The objective (or purpose) of the experiment

One of the leading over-the-counter drugs with the highest sales is aspirin. The drug is commonly referred as acetylsalicylic acid. As such, the medication was widely used in relieving pain, fevers, managing swellings. Currently, more than 19 million pounds of the drugs are retailed yearly in the USA. The drug is synthesized from salicylic acid. The acid is initially made from salicin. The above compound is majorly obtained from the bark a willow tree. The tree’s extracts have been exploited for centuries. As such, the use of its aqueous extracts to manage fever and aching was first testified in late 18th century in Europe. In the middle 19th century, salicylic acid was extracted a willow bark. The extracts were found to be a powerful analgesic and antipyretic products. The drug progressively hydrolyses when exposed to water or salicylic acids.

Analgesic tablets usually comprise of aspirin, acetanilide, and sucrose. The mixture of these components is said to be used in managing migraine headaches. Acid-base extraction isolates these compounds since they have dissimilar acidities. The experiment sought to separate the different components of a VCU analgesic drug named Phensuprin. The product comprised of aspirin, acetanilide, and sucrose. Aspirin acts as an analgesic element. Acetanilide also serves as an alternative analgesic product. On the other hand, sucrose is used as fillers. In the experiment, these components were isolated based on the dissimilar solubility and reactivity of each respective constituent. After that, the quantity of each component in the mixture was determined. The melting point of each compound illustrated its purity. The key objectives of conducting the experiment are indicated below:

- To understand the technique of acid-base extraction

- To isolate aspirin from acetaminophen using the extraction technique

- To understand the process of drying organic solvents and vacuum filtration

- To investigate the purity of the aspirin and acetaminophen samples using HPLC exploration

The structures (pictures), hazards, and physical properties of all reactants and products

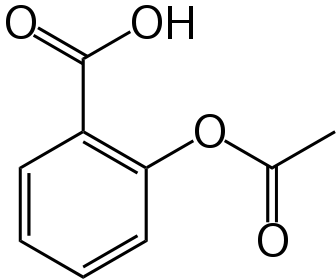

Aspirin is a white crystal-like and a feebly acidic substance. It exhibits a melting point of 136°C and a boiling point of 140°C. The compound has a molar mass of 180.157 g/mol. The product should be used under the direction of a physician because of its adverse effects. The drug causes gastrointestinal bleeding in patients allergic to aspirin. Similarly, the drug can induce swelling of the skin tissues in some people. Indicated below is the chemical structure of aspirin:

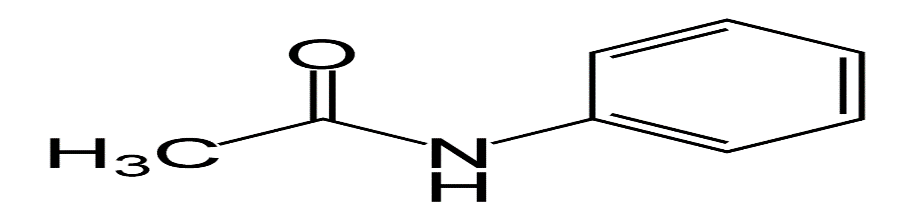

Acetanilide is derived from aniline. As such, the substance is white to gray solid in color. The component has a molar mass of 135.17 g/mol. It has a melting point of 237.7°F or 114.3°C. Signs of exposure to this material may comprise of contact dermatitis, cyanosis, and eczematous skin flare-ups. Notably, the substance is an irritant. It releases poisonous vapors when heated to decomposition. Indicated below is the chemical structure of acetanilide:

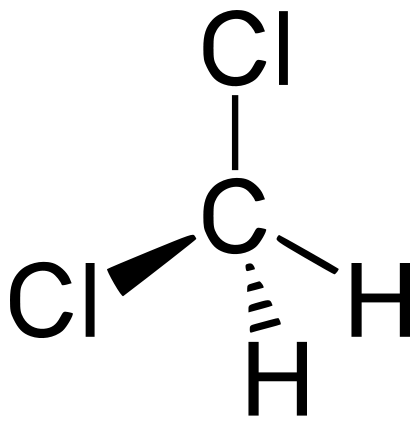

Dichloromethane is commonly known as methylene chloride. The product is an organic compound. The component has a molar mass of 84.93 g/mol and a boiling point of 103.3°F or 39.6°C. Its density is 1.33 g/cm³. It is widely utilized as a solvent. As such, the compound does not mix with water. However, it dissolves in organic solvents. The substance is synthesized by mixing chloromethane or methane compounds with CL gas. The synthesis is undertaken at a temperature of 400°C to 500 °C. Under these temperatures, the two compounds go through a sequence of reactions gradually generating extra-chlorinated products. Dichloromethane is the least poisonous of the basic chloro-hydrocarbons. However, the product is not void of health hazards. As such, its high explosiveness makes it a severe inhalation threat. Signs of acute exposure to DCM through inhalation are concentration difficulties, vertigo, exhaustion, vomiting, headaches, impassiveness, paleness, and irritation eyes, and breathing tract. Additional serious consequences may comprise of asphyxia, loss of cognizance, and death. Indicated below is the chemical structure of dichloromethane:

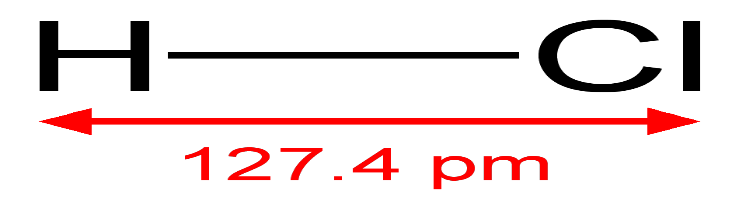

Hydrochloric acid is a strong, pale, and very sharp-tasting solution. The solution comprises of a mixture of HCL and water. It is a very acidic strong mineral solution with a molar mass of 36.46 g/mol. Its boiling point is 108.6 °C (227 °F). Similarly, it has a density of 1.017 g/mL. Under high concentrations, HCL acid forms acidic vapors. In liquid and vapor forms, the product exhibits a scarring effect on body tissues. It has the possibility to impair respiratory organs, eyes, skin, and bowels permanently. Indicated below is the chemical structure of dichloromethane:

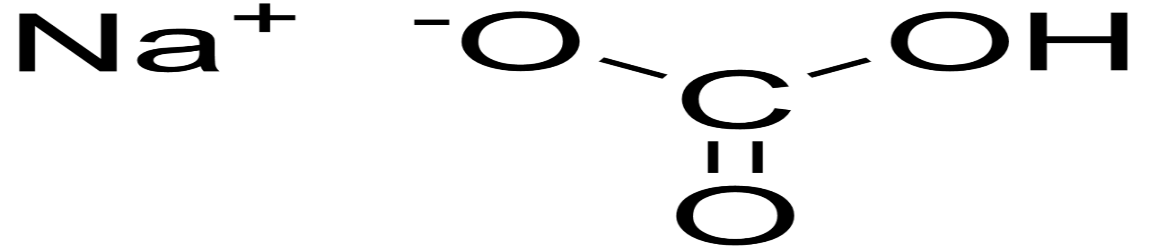

Sodium bicarbonate is an inorganic compound represented using the formula NaHCO3. The compound is a snowy solid, which is crystal-like but regularly looks like a fine powder. It has a melting point of 122°F (50°C). Its molar mass is 84.007 g/mol. The chemical structure of sodium bicarbonate is illustrated below:

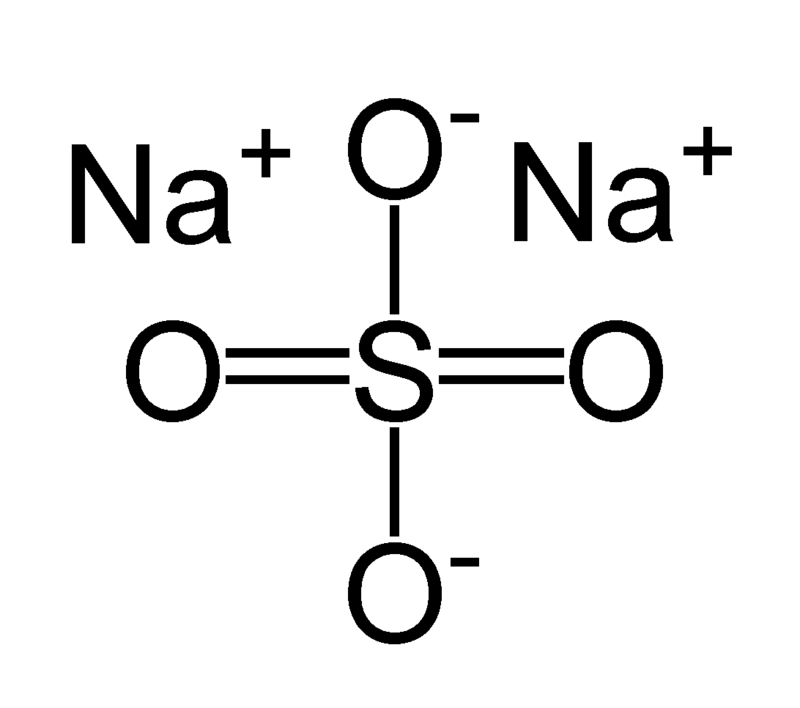

Another reactant used in the experiment is sodium sulfate. The salt is synthesized from sulfuric acid. The salt is chemically stable with a molar mass of 142.04 g/mol. Its melting point is 1,623°F (884°C). Even though the salt is usually considered as non-toxic, students should handle the chemicals with care. As such, the salt can trigger impermanent asthma or cause eye itching. Thus, protective gear like latex gloves, eye spectacles, and chemical-resistant attire should be worn to reduce the threats when handling sodium sulfate.

The entire procedure, as performed in lab

Phensuprin sample of 2.0 grams was correctly weighed and poured in into a 125 ml Erlenmeyer flask with the capacity of 125 milliliters. 50.0 ml of dichloromethane of 50ml was added and briskly stirred. The solution was shaken up until no additional solid appeared to dissolve. During the stirring process, care was taken to ensure that no clumps of solid were fragmented. Later, a piece of paper was weighed and fluted. The concoction was filtered through the pre-weighed filter paper. The filtered solid was then mixed with 5.0 ml of dichloromethane. After that, the filter paper enclosing the collected sucrose was placed in a beaker to dry for seven days. When the filter paper and the sugars are completely dry, they were weighed. After that, the amounts of sugars recovered were calculated. The results were reported as mass and percentages with respect to the total weight of Phensuprin.

To separate aspirin a filtrate was added. The filtrate comprised of the dichloromethane solution. The mixture was extracted using a separatory funnel and sodium bicarbonate solutions. To achieve this, a portion of sodium bicarbonate solution was added into the funnel comprising of the dichloromethane solution. Thereafter, the funnel was stoppered. A finger was placed over the stopper to keep it in position while shaking the funnel gradually for 3 minutes. Every few seconds, the funnel was overturned as its stopcock was opened to discharge the pressure. While doing so, care was taken to enhance safety. As such, the tip of the funnel was faced away from the students before pressure was freed. Afterward, the stopcock was closed and the funnel shaken continuously. After the extraction period expired, the pressure was released before the stopcock was shut, and the funnel positioned in a clamp.

After that, the stopper was isolated. Immediately the deposits get detached, the lower layer comprising of dichloromethane were drained into a 125.0 ml Erlenmeyer flask. Subsequent to the removal of the dichloromethane layer, the stopcock was shut. Then, the aqueous layer was poured out of the funnel into a 400.0 ml beaker. Afterward, the dichloromethane layer was returned into the funnel and the process reiterated using the second ration of sodium bicarbonate solution. Later, the two aqueous deposits were combined before the dichloromethane cover was saved for the last stage.

The two aqueous coatings were then cooled in an ice immersion. With the help of transfer pipet, 10.0 ml of concentrated HCL were gently added while stirring. At this stage, foaming was expected. The beaker was swirled amid the hydrochloric acid additions. After the addition process had been done, the PH levels of the solution were evaluated and recorded. The process was conducted by introducing a glass bar into the solution. The solution at the end of the glass was placed on a portion of the PH paper. When the PH level was above 2, small amounts of HCL were added into the solution up until the levels dropped below 2. The solution was further cooled in ice immersion up to the time the solid acetylsalicylic acids were formed. The solid particles were collected using vacuum filtration process. After that, the filtrate was collected using 5.0 ml of cold water. To totally dry the solid, the vacuum was kept running for numerous minutes after the filtration process was finished. Later, the collected solid was moved to an un-capped taster vessel to dry for a week. After the solid had dried, the mass of acetylsalicylic acid recuperated was recorded in terms of the Phensuprin components.

