Background

Architecture and construction are of great importance in today’s realities. One of the essential parts of constructing a private house, commercial building, and so on is electricity. This is caused not only by the fact that electricity plays a huge role in our modern life, but also by the understanding that the state of electrical networks directly affects the performance and efficiency of other engineering and communication systems in any building.

Electrical wiring is a highly responsible event. Even the slightest inaccuracy or mistake in connection can lead to disastrous consequences, including damage to devices and, in the worst case, a fire. For this reason, it is essential to pay close attention to the layout of the electrical system from the planning stage of the electrical installation to ensure the safety of the user and those around them.

All structural buildings require completion within a specified time and schedule. However, there are many people involved in such project works, including authorities, contractors, designers, clients, and suppliers, who share the same goal of reducing costs and delivery time. The construction project delay has numerous consequences, including cost overruns, stress among contractors, disputes among all involved parties, and poor-quality work due to the rush. To eliminate the ramifications and derive the benefits, it is necessary to minimize construction project delays (Rachid et al., 2019).

Many building clients frequently become frustrated with the locations of electrical outlets or anticipate changing the switch positions in the building. To a greater extent, that is why electrical structural engineers develop an electrical plan (electrical drawing), which is the rough layout of what a building’s electrical system resembles before installation, to avoid construction delays. The electrical drawing is not only essential to the electrical engineer but also for the customer (Adelakun et al., 2020). Not acquiring the electrical layout for the building (ELB) causes project delays, which negatively affect the success of the entire project.

Notably, a technical drawing refers to a visual representation of the locations where all the building’s electrical points need to be situated. Therefore, it describes the number of switches, sockets, circuits, and outlet locations. Despite that, it showcases entire electrical appliances and lighting fixtures. Different symbols are used during the electrical plan to highlight which materials need to be used at a given point; the arrangement of these symbols in the buildings significantly determines the electrical drawing.

A study by Adelakun et al. (2020) demonstrated that electrical drawing is crucial, as it ensures building safety by enabling the electrical system to operate smoothly and safely. Having an electrical diagram enables all the crucial electrical preparation processes to be completed before proceeding to the next step of building construction. However, most of the ELB done by consultants contains massive errors and defects, both in the design itself and the electrical calculations, which can cause building electrical hazards to the occupants of the buildings.

The consultants are responsible for designing the entire electricity system of the building, which will be submitted to the relevant authority. During this process, the electrical engineer working for the authority conducts an electrical drawing audit to ensure that the layout meets the authority’s requirements for approval. Otherwise, the electrical engineer working in the authority provides feedback regarding the electrical design and calculations for the electrical drawing consultants, for example, calculating the proper circuit breaker (CB) and type of CB, among other calculations, including the capacitor bank. Such errors give the electrical engineer ample time to revise the design, which may deter their approval, and may result in financial losses before the consultant is sent to correct the technical drawings (Kamal et al., 2020). The delays in obtaining approvals also lead to setbacks, including delays in the construction process.

Primary and secondary data were collected during the research work. Preliminary data consists of the collection and analysis of 10 technical drawings from the authorities. The study of the drawings and the project in progress revealed that most of them are incorrect in terms of design, primarily due to the incompetence of young employees. Secondary data were obtained through interviews with experts and specialists in the field; they were provided with drawings and asked to comment on the work of state employees.

Building construction companies are currently operating in an increasingly competitive marketplace. Regardless of their size and experience, they are forced daily to offer the highest quality electrical diagrams with no defects. Companies that fail to enhance productivity, quality, and client satisfaction face a bleak future, where business rivals overtake their market share, resulting in significant financial losses. Business contracting consultants need to offer them the best guidelines and measures to compete effectively in this rapidly changing construction environment. In our case, for the consultants to fix the errors in their electrical drawings, they require executing a systematic methodology, such as Lean Six Sigma (DMAIC), to attain vast improvements in productivity, quality, and client satisfaction (Sreedharan et al., 2018).

Introduction

One of the biggest concerns for consultants working in construction companies is eliminating defects, such as electrical drawing, calculation, and design errors, which can delay project approvals. In that case, the firm’s consultants waste their resources and time reworking the ELB process, which can lead to a loss of client trust and satisfaction due to the delayed construction process (National Academies of Sciences, Engineering, and Medicine, 2017). Companies and consultants need to improve the quality of their technical drawing processes to create a strong business strategic advantage and establish themselves as an international firm for future prospects.

This study plans to decrease the lead time of the ELBs approval process, which is associated with and results from electrical drawing quality issues, and offers a solution to minimize the most critical errors. To achieve this, the study proposal advocates for the use of the most effective quality management and improvement methodology, namely Lean Six Sigma, specifically DMAIC, as a problem-solving and improvement model.

The study undertakes a literature review of DMAIC, highlighting the positive impact and benefits of the theory on the electrical drawing process for eliminating defects and facilitating quick approval. Therefore, the study aims to speed up the approval lead process of ELBs by enhancing the electrical technical drawings undertaken by the consultants. By integrating and executing Lean Sigma (DMAIC) in the ELBs, the study outcomes minimize the defects from the ELB that are submitted by the consultant to the authority engineers, therefore reducing ELB auditing time for the electrical engineers in the authority, which will improve the construction process due to approving it in a shorter time.

The research report for the study involved a literature review, which discussed the major accomplishments in the ELBs, the use of the DMAIC tool in the construction sector, improvements in technical drawing problems, causes of project delays, several topics related to Lean Six Sigma applications, the research gap, and provided a critical discussion. The report outlines the research methods, study aims, and objectives, and presents a feasible case study aimed at reducing approval time and minimizing construction project delays by improving the electrical layout for buildings. This paper discusses the causes of construction project delays, the application of Lean Six Sigma in ELB development across different sectors, the methods used in the study, the evaluation of the results, and recommendations for addressing the issue of construction project delays.

List of Abbreviations

- DMAIC – Define, Measure, Analyze, Improve, Control.

- ELB – Electrical Layout for Building.

- PDCA – Plan, Do, Check, Act.

- CB – Capacitor Bank.

- DB – Distribution Board.

- BIM – Building Information Modeling.

- SLD – Single-line diagram.

- AI – Artificial Intelligence.

- SMDB – Sub Main Distribution Board.

- MDB – Main Distribution Board.

Literature Review

Causes of Construction Project Delays

According to Ren et al. (2021), numerous factors contribute to construction project delays. The first one is budget inaccuracies. A building project’s budget might suffer greatly if an incorrect estimate is provided. To avoid overspending, estimates must be accurate. Software streamlining bids, estimates, and financial project planning reduces the risk associated with the process.

As a result, contractors need a simple method to enter the job into their construction management platform and start to work. Real-time access to data is essential after work has started to assess progress compared to expenses. The literature provides the causes of project delays, but fails to show how they should be effectively implemented to achieve results.

