Introduction

Solar energy remains one of the most under-exploited most yet abundant sources of energy at the disposal of humanity. This aspect often creates the notion that solar energy is a relatively new phenomenon; however, solar energy is among the energy sources that have served humankind for the longest time. As early as the 7th century B.C., people had started to concentrate the sun’s rays into beams that could light fires (Garg 10).

Over the centuries, a plethora of developments in the harnessing and use of solar energy has been witnessed all over the world. However, it was not until the 20th century that the world’s first solar powered furnace was successfully constructed. Under the guidance of Professor Félix Trombe, the world’s first solar furnace was constructed in the year 1949 in Mont Louis, Southern France (P-O Life Par.1).

This project was a revelation especially for its originator because through it, it became apparent that solar energy could be used to power large-scale furnaces that could be used for commercial purposes. About 20 years later, “Professor Félix Trombe led the construction of the world’s largest solar furnace in Odeillo, Southern France” (P-O Life Par.1).

The furnace stands as a demonstration of the potential of solar energy to the world and it remains amongst the world’s greatest projects especially in the line of solar energy exploitation. This essay focuses on the solar furnace at Font Romeu – Odeillo, France.

Solar Furnace (Font Romeu – Odeillo, France)

History

The world’s largest solar furnace was the brainchild of Professor Félix Trombe, a French engineer. In the period before its construction, several successful attempts had been made to use solar energy for electricity generation and home heating. However, the principle behind using solar energy for electricity generation is slightly different from the idea behind the operation of a solar furnace.

Attempts to use the principle behind the operation of a solar furnace date back to the 7th Century B.C. when simple magnifying glasses were used to converge sunrays into hot beams that could be used to light fires (Garg 10). It is also believed that in the 2nd century B.C. Greek Scientist, Archimedes used this same principle to ward off Roman war ships, which were on a mission to besiege Syracuse (Garg 10).

Archimedes achieved this feat by setting the ships on fire to stop them from reaching the town. This aspect makes the idea of using reflectors or mirrors to concentrate solar energy into hot beams for different purposes the oldest known use of solar energy.

Professor Trombe placed the idea under serious scrutiny in 1946 when carrying out an experiment to determine the possibility of attaining high temperatures rapidly and the effect of the high temperatures on different materials in a pure environment using an air defense mirror to converge the light from the sun into a hot beam.

In the quest to actualize this experiment under controllable circumstances where different possibilities could be tried out, Professor Trombe built the world’s first solar furnace at Mont Louis, Southern France in 1949 (P-O Life Par.1).

This project was enormous as it incorporated 1420 mirrors to form the light converging surface (P-O Life Par.1). The furnace has since undergone massive renovation to make it fit for commercial purposes it serves today.

The success of the Mont Louis furnace inspired professor Trombe to build the world’s largest solar furnace a few miles away from his initial project. The solar furnace in Odeillo was an improvement of the pioneering project that had been 20 years earlier. Since its construction, the furnace remains the largest and most important solar furnace in the world (P-O Life Par.2).

This reputation stems from the fact that even though there are numerous other such furnaces across the world, none of them is capable of producing the temperatures that the furnace at Odeillo can produce. Thus, it remains Professor Trombe’s biggest achievement as it continues to contribute immensely to the wellbeing through enabling vital experiments that cannot be conducted elsewhere.

Overview of the project

This project is located at Font Romeu- Odeillo, in the Pyrenees of Southern France. The location was chosen because it boasts of clear skies for up to 300 days in one year (P-O Life Par.5). The air quality of the region was also considered the most suitable for this kind of project within France.

It comprises a large concave mirror (formed by putting together 10,000 smaller mirrors) that is mounted on an eight-story building. The concave mirror is about 2000 square feet (P-O Life Par.4).

The light that it converges to a focal point, which is the size of a cooking pot, is supplied by 63 heliostats that are mounted on the hillside facing the concave mirror. The heliostats (flat self-adjusting mirrors that reflect light to a pre-determined target) are arranged in eight terraces to allow them to cover the entire surface of the concave mirror.

The furnace is capable of giving temperatures of up to 3500 degrees Celsius or 6330 degrees Fahrenheit (P-O Life Par.4). As a result, it is the most appropriate place for research that involves very high temperatures.

There are other similar furnaces, but the solar furnace at Odeillo remains the most illustrious among them by virtue of its size and output. However, it is important to note that like this furnace, all other solar furnaces in other parts of the world are majorly used for research experiments.