To conclude, the residual organic mixture was dried over anhydrous sodium sulfate. A portion of the anhydrous sodium sulfate was poured into a solution of methylene chloride and swirled. During the process, the hydrating agents clamped together. Sodium sulfates were introduced in small percentages until a portion of dehydrating agents flowed freely. Later, the mixture was swirled for some minutes before being sieved into a sterilized and dry round bottom 100.ml container. Afterward, the methylene chloride was evaporated using a rotating evaporator. Evaporation process was undertaken until all the solvent had been eliminated. Acetanilide constituent was left behind as solid particles. The residues were saved in the un-stoppered plump-bottomed container for the subsequent lab period. In the next lab, all the solids had dried. The solids were evaluated. The amounts of each component recuperated were evaluated. The results were reported with respect to the mass and percentage of the entire weight of the Phensuprin. The melting point of every constituent was recorded and matched with the standard figures to assess the purity of every component of the compound,

Calculation of percent composition of all three compounds in the mixture

After the product had been thoroughly dried sufficiently, the percentage composition was evaluated. Theoretically, 100% of each constituent should be recovered. However, the above case is not possible during the practical. To assess the success of the recovery process, the percentage yield is estimated as follows:

Percent recovery = (actual recovery (g)/ theoretical recovery (g)) x 100 Percentage composition of sucrose = 0.77/1.34 x 100=57.46%

Percentage composition of acetylsalicylic acid=0.17/1.34 x 100= 12.69%

Percentage composition of acetanilide =0.40/1.34 x 100= 29.85%

A short synopsis of the results obtained

The initial step of the experiment comprised of separation. As such, it was noted that sucrose dissolved easily in water. acetylsalicylic acid and acetanilide did no dissolve easily. Nevertheless, the two components were soluble in dichloromethane whereas sucrose is insoluble in the solution. Initially, Phensuprin was mixed with dichloromethane. After that, sucrose was isolated through a filtration process. Next, the dichloromethane was removed using sodium bicarbonate. The acetylsalicylic solution is an acidic paste. On the other hand, sodium bicarbonate is a basic solution. The two products react to form salt. The salt dissolves in water. Notably, acetanilide is unaffected by the sodium bicarbonate solution. Thus, the component remained liquefied in the dichloromethane. Because water and dichloromethane do not mix, the deposits can be isolated with ease to get two different analgesic components. The acetylsalicylic acid was then recovered by transforming the salt back to its original form using concentrated HCL solution. The calculations obtained are indicated in below:

Weight of filter paper =0.91 g

Weight of filter paper + sucrose =1.68 g

Weight of recovered sucrose = 1.68- 0.91 = 0.77 g

Weight of filter paper + acetylsalicylic acid = 1.08 g

Weight of recovered acetylsalicylic acid = 1.08 – 0.91 = 0.17 g

Weight of round bottom flask (100ml) = 59.08 g

Weight of round bottom flask (100ml) +acetanilide = 59.48 g

Weight of acetanilide recovered =59.48 – 59.08 = 0. 40 g

Total weight of all the three compounds = 0.77 + 0.17 + 0.40 = 1.34 g

Starting Phensuprin mass was 2.0 g

Total percent recovery from Phensuprin = (1.34/2.0) x 100 = 67%

Percentage composition of sucrose =57.46%

Percentage composition of acetylsalicylic acid = 12.69%

Percentage composition of acetanilide =29.85%

Melting point of sucrose = 366.8°F (186°C)

Boiling point of acetylsalicylic acid = 284°F (140°C)

Melting point of acetanilide = 237.7°F (114.3°C)

A short discussion of the results and outcome of the experiment

The experiment above isolated the different constituents of Phensuprin. The products separated were aspirin, acetanilide, and sucrose. Aspirin acts analgesic element. The above components were isolated based on the dissimilar solubility and reactivity of each respective constituent. After that, the quantity of each component in the mixture was determined. Through the above experiment, students were able to learn the process utilized in acid-base extraction, isolate aspirin from acetaminophen using the procedure. The students were also able to learn the process of drying organic solvents and vacuum filtration. The students obtained the percentage of sucrose, acetylsalicylic acid, and acetanilide as 57.46%, 12.69%, and 29.85%. When added the above percentages total up to 100%, which is indicated in the works of literature. The above imply that the experiment was successful because it attained its objectives.

