeries position in the industry.

Therefore, it is vital for the company to undertake strategies that would help maintain its competitive edge. Automation of the production systems would help the company maintain its competitive edge. Automation would enable the company increase its production capabilities significantly. In addition, automation would reduce the cost of production and increase efficiency of the production systems.

Project Management

Organizations exist in rapidly changing environment. Therefore, they must always take measures to ensure that they maintain their competitive edge in their operating environment. Organizations strive to reduce their operating costs and improve quality of their products to maintain their competitive edge.

Organisations ensure that they have highly efficient production systems. Companies take advantage of technological advances to improve their production systems. Technology enables companies to improve the efficiency of their production systems. Automation of production systems increases the efficiency of the production system. Automation reduces human errors and the cost of production (Campbell, Clapton & Tipton, 2002).

Premier Bakeries Limited is one of the leading companies in production of biscuits, bread and other bakery products. However, the company does not have automated production systems. The company’s competitors have automated systems automated production systems, which are highly efficient. Therefore, Premier Bakeries should automate its production systems to increase their efficiency. Automation of the company’s production systems should be systematic and include the relevant departments of the company.

Founded in 1956, Premier Bakeries has grown to be one of the leading companies in production of cakes, biscuits, bread and other bakery products. The company owes its success to shrewd management and production of high quality products. Premier Bakeries production systems have been in use since the onset of the company.

The company has undertaken minimal changes in its production systems since its inception. New companies that use modern production systems threaten Premier Bakeries’ position as the leader in production of bread, biscuits and other bakery products. Therefore, it is vital for the company to upgrade its production systems to enable it cope with the challenges of increased competition.

In addition, automation would increase the company’s production capabilities. Automation of the company’s production system is one of the measures that would enable the company to cope with the increased competition. Automation would reduce the company’s cost of production significantly. In addition, automation would increase the efficiency of the company’s production systems by reducing human errors.

However, automation of the company’s production systems should be systematic. Failure to use the proper procedure in automating the production system would not make the company benefit from automation. Following the wrong procedure in automation of the production system may make the project face resistance from the company’s employees, as the project would lead to a significant reduction of the company’s staffing levels.

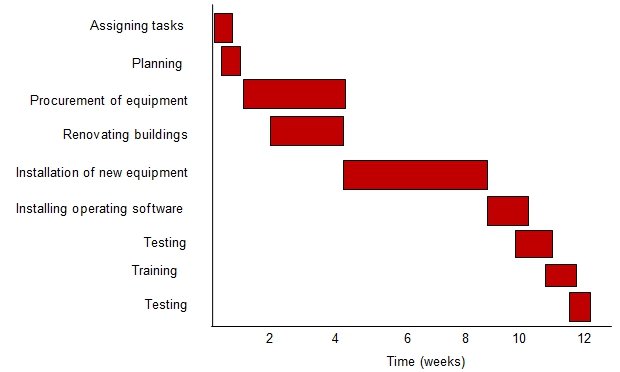

A Gantt chart would provide a concise course of action that Premier Bakeries would follow in implementation of the project. A Gantt chart shows the series of tasks that the company would follow in project implementation. A Gantt chart displays tasks in the vertical axis and time in the horizontal axis.

A Gantt chart has bars that signify the beginning and end of various tasks (Shelly, Cashman & Rosenblatt, 2009). Automation of the production system is the most complex project that Premier Bakeries has ever undertaken. Therefore, it is critical to have proper planning and incorporate all the relevant departments in project implementation. Below is the Gantt chart for automation of Premier Bakeries’ production systems.

Prior to the beginning of the project, the company should create a team that would help in coordination of various tasks of the project. The team would consist of members from the production, procurement and finance department. The production manager would head the project as automation directly affects the production department. The production manager’s knowledge on production systems would greatly help in project implementation.

It is critical to include members of the finance department since the project requires funds to finance various activities. This would ensure that there are not hitches in procurement of various materials and services that are critical in project implementation. Team members from the procurement department would use their knowledge to ensure cost effectiveness of procuring various materials as services for the project. They would use their skills to ensure that the company gets vital products and services at the right time.

Employees of the production department would also form part of the team. The company should take measures to reduce employees’ resistance on the project. Employees’ resistance is mainly because the project would lead to sacking of some employees, as machines would replace their activities. In addition, since the employees would the ultimate users of the new production system it is critical to obtain their support.

The project would begin with assigning of various tasks to different members of the team. This would ensure that team members do not undertake conflicting tasks, which would jeopardise the success of the project. The next stage would be development of a plan for the new production system. The skills of team members from the production department would be critical at this stage. The plan should take into consideration the shape and size of the production building.

The company would then obtain equipment for the new production system. Premier Bakeries would not replace all production equipment with new production systems. The company would strive to automate the old production equipment. The company would only buy new equipment if it is impossible to automate the old production equipment. Automation of the old production systems would reduce the cost of undertaking the whole project as sourcing of equipment is one of the major costs of project implementation.

The company would then undertake renovations on the production buildings to enable the new production system fit in the buildings. Thereafter, the company would install the equipment for the new production systems and undertake renovations on the old production systems to enable it blend effectively with the new production system. After installing the new equipment, the company would install software on which the new production system would run.

At this stage, the company would have undertaken all the major steps in implementation of the project. All that remains is to test whether the production system is running effectively. Testing of the new production system would help in detecting errors within the system. Testing would help in fine-tuning the new production system to increase its efficiency (Wotring, Potter & Ranum, 2005)

After determining that the production system is working effectively, the company should train employees who would be using the new production system. Training would equip employees with the necessary skills for operating the new production system. The company would then undertake sample production tests.

Testing would determine the right conditions for running the new production to ensure it produces high quality products. This would be the final stage of the project. Premier Bakeries can now start using the new production system in baking various products. The improved efficiency of the new production system warrant the high cost of implementing the project.

References

Campbell, B., Clapton, B. & Tipton, C. (2002). Food technology. Oxford: Heinemann.

Shelly, G.B., Cashman, T.J. & Rosenblatt, H.J. (2009). Systems analysis and design. Belmont, CA: Cengage Learning.

Wotring, B., Potter, B. & Ranum, M.J. (2005). Host Integrity Monitoring: Using Osiris and Samhain. Rockland, MA: Syngress.