According to Umar (2018), laborers abstaining from construction work is a major cause of building delays in modern-day. While many skilled individuals who were laid off during the crisis could find employment in other areas, the downturn affected this business. Construction jobs have seen a decline in popularity among newer employees entering the market. That dynamic is shifting due to the use of technology to streamline human resources and labor management processes in construction companies. Building a construction schedule may be made or broken by correctly assigning a team.

Approvals also cause construction delays. Government authorities require buildings, particularly commercial, industrial, and residential buildings, to obtain permits. Lack of compliance with the requirements may result in approval denial; thus, construction delays increase wait time (Ren et al., 2021). The project obstruction is frequently caused by overreliance of experts in each stage due to the extensive paperwork involved and their reluctance to execute their duties and responsibilities (Bhawika et al., 2019).

When owners are in charge of a project, they must make choices that keep it moving forward. Keeping construction projects on schedule and within budget may be achieved by swiftly coordinating and approving tasks. The literature indicates how approvals can cause project delays and their benefits, but fails to highlight the consequences of not acquiring them.

A study conducted by Wogan et al. (2017) indicated that every subsequent task on the construction site might be delayed if a subcontractor is overworked or uninformed about the timeframe for the larger project. There is an increased likelihood of legal challenges or disputes if a contractor fails to comply with their bonding, licensing, or other contractual requirements. To ensure that initiatives run smoothly, open communication is essential. The literature indicates that a subcontractor causes project delays but fails to highlight the associated consequences.

According to Ren et al. (2021), projects might be delayed or even done wrong if the right and left hands aren’t communicating. It does not matter whether it’s an owner, customer, in the field, or in the office; everyone should be kept up to speed on any new information that comes to light. In the event of a disagreement, the general contractor may rely on the communication and cooperation audit trails to ensure that teams have all the necessary information to address problems before they escalate into a project issue.

The literature demonstrates how a lack of communication causes building delays, but it fails to show how it affects the overall success of the construction project. Table 1 summarizes the most important reasons for construction delays and the sources of information.

Table 1. Causes of construction delay and the source of information

Major Accomplishments in ELBs

According to Sreedharan et al. (2018), over several years, the electrical drawings have evolved from manual design and calculations to specialized software, which aids in minimizing layout errors. The availability of the maps has enabled electricians and other construction workers to have full details on how to install and repair the electrical systems. Over the years, several building approval agencies have been established to ensure that buildings adhere to safety standards, thereby ensuring the well-being of occupants. In that case, most companies have invested heavily in having highly trained and qualified engineering consultants to develop the best ELBs (Saldarriaga et al., 2019).

The literature has pinpointed the role of approval authorities in designing the best ELBs, but it has not showcased how the approvals assist in reducing layout errors. A study by Zarei et al. (2018) demonstrates that through internal and external consultations, errors and defects associated with electrical drawings are effectively addressed, enabling approval for the commencement of the building construction process. The increasing availability of computers and computer software has led to more effective technical drawings. In that case, the technical diagrams contain an extensive database regarding the site plan, including external wiring, floor plans, and structural location.

Sreedharan et al. (2018) demonstrated that wiring diagrams serve as a blueprint for electrical circuits and their physical connections. The literature identified defects for ELBs for buildings, but it did not offer recommendations to improve or eliminate the errors. According to the statistical reports, all ELBs must include comprehensive details, such as light fixtures, power transformers, main and fused switches, and tiebreakers. Other information necessary to integrate into the technical drawings includes the interconnection and switching of electrical system parts, such as electrical wires, as well as calculating the size and voltage of equipment, including generators, batteries, and solar panels (Madsen & Madsen, 2018). Such measures have been implemented to eliminate design errors associated with electrical drawings (Saldarriaga et al., 2019).

The literature identified the primary components of ELBs, but it did not show that their absence causes a delay in construction projects. Various studies have been conducted on how to enhance electrical drawings. However, the available literature does not indicate how much electrical drawing errors contribute to delays in approval, resulting in increased wait-time during the construction process.

All the components of wiring diagrams should be designed error-free to ensure the quickest approval of the projects (Madsen & Madsen, 2018). Multiple research studies advocate for interscapular knowledge exchange, whereby qualified engineers from the client company and consultants work together to achieve non-defective technical drawings during the design process. The study does not provide data on how technical diagram errors cause construction project delays; however, it advocates for interdisciplinary fields to work together.

Lean Six Sigma Application

According to Rosa and Broday (2018), most companies, including those in healthcare, manufacturing, business, and customer marketing, apply the Lean Six Sigma model in their daily operations. Car production firms deploy the approach to help them reduce costs and increase profitability. DMAIC Six Sigma focuses on process improvement, waste elimination, and inventory reduction.

The methodology philosophy emphasizes maximizing available resources, particularly in production firms, to help them identify the most critical problems that may affect their manufacturing operations. The operational efficiency improvement creates awareness for the team. In manufacturing entities, the Lean Six Sigma method is applied to create flow after pinpointing, specifying, and mapping a given item’s value stream.

Therefore, it facilitates the completion of product manufacturing and the general improvement of the cycle lead time, creating a ceaseless flow of work elements with minimal stoppages and frequent queues. The literature pinpointed how manufacturing industries can apply Lean Six Sigma to reduce costs and eliminate waste, but it failed to showcase the methodology’s demerits when deploying it.

A study by Chiarini and Kumar (2021) showed that many business organizations applying the Lean Six Sigma method create products according to market value expectations or in response to customers’ perceptions, thereby minimizing complaints. During marketing, the lean model is applied to analyze the processes determining the release of a commodity to consumers. Companies continue to receive negative feedback, particularly when customer satisfaction levels deteriorate.

The availability of feasible assembly lines is crucial in achieving smooth production system operation and flexibility. The Lean Six Sigma methodology can enhance an item’s quality and facilitate fast delivery to the market at an optimal price, thereby aiding firms in meeting or exceeding projected client demands. The literature provides an overview of how Lean Six Sigma is applied in business organizations to minimize customer grievances and enhance their level of satisfaction.

The Use of the DMAIC Cycle in the Construction Sector

Literature has advocated using the DMAIC tool and technique to improve wiring diagrams, which employs other quality and performance improvement models, including control plans, measurement system analysis, Pareto charts, fishbone diagrams, and capability analysis. The DMAIC approach helps analyze a process before implementation, which enables the identification of issues that can impact the entire project (Wogan et al., 2017).

The use of the DMAIC process during the ELB approval process by authorities can minimize construction project delays, ultimately leading to its success. The phenomenon generally results in improved performance and ultimately filters through to happier clients. Through rectifying the electrical drawing defects, the literature suggests methods, including DMAIC, to ensure process improvement, minimize approval delays, and reduce recurrent reworking (Newbery et al., 2021).

The literature gives statistics on the importance of using the tool. According to Wogan et al. (2017), despite improving design quality, DMAIC acts as a management strategy and philosophy applied to each process, such as electrical drawing, to eliminate the root causes of errors. To a greater extent, several authors argue that the primary advantages of building electrical design development companies in applying Six Sigma are. They include defect elimination, cycle time improvements, cost reduction, increased profits, and enhanced customer experience.