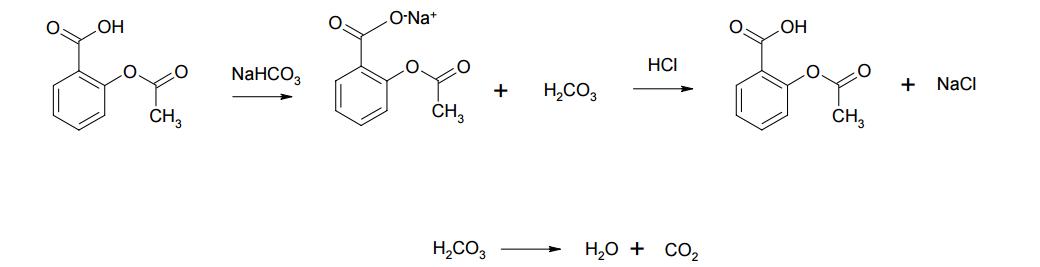

To begin with, Phensuprin was mixed with dichloromethane. Afterward, sucrose was isolated through a filtration process. Then, the dichloromethane was removed using sodium bicarbonate. The acetylsalicylic solution is an acidic paste, while sodium bicarbonate is a basic solution. The two products react to form salt. The chemical reaction is indicated below:

When HCL is mixed with oxidizing agents like sodium hypochlorite or potassium permanganate, chlorine gas is emitted as indicated in the equations below. The gas is very poisonous. Therefore, measures should be taken to prevent inhalation. Therefore, protective gear like latex gloves, eye spectacles, and chemical-resistant attire should be worn to reduce the threats when using hydrochloric acid.

NaClO + 2 HCl → H2O + NaCl + Cl2

2 KMnO4 + 16 HCl → 2 MnCl2 + 8 H2O + 2 KCl + 5 Cl2

PbO2 + 4 HCl → 2 H2O + PbCl2 + Cl2

In the experiment, sodium sulfate was used as an inert dehydrating agent. At higher temperatures, it can be reverted into sodium sulfide through carbothermal process as shown below:

Na2SO4 + 2 C → Na2S + 2 CO2

When NaHCO3 reacted with HCL a salt and a carbonic acid is released. The component has no physical hazard. The carbonic acid quickly disintegrates into water and CO2 as indicated below:

NaHCO3 + HCl → NaCl + H2CO3

H2CO3 → H2O + CO2 (g)

The major errors experienced in the demonstration include human errors and calibration errors. They comprised of taking incorrect measurements, accidentally contaminating reactants with other substances, and using contaminated instruments. Apparatus limitations were also identified as the major sources errors. For instance, the weighing tool utilized in the experiment was calibrated to two decimal places. It could have been better if the tool had been calibrated to three decimal places or more. Taking measurements during demonstrations were also identified as the potential causes of observation errors. For example, when a thermometer was inserted into hot solutions a slight drop in temperature was expected. Though the decrease in temperature is likely to be minor, the fall is nonetheless the impact of an observation fault.

Answer the following questions

- The original organic solution was extracted two times with aqueous sodium bicarbonate. After the extraction, what compound(s) were in the organic layer? What compound(s) were in the aqueous layer?

After treatment with NaHCO3, acetanilide remained in the organic layer, while acetylsalicylic acid transferred to the aqueous layer - Assume that both acetylsalicylic acid and acetanilide are soluble in diethyl ether, and that diethyl ether was used in place of the methylene chloride. Would the ether layer be the bottom layer in the separatory funnel or the top layer? Explain your answer.

It will be the top layer because diethyl ether is less dense than H2O - Assume that both acetylsalicylic acid and acetanilide are soluble in methanol, and that methanol was used in place of the methylene chloride. What problem(s) might occur during the extractions? (Careful, this is a trick question.)

Methanol will mix with water affecting the experiment process - Historically, the solid residue that is left after the methylene chloride solution is evaporated has a lower melting point that its literature value, due to impurities. Explain what impurities are present and why.

The leftovers will comprise of acetylsalicylic acid since extraction is not appropriate method of purifying mixtures of organic products.

References

Gilbert, John. Experimental Organic Chemistry. Fort Worth: Harcourt College Publishers, 2002. Print.

Kislik, Vladimir. Burlington: Elsevier Science, 2011. Print.

Lilley, Linda. Study Guide For Pharmacology And The Nursing Process. London: Elsevier Health Sciences, 2013. Print.

Mitra, Sam. Sample Preparation Techniques In Analytical Chemistry. Hoboken, N.J.: J. Wiley, 2003. Print.

Wilbraham, Antony C. Prentice Hall Chemistry. Boston, MA: Pearson Prentice Hall, 2008. Print.

Williamson, Kenneth. Macroscale and Microscale Organic Experiments. Belmont, CA: Brooks/Cole, 2011. Print.