Introduction

A new revolution is dawning: the unconventional oil and gas revolution, which has created a huge economic impact. In particular, this will impact the broader economy, increase the U.S. gross domestic product (GDP), address the country’s unemployment problem and add more revenues to the country’s coffers. Because of the vast demand for conventional oil and gas, the United States has long embarked on oil exploration and in these past few years the country has experienced the increased availability of shale energy. Many Americans have to learn the nature and benefits of shale energy but researchers and the government, in particular, know that this form of unconventional energy will address the large energy demand and the benefits will expand to all the 50 states.

The GDP contribution of unconventional oil and gas (UOG) reached $284 billion in 2012, with upstream operations accounting to $238 billion, and an additional midstream and downstream operations of $39 billion (IHS, 2013). Midstream refers to initial activities encompassing transport from sea to land to pipelines; whereas, downstream refers to converting the natural gas liquids into consumer products which involves refining, processing or upgrading (IHS, 2013)

. A United States study reveals that the total unconventional oil and gas (UOG) produced in the Lower 48 states reached $63 billion for the federal, state, and local tax revenues in 2012, and by 2020 this could reach $113 billion (Hausman & Kellogg, 2015). The higher unconventional energy production, which Hausman and Kellogg (2015) described as supply boom, was triggered by technological development in extraction. Horizontal drilling applied with hydraulic fracturing is an innovation that allows easy and low-cost extraction.

The Energy Information Administration reports that in the U.S. alone, investigators and engineers have pinpointed at least 2,203 trillion cubic feet of gas reserve, enough for the country to survive for 93 years, as estimated by policy makers based on current rates of consumption (Sprague, 2015). Trapped in shale rock in the U.S. are estimated 2,431 billion barrels of what scientists call wet natural gas, while in the Niobrara shale rock, there are about 4.1 billion barrels (Sprague, 2015). In Colorado, there is an estimated 20,666 billion barrels of gas reserve. Colorado is the forerunner of oil and gas development in the West (Noel as cited in Sprague, 2015).

OUG exploration can drill 1 to 2 miles below the earth’s surface, taking out oil and gas through steam injection, added with chemicals to create ruptures on rock formations (Jemielita et al., 2015). First, engineers use remote sensing technique and apply spectral measurements and chemical tests to retrieve oil and gas information and data. Scientists also use and analyze high-resolution images in order to get the most reliable information about oil and gas (Song, Yang, Zhen, & Li, 2014).

Success in Unconventional Oil or Gas Exploration and Recovery

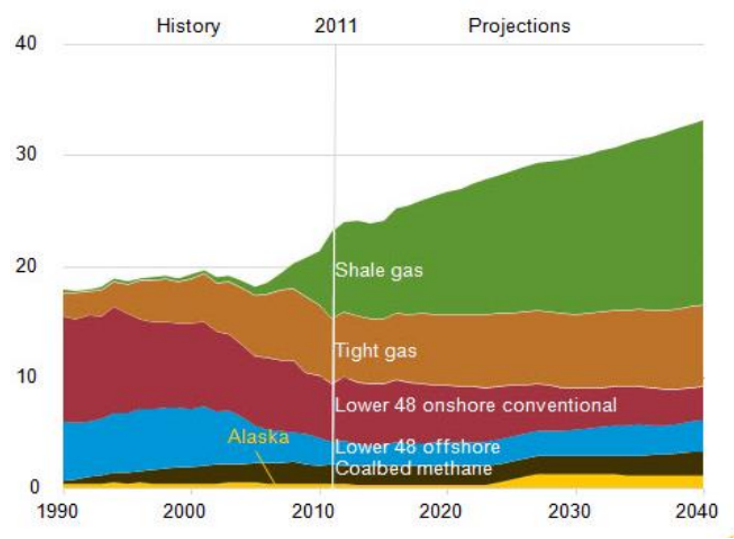

Since 2006, the United States has been successful in shale gas production, particularly in Texas, which has the predominant Barnett Shale. This has encouraged shale gas recovery technologies for firms to hasten their shale development activity. The combination of two technologies – horizontal and hydraulic drilling – generated less costly shale gas production and stimulated growth (Kharabah, 2014).

Conventional reservoirs are smaller than unconventional ones but the unconventional reservoirs have larger oil or gas in place and difficult to develop. Unconventional reservoirs need high technology and are much more costly to develop. International gas companies are continuously searching for unconventional gas reservoirs in order to meet the huge demand. The resource triangle for conventional and unconventional reservoirs is shown in figure 1.

