Modern technology has made it easier for different engineering companies to come up with new pipes that offer numerous benefits to petrochemical industries. For example, the innovation of reinforced thermoplastic pipes (RTPs) has revolutionized “the operations of many oil and gas companies. RTPs are high pressure plastic pipes known for their reliability, strength, and effectiveness” (Kutz 17). This technology was developed in France by three companies. These companies included Tubes d’Aquitaine, Wavin Repox, and Akzo Nobel (Kutz 19). This study therefore explores RTP pipes’ market in Saudi Arabia. The essay will also analyze the technical aspects and benefits of these revolutionary pipes for petrochemical companies such as Saudi Aramco.

RTP Pipes’ Market: Size and Value

Within the past two decades, the demand for non-corrosive pipes in the gas and oil industry has been on the rise. Consequently, the production of RTP pipes has continued to respond to this demand. In the Middle East, the demand for RTP has been growing steadily since 2000 (Kutz 62). Steel pipes are currently being replaced with RTPs because they corrode very fast.

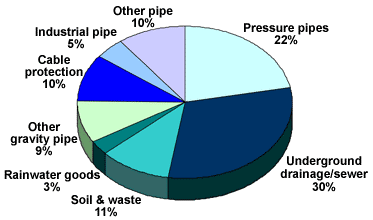

A study conducted in 2015 indicated that the global market for plastic pipes was on the rise. In Saudi Arabia, the industry has a leading share of over 40 percent (“Saudi Arabia Facts and Figures” par. 4). Estimates indicate that the demand for RTP pipes in the oil and gas industries will increase in the next one decade (Kutz 28). As well, experts argue that RTP will replace steel pipes in different parts of the globe. This change is catapulted by the economic growth experienced in every corner of the world.

Demand for Plastic Pipe in Saudi Arabia

Plastic pipes are characterized by reduced installation and production costs. They are also becoming appropriate for gas, oil, and water supply in different parts of Asia. This fact explains the demand for plastic pipes in countries such as Saudi Arabia is on the rise. The demand for plastic pipe is therefore expected to re-emerge as building and oil transportation activities continue to take center-stage in different parts of the country (“Saudi Arabia Facts and Figures” par. 2).

According to the Organization of the Petroleum Exporting Countries (OPEC), Saudi Arabia has around 18 percent of the world natural gas and oil reserves (“Saudi Arabia Facts and Figures” par. 3). This makes the country the leading exporter of refined and crude oil. Oil exploration and production have transformed the activities of different oil companies in the country. Many companies are therefore focusing on the effectiveness of plastic pipes over steel conduits. In order to maximize their oil exploration activities, firms such as Saudi Aramco have therefore embraced the use of plastic pipes. Such pipes are also being used for water transportation in the country.

Brief Overview of End users of RTP Worldwide: Significance for the Petrochemical Industry

Reinforced Thermoplastic Pipes (RTPs) are acknowledged as “the best alternative to steel for oilfield applications” (Bai and Bai 12). Many oil companies, construction firms, and gas operators are presently using RTPs in order to achieve their goals much faster. That being the case, the end users of RTP pipes have increased in the recent past. Some of the leading consumers of RTP in the oil industry include Petrobas, Beyond Petroleum (BP), Shell, and Saudi Aramco (Kutz 12).

RTP has also been widely used by several gas distribution companies in different corners of the globe. For instance, AltaGas Utilities Incorporation (AUI) of Canada has been using RTP for gas extraction since 2006 (Bai and Bai 25).

Many countries such as the United States, Canada, China, France, and the United Kingdom have installed RTP pipes to distribute gas (Conley, Weller and Sakr 4). This means that RTP has become a favorite choice for both gas and oil applications. Municipal governments are also using RTP pipes to dispose waste water. This overview shows clearly that the end users of RTP will increase in the next few years.

The significance of RTP for the global petrochemical industry cannot be underestimated. To begin with, factors such as cost, reliability, workability, availability, and strength have always dictated the nature of innovation embraced by many companies in the oil industry. The use of steel as the best option has met a wide range of obstacles such as corrosion and contamination. This situation has led to the use of polyamide and polythene to transport gas and oil. The invention of RTP overcame most of the inherent limitations associated with thermo-set composites, steel pipes, and unreinforced plastics (Conley et al. 5).

Companies using RTP have recorded high efficiency and cost reduction. Such pipes are easy to acquire and install. They also have high pressure capabilities thus making them admirable. RTPs pipes reduce installation time, minimize cost, and reduce chances of contamination (Kutz 52). The number of companies in the petrochemical industry embracing the use of these pipes is expected to increase significantly within the next ten years (Kutz 103).

RTP: Uses, Manufacturers, Suppliers, and Technical Features

RTP is widely used in “the upstream gas and oil industries for a wide range of applications such as water injection, gas gathering, water disposal, and oil gathering” (Pavlou 9). The pipes are also used to distribute gas. The production and marketing of RTP pipes is undertaken by a few companies. One of these manufacturers is PipeLife International. The company is known for producing Soluforce pipes (Kutz 132). The other producers include Master Tech Company, Oloyan Group, Saudi Pipe Systems Company, and Saudi Arabian Amiantit. These companies are also known to supply their products to the growing number of consumers.

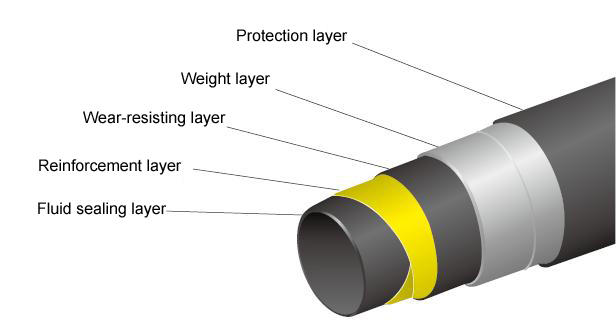

RTP is characterized by a number of technical features. For instance, the product is constructed using polyamide-11 and polyethylene (PE). These compounds are reinforced using polyester or Aramid (Kutz 48). The pipes tend to have pressure ratings ranging from 30 to 100 bar (MPa). The pipes can be produced in coils of around 300-500 meters. This feature makes it easier for oil companies to reduce installation time. The pipes also have several layers to make them effective and durable. The layers are portrayed in the diagram below.

Factors Supporting the Growth of ‘RTP’

The attributes of reinforced thermoplastic pipe (RTP) systems explain why their use will increase in the future. Companies using such pipes have managed to construct high pressure water, gas, and oil transport systems. This is the case because such pipes are usually flexible, portable, and essay to install. Such pipes are also effective whenever planning to install long lengths of pipeline systems. The pipes have few connections thereby minimizing installation costs (Pavlou 27).

They have successfully minimized costs for many companies in both oil and gas industries. Steel is less expensive than RTPs. However, steel requires extensive welding techniques and time. It is also corrosive thus forcing many firms to monitor the pipes frequently.

RTPs have also fulfilled all the major requirements for international specifications (Kutz 76). Most of physical mechanical tests conducted on these pipes have presented desirable results. The pipes can be connected using various techniques thus minimizing costs. They are durable and can be relocated without compromising their effectiveness. Such pipes have also been observed to resist third-party digging activities (Pavlou 29). Industries transporting a wide range of products at high pressures will therefore continue to benefit from the continued use of these RTP pipes. These factors support the increasing consumption of RTP in every continent.

Saudi Aramco’s Interest in RTP

Saudi Aramco is one of the leading companies concerned with the implementation of RTP (“Saudia Aramco” par. 2). The company has been conducting extensive research to understand how the problem of corrosion can be dealt with. According to experts at the company, RTP is a modern technology that has the potential to offer numerous benefits. Saudi Aramco was one of the companies that created the Joint Industrial Project (JIP) to test and develop a standard for using RTP (“Saudia Aramco” par. 2). RTP is cost effective, durable, and reliable.

Within the past eight decades, Saudi Aramco has remained a global leader in petroleum production, distribution, exploration, and marketing (“Saudia Aramco” par. 4). The company is focusing on the use of RTP to create a reliable gas and oil production infrastructure (“Saudia Aramco” par. 5). The use of RTP is thus expected to deliver reliable oil that makes every new opportunity possible in Saudi Arabia and beyond. The company believes that the use of RTP will deliver positive results and profits in the long run (“Saudia Aramco” par. 4). In conclusion, firms in the petrochemical industry should embrace the use of RTP in order to achieve their potentials and quench the increasing demand for various oil products.

Works Cited

Bai, Qiang, and Yong Bai. Subsea Pipeline Design, Analysis, and Installation. New York, NY: Elsevier, 2014. Print.

Conley, Jeff, Blaine Weller and Assaad Sakr. Recent Innovations in Reinforced Thermoplastic Pipe. Web.

Kutz, Meyer. Applied Plastics Engineering Handbook: Processing and Materials. New York, NY: William Andrew, 2010. Print.

Pavlou, Dimitrios. Composite Materials in Piping Applications. New York, NY: DEStech Publications, 2015. Print.

Saudi Arabia Facts and Figures. Web.

Saudia Aramco. Web.