Introduction

As consumers become increasingly sophisticated, more knowledgeable and their needs grow, the sure method that any company can thrive under these circumstances is by providing a dedication to quality. The Quality Management Systems stipulated in the various standards gives the management framework that enables a company to institute necessary control measures to tackle risks, evaluate, and assess progress of the company.

The quality standards are also essential in improving the image and reputation hence permits the company to search for new developments through external and internal contacts. Quality Management Systems are applicable in any organization that aspires to enhance its operations and management, in spite of its size or sector.

Nevertheless, the most benefits on investment are from those organizations that have practiced it all through their structures rather than at only specific sites or hierarchy level. This paper discusses the process, monitoring, and evaluation of the quality management systems.

ISO 9001:2000

The ISO 9001:2000 is a well-grounded international standard for quality control that cuts across all organizations. It is the most predominantly used quality system in improving the various aspects of an organization (British Standards Institution, 2009, para.8).

The standard has evolved from theoretical aspects from the time of its creation to emphasize on practical and process-oriented approach as a basis for quality control.

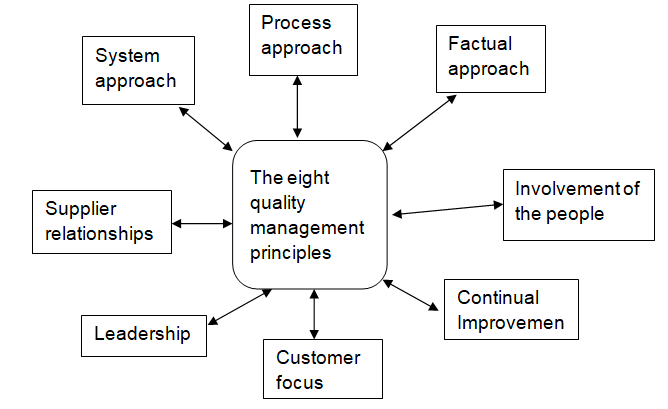

The underlying quality management principles that are the basis of ISO 9001:2000 are ““customer focus, leadership, involvement of the people, process approach, system approach to management, continual improvement, factual approach to decision making, and maintaining beneficial supplier relationships” (International Organization for Standardization, 2009).

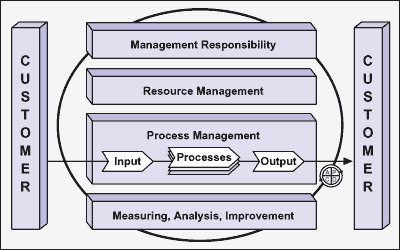

To achieve quality goals and satisfy the needs of the customers, an organization must recognize and illustrate processes that are efficient, accessible and properly understood, evaluate the progress of these processes, and identify and apply developments to these processes.

The Quality Management System (QMS) is the emphasis of clause 4.0 ISO 9001: 2000 standard. The goal of this clause is to make sure that the organization recognizes and manages all the processes that are necessary in realizing uniformity and consumer contentment. The organization must come to terms with processes together with the association that exists amongst the various processes.

It is necessary to establish these processes and apply them to contain the whole QMS. This quality standard also encourages organizations to control and periodically enhance their processes. Sub-clause 4.2 is considering the role of documentation of QMS. The QMS comprises of quality policy, quality objectives, a quality manual and all supporting procedures.

The documented procedures envelop the areas of “document control, control of records, internal audits, control of non-conforming products, corrective actions and preventive actions.” Every organization ought to include all the processes, procedures, and documents they may require.

Documentation is necessary since it is a means of changing tacit skills to explicit skills in order for individuals to share their various experiences and work efficiently.

One of the merits of this quality system is that it stipulates the requirements that make an organization to evaluate itself. The assessment usually commences with internal audits undertaken once or twice a year and proceeds to yearly external audits undertaken by a reputable third party body.

These set standards keeps the ISO 9001:2000 focused and up-to-date, repelling the perception that an organization accredited with this quality standard seeks a mere show of paperwork and compromise.

