Workflow at Shuzworld (Discussion and Recommendations)

Shuzworld’s case embraces the aspects of workflow. This section of the paper discusses the workflow provisions and provides appropriate recommendations applicable in this context.

This will ensure credible workflow augmentation in the Shuzworld Company with specific reference to Chinese plants. For example, the workflow in the production system is not efficient enough to serve growing demands for several types of shoes globally.

It is notable that the company takes nearly 46 minutes to produce one Rugged Wear Workboots product. There are recommendation on how this timeframe can be reduced (per process) to ensure efficiency, quality, and enhanced output.

Workflow recommendations and Justifications

Firstly, it is recommendable for the company to use sound management principles and decision analysis in order to make sense of the available options. Although it is impossible to merge some of the processes due to protocol disparities, it is recommendable to restructure the production line as Catherine Pang drew it on the white board.

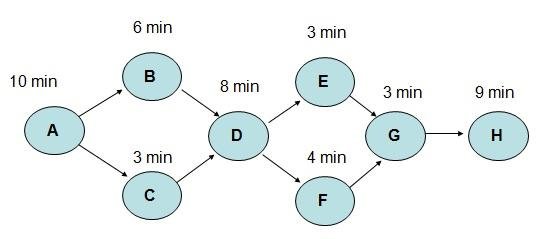

The company will save time and money as demanded by any proficient workflow. This is a critical provision when considered critically. It is notable that the workflow can either proceed to B or C after passing through process A.

Process E and F can also be selected for viability and time factor. Supportively, Shuzworld should use process ACDEGH, which will consume only 36 minutes instead of the current 46 minutes. Thus, it is appropriate to assert that the company should restructure its production line/processes as shown the subsequent output forms.

Another recommendation is that the company can increase the number of its workstations within china in order to curb the workflow challenges. Additionally, it can purchase more machines that will be able to handle numerous tasks simultaneously.

Relying on fewer machines might distract the production system especially when one machine breaks down. Another recommendation is for the company to hire proficient and reliable workforce capable of operating the machines faster and accurately.

This will help in enhancing the workflow and other related concerns. Additionally, Shuzworld ought to improve the efficiency of its plants by enhancing competence and providing the correct number of workstations.

The company should also schedule the production of new products coherently in order to enhance the workflow. It is also important to enhance the reliability of the three machines meant to produce casual deck shoes. One production process should not interfere with others.

Notably, the company has been grappling with the reliability of machines. If one machine breaks down, the production is highly affected. Indeed, no shoes are produced if one machine has a problem. Therefore, there is the need for the company to improve the reliability of the machines in the plant by acquiring other reliable ones.

These should be put on standby waiting to replace the broken ones. This will obviously enhance operations and the ultimate output of the concerned operators.

Alternatively, the company can hire new employees, train them appropriately, and nurture their workmanship in order to enhance the workflow, productivity, and profitability of the company. This decision will reduce delays, lower labor costs and improved output.

With regard to frequent machine breakdowns, the company can acquire new machine models or hire qualified machine repairers then distribute them to different plants for reliability and efficiency. Another recommendation is to assign operators on jobs they know best.

Instead of having four operators, whose labor costs shift from one process to another, the company can facilitate the specialization of employees on single jobs. For instance, job machine operator C ought to handle process 1 owing to reduced amounts of costs.

Indeed, the company can save at least $3 dollars in this process. Second, Machine operator B ought to handle process 2 due to the cost efficiency as well. Process 3 should be the work machine operator D while the last process should be the work of operator A.

Justification Output

By improving the company’s workflow, the company will increase its output. At the outset, there will be an apparent and a marginal reduction of labor costs ($4) associated with machine operators. Besides, specialization improves the quality and the flow of work due to the improved skills for the specialists as depicted by Ryan (2009).

Second, the company will also enhance its ability to meet its customers’ needs without having by increasing its machines and hiring some skilled professionals. Although the company will incur significant costs by hiring more laborers to handle the new sandal line, it will break even within the second month of operation. Therefore, no customers will be waiting in the line. Below is the output form after the required changes.

Copy of the prospected output

Output for machine operators

Work Flow Analysis Tool

The Shuzwolrd case demand a viable workflow analysis tool, which addresses all the issues fronted to the new employee ranging from the assembly line issues to inventory challenges. The decision analysis tool was chosen because it was comprehensive and could tackle all the issue that faces the company.

Additionally, it could give quick and well-analyzed resolutions to the issue faced within the company and the industry at large. Concurrently, the tool could be used specifically in some areas to address particular issues raised by Cynthia Crowninshield, Alistair Wu, Catherine Pang, and Gloria Rodriguez among others.

For example, when analyzing the mall store sales, the tool can prefers on employing one efficient cashier for cost effectiveness. Another reason behind this choice is the ability to attain precise decisions on critical matters.

It is important to claim that the analysis tool used in scrutinizing the mentioned workflow and other relevant provision is viable, feasible, and applicable in various contexts. It is from this concern that the entire workflow concerns rest.

