It is quite common to sub-contract the making of components to specialist firms or to cheaper producers. This practice does increase their dependence on outside suppliers and reduces to some extent their control on the quality of the components. The opportunity cost approach to this type is obtained from alternative uses of the productive capacity releases as the result of subcontracting the making of components.

This is a case of outsourcing where relevant costs analysis is carried out. Outsourcing is the ordering of goods or labor from outside the plant. In this case the ,company is intending to outsource the production of 8000 GPSN from Thailand rather than producing them in the US. The decision to be made here is about whether the goods should be outsourced or produced in-house. Apart from the quantitative analysis, qualitative factors will also be considered as necessary. The qualitative factor that should be considered in this case is the factor of transfer of technology to Thailand and the loss of business incase the firm decides to produce without referring to the company after the expiry to the contract period.

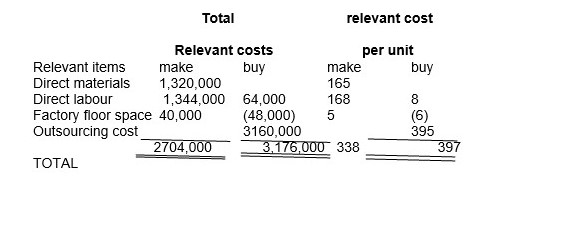

In the analysis in this case, we shall consider relevant costs only in this case of by of outsource or produce locally. Let us now consider the possibility that the firm accepted the offer, the productive capacity released as a result will not remain idle, and will be used to extend the production line of Global Positioning system navigator (GPSN). The following is the calculation of the 8,000 units that will be incurred.

The difference in the production in house and outsourcing is 472,000 in total per month after taking into consideration all relevant costs. It is expensive for the company to outsource this product at a cost of 395. This is after considering two expenses general company overhead and supervisory labour as a fixed overhead which will be incurred either way. The supervision labour will be incurred whether the production is in house or outsourced. This makes it a fixed cost. From this case, I will advise the company to not outsource the production of this units unless the company that wants to outsource offers a price which is lower than 338.

The allocated fixed costs are irrelevant to the decision since they are not affected, and will continue to be incurred by Behemoth Motors Corp (BMC) irrespective of whether the parts are made or outsourced. Since the relevant costs of making are less than the costs of buying the firm should reject the offer and continue to make the parts.

In the examples which we have examined so far, the selection of alternative courses of action has been made on the basis of seeking the most profitable result. Business enterprises are limited in the pursuit of profit by the fact that they have limited resources at their disposal, so that quite apart from the limitation on the quantities of any product which the market will buy at a given price, the firm has its own constraints on the volume of output. Hence at a given price, which may be well above costs of production, the firm may b unable to increase its overall profit simply due to its inability to increase its output.

The limiting factors which affect the level of production may arise our of shortages of labour, material, equipment and factory space to mention but a few obvious examples. Faced with limiting factors of whatever nature, the firm will wish to obtain the maximum profit from the use of the resources available, and in making decisions about the allocation of resources between competing alternatives, management will be guided by the relative competing alternatives, management will be guided by the relative contribution margins which they offer. Since the firm will be faced with limiting factors, however, the contribution margins must be calculated not in terms of units of product sold which fail to reflect constraints on the total volume of output, but should be related to the unit of quantity of the most limited factor. A simple example will serve to explain.

Outsourcing has its own risks such as the company that is going to produce may compromise quality thus affecting the input. They may also increase price as well as affecting delivery time. The only operation available in that case is to enter into long term contractual agreement if they agree to produce a price which is lower than 338. The company should also enter into strategic alliances with suppliers in order to ensure production is ongoing without a hitch.

It is claimed that contribution is more relevant to management in tendering than are costs prepared with a loading for fixed expense. It is pointed out that the loading must, of necessity, vary with the level of output considered. This implies that when trade is bad and level of output considered. This implies that when trade is bad and output small an attempt to recover all fixed overhead will result in an uncompetitive price. It is accordingly claimed that in practice many opportunities exist of obtaining to fixed expenses, and that therefore a contract so obtained will result in a greater overall net profit (or smaller net loss) than is the contract were not obtained.

References

- Dean G., Joyce and Blayney(1991); strategic management accounting survey

- Glautier M. W.E & Underdown B (1977); Accounting theory and practice P. 422

- Horngren C.T Datar S.M and foster G (2003);Cost accounting: a managerial emphasis Prentice Hall Page 375-377 (2003)