Abstract

Over the past few decades, disruptions in various supply chains due to risks and uncertainties have been a cause for concern for many businesses. The sources of these risks have been as a result of globalization, new business trends such as outsourcing, and technological advancements that have made competition stiffer than ever before.

To address these issues, business scholars among other interested parties have in the recent past developed strategies that aim at mitigating risks along supply chains. Key among them is supply chain risk management (SCRM), a concept that improves efficiency, sustainability and reliability within a given supply chain.

The main focus of this study shall be to evaluate this concept and its applications in today’s business environment. This shall be done by defining terms used in this area of study, reviewing credible literature on this topic and assessing the applicability of the concept through a case study.

Introduction

Today’s business environment is characterized by aggressive competition, rapid technological advancement and social challenges. All these factors have forced business entities to develop new and better means of tackling these uncertainties. However, due to globalization and increased demand for goods and services, both local and international firms face new and complex uncertainties in their efforts to capture a large share of the global market.

As a result, various scholars and specialists have over the past few decades developed models and theories that best equip business entities with the necessary skills needed to handle risks affecting their supply chains. It is from such underpinnings that the concept of supply chain risk management (SCRM) was coined. Considering the numerous uncertainties present in today’s business environment, SCRM has provided business entities with an avenue through which risks can be effectively mitigated and managed.

This paper shall setout to explore the concept of supply chain risk management (SCRM). This shall be done by reviewing relevant literature on the topic and critically analyzing case studies associated to this topic. An overview of the SCRM processes and operations utilized in the manufacturing industry shall be evaluated and discussed.

Supply Chain Risk Management: Overview and Definition of Terms

Supply Chain

The success of any business greatly depends on its ability to supply its goods or services in a timely manner to consumers. As such, the supply chain used to achieve this aim should be effective, efficient and feasible if profitability is to be maintained. Cucchiella and Gastaldi (2006) define a supply chain as the stages followed by materials as they move from their original source to the end consumer.

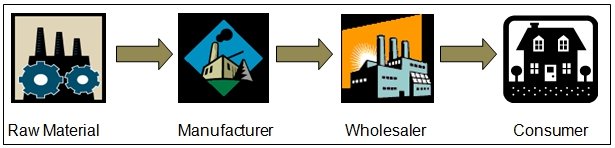

However, it should be noted that it is a complex process consisting of a number of retailers including but not limited to: wholesalers, transporters, storage services and suppliers among others. While the definition may appear simple