New Product Development

New Product Development refers to a distinct set of activities that companies use to develop and introduce a product into the market. It has a two concurrent phases. On one hand, there is the product design process culminating in a viable market, while on the other hand, there is the marketing component that starts from market research and ends with the purchase of the product by the eventual consumer. Solar Technical (SL) is a medium sized company that distributes solar products.

It specialises in solar water heating systems. It fabricates solar water tanks for clients that have needs not covered within the conventional systems provided by manufacturers. There have been some problems with the current operations because of problems with the company’s supply chain. This paper will investigate the potential to improve the supply chain performance of the company. In particular, it will compare the potential to improve the supply chain by examining the New Product Development process at SL.

Current Operations and Supply Chain

SL is a medium sized company with about thirty employees. It has a technical department that deals with the installation of solar water equipment in client premises. It also fabricates special order tanks and accessories to meet unique needs of the specific clients. It also coordinates Research and Development (R&D) activities. Other departments of interest include the sales and marketing department that create and execute a marketing strategy.

The company deals with a high number of suppliers that includes international manufacturers of solar power equipment. The company aims at holding the widest variety of solar water heaters as its specialty. It also resells products made by local manufacturers as a distributor.

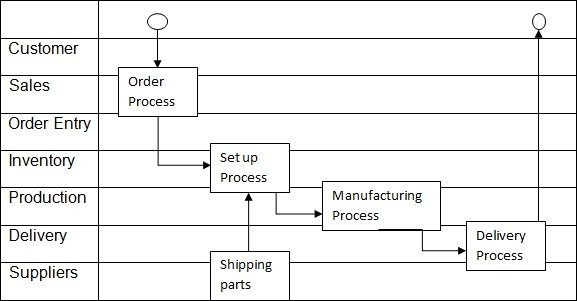

For some brands, the company serves as the distribution point to smaller retailers in the solar industry. When the company fabricates tanks, it sources for components from a wide array of suppliers, both locally and internationally. Table 1 shows the process diagram used to deliver the tanks to the clients.

Table 1: Process diagram for fabricated water tanks

Strengths of the Current Supply Chain

The current supply chain has two strengths. The organization of the technical department tries to use Just in Time manufacturing methods to produce the tanks as soon as it establishes the demand for them. The department does not keep an inventory to make the tanks, except what in need to fill in a week’s demand based on demand foresting figures.

This measure is responsible for the reduced need for storage places for materials, and losses due to damage to materials. Delays in supply of materials are rare and far between because the suppliers of most of the components also supply other industries in the regions with the same materials.

The second strength of the current supply chain comes from the highly streamlined manufacturing process that uses computer based modelling to develop designs. The department also uses computer aided manufacturing methods for cutting the aluminium sheets that form the body of the water tanks.

The welding process takes place by manual means because of the differences in the shapes of the tanks. The welding workshop connects to the testing centre where the company tests the tanks for leaks before the final assembly. This reduces the risk of defective work and returns from clients further down the supply chain.

Weaknesses of the Current Supply Chain

The most serious weakness in the supply chain is the exposure to disruptions in supply of materials. While the company do have a record of any serious disruption in the supply of any of the material it needs for its solar water tanks, it is always aware of the disruption in business such a disruption would cause.

The second weakness in the supply chain is a weakness in the manufacturing process. The quality of the tanks depends a lot on the skill of the welders that they seem to be indispensable. This puts the company at the risk of losing its manufacturing prowess if any of the welders move on. The impact of losing the welders can cost the company a lot of money in lost business.

The third problem with the current supply chain is that there is always need to send a technical person to a client’s location to determine the required dimensions for the custom tanks. This work is too skilled for the marketers. However, it costs the company a lot more time to get this information because after the marketing team finds an interested client, then the company sends an engineer to the site. This brings about a high cost of labour.

Application of New Product Development

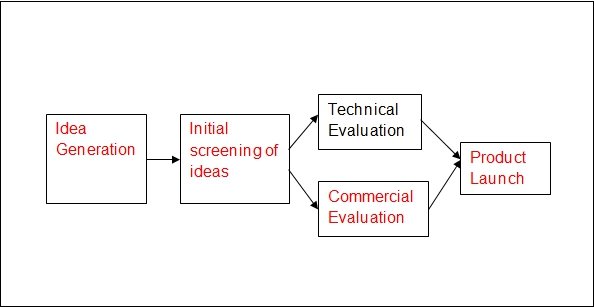

The new product development process can help SL to develop a better way of managing its productions process. The solutions are not in the reengineering of the processes but increasing their efficiency. New product development follows a distinct path

Idea Generation

This is the first step in developing a new product. The need for new ideas comes from various aspects. In the case of SL, there is always a need to consider the best shape to use to construct solar hot water tanks. The main reason for this is that most of the clients that ask for custom tanks cannot use standard ones to meet their construction needs. Such needs include very small spaces to fit the tanks, or unusually shaped spaces where conventional tanks cannot fit.

Initial Screening of Ideas

After generating different ideas, a team should reduce them to a few workable ones based on thermal qualities, manufacturability and cost. This stage will reduce the risk of creating a tank that is too expensive, or one that will take too long to fabricate.

Technical Evaluation

This stage addresses the need to evaluate in detail the final design that makes it past the initial screening. The role of technical design is to determine the manufacturability of the product along the lines of the processes required, the availability of the tools, materials and expertise.

Commercial Evaluation

The question for SL in this stage is to determine whether the client can meet the cost of production of the tank. This stage will determine whether the tank will come off the production line or otherwise. If a tank requires more money than a client is willing to pay, then it is not viable to produce it.

Final Development

Finally, SL can settle down to produce the product. In this case, it will involve checking the inventory to ensure all the materials are in the store, setting up the manufacturing line, and alerting all staff on the production line to play their role. After production, the installation team takes it to the client. SL should always plan for more than one tank when the manufacturing is going on to ensure that the client has other options ready for manufacture if the client rejects the best tank offered by the company.

In the case of SL, the product launch would compare to the delivery of the product to the client. Table 2 below shows the resource implications of new product development, while Table 3 shows the network diagram for the same process.

Table 2: Resource implications of the new product development cycleTable 3: Project network diagram with critical path

Reference List

Flannes, S. & Levin, G., 2005. Essential People Skills for Project Managers. Vienna, VA: Management Concepts.

Gilson, S., 2010. Creating Value Through Corporate Restructuring: Case Studies in Bankruptcies, Buyouts, and Breakups. New York, NY: John Wiley and Sons.

Iliescu, D.C., 2008. Customer Based Time-to-Event Models for Cancellation Behaviour: A Revenue Management Intergrated Approach. Dissertation. Gorgia: ProQuest Georgia Institute of Technology.

Kerzner, H., 2009. Project Management: A Systems Approach to Planning, Scheduling and Controlling. 10th ed. Hoboken, NJ: John Wiley and Sons.

Kopezak, L. & Lee, H., 1994. Coordinated Product and Supply Chain Design. Case Study, pp.331-404.

Meredeth, J.R. & Mantel, S.J., 2011. Project Management: A Managerial Approach. 8th ed. Hoboken, NJ: John Wiley and Sons.