Construction of the Project

Solar energy is harnessed all over the world using a variety of technologies for different purposes. These include solar water heating, photovoltaic cells, solar space heating, and concentrated solar power among many others (Garg 213). The idea behind the operation of a solar furnace falls in the category of concentrated solar power systems. In this category, several different technologies can be employed to harness the sun’s energy.

These include parabolic troughs, power towers, dish/engine systems, and concentrated solar power (CSP) (Garg 290). Although these systems vary in design and construction, the idea behind their operation is the same. All of them use reflecting surfaces to concentrate the sun’s energy to a desired location.

These concentrated solar power systems can amplify the sun’s energy up to 5000 times its original intensity to achieve the purpose for which the particular project is designed (Hinkley et al. 1).

Solar furnaces fall in the CSP category where they employ a large parabolic reflector and a set of reflectors. In other words, the system uses sets of reflecting surfaces. The first set of reflecting surfaces collects the sun’s energy and reflects it to the parabolic reflector, which then concentrates it to a focal point that is often a small area (Hinkley et al.1).

This area is only roughly the size of a cooking pot for the world’s largest solar furnace in Odeillo, France (P-O Life Par.3). This kind of system requires strong supply of sunlight throughout the day, thus the first set of mirrors are designed to track the sun automatically at its varying positions during the day to maintain a strong supply of the sun’s energy to the parabolic reflector. These solar tracking mirrors are referred to as heliostats.

A heliostat is a device that incorporates a plane mirror(s) that keep changing position relative to sun’s position to ensure that it maintains a strong reflection of the sun’s energy to a predetermined surface (Garg 301). This goal is achieved by ensuring that the reflecting surface of the heliostat is maintained perpendicular to an imaginary line that bisects the angle between the sun and the target of the reflection (Garg 301).

The targeted surface is normally a stationary object or surface that does not follow the movement of the heliostat. In this manner, the heliostat follows the sun, but it keeps reflecting the light to a fixed position on the target regardless of the position of the sun.

Older heliostats were controlled manually by hand or by use of solar trackers or clockwork, which enabled them to self adjust in accordance with the position of the sun (Garg 301). However, the old versions cannot be compared to modern heliostats, which are computer controlled and are thus able to perform their function with utmost precision.

Since the solar furnace at Odeillo is a CSP system, it needed two sets of reflectors. A heliostat system to collect a greater amount of sun’s heat and reflect it to the concentrator and a concentrator, which serves the purpose of converging the sun’s heat to the focal point where it is used for high temperature endeavors. All the other constructions such as laboratories are supportive, but the facility can operate without them.

This furnace employs one of the two designs that are possible for solar furnaces, viz. the on-axis design and the off-axis design. Odeillo solar furnace is an on-axis design, which implies that the focal point of the parabolic mirror or concentrator stands between the heliostats and the concentrator (Hinkley et al.1).

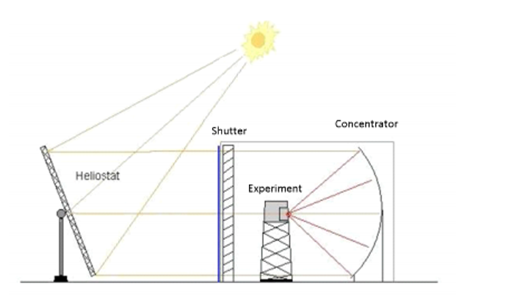

This arrangement has the disadvantage of the focal point unit blocking some of the light and heat from the heliostat. It appears as shown below.

Figure 1: On-axis design solar furnace design

Source: (Hinkley et al. 2)

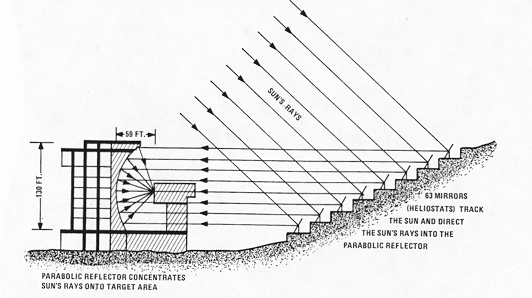

The Odeillo solar furnace employs this arrangement, but since it is a large-scale project, it comprises “63 heliostats, which are 24.6 by 19.7 feet, each” (CNRS 2). Each heliostat in turn comprises 180 mirrors each measuring 19.7 by 19.7 inches. They are arranged in eight tiers along the rising hillside that faces the parabolic reflector (CNRS 2).