The ISO 9001:2000 lays more emphasis on customer satisfaction as a vital ingredient in the well-being of an organization. Since the goal of any organization is to meet the needs of the customers, they have no choice but to comprehend the varied needs of the customers and fulfill them. Customer focus involves the organization executing tasks to comprehend their needs and expectations.

“Disciplined requirement elicitation, regular customer feedback, surveys and understanding market trends” are some of the methods of realizing this goal (Kishore, 2003, p.50). The organization goals relate to the customers and therefore it does not make sense when the organization does not focus on this as one of its strategic objectives.

It is also necessary to stretch customer needs throughout the organization even to those sites and departments that are not directly linked to the customers requirements. If the internal departments come to terms with the varied customer needs and expectations and the necessity of meeting them, then the organization will ultimately flourish.

For the success of any organization, the various stakeholders must be involved adequately in the daily running of its activities. The ISO 9001:2000 asserts that individuals at all categories of the organization and their total participation allow them to be productive in the place of work (Global Quality Village, 2009). Individuals who feel part of the success of the organization often bring more commitment and energy to the organization.

It assists when individuals comes to terms with their significance in the context of their organization. Investment in people yields to more efficiency in their productivity as they give suggestions on ways of enhancing the goods and services of the organization. Involved people also feel committed to realize the goals of the organization and strive in accomplishing the targets.

The ways of making sure that individuals are involved must focus on realizing that individuals are a valuable resource to the organization and are liable to be esteemed. Involvement of people in making decisions and directions for an organization implies recognizing that they perform their duties faithfully and reliably. Performing their duties satisfies them; hence, they are always on toes to fulfill the goals of the organization.

In order to accomplish effectively its vision, an organization must work together in harmony with the various stakeholders. This quality management principle identifies the role of leadership in endowing the organization with purpose and direction.

Leadership is of essence since it involves creating a good working environment where all the individuals in an organization experience equal participation and perform tasks collaboratively to realize the targets of the organization

Six Sigma

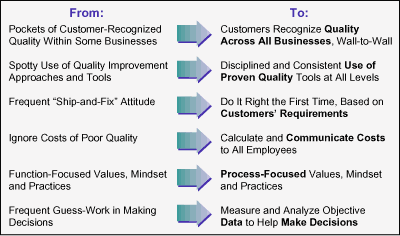

Six Sigma is an elaborate and flexible quality system for achieving, sustaining and maximizing the success of an organization. This quality system is associated with a close focus on “the requirements of the customers, disciplined use of facts, data, and statistical analysis, and diligent attention to managing, improving, and re-inventing business processes.” (Pande et al., 2000, p.xi).

This business management strategy makes every effort to enhance the quality of process outputs by recognizing and eliminating sources of defects and lowering the inconsistency in production and organization processes.

It employs a variety of quality management systems, such as statistical methods, and forms a unique resource of individuals in an organization, consisting of “Black Belts”, “Green Belts”, and others, who have advanced skills in its implementation.

Every Six Sigma task undertaken in any organization is based on a well-illustrated series of steps with quantified objectives to be met. These objectives can be monetary (minimization of costs or maximization of profits) or anything that is significant to the end user of that process (cultural change, reducing cycle time, lack of danger, and others).

Some features make Six Sigma to correspond to the other quality management systems. Six Sigma doctrine affirms that constant endeavors to realize stable and achievable process outcomes, for example lowering process inconsistencies, are essential in realizing the triumph of any organization.

The processes in successful running of any organization have characteristics that are able to be quantified, evaluated, enhanced, and monitored. It also asserts that the process of realizing long-term quality objectives needs dedication from all parts of the organization, especially from the people in the top-level leadership positions.

On the other hand, some aspects of Six Sigma distinguish it from the other quality management systems. It emphasizes on a clear focus on realizing computable and scientific financial outcomes when undertaking any Six Sigma task. There is more weight added to the importance of good management leadership and incorporation of everyone in proper running of the organization.

To ensure that the goals of the Six Sigma approach are met, a unique resource of people is categorized into various belts to steer its projects. Six Sigma asserts that assessments are to be made based on provable facts, as opposed to making guesses.