The literature suggests that the DMAIC methodology is utilized in enhancing the design process. It can be expanded to improve other business elements, including legal and purchasing, and is often attached to electrical drawings. Incorporating DMAIC with other techniques encourages employee participation in the project, increases the process knowledge of less qualified and inexperienced building specialists, and fosters problem-solving by applying statistical thinking concepts (Bhawika et al., 2019). The literature does not provide the names of other techniques that can be incorporated with DMAIC to improve construction delays, despite identifying the root causes of ELB failure.

According to diverse research undertaken, utilizing DMAIC in this research project will enable all individuals involved in the electrical diagram to enhance their skills and knowledge, thereby effectively solving problems through the gained statistical expertise (Hsu et al., 2017). Therefore, all consultant engineers who receive high ratings—even if those ratings have recently declined—will gain better experience in refining electrical drawings to ensure they are free of errors. The study will benefit from the five interlinked phases: define, measure, analyze, improve, and control. The literature identifies DMAIC stages, but it does not demonstrate how they can reduce project construction delays.

Regarding the define stage, this phase entails determining the project team’s responsibilities, customer requirements, and expectations; elaborating on the project scope and limits; and establishing the project’s identified goals using the project charter (Wogan et al., 2017). The other step involves mapping the electrical drawing process to help comprehend the defects in the implemented design.

The measure stage involves selecting the measurement factors to be enhanced, providing a structure to assess existing performance, and evaluating, contrasting, and monitoring subsequent improvements and capabilities. The frequent revision of electricity drawings shows that the operation failure costs exceed the target of escalated design defects over time due to denied approvals (Newbery et al., 2021). Riva et al.’s study (2019) suggests that it is crucial to prioritize the causes of frequent failures in the electricity design process. This can be achieved by integrating the Pareto chart to showcase the highest triggers of wiring diagram errors that the design quality inspector might not detect.

The analyze phase focuses on determining the root causes of the problem, understanding why defects have occurred, and comparing and prioritizing opportunities for improvement. The study encourages the incorporation of a fishbone (cause-and-effect) diagram to pinpoint the root causes of the electrical drawing failure. Improper design, maintenance, and poor process release procedures can contribute to such defects. The improve stage concentrates on deploying statistical techniques to create future improvements to minimize the number of quality issues.

Last is the control phase, which focuses on sustainability enhancements and monitoring the ongoing performance. The stage enables the institutionalization and documentation of ELB improvements by training wiring operators on the newly used tools and the current modified processes, and updating the control plan, which is essential for this project. The literature provides a vivid description of each DMAIC process phase and its associated advantages in minimizing construction delays for the ELB.

Improvements in Technical Drawing Problems

Several study sources have developed methods to improve the quality of electricity diagrams, resulting in faster approvals. Literature suggests utilizing Deming’s continuous learning and process enhancement model, the plan-do-check-act (PDCA) cycle (Realyvásquez et al., 2018). Despite PDCA being a learning model intended for executing advancement activities, it also envisions data collection and analysis directed towards finding the problem associated with the electricity layout.

The literature fails to compare PDCA with DMAIC to demonstrate which is more effective in reducing construction delays, despite acknowledging the benefits of both in improving ELB. According to the literature, such a phenomenon enables project team members to take decisions and courses of action grounded in actual and scientific statistics, rather than relying on personal knowledge and experience, as with many consulting firms. The literature does not highlight the effective decisions that the project team should undertake, despite advocating for them.

Lean Six Sigma Application

Time Reduction

One of the most effective strategies and methodologies for increasing the speed of service and production industries is the Lean Six Sigma model. The philosophy enhances the momentum of entire processes across the firm, reducing wastage and thereby improving firm performance. Typical waste types that increase operational time include inventory, extra processing, defects, motion, transportation, waiting, overproduction, and underutilization of talent (Makwana & Patange, 2021).

Lean Six Sigma employs various statistical techniques and tools, integrating a team of qualified experts to enhance total quality management. The complex areas are well-managed, and errors are addressed promptly. The minimization of waste and defectives, along with streamlining value flow, results in time reduction. The method facilitates the proper deployment of lean thinking, rectifying slow processes by developing a well-structured blueprint to reduce variability (Trakulsunti et al., 2022).

In the ELB, Lean Six Sigma methodology can be successfully applied to reduce time by eliminating defects that cause rework. The literature indicates that the lean methodology helps eliminate waste, resulting in time reduction, but fails to highlight the repercussions of not utilizing the method. The Lean Six Sigma tools and principles serve as the most systematic and organized techniques for reducing cycle time.

The method enables the effective allocation of duties and responsibilities to personnel involved in a particular project, leading to increased commitment and focus on the immediate issues arising (Honda et al., 2018). The highly qualified group leaders train others without seeking external consultation. The application of the lean model involves a review of existing workflows, updates to processes, dedication to scheduled maintenance, and maintaining optimal inventory, which helps minimize the time spent on specific activities (Trakulsunti et al., 2022). The literature demonstrated how qualified experts could provide support to their subordinates and utilize the standardized process of Lean Sigma to reduce time. In addition, the method helps measure the total setup time for the electrical drawing, pinpoint external and internal components, and standardize new procedures to reduce the time required for product development or project completion.

Reducing Rework and Defects

A study by Thapa et al. (2018) demonstrated that the application of Lean Six Sigma substantially reduces defects and rework by gathering sufficient data about an error and how to rectify it. Lean Sigma helps define the problem, measure deviations using control plans, analyze root causes, and set countermeasures to minimize established defects and enhance operational efficiency. Some notable errors in building projects include poor design resulting from the use of incompetent and unqualified personnel.

Lean Six Sigma reduces variations and waste defects, which cause delays in completing a house construction project. The methodology helps create waste reduction phases to improve the timely delivery of the final product to the client. Most forms of defects are eliminated through the application of lean methodology, including rejects, movement, extra processing, inventory, and waiting (Rezaei et al., 2019).

The model provides a more comprehensive and innovative perspective on examining problems and developing improved solutions. The quality experts design a blueprint for their planned projects to prevent recurring rework. The literature described how Lean Six Sigma could be employed to minimize defects and rework; however, it did not demonstrate the impact of not utilizing the methodology.

Research Gap

The research identified a gap in studies on electrical drawing failures and their impact on permit approval acquisition. The DMAIC methodology is particularly useful in reducing the approval lead time process for ELBs. However, the literature review reveals a lack of evidence indicating that the DMAIC methodology has been implemented in this area.

Research Aim and Objectives

The research aims to reduce the lead time of the ELBs approval process using Lean Six Sigma to avoid construction project delays.

Several research objectives exist that will guide the attainment of the study’s aim. They include:

- To identify the main reasons for delays in the ELBs approval process.

- To identify the root causes of the electrical layout drawings’ defects.

- To minimize the defects in electrical layout drawings.

Methods

The research was conducted by reviewing the literature and undertaking interviews. This will ensure that the results obtained from the research indicate that the utilization of DMAIC is essential in improving the ELB to avoid construction project delays. The tools and techniques for collecting and analyzing data will include interviews, case studies, and observations. They will help preserve the information used in the future interpretation of the research findings (Prashar, 2020).