Each of the heliostats has a specific point on the concentrator, which has to illuminate constantly with a strong supply of solar reflection when the furnace is in operation.

This arrangement was thought to be necessary because the parabolic reflector is too large to track the sun in order to maintain the required intensity of solar energy (CNRS 2). The arrangement of the heliostats and the parabolic reflector at Odiello furnace is as shown below.

Figure 2: Schematic diagram of Odeillo solar furnace

Source: (CNRS 3)

The parabolic reflector on the other hand is a large concave arrangement that was constructed from about 10,000 smaller mirrors measuring 17.7 inches by 17.7 inches each (CNRS 2). These give a concentrator that is 130 feet high, 175 feet wide and close to 23,000 square feet in terms of area.

It is important to point out at this point that the size of the concentrator and the numbers of heliostats employed are entirely dictated by the power requirements for the project. During the construction of the Odeillo furnace, the mirrors were “silvered and aluminized by vacuum evaporation in order to give a reflective surface that could reflect up to 90% of the sun’s energy onto a desired target” (CNRS 4).

Other materials such as silver could serve the reflection function, but it was not possible to obtain an optical surface by polishing. The choice of glass over all the other materials has proved itself a worthwhile choice because the facility remains the largest and most important because it 1000 kW capacity is unrivalled elsewhere in the world (CNRS 6).

The building that supports the parabolic reflector is an eight-storey building, which also hosts the CNRS research facilities that are based at the site (CNRS 5). Its construction was much like the construction of any contemporary eight-storey building, but the idea of one side being left out for the concentrator had to be factored in during the process.

The construction went on amid ongoing research until it was completed because at the time, there was no similar facility except for the smaller furnace that had been constructed by Professor Trombe earlier on. He was building on the same idea, but on a larger scale using a slightly different approach.

The project factored in conventional construction ideas, which are necessary for erecting an eight-storey building. The sampling of the soils of the region to determine the kind of reinforcement that the building needed called for the selection of the right materials, which could bear the stresses and strains that the load of the parabolic reflector would place on them.

Material selection needed to be done very carefully because this was the first structure of its kind and it could not be compared to any other structure elsewhere.

The framework that holds the parabolic reflector in place entails a network of metals that is capable of providing a strong base for the concentrator, but at the same time, it should be relatively light, which means that the project involved the input of many other specialists apart from Professor Trombe.

The project, having been built in the 1960s and brought into operation in the year 1970, is not much of an ancient project. This assertion is founded on the view that the same idea that lies behind the operation of the Odeillo furnace remains the main idea behind the operation of several other smaller solar furnaces that have been constructed after it.

Odeillo solar furnace was among the pioneering projects in the field of solar furnaces, but the technology it employed has been used elsewhere for different solar projects. Heliostats are today widely used for other applications such as major solar electricity plants and solar water heating arrangements among others (Hinkley et al. 2). The solar furnace at Odeillo was constructed at a cost of $200,000 to completion.

How it would be constructed today

The solar furnace at Odeillo is slightly over 40 years old. The technological landscape has greatly changed within this period. This aspect means that although the furnace is not very old, its construction would be approached differently if it were constructed today. The operation principle would remain the same, but the materials and construction methods would be different.

The first aspect of the project that would be altered is its design. There are two main designs for solar furnaces namely the off-axis design and the on-axis design. Odeillo was an on-axis design as already noted, but there is a need to improve the arrangement of the heliostats and the parabolic reflector.

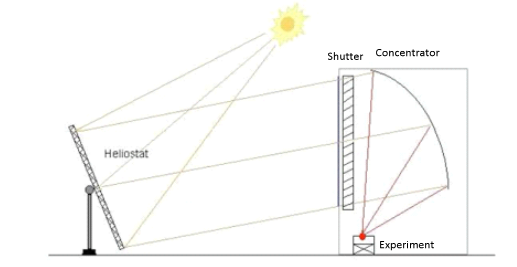

Since the conventional off-axis design has the disadvantage of the furnace blocking off some reflections from the heliostats to the concentrator because it stands in between the two, it would be a better idea if the design were such that the furnace is away from the path of the heliostat – reflected beams. The figure below shows a hybrid design that may be better that the Odeillo furnace design.

Figure 3: On-axis optical design solar furnace design (alternative)

Source: (Hinkley et al. 7)

This kind of design has the advantage of all the reflected beams of light from the sun reaching the parabolic reflector without any hindrance in between. It can even be better if this arrangement is duplicated on opposite sides of one building such as the one that holds the solar furnace of Odeillo.

