Introduction: Waste Disposal in the XXI Century

In the XXI century, the limited amount of certain natural resources has become especially evident, which has resulted in the need to search for alternative means of utilizing the available sources. The concept of recycling was a natural result of the discussions regarding the exhaustibility of resources.

As a result, the companies that use recycled materials in their production process are valued especially high in the modern business world (Mayor of London, 2011). However, logistics issues, or, to be more exact, the issues concerning transportation of the raw material and the end product, as well as the costs for this transportation, have been quite an issue in the given sphere.

Despite the fact that the recently adopted strategies suggest that the landfill sites should be located in close proximity to the companies utilizing recycled waste, the costs for the transportation of these materials, as well as the fact that the transportation is often handled with the help of partner companies, which demand additional payment, create rather unfavorable financial conditions.

By reconsidering the logistics of the currently adopted innovational strategy regarding recyclable waste transportation and the integration of technology, as well as cooperation with foreign partners, recycling companies will be able to prosper and raise their revenues impressively, which the given platform project (Mantel, 2010, p. 32) is going to prove.

Project Description: Outlining the Key Features

Seeing how the manufacturing process includes the location of the resources and the transportation of the given resources to the end customer and, in fact, cannot be viewed outside the manufacturing process, it will be reasonable to reconsider the logistics strategy within a recycling company manufacturing process.

Indeed, with a more efficient logistics strategy introduced, the process of manufacturing will be increased impressively, since a number of obstacles, such as time restraint and the unavailability of resources, will finally be removed.

The project can, therefore, be defined as the reconsideration of the logistics strategy within the context of an otherwise reasonable and adequate manufacturing approach and will include several stages. To start with, it will be required to reconsider the specifics of the inbound and outbound logistics strategies for an average recycling company.

Another important element that is included into the manufacturing process and related to the company’s logistics strategy, the production logistics will also have to be addressed. By introducing new technologies, such as UHF, one will be able to increase the speed of the manufacturing process within a recycling company in several times.

The UHF will make it possible to introduce a better cohesion between the departments, since it will contribute to a more efficient communication between the members of the staff. In addition, it is crucial that the technology allowing to sort the raw materials into types in accordance with the type of substance that these materials are made of, i.e., plastic, glass, paper, etc., will be required.

As soon as the issues regarding the inbound logistics are solved, the outbound logistics problems that most recycling companies have to face will need to be dealt with. Another part of the manufacturing process, the outbound logistics will require that the cooperation between a company and its partners, as well as the clients, should be improved.

Likewise, the given problem can be solved by integrating technology, such as social networking, into the manufacturing process in order to gather the clients’ and partners’ feedback and introduce corrections into the manufacturing process accordingly.

Project Plan: A Working Schedule and Deadlines

Assigning Participants with Roles and Responsibilities

While the manufacturing process design is obviously the top priority of a recycling company at present, it still needs efficient coordination and supervision. No matter how flawless the technology might be, there will always have to be someone making sure that the manufacturing process runs in chord with the plan.

Therefore, it will be required that the manufacturing department should cooperate with that one responsible for logistics somewhat closer. To be more exact, it will be reasonable that the leader of the manufacturing process and the logistics manager should coordinate the process of the new strategy implementation.

Their assistants will be assigned with the role of information managers, since their roles will be restricted to gathering information for the managers to process and make corresponding decisions. The IT department will make sure that the information exchange processes run smoothly.

Finally, the rest of the staff will be concerned with the production process itself. It should also be noted that an adequate business model should be introduced, since “in essence, a business model embodies nothing less than the organizational and financial ‘architecture’ of a business” (Teece, 2010, p. 173)

Budget Plan: Pessimistic, Normal and Optimistic Perspectives

Despite the fact that the integration of the information technologies and especially the new logistics principles might have rather unexpected results on the company’s revenues, it can be assumed that the recycling company will do rather fine.

However, it will still be necessary to take precaution measures and design the plan that will help the recycling company survive the most negative outcomes possible. It can be assumed that a medium recycling company is likely to expect the following outcomes:

Secured income (pessimistic): $75 per ton ($10,000 per month)

Judging by the current demand for the recycling material in question (primarily metal), the recycling company in question is likely to acquire $75 per ton of the product.

Additional income (neutral): $15,000 per month

By cutting some of the costs, including the cost for transportation, the company will acquire additional $5,000.

Optimistic secured income: $20,000 per month

In case the selected strategy works, the income is going to be doubled.

Optimistic additional income: $30,000 per month

Once the rivals are beaten with the help of improved technology and a better analysis of the information available, the company will be able to make three times more than the pessimistic income prospects say.

Net profit: 75%

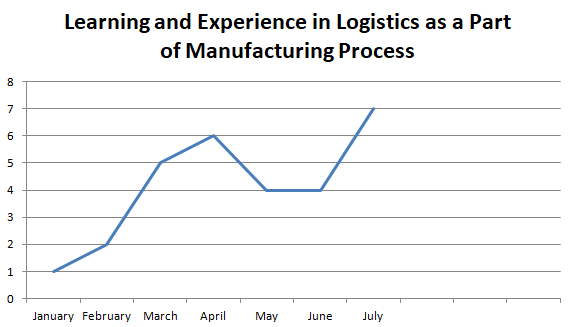

The Significance of Learning Curves: Costs Calculation

Conclusion: When the Time to Reinvent the Strategy Comes

Even though the strategy adopted recently for the major recycling companies to follow is rather reasonable and efficient, it still lacks enough thought concerning the logistics aspect of the companies’ operation, which can be solved by incorporating innovative technology and establishing stronger links with foreign partners; coupled with a careful analysis of the landfills location and a faster information acquisition process, it will be extremely efficient and help a recycling company expand.

Reference List

Mantel, J. (2010). Project management in practice, 4th ed. New York, NY: Wiley & Sons.

Mayor of London (2011). Making business sense of waste. London, UK: Greater London Authority.

Teece, D. J. (2010). Business models, business strategy and innovation. Long Range Planning, 43(2-3), 172–194.