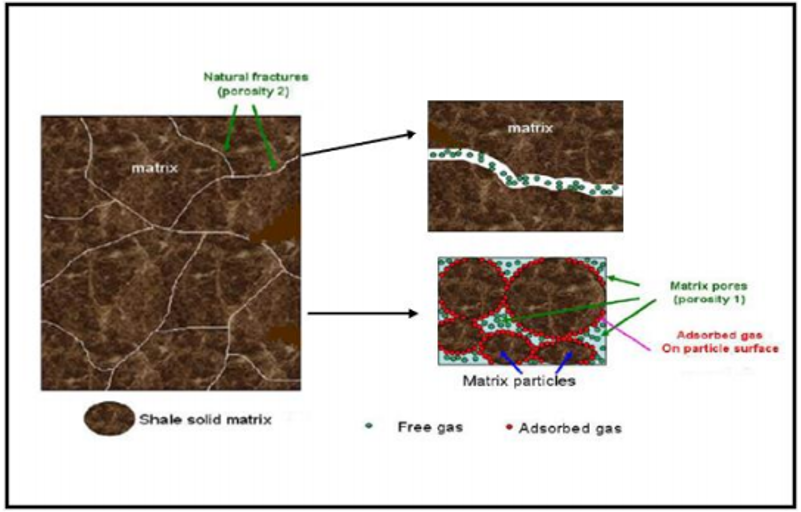

Shale refers to a type of clay or mud that can easily split into layers and have transformed into rocks by way of geological circumstance. Shale formations function as source rocks and seals for conventional reservoirs. Gas gets out from the source rock to sandstone or carbonate reservoirs, in which gas is trapped in the sandstone forming a gas reservoir. Shale gas reservoir is considered extremely organic with a permeability ranging from 0.1 mD to 10-7 mD (Siripatrachai & Ertekin as cited in Kharabah, 2014). Natural gas and oil are found in permeable sandstones, shale rocks, and coal foundation (Jemielita et al., 2015).

Gas deposit has been categorized by scientists as: free gas, which is predominant in pores and has low permeability; free gas, which has higher permeability; and the last is adsorbed gas predominant on the shale’s surface. Adsorbed gas can be primarily characterized by two parameters: Langmuir Volume (VL) and Langmuir Pressure (PL). Methane is the gas produced in shale, but there can also be wet gas. This is shown in figure 2.

Horizontal drilling is the conventional method of drilling shale gas. Horizontal drilling is done after a vertical one wherein the drill penetrates the “kickoff point,” proceeds to a curve to reach the “entry point” in the reservoir. The bottom hole is then located. This method helps to infiltrate a maximum distance of gas-bearing rock and a maximum number of vertical rock formations (Jemielita et al., 2015).

Horizontal wells are more recommended than vertical ones, particularly when drilling in a Marcellus shale reservoir. In this kind of reservoir, the natural fractures are vertical and when a vertical well is drilled, very few vertical fractures are intersected. In a horizontal well, many vertical fractures are intersected (Kharabah, 2014), which is considered productive as the well can get as much gas to be brought to the surface as possible. Horizontal wells are very costly: an average newly drilled horizontal well costs about 1.5 to 2.5 times more than a vertical well (Joshi as cited in Kharabah, 2014); but the productive benefits for a horizontal well exceed those of the vertical well.

Hydraulic fractures

Hydraulic fractures are created in the reservoir to allow free flow of oil or gas. There are two types of these, which can be determined by the direction of the stress field (vertical or normal to the horizontal minimum stress) in generated formation. If the horizontal well is drilled parallel to the minimum horizontal stress, it is expected that the fractures created will be perpendicular to the horizontal well, thereby, creating a transverse well, while the other limiting case can be generated if a horizontal well is drilled perpendicular to the minimum horizontal stress, creating a longitudinal fracture (Sprague, 2015).

Hydraulic fracturing uses a combination of water and chemical, others include sand, in retrieving oil and gas deposited in the shale rock (EIA as cited in Sprague, 2015), On the other hand, longitudinal fractured wells are enormously effective in high permeability reservoirs, but in Marcellus shale reservoirs, engineers use transverse fractured horizontal well for productivity instead of longitudinal fractured horizontal well (Kharabah, 2014)

. At a depth of 1,000 to 4,000 feet, steel casings are pushed to the bottom of the shale to prevent water from mixing with the oil or gas. The casing and the wellbore are separated with cement. When everything is in place, drilling proceeds until it reaches 6,000 to 10,000 feet where the oil and gas can be extracted from the shale reservoir (The Groundwater Protection Council as cited in Sprague, 2013).