Precisely, the tool used is practicable, considerable and comprehensible indicating its applicability in this context. This is an important consideration.

Cost Analysis

Analysis of the initial and ongoing costs

The entire costs that the company incurs include the costs associated with inefficiencies evident in highlighted workflow analysis ranging from assembly line issues to transportation factors among other provisions. The Maui Sandal Project presents the company with a huge opportunity to improve its global appeal and ultimately its revenues.

The production costs of women’s shoes are quite varying. This depends on the four machine operators with regard to which job type each one of them assumes (Fischer, 2008). It is important to assign each operator on a job, which he does best. This will help in reducing the costs indicated upon analysis.

Additionally, the transportation costs assumed by each plant while serving each of the three warehouses vary considerably. It is notable from analysis that the cost incurred by Shuzworld F (on a per unit basis) is higher when shipping products to warehouse 3 ($6 per unit). Nonetheless, it is cheaper to move from Shuzworld F to warehouse 1 ($2 per unit).

Concurrently, the Shanghai plant incurs a considerable cost when transporting products to warehouse 1 ($4 per unit). It is crucial to note that the three plants can reassign their operations such that each plant ships its products to less costly destinations.

Additionally, the plan by the Shanghai plant to increase its capacity from 1300 units to 2800 units translates to additional costs despite the benefits. Nonetheless, demand for more products has not increased as stated by Alistair Wu.

The inventory costs are equally infuriating. Shuzworld utilizes 300,000 pairs of shoelaces annually. The cost is estimated at $125 each time an order is made to the supplier. Since the cost of storing shoelaces in inventory is 10 cents a pair, it is improper to stock or purchase more than necessary. This is costly for no apparent reasons.

The company will also have to incur set up costs since the batches of sandals will have to begin after setting up the machines. Besides, the costs of designing the efficient processes that will oversee the production of singular units notwithstanding the pairs of sandals that is in a batch (Sharp & McDermott, 2011).

The costs in this case are able to enhance sustainability of the sandals. It is also important to notice that the company may also have to incur overhead costs associated with acquisition or maintenance of machines.

These are output related costs since the efficiency of machines changes with the number of sandals that they produce. Finally, the company also ought to contend with costs associated with management of the plant, renting the plant and insuring the plant against various risks. These costs aim at sustaining the plant to enhance predictable and sustainable production of sandals.

Impacts

The impacts of the above costs are numerous and devastating to the wellbeing of the business. Huge costs reduce profitability and expansion of the company. The production of new Maui sandals is costly and this might affect the continuity of its production.

It is important to consider this provision in a critical context. Pang clears her throat and then begins. Based on the experience of the company with previous new lines of footwear, it is estimated that first batch will take 1,000 labor hours to produce.

Concurrently, the costs on an hourly rate average US$1.08. This is quite expensive and might affect the company negatively if the prospected sales are not realized. Based on the above analysis of the cost that could accrue the company, certain decisions will prove important before embarking on a fully-fledged production of Maui Sandals.

Its impacts are devastating to the company despite the prospected benefits. All these should be informed by existence of demand for Maui Sandals. Besides, the company will have to invest on more machines, warehousing facilities, and shipping requirements.

These are additional costs to the company that operates against the production of the new product lines. Additionally, it will force the company to enhance its marketing strategies (hence impact on costs) without which, competitors will dominate the footwear market despite the expenses that Shuzworld will incur.

Cost Analysis Tool

The choice for the cost analysis tool used in this context lied on its viability with regard to this case study. Firstly, the current challenges facing the company call for viable, stringent, and prospective decisions in the Shuzworld context.

The tool is capable of addressing the assembly line issues, production challenges, soaring operational costs, reliability challenges, inventory challenges, customer service standards, and other viable organizational provisions. Since the company battles issues related to costs in the realms of machine operators, turnaround times, inventory challenges with regard to shoe laces, and shipping costs to the three operational warehouses, the analysis tool is obviously appropriate in this context.

There are numerous provisions emerging from the cost analysis of Shuzworld. These provisions have necessitated the use of appropriate analytical tools as indicated before. The reasons lie on the applicability, appropriateness, and relevancy of the method used to the aspects of modernity and precision.

Staffing Plan Recommendation

Staffing Plan for Job Machine Operators

Apparently, there is the need to have a staffing plan for job machine operators and the four assignments given to the new employee in the Strategic Planning department. This is in lieu of the truth that there is the requirement of skilled operators to meet the demand for women shoes.

Currently, the four operators complete same task at different times. It is therefore possible to staff the plant to have uniform and predictable completion time and task (Sharp & McDermott, 2011). Gruber (2003) explicates that finding the accurate number of staff can assist an organization to avoid unnecessary overhead expenses.

Hiring so many workers may prove unfruitful and cost ineffective while too few laborers may become unproductive due to stress and overwork. To strike a balance, a staffing plan is important especially in Shanghai where the line manager attests that it would cost reduced amount of money if specialization were to take place.

First, it is advisable to comprehend the current workforce’s productivity. This will entail keeping the right records of all the machine operators and understand the most productive. Besides, the company should be ready and willing to develop plans to train the workers.