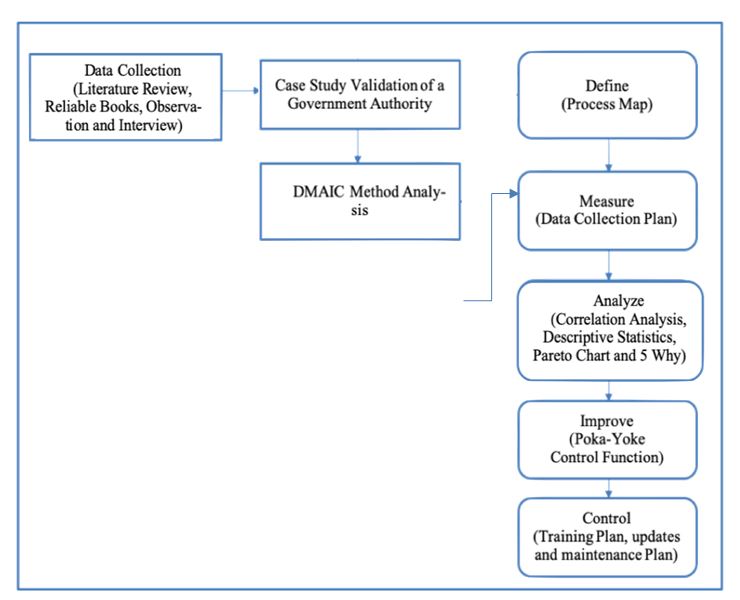

According to a study done by Sarstedt et al. (2019), the research methodology diagram is essential as it guides the researcher in pinpointing the links between the study topics and earlier deployed methodologies by other investigators. It becomes easy to identify the research gap by using it. The data collection, involving interviews and the use of regression analysis, helps identify any errors committed during the calculation and design of ELBs.

The data was gathered through both primary and secondary data collection methods. After that, Data Analysis between two parameters, which are the number of lead days and the total number of errors is implemented by using regression analysis, descriptive statistics, ANOVA, and 5 Whys in the authority case study, the DMAIC method is used, and each phase used a different tool to ensure whether they will improve the ELB errors made by the consultants. Figure 1 represents the research methodology diagram that will be followed.

Primary Data Collection Method

The primary method involves data collection directly from the first-hand source by the researcher (Sarstedt et al., 2019). The primary data collection method included interviews and field observations. The interviews were conducted with electrical domain experts, including consultants and engineers, to collect data. Moreover, discussing the most frequent errors in auditing ELBs and the solutions for them.

Secondly, through field observations of the technical drawings of ELBs, data were assembled regarding the frequent errors that occur in ELBs, along with the time taken to obtain approval. Moreover, a schedule was prepared to indicate the number of consultants committing the most mistakes in the ELBs, along with the period for each case. In that case, the data helps enhance the ELB auditing process and facilitates its adoption quickly.

Questionnaires were provided to collect the opinion of experts, the purpose of which was to assess the level of drawings and their suitability. According to expert interviews, the primary reason for defects in the drawing was attributed to consultants who had higher job ratings and were unfamiliar with major construction projects. In addition to critiquing the construction drawings, the specialists were given questionnaires whose purpose was to describe exactly what was wrong with the drawings they were given.

Additionally, the primary data collection process is associated with the collection of quantitative data. In particular, the research deals with technical drawings from the responsible authority. These documents are essential since they demonstrate how ELBs should be created according to official standards. Thus, it is necessary to compare actual ELBs to these standards to identify whether everything is done correctly. Furthermore, the data on lead times and consultants, along with the corresponding histogram, represent another set of quantitative data.

It is worth noting that specific procedures were implemented to organize the interviews and questionnaires. On the one hand, structured interviews were organized to ensure that the respondents provided the required information to meet the research objectives. Structured interviews are time and effort-consuming, which is a significant advantage. On the other hand, online questionnaires were conducted because they are convenient for the respondents and the researchers.

The questionnaires are distributed through Google Forms, which is a free and accessible research tool. This information demonstrates that the study utilizes specific and free tools that enable researchers to collect the required information effectively. This condition enables the study to collect high-quality information for further analysis. It is challenging to overestimate the significance of this fact because properly collected data increases the probability of performing the correct analysis.

Secondary Data Collection Method

The secondary method involves acquiring information that is already available for use (Prashar, 2020). Regarding the secondary data collection method, a literature review of journals, conference papers, and databases, including SCOPUS, EBSCO, ProQuest, and Google Scholar, was conducted to gather information from thirty-seven sources. The DEWA Circular & Regulation Book, as well as the SEWA Rules and Regulation Book, were used to gather data, as they provide extensive information regarding the company relevant to the study question. Moreover, the authority checklist comprises the primary rules and regulations related to the electrical layout of the building.

The data collection plan is deployed in the second phase. In the ‘analyze’ phase, the root causes of the ELB’s defects and failures are established, and strategies for improving them are adopted. Correlation analysis, descriptive statistics, a Pareto chart, and the 5 Whys method were used to identify the relationships between the variables. The ‘improve’ stage is geared towards minimizing the quality issues of the ELBs that will lead to achieving the project’s aim, which is to reduce the lead time of the ELBs approval process.

It is essential to note that the literature review and identified interviews yield qualitative data. This information is significant because it reflects the views of experts and other professionals on the issue under analysis. Qualitative data is less straightforward compared to quantitative evidence because researchers must make an effort to analyze qualitative responses and discern their actual meaning. The combination of qualitative and quantitative data in the research significantly increases its reliability and credibility.

Case Study Validation

To gain a tangible, contextual, and in-depth understanding of a real-world issue, a case study is the ideal research design. It provides an opportunity to explore the case’s key characteristics, implications, and consequences (Umar, 2018). The authority was used as the case study. It is located in the United Arab Emirates (UAE) and is a government facility that provides residents with water and electricity.

It has over 4,500 employees and more than 35 branches nationwide. The authority is a state-owned enterprise (Umar, 2018). The DMAIC methodology helped to eliminate inconsistencies in the ELBs when assessing and auditing ELBs from consultants to ensure they meet the requirements, resulting in a shorter approval time. As a result of this achievement, project approval times were reduced.

The define phase establishes the project scope and limits, as well as defines the project problem and opportunity. The process map tool is used in this initial DMAIC stage. The second phase is measure, which identifies the highest triggers of ELB defects (Newbery et al., 2021). The management tools, including the Poka-Yoke control function, were used to create the improvements. The control phase focused on sustainability and monitoring ongoing performance (Riva et al., 2019). Training, updates, and maintenance plans are utilized in this phase to ensure the documentation and institutionalization of ELB enhancements through training all wiring operators.