Economic Benefits

After recovery, natural gas requires fewer processing steps before it is consumer ready. Eighty percent of natural gas used in America is produced domestically; but the country imports over 50% of its needed oil from other countries (American Gas Association as cited in Stoekl, 2012). Oil will be cheap because of the law of supply and demand, coupled with more unconventional oil and gas recovery. This is not to mention the increased oil production (Stoekl, 2012).

Unconventional energy transforms local energies in the U.S., providing jobs and leveling oil prices for the common American consumers (Stoekl, 2012). There has been an annual increase of U.S. GDP since 2012 due to midstream and upstream operations (IHS, 2013). The sector has provided 2.1 million jobs to Americans and expatriates, with 377,000 of the jobs coming from midstream and downstream operations (IHS, 2013). Upstream activity also contributed trillions of dollars to government revenue. U.S. net trade from unconventional energy will reach $22 billion and it will be at a higher level in 2022. States which do not have major unconventional energy activity can provide at least 500,000 laborers through diverse energy-related businesses (IHS, 2013).

Yergin, IHS executive, says that the unconventional energy revolution has created impact in the entire United States, including those states which are not involved in oil production, with the largest economic contribution provided by Texas and Pennsylvania. However, New York and Illinois have assumed roles of producing goods and services relevant to the supply chain. The unconventional energy producing states have contributed approximately 1.3 million jobs (IHS, 2013). John Larson, IHS vice president, indicated that the UOG revolution will have a wider impact on the US economy.

Energy-intensive firms using chemicals, including the food sector, are putting a portion of their capital for energy operations due to decreased domestic prices. It has been forecasted that energy-intensive sub-sectors, particularly those involved in iron and steel production, chemicals like resin and synthetics, including those used in agriculture, will surpass the entire US industrial economy (IHS, 2013).

The chemical industry is one of the greatest beneficiaries of the shale gas boom. U.S.-based chemical companies use natural gas-based feedstocks such as ethane to produce raw materials for a wide range of products including plastics, films, and adhesives (Huh, 2013). It is projected that after 2030 the chemical industry would become the fastest growing industry. Additionally, there has been a dramatic increase in U.S. chemical exports recently, and this is correlated with increasing oil-to-gas ratio.

Environmental Impact

Since natural gas burns cleaner than other fossil fuels, many companies and municipalities are deploying fleets of natural gas-powered cars, trucks and buses in attempt to reduce emissions. Clean Energy Fuels Corporation in the U.S. is rapidly developing a coast-to-coast network of compressed natural gas (CNG) filling stations. An 18-wheeler running on CNG can haul cargo to nearly every major city across the U.S. (Huh, 2013).

However, there are environmental ramifications in the UOG exploration and recovery. While unconventional energy is mostly organic, it can still have environmental impact, particularly in the drilling and recovery activities. Compared with wind and solar energy, which do not need the long process of extraction, unconventional energy extraction affects the ecosystem. The presence of multiple stressors has a negative environmental effect. Unconventional energy development has been criticized as an environmental stressor as it could affect stream sedimentation and the aquatic ecosystem around UOG development (Entrekin et al., 2015).

Entrekin et al. (2015) argue that unconventional energy exploration and recovery from shale rock can negatively affect rivers and streams through water withdrawals, land changes, and other changes in the ecosystem. However, they also indicate that the extent of environmental damage, such as the negative impact on the stream ecosystem, is still unknown. As described earlier, shale is mud that transforms into rock through geological circumstance; shale holds a large reservoir of oil and gas, believed to be present in 41 countries around the world, holding as much as 7,299 trillion cubic feet of natural gas and hundreds of billions of barrels of oil (US DOE/EIA as cited in Entrekin et al., 2015).

Activities like infrastructure installations, drilling and fracturing, water use and waste management can disturb aquatic communities and provide ecological impact. Infrastructure activities include construction of roads and bridges, pipelines, which can affect underlying communities and small-scale farming. Water flows which sustain natural habitats will be altered (Entrekin et al., 2015). There is also the fear of environmental accident that might cause chemical contamination or leaking wastewater storage systems, liquid-truck or train accidents, pipeline leakages, and so forth. Lack of empirical studies on the environmental impact of UOG has exacerbated fears of environmental groups, especially since UOG development has been remarkably fast due to the increased demand of oil and gas.