Friedman (2005) says that this will go a long way in ensuring that the manager is able to identify the bottlenecks of the entire footwear production system. Using the available statistics regarding the workers ability to fulfill specific task will help the line manager to get a glimpse of the average output of the workers.

At Shanghai, the average number of footwear produced by worker should assist the manager to understand the entire work. Another factor that could influence the number of machine operators is the peak and low seasons. In particular, when the numbers of women footwear that require particular skills is high and when it is low.

Given that the manager now understands the average output of workers, the next stop would be to calculate the requirements of labor and the exact number of workers that would cater for the needs of the customers during both the low and peak season (Sharp & McDermott, 2011). In this case, it is important to retain those workers whose productivity is unquestionable.

This assists the company to avoid overhead costs that result from training new employees. At this point, Shanghai plant should not consider increasing the number of machine operators since the current customers are very few for the company to hire more laborers.

In case of a boom in the number of orders, it is advisable that the company should be able to contract new workers to deal with temporary increase of demand for footwear (Sharp & McDermott, 2011).

The recommendations applicable in this context regard the four machine operators and the four assignments given to the new employee in the Strategic Planning department. Firstly, for the company to enhance its output and efficiency, machine operator who work faster at a limited cost for a given job task should be allowed to only specialize in such tasks.

For example, operator A can specialize in job 3 where he is efficient, operator B can go for job 2 while operator C and D can either go for job 1 or 4 as indicated on the table. Another recommendation is that the company should hire proficient machine operators to save time and cost.

Additionally, new and efficient machines should be bought or some complex jobs can be outsourced. It is important for the plant to increase the efficiency of the workers within the plant. This will enhance the reduction of already many processes in the production of such products as the new sandal line.

Besides, the plant ought to consider recruiting new laborers in the long-term to assist in the maintenance of machines as well as production of specific lines of production. The assembly lines should be adequately and appropriately staffed in order to enhance efficiency within the plants. Appropriateness will also help in meeting the inventory challenges noticed within the organization.

Staffing Plan Output

An evident output of the staffing plan is improved skills, efficiency, appropriateness, novelty, and creativity in the company. As mentioned earlier, to enhance effectiveness of the machine operators, the line manager should encourage specialization (Friedman, 2005).

After the implementation of the plan, the company should be able to save at least 256. 28 hours that had initially been lost due to inefficiencies of machine operators. In addition, Shuzworld will reduce the labor costs in the long term due to deployment of new and highly skilled labor costs.

Specialization and breaking down the tasks to suit each employee could reduce the company’s current inefficiencies. Additionally, the output of the factories will increase as indicated below. This is contrary to the initial figures. Additionally, there will be improvement on the efficiency of machine operators if the trends are changed.

Short-Term Scheduling Techniques

Scheduling techniques provides the company with the demanded coherency in its endeavors. It is important to schedule the activities of the production systems in Shuzworld. As a short-term measure, the company should adopt an activity network technique in order to recognize the full efficiency of the project.

This scheduling technique is also referred to as Project Evaluation and Review Technique (PERT) and it facilitates an organization’s ability to comprehend the bottlenecks and different sources of operational problems (Sharp & McDermott, 2011).

The technique is typical of a network of activities that a company would wish to complete given a specific timeframe. Shuzworld has myriads of activities in different plants that require to be completed under specified time. The company should therefore prioritize the activities and the order for completion of a specified task.

In addition, it should highlight the variables and risk factors that may present a challenge to the completion of a task (Monahan, 2000). When scheduling, activity network ought to be presented in a graphical way and may be an easy way for managers to pin point ineffectiveness of a system

The activity network includes diagrams consisting of circles. The circles represent the activities such production of new sandal lines and subsequent time that the product would realized (Fischer, 2008). Connecting the circles are lines that depict the tasks and are identified in accordance with their respective timeframes.

Shuzworld therefore stands to benefit from such a schedule in that; it will be able to identify the critical path in which an activity can be completed most efficiently. In other words, critical path is the longest path in the network and it implies that a problem in a specific line of production will ultimately cause a delay and an increase in the duration of critical deadline (Friedman, 2005).

This means that the project will therefore be poised to delay substantially. As such, all tasks that fall in the critical path should receive attention and be evaluated frequently to improve their effectiveness.

References

Fischer, L. (2008). Excellence in Practice: Innovation and Excellence in Workflow and Business Process Management. New York, NY: McGraw Hill Publishers.

Friedman, T. (2005). The World Is Flat: A Brief History of the Twenty-first Century. New York, NY: Straus & Giroux Press.

Gruber, W. (2003). Modeling and Transformation of Workflows with Temporal Constraints. Birmingham: IOS Press.

Monahan, G. (2000). Management Decision Making. Cambridge: Cambridge University Press.

Ryan, K. (2009). Business Process Management (BPM) Standards: A Survey. London: Emerald Group Publishing Limited.

Sharp, A. & McDermott, P. (2011). Workflow Modeling. Massachusetts, MA: Artech House Publishers.