Six Sigma plays a vital role in assisting organizations to achieve the highest value while utilizing minimum input of resources. It realizes this by rationalizing the management by applying scientific techniques to processes and products.

When an organization adopts the Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) approach, processes or products are enhanced in that they are more effective and efficient, or both.

On the hand, if no process or products are present within the organization, or if the current processes or products have extensively undergone deterioration, then design for Six Sigma (DFSS), also referred to as DMADV (Define, Measure, Analyze, Design, Verify),strategy is employed to come up with effective and efficient processes or products.

When Six Sigma approach is adequately incorporated in an organization, it reduces the negative influence that politics have on the well-being of an organization, better service to owners and customers, and the working environment becomes conducive for workers.

The making of decisions is grounded on reason and rationality, as opposed to a mere back-room politics (Pyzdek, 2003, p. xv). Six Sigma uses various tools to meet the various quality requirements. These includes dashboards which serves the purpose of monitoring the processes of the organization, operational definitions, and data displays to assist in coming up with justifiable data.

Comparing it with ISO 9001:2000 illustrates the possibility of relating both quality systems with one another. The evaluation tools for Six Sigma are usually added after its adoption in the organization. ISO 9001:2000 plays the role of evaluating the internal and external requirements of organizations.

By incorporating the Six Sigma approach to the ISO 9001:2000, an organization is able to establish Six Sigma as a component of its quality management system and therefore tremendously enhance the success of the Six Sigma program.

ISO 14000

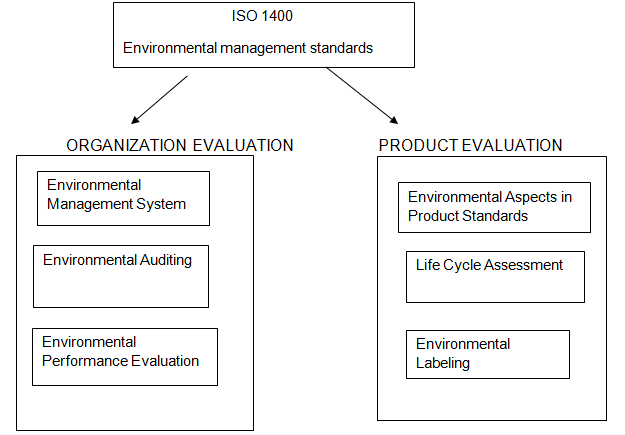

The ISO 14000 is a quality standard for environmental management systems that is relevant to any organization, despite of its market share, geographical location or status. Environmental sustainability has been the focus of most organizations for a long time now.

The objective of the standard is to lower the environmental footprint of an organization and to reduce the level of contamination that an organization generates.

Years of misuse and degradation has strained the environment to the point that continued toleration of this practice may leave nothing for the future generations to enjoy. In structure, it is parallel to ISO 9000 quality management systems and all of them are applicable together.

The focus areas illustrated in ISO 14000 is into two different areas. The first appertains to the management and evaluation systems of an organization; the next, appertains to environmental tools for product evaluation.

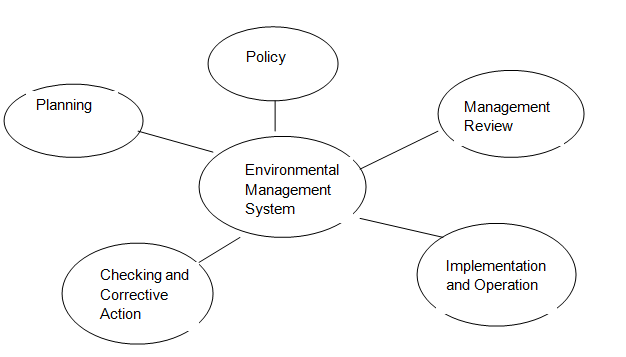

The ISO 14001 focuses on setting up of one or more environmental programs that seeks to realize the objectives and targets set by the organization (Piper et al., 2003, p.21; Morris, 2004, p.15). Management analyzing the benefits realized by implementing these environmental programs occasionally evaluates the relevance and efficiency of Environmental Management System (EMS).

That advancement is assessed by performance estimation subsystem that injects its outcome expressly into the analysis process of the management. An important aspect of the management analysis process is derived form the routine EMS audits that are aimed at ensuring the sustenance of EMS and its proper working.

The establishment of EMS is such that it gives structural and systematic approach to overall environmental management. The definitions in Section 3 of ISO 14001 help users in realizing standard interpretation and application of its requirements.

“Rather than being prescriptive, the definitions serve to set the tone for the underpinnings of the standard, and provide guidance for the key elements of the environmental management system” (Cascio, Woodside & Mitchell, 1996, p.37).

Conformance to the set standards of ISO 14001 is a pointer of an organization’s readiness to preserve the environment. Application of environmental management strategies in a programmed manner gives the chance for environmental protection and uniformity in realizing environmental sustainability. The ISO 14001 stipulates technological specifications for organizations.

The standards are applicable in any type of organization. ISO 14001 motivates organizations to reflect on application of the best readily available technology where necessary and financially within their means. This standard advocates for prevention of environmental contamination when installing new products or systems.

Protection of the environment involves the “use of processes, practices, materials, or products that avoid, reduce, or control pollution, which may include recycling, treatment, process changes, control pollution, which may include recycling, treatment, process changes, and efficient use of resources” (Cascio, Woodside & Mitchell, 1996, p.38).

The advantages of adhering to this standard include lowering of the rate of environmental degradation, increased performance, and reduction of costs.

The environmental performance indicators may include “adherence to environmental permit, reporting, and other regulatory requirements, adherence to administrative requirements such as labeling, adherence to training schedules, and improvement in environmental areas such as recycling, energy conservation, and pollution prevention strategies.”

The five major elements contained in ISO 14001 are illustrated in the following figure.

Conclusion

Organizations ought to come up with products and services that are of quality to meet the requirements of the consumers. In order for the consumers and the organization to have no fear that the needs and expectations of the customers will be satisfied, means that the organization must use processes that are quality oriented. The organization’s leadership ought to come up with an appropriate quality policy.

This policy will give the framework of the organization’s overall aspirations and direction that appertains to quality. This policy is therefore the foundation for establishing quality objectives for different tasks and levels in the organization. Evaluating its efficiency and maintaining its improvement is essential after implementing the QMS.

The areas that the management of any organization ought to look at that influence quality are “management activities, resources, product realization, and measurement of the implementation progress. In the process of defining their QMS, an organization should identify a structure that is relevant to its status.

For example, an upcoming organization with easy procedures may establish a small QMS and may decide to incorporate the whole of it in a single document.

On the other hand, a large organization with intricate procedures may decide to establish one top level Quality manual that clearly is a component of more elaborate process definitions found in different manuals. Every department may possess its own manual or alternatively, each type of business may have its own manual.

References

British Standards Institution, 2009. ISO 9001 Quality. Web.

Cascio, J., Woodside, G., & Mitchell, P., 1996. ISO 1400 Guide: The New International Environmental Management Standards. New York: The McGraw-Hill Companies, Inc.

Global Quality Village, 2009. Seven principles of Quality Management. Web.

International Organization for Standardization, 2009. Quality management principles. Web.

Kaufmann, U.H. & Bieschke, A., 2009. Using the Power of ISO 9000 and Six Sigma Together. Web.

Kishore, 2003. ISO 9001: 2000 For Software Organizations. New Delhi: Tata McGraw- Hill Publishing Company Limited.

Morris, A., 2004. ISO 14000 environmental management standards: engineering and financial aspects. West Sussex: John Wiley & Sons Ltd.

Pande et al., 2000. The Six sigma way: how GE, Motorola, and other top companies are honing. New York: The McGraw-Hill Companies, Inc.

Piper et al., 2003. Continual improvement with ISO 1400. Stockholm: SINF miljo&kvaliter AB.

Pyzdek, T., 2003. The Six Sigma handbook: a complete guide for green belts, black belts. New York: The McGraw Hill Companies, Inc.