At present, there are five shale plays in the United States which supply as much as 80 percent of shale gas in the country. Notable among these shale plays is the Appalachian basin and the Williston basin, but development in other areas is rapidly increasing, such as those in Pennsylvania and West Virginia. UOG extraction in New York and the Delaware River Basin has been placed on hold due to suggestion by some groups that more research should first be conducted (Entrekin et al., 2015).

In measuring the environmental effects of human activities, researchers used the vulnerability metric or threat index, which focuses on agriculture, urbanization, and mining. Vulnerability refers to exposure of the ecosystem to environmental stressors, which can be anthropogenic, construction of roads, bridges and other infrastructure, and the natural sensitivity of the ecosystem. Ecosystems are considered most vulnerable if they have “the most natural sensitivity and exposure to natural stressors” (Entrekin et al., 2015).

Conclusion

The US economy can gain much from refining of crude oil and natural gas liquids production. Rich gas has to be transported to processing plans, be “cleaned” of residue, transported to the NGL fractionator, and then sold to refiners or retailers. The process adds value to the product and creates more economic activity (IHS, 2013).

In addition to the industries that directly take in natural gas as their feedstocks or as fuels to generate electricity, there are those that will benefit from low cost of natural gas. Many energy-intensive industries such as aluminum, steel, glass, cement, etc. are gaining global competitiveness from a significant reduction in operating costs due to cheap energy. Similarly, residential and commercial customers will benefit from lower costs of power, heating and fuel. Savings from lower gas prices will amount to $926 annually in disposable household income, and these savings would increase to nearly $2,000 per household (Huh, 2013).

This will most likely stimulate consumption, and the effects could be similar to a sizable tax or interest rate cut. Nonetheless, little growth in terms of natural gas demand is expected to come directly from the residential and commercial sectors; some conversions from oil heating to gas are underway in the Northeast, but as the population shifts to warmer regions where electricity dominates the space heating market, it is likely that less gas will be used for heating and more gas will be used to generate electricity for space heating and air conditioning. Some heating-related gas demand shows up as power sector demand for gas (Huh, 2013).

Despite the economic benefits, the U.S. should consider the environmental impact and conduct more empirical studies on the relationship of UOG and the aquatic ecology.

Entrekin et al. (2015) have noted that there is a relatively small but increasing literature exposing the relationship between UOG extraction and recovery and “the ecology of aquatic ecosystems” (p. 3-28). The geological shape, soil composition, and vegetation can change water, sedimentation, and the movement around the ecological system in areas where there is UOG development. As a whole, the natural environmental conditions, along with prevailing stressors, will certainly affect aquatic communities around these man-made activities.

References

Entrekin, S., Maloney, K., Kapo, K., Walters, A., Evans-White, M., & Klemow, K. (2015). Stream vulnerability to widespread and emergent stressors: A focus on unconventional oil and gas. Plos One, 10(9), 1-28. Web.

Hausman, C., & Kellogg, R. (2015). Welfare and distributional implications of shale gas. Brookings Papers on Economic Activity, 1(1), 1-45. Web.

Huh, H. (2013). Sustainable development of shale gas and gas-to-propylene (Master of Engineering thesis, Albert Nerken School of Engineering, New York). Web.

IHS: America’s new energy future: The unconventional oil and gas revolution and the US economy. (2013). Web.

Jemielita, T., Gerton, G., Neidell, M., Chillrud, S., Yan, B., Stute, M.,…Panettieri, R. (2015). Unconventional gas and oil drilling is associated with increased hospital utilization rates. Plos One, 10(7). Web.

Kharabah, A. (2014). Estimating ultimate gas recovery from unconventional gas reservoir (Doctoral thesis, West Virginia University, Virginia). Web.

Song, X., Yang, F., Zhen, H., & Li, X. (2014). Synergistic analysis and correlative study on remote sensing and chemical exploration data for oil-gas exploration. International Journal for Remote Sensing, 25(21), 4675-4684. Web.

Sprague, C. (2015). The nexus of farming and energy: Navigating social tensions at the intersection of sustainable agriculture and unconventional oil and gas drilling (Master of Arts thesis, Colorado State University). Web.

Stoekl, A. (2012). Unconventional oil and the gift of the undulating peak. Imaginations Journal, 3(2), 35-45. Web.