This consideration becomes important as the world needs other solar furnaces, which are in the same caliber as or better than the one at Odeillo because over 40 years after its construction it remains the only one of its caliber. This aspect forces scientists and researchers from all over the world to flock to the site for experiments, which require temperatures that only this facility can provide.

The double arrangement can accommodate more experiments at the same time and thus enable experimentation and research to be done with ease. However, it can cost more than the Odeillo solar furnace.

If an assumption is made that the cost of constructing a furnace similar to the one at Odeillo would be the same as it was 40 years ago due to the development of cheaper materials and technologies, constructing it in this proposed dual arrangement cannot cost double the amount that was used to bring Odeillo solar furnace to completion.

It will be in between, probably three quarters of the double cost or so because even with the dual arrangement, only a single building is necessary to hold both parabolic reflectors in place.

The heliostats would be slightly different today compared to the ones that were used at Odeillo. The technology behind the operation of a heliostat has slightly improved since the time Odeillo solar furnace was constructed. Today, a heliostat that would be used in a solar furnace is lighter and stronger than it was 40 years ago (Hinkley et al. 6).

However, the most important difference that is possible for a heliostat today is that with the advent of computers, all high precision equipment are computer controlled, which is also possible for solar furnace heliostats. In the past, these gadgets were controlled manually using clockwork or using solar trackers to maintain a steady beam on the parabolic reflector regardless of the position of the sun.

Today, heliostats are computer controlled. The computer is supplied with the longitudinal and latitudinal details of the heliostat as well as the date and time of the day. Equipped with these details, the computer calculates the position of the sun and triggers a connected mechanism that adjusts the mirror to the right position with such a precision that could not be achieved in the past (Hinkley et al. 6).

The parabolic surface would be constructed using modern mirrors, which are stronger and lighter just like in the case of heliostats. In a bid to achieve the parabolic shape more easily, the arrangement would be composed of hexagonal mirrors rather than rectangular or square mirrors. Due to the dual arrangement, a parabolic reflector the size of the one at Odeillo is a good size.

It can be slightly bigger to deliver more than 1000 kW to enable it serve purposes that could be beyond the scope of the current Odeillo furnace. This arrangement of hexagonal mirrors to form the concentrator has been used in the construction of relatively recent solar furnaces.

Apart from serving its intended purpose, it would add to the aesthetic value of the structure, which is important because the Odeillo furnace and the Mont Louis furnace are known to attract tourists.

In the current Odeillo furnace, the eight-storey building that supports the parabolic reflector hosts other activities within the available space and the case would be similar in the new construction. This claim is made based on the view that in the design for the new construction, the parabolic reflector needs to be elevated higher and tilted slightly downwards to ensure that it focuses the beams that it receives to a target somewhere below it as shown in figure 3 above.

This assertion means that probably the parabolic mirror would not affect the first two floors. The space availed by the two floors can host all the different activities that might be necessary at the site. Alternatively, in addition to the two floors, a basement room can also host some vital activities if the two floors are not sufficient to host all the activities that are ongoing at Odeillo solar furnace.

This way, the world can have a solar furnace that would be in a position to serve a bigger number of experiments at ago. Alternatively, since the solar furnace in question is a dual arrangement structure, one side could be dedicated to experimental and research activities as the other side serves commercial activities.

Such an arrangement can be advantageous as the challenges encountered by the commercial furnace users will be easily solvable by the researchers more easily and faster as both activities go on in the same facility and any unusual occurrences can be handled right away.

Conclusion

The principle behind the operation of the solar furnaces is an idea that has existed for long and it has been used for numerous purposes. However, Professor Trombe’s move to actualize its large-scale application in a solar furnace was a huge development as no one else has come up with a better way of harnessing the sun’s energy for use in a solar furnace.

Many that have been made utilize the same idea albeit with varying designs. In this sense, Professor Trombe remains the greatest contributor to the development of solar furnaces and this scenario is likely to remain so for many years to come.

Works Cited

CNRS., High temperature solar energy. 2013. Web.

Garg, Prakash. Solar Energy: Fundamentals and Applications, New Delhi: Tata McGraw-Hill Education, 2000. Print.

Hinkley, Jim, Robbie McNaughton, and Andreas Neumann. Development of a High Flux Solar Furnace Facility at CSIRO for Australian Research and Industry, Frenchs Forest: AuSES, 2010. Print.

P-O Life: The biggest solar furnace in the world Font-Romeu-Odeillo-Via 2010. Web.