Implementation

Define Phase

Limited experts in ELB-specialized companies monitor ELBs in accordance with the authority’s requirements. The research aims to resolve the issue of approval delays encountered by ELB and suggest improvements. The case study reveals that frequent ELB revisions suggest that consultants are developing defective electrical systems for clients, which may lead to fire hazards and deny access to the plan during an emergency. After rectifying, the client’s safety is enhanced as they receive a building free from electrical defects.

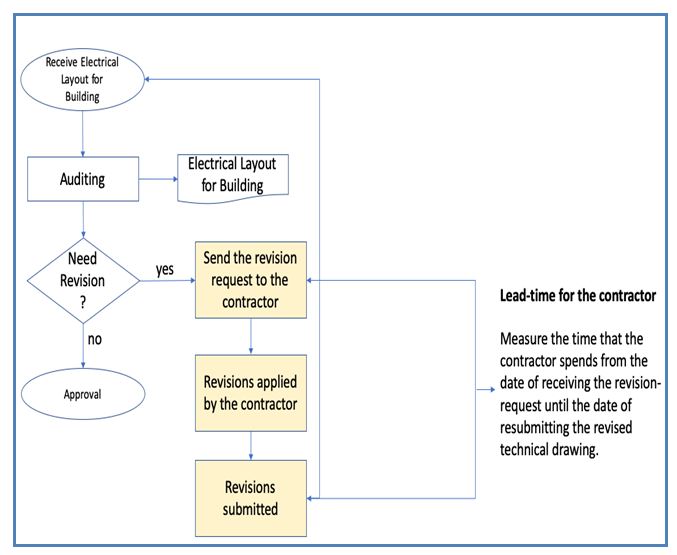

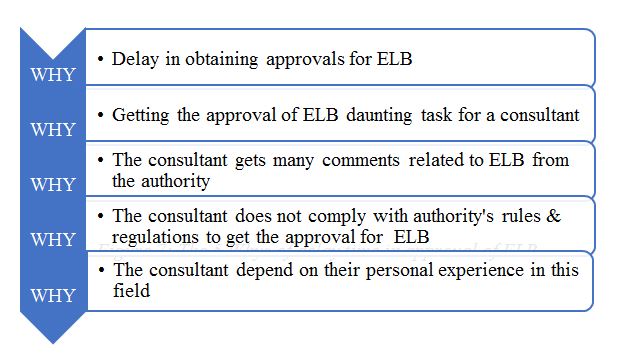

The primary problem is approval delays resulting from non-compliant ELBs performed by consultants. The issue can be pinpointed by undertaking ELB auditing and assessing whether revisions are needed. The occurrence of revisions indicates a present issue that needs to be corrected. Figure 2 illustrates the process map for the defined phase.

Figure 2 represents the procedure for the auditing and approval process for the ELB. Firstly, the authority will receive the ELB, which is submitted by the consultant. Engineers in the authority will start auditing the ELB, and they will check if it meets the authority requirements. If it meets the authority requirements, it will be approved; otherwise, a revision request will be sent to the consultant for approval. The table below outlines the Project Charter, which describes the implemented project.

Table 2. Project Charter

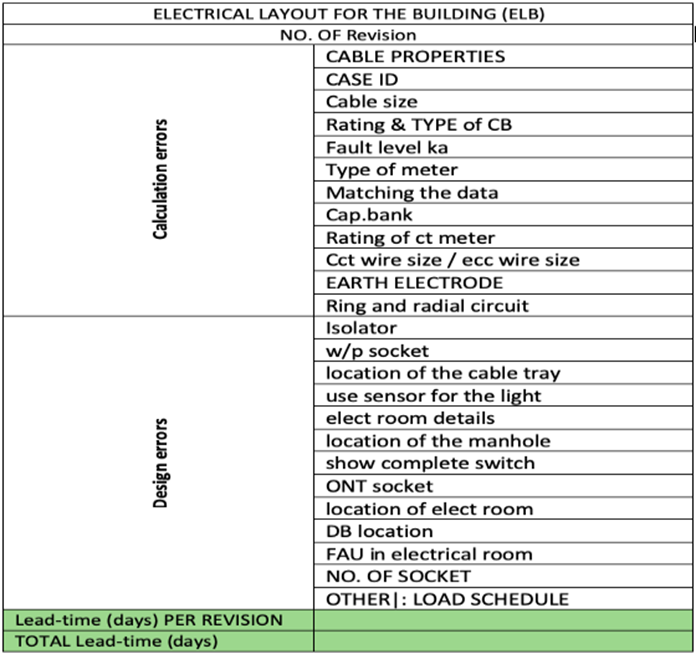

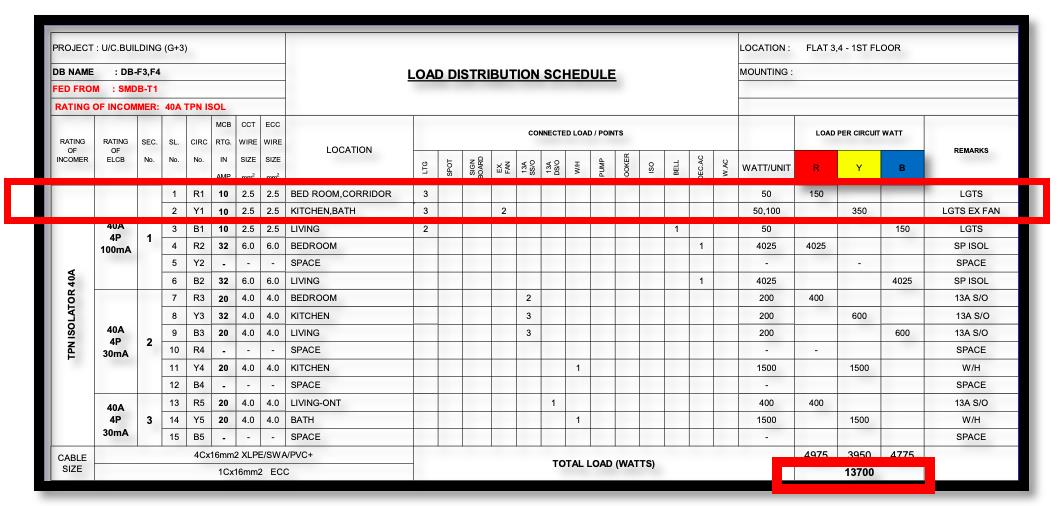

Measure Phase

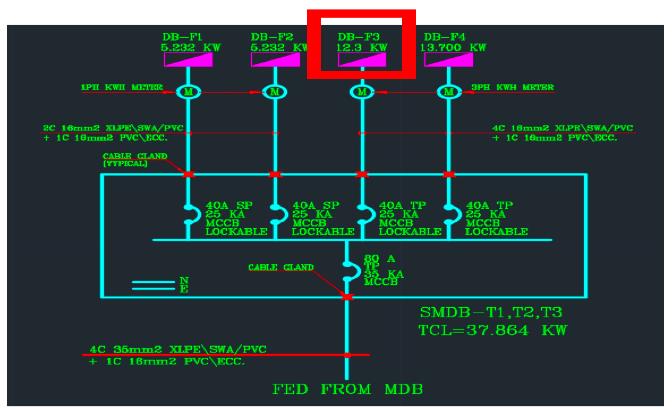

An employee with direct access to the authority gathered the available data. The worker determined the time taken for ELB approval and the number of faults committed by each consultant in each ELB. Some calculation errors include cable properties, cable size, case ID, rating & type of circuit breaker (CB), earth electrode, matching the data, and other defects that occur in figure 3, while design faults are isolator, weatherproof (W/P) socket, manhole location, and DB location, location of the electrical room, location of cable tray and other errors needed to enhance to reduce the approval and auditing time for the ELB by the consultants.

Thus, the data obtained will have a sufficiently long time for interpretation. This will help to have a clearer understanding of their true value and essence for the project as a whole. Lead times will be measured in days, while the total number of units will be measured in whole numbers.

Figure 3 illustrates the data set for the number of ELB revisions. The data gathered and measured indicate that matching the data defect in the ELB has the most significant number of errors among other defects (43 faults). A matching data error occurs, as the ELB process involves matching electrical cables and wires, as well as other components, which consumes the consultant’s time.

Additionally, the electrical room and distribution board (DB) location areas have no faults, as the DB location enables the consultant to efficiently analyze how they relate to the building’s overall layout. The electrical room location has a minimum value of 0 as well, since this specific error results in financial fees, which lead to a lower chance of rising faults. The average lead days (time taken to modify the defects in the ELBs) was 17.5161 (obtained by computing the average of all lead times).

Several locations such as ELB1, ELB2, ELB4, ELB5, ELB6, ELB7, ELB8, ELB10, ELB11, ELB12, ELB15, ELB17, ELB18, ELB22, ELB23, and ELB24 have lead times below average. The test cases, including ELB3, ELB9, ELB14, ELB16, ELB17, ELB19, ELB20, ELB21, ELB25, ELB26, ELB28, ELB29, ELB30, and ELB31, have lead times above 17.5161 days.

As evidenced, most delays in obtaining ELB approvals arise from auditing and non-compliance as the 1 value for all consultants involved. The complex calculation and measurement tasks required make the consultants prone to making crucial mistakes. For example, this aspect causes consultant J to take 46 days to obtain ELB approval and is mandated to ensure that the layout measurement falls within the standard ranges, which can prompt errors. From the gathered data, most mistakes (approximately 43) are made by consultants during the matching of data on the ELBs.

For this phase, the key activity is contrasting different types of defects arising from various parameters and relating to the number of days multiple chosen consultants take to approve the ELB. The results involve the scores of various consultants and how different parameters contribute to errors. The cycle phase, on average, should take about 29 days; in this case, it took 46 days to complete the task. Such a long delay incurs significant economic costs for the company, reputational losses among customers, and a workflow extension of several weeks.

Analyze Phase

Logically and obviously, the correlation between the number of days taken and the number of ELB revisions is positive. This means that reducing the number of ELB revisions by the consultants can substantially lower the time taken for approval and the period required to rectify them.

Figure 5 presents a descriptive analysis summary aimed at determining the statistical significance between the number of lead days and the number of identified faults. The total number of errors recorded in the analysis is 31 within the 31 lead days analyzed. In addition, the range of statistics is 43, with a maximum statistic value of 3 and a corresponding maximum of 46. The total number of variables/values included in this case is 543, with a mean value of 17.5161 and a standard error of 1.76700, indicating the samples are closely distributed around the standard mean.

The standard deviation is 9.83826, with a statistical variance of 96.791. The large standard deviation indicates that the values are widely spread out, which is confirmed by the large variance. Regarding the skewness of the analyzed data, the standard error is 0.421, and the statistical value is 1.230, indicating a relatively small number of errors. The kurtosis statistical value is 1.063, with a standard error of 0.833, implying the data set has a small tail.

Causes and Effects

According to Figure 6, the 5-whys method was implemented, which helps to get the root cause of the problem. The main cause of the problem in the optimization phase is data mismatch. This data mismatch leads to another problem associated with the project under investigation in DMAIC. If the data in the layout does not match the data in the load schedule and SLD down to the last detail, we consider this a mismatch. The effect of this problem on the project is that it causes stress and misunderstanding among employees, resulting in poor-quality services due to the rush in the project and a tendency to submit to authority.

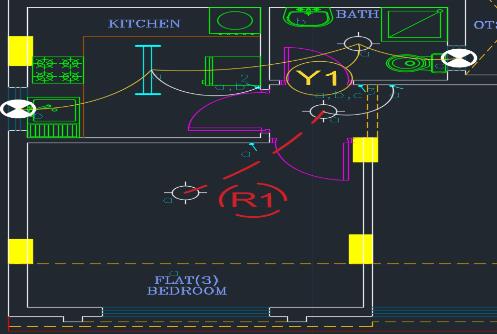

The root of this problem is that many employees are working on one project with no communication between them. For example, the consultant designs the building using AutoCAD software and distributes all the required components, such as lighting, sockets, air conditioners, and other necessary components, in the correct quantities. On the other hand, another employee prepares a schedule of loads using Excel. This employee counts all the components that have been placed in the layouts and determines the loads for each component. Due to the lack of communication between the consultant and the employee, many errors occur in the mismatching of the data. This problem raises several issues.

Additionally, this error results in inaccurate budgeting during construction projects. An inaccurate estimate can severely damage the financial outlook of a construction project. Accurate budget forecasts are crucial for controlling costs and the rate of electricity generation for each project. Therefore, consultant need a direct means of documenting the task in their construction management system.

The figures below show the types of errors made in the ELB against the cumulative percentage that causes delays in approval. For example, the most significant error that occurs in the ELBs, which leads to a delay in the ELBs approval process, is matching data with 43 problems committed by the consultants, with the highest cumulative percentage of 85%. It is followed by electric room details, Case ID, and the location of the cable tray in that order. The ONT socket, CT meter rating, ring and radial circuit, location of the electrical room, and DB location had 0 errors with a cumulative percentage of 0, indicating they were not recorded.

Matching Data Error

- Two lights are connected to the (R1) phase.

- Two exhaust fans & two lights are connected to (Y1) phase.

- Three lights are connected to the (R1) phase.

- Two exhaust fans & 3 lights are connected to (Y1) phase.

- Total connected load is 13,700 kW.

- Total connected load for DB-F3 is 12,300 kW.

Matching the data for ELB means:

- Match the DB load schedule with the lighting & power layout & CKT. NOS.

- Match the DB load schedule in the SMDB with the load schedule (check breakers, cables, phasing & loads).

- Matching the SMDB load schedule in the MDB load schedule (check breakers, cables, staging, and loads).

- Matching the SMDB and MDB load schedules in SLDs (Check Cutters, Cables & loads Ratings).

- Matching A/C load summary values in calculations.

The electrical drawing above shows two lights connected to the (R1) phase and two exhaust fans with two lights connected to the (Y1) phase, whereas the load schedule lists three lights on the (R1) phase and two exhaust fans with three lights on the (Y1) phase. The total connected load in the load schedule is 13,700 kW, while 12,300 kW is in the single-line diagram. This mistake will lead to another issue, namely that the total connected load for the project will be either less or more than required. Therefore, all data included in the layout should be identical to that included in the load schedule and single-line diagram (SLD).

Improvement Phase

The main phase of DMAIC is the improvement phase. The primary focus of the improved phase is to identify solutions to the problems highlighted in the previous three stages of DMAIC. During this phase, the possible causes of troubles will be eliminated, and improvement plans will be implemented. Errors in the construction process, such as incorrect calculations on electrical drawings or poor design, can lead to significant delays in obtaining project approval (Oza, 2022). This phase proposes solutions to the mismatching problem.

As a result of the literature review and interviews with field experts, it is concluded that software with a Poka-Yoke control function would eliminate the problem of mismatching when creating ELBs (Sulistianto & Nasihien, 2022). Poka-Yoke is the application of any mechanical device or method that either eliminates the potential for a mistake or quickly identifies when an error has occurred. It is often used in process analysis.

Poka-Yoke is a technique that prevents faults, eliminates errors, and eliminates non-value-added processes by verifying that all necessary components are in place before proceeding with a process step. To the extent that this is not practicable, it is often referred to as “error-proofing” or “mistake-proofing”. Poka-Yoke acts as a detective to find and eliminate process flaws as soon as they are detected (Quatrini et al., 2020). Poka-Yoke is a set of simple ideas and approaches that can be applied to designing products and processes to prevent human errors and mechanical mistakes, as well as making it impossible to make mistakes.

Revit software is superior to AutoCAD in matching data. In Revit software, matching the data is handled automatically. Unlike in AutoCAD, it is mandatory first to construct the layouts and distribute the appropriate components on them, then count each component individually and put it in the load schedule established in an Excel Sheet (Quatrini et al., 2020). Providing quality, precision, and control, Revit is more than simply software; it is a vital tool for professionals who produce construction projects. Revit is a need for anyone seeking employment or advancement in the fields of architecture, Electrical engineering, or interior design.

Using Revit software is more accurate and efficient than using AutoCAD. AutoCAD is design software, while Revit is building information modeling (BIM) software. In contrast to AutoCAD, which is a more general-purpose drawing tool, Revit is a design and documentation solution that can be used throughout a building project, from planning to construction documentation. In the interviews with the field experts, they explained how to use the Revit software and its efficiency.

In the Revit software, the program must be defined for each component and in which DB it will be present. After placing the component in the layout, it will be automatically placed in the load schedule in the same software. First of all, each component is labeled with the load and which DB is present. Then, the component will be placed in the correct place in the layout, and automatically, the component will be placed in the correct load schedule with the correct data. Table 3 compares AutoCAD and Revit Software.

Table 3. Comparing two software: AutoCAD and Revit Software

The use of Revit software resulted in improved design accuracy, a significant plus for a wide range of projects. The Revit software has revolutionized the use of drawings for architectural modeling and documentation. It was necessary to test how the use of additional software would affect the speed and quality of the work. To start with, we took the last result of a consultant who had received a permit within 33 days.

Next, to optimize the process, the consultant was given access to Revit software, which is required for data management, architecture, modeling, analysis, and BIM. In this way, it is easier for the consultant to study and build ELBs with high accuracy, because, in the event of an error, the program itself will point it out. After using Revit software, the consultant was approved in just ten days.

From 33 to 10 days, using Revit software is a solution to mismatching. Specialists can benefit from Revit software’s design planning and construction accuracy. With the use of Revit software, teams worked together on projects more precisely, knowing that any changes made in one part of a drawing would be accurately reflected across the entire drawing. Using Revit, the project’s data is consolidated into a single location, eliminating the need to search elsewhere. People have found that having everything in one place helps save money and keeps everyone informed.

Control Phase

Training the Employees for Software Use

The consultants play a crucial role in ensuring that the project is completed on time. They should be trained in the knowledge of Revit software to learn presentation skills, gain valuable exposure to BIM, and maximize design possibilities. Moreover, provide training to learn how to use Revit software to set up work drawings, which will help consultants collaborate better on the design and calculation of components, while improving the time and cost efficiency of the project as a whole (Dogan and Gurcan, 2018). The consultant will utilize the Revit software approach to strengthen their expertise and abilities, ultimately enabling them to resolve issues more efficiently. Therefore, all consultant engineers receiving high stars, despite having decreased ratings, will have improved experience in refining the electrical drawings to make them error-free.

Regular Updates and Maintenance of the System

Regular updates and maintenance of the software system should be implemented at appropriate intervals to control mismatched data. Regular system maintenance reduces the risks of hacking and overloads, thereby minimizing the chances of system failures and improving operations to control data-mismatching problems (Suofian, 2022). To safeguard the system and ensure improvements in producing correct results, the system needs to be analyzed to prevent errors in the Revit software. To reduce costs and make repairs and maintenance more manageable, it is recommended to use Revit Drawings, which provide a perspective and 3D view of the system. Regular updates ensure that the system remains efficient in resolving data mismatch issues.

Discussion

This case study presents a solution to the problem of data-mismatching errors in the ELB using the Revit software’s control function, which helps prevent human errors and mechanical mistakes. Revit software automatically matches the data, unlike AutoCAD software, which does not integrate with automated systems. The results were positive in Refit software, as it eliminated errors caused by mismatches and improved the quality of the ELB, delivering it in a faster time compared to AutoCAD, which would take longer to submit an ELB that meets the authority’s requirements. This result will lead to a reduction in construction delays. It’s a great accomplishment because it will reduce the lead time of the ELB approval process and reduce mismatching errors. It’s challenging to achieve this result unless you follow the suggestions from the improvement phase.

Conclusions

To a greater extent, the ELB errors committed by the consultants tend to necessitate numerous revisions to obtain approvals, which in turn leads to a delay in approvals. The key findings established a positive correlation between the number of lead days and the total number of errors. Errors committed by the consultant may take different lead times to rectify. The average lead time required to approve ELBs is 17.5161 days, as determined in the measure phase.

The root causes of the ELB errors are determined in the analysis phase, which is the mismatched data error that displayed at 85%. The improvement phase addresses data mismatching by utilizing Revit software to efficiently correct the issue, resulting in a reduction of lead times from 33 days to 10 days to rectify ELBs. Lastly, during the control phase, the obtained solutions are validated, and all related changes, such as regular updates and maintenance, as well as training consultants, are implemented. The consultant will utilize the DMAIC approach to enhance their knowledge and skills, resulting in more efficient issue resolution.

Recommendations and Future Work

Creating an AI program that reads and corrects calculation errors, such as cable size rating of CB type of meter, earth electrode, capacitor bank rating, fault levels, wire size, cable properties, and w/p socket. It will reduce the error by a high percentage, which will contribute to delivering ELB to the authority with the least possible percentage of errors. All future complicated decision-making will rely on the foundation of artificial intelligence, the basis of all computer teaching (Quatrini et al., 2020). Utilizing AI machines to resolve errors offers numerous benefits, including maintaining the highest possible degree of accuracy, acting quickly and reliably, analyzing data with greater depth than humans, and arriving at decisions efficiently.

Some solutions can be implemented by the authority to help improve the consultant’s performance. This can be achieved by training them quarterly to leverage the experience of Authority engineers and share knowledge. Moreover, the authority can charge fees for each revision. This way, the consultant will take the project seriously and work diligently to deliver a flawless ELB, thereby obtaining approval more quickly.

References

Adelakun, N. O., Olanipekun, B. A., & Asogba, S. O. (2020). Design of an Electrical Installation of a Storey Building. SSRN Electronic Journal, 1(4). Web.

Chiarini, A., & Kumar, M. (2020). Lean Six Sigma and Industry 4.0 integration for Operational Excellence: evidence from Italian manufacturing companies. Production Planning & Control, 2(5), 1–18. Web.

Dogan, O., & Gurcan, O. (2018). Data Perspective of Lean Six Sigma in Industry 4.0 Era: A Guide To Improve Quality. Web.

Emeara, M. S., AbdelGawad, A. F., & El Abagy, A. H. (2021). A novel renewable energy approach for Cairo International Airport (CIA) based on building information modeling (BIM) with cost analysis. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences, 85(2), 80–106. Web.

Engineering and Physical Sciences National Academies of Sciences. (2017). Enhancing the resilience of the nation’s electricity system. The National Academies Press.

Fargnoli, M., Lleshaj, A., Lombardi, M., Sciarretta, N., & Di Gravio, G. (2019). A BIM-based PSS approach for the management of maintenance operations of building equipment. Buildings, 9(6), 139. Web.

Honda, A. C., Bernardo, V. Z., Gerolamo, M. C., & Davis, M. M. (2018). How lean six sigma principles improve hospital performance. Quality Management Journal, 25(2), 70–82. Web.

Hsu, C.-H., Chen, P.-S., & Yang, C.-M. (2017). An application of Six Sigma for improving the efficiency of the power supply. TELKOMNIKA Indonesian Journal of Electrical Engineering, 11(10). Web.

Madsen, D. A., & Madsen, D. P. (2018). Engineering drawing & design. Cengage Learning.

Makwana, A. D., & Patange, G. S. (2019). A methodical literature review on application of lean & six sigma in various industries. Australian Journal of Mechanical Engineering, 19(1), 107–121. Web.

Matos, R., Rodrigues, F., Rodrigues, H., & Costa, A. (2021). Building condition assessment supported by building information modelling. Journal of Building Engineering, 4(10), 102186. Web.

Newbery, D., Pollitt, M. G., Ritz, R. A., & Strielkowski, W. (2018). Market design for a high-renewables European electricity system. Renewable and Sustainable Energy Reviews, 91(21), 695–707. Web.

Oza, H. (2021). Importance and benefits of artificial intelligence | HData systems. Www.hdatasystems.com. Web.

Pandey, P., & Pandey, M. M. (2017). Research methodology: Tools & techniques. Bridge Center.

Prashar, A. (2020). Adopting six sigma DMAIC for environmental considerations in process industry environment. The TQM Journal, ahead-of-print(ahead-of-print). Web.

Quatrini, E., Costantino, F., Di Gravio, G., & Patriarca, R. (2020). Machine learning for anomaly detection and process phase classification to improve safety and maintenance activities. Journal of Manufacturing Systems, 56(20), 117–132. Web.

Rachid, Z., Toufik, B., & Mohammed, B. (2018). Causes of schedule delays in construction projects in Algeria. International Journal of Construction Management, 12(51), 1–11. Web.

Realyvásquez-Vargas, A., Arredondo-Soto, K., Carrillo-Gutiérrez, T., & Ravelo, G. (2018). Applying the plan-do-check-act (PDCA) cycle to reduce defects in the manufacturing industry. A case study. Applied Sciences, 8(11), 2181. Web.

Reddy Gangidi, P. (2019). Application of six sigma in semiconductor manufacturing: A case study in yield improvement. Applications of Design for Manufacturing and Assembly, 1(8). Web.

Ren, X., Li, C., Ma, X., Chen, F., Wang, H., Sharma, A., Gaba, G. S., & Masud, M. (2021). Design of multi-information fusion-based intelligent electrical fire detection system for green buildings. Sustainability, 13(6), 3405. Web.

Riva, F., Gardumi, F., Tognollo, A., & Colombo, E. (2019). Soft-linking energy demand and optimisation models for local long-term electricity planning: An application to rural India. Energy, 166(22), 32–46. Web.

Rosa, A., & Broday, E. E. (2018). Comparative analysis between the industrial and service sectors: a literature rewiew of the improvements obtained through the application of lean six sigma. Undefined, 50(58). Web.

Saiful Hasan Tariq. (2021). Electricity consumption towards human comfort. Researchitect. Web.

Saldarriaga-Cortés, C., Salazar, H., Moreno, R., & Jiménez-Estévez, G. (2019). Stochastic planning of electricity and gas networks: An asynchronous column generation approach. Applied Energy, 233-234(15), 1065–1077. Web.

Sarstedt, M., & Mooi, E. (2019). A concise guide to market research. In Springer Texts in Business and Economics. Springer Berlin Heidelberg. Web.

Sreedharan V., R., S., R., Kannan S., S., P., A., & Trehan, R. (2018). Defect reduction in an electrical parts manufacturer: A case study. The TQM Journal, 30(6), 650–678. Web.

Thapa, R., Saldanha, S., & Prakash, R. (2018). Application of lean six-sigma approach to reduce biomedica equipments breakdown time and associated defects. Journal of Evolution of Medical and Dental Sciences, 7(34), 3771–3779. Web.

Trakulsunti, Y., Antony, J., Edgeman, R., Cudney, B., Dempsey, M., & Brennan, A. (2021). Reducing pharmacy medication errors using lean six sigma: A Thai hospital case study. Total Quality Management & Business Excellence, 13(54), 1–19. Web.

Umar, T. (2018). Causes of delay in construction projects in Oman. Middle East J. Of Management, 5(2), 121. Web.

Vora, J., Patel, V. K., Srinivasan, S., Chaudhari, R., Pimenov, D. Y., Giasin, K., & Sharma, S. (2021). Optimization of activated tungsten inert gas welding process parameters using heat transfer search algorithm: With experimental validation using case studies. Metals, 11(6), 981. Web.

Widi Bhawika, G., & Suef, M. (2019). Acceleration for the Administration Process of Project Contract in Power Plant Service Company using DMAIC. Journal of Physics: Conference Series, 1175(1), 012196. Web.

Wogan, D., Pradhan, S., and Albardi, S. (2017) GCC energy system overview–2017. King Abdullah Petroleum Studies and Research Center: Riyadh, Saudi Arabia.

Zarei, B., Sharifi, H., & Chaghouee, Y. (2017). Delay causes analysis in complex construction projects: A semantic network analysis approach. Production Planning & Control, 29(1), 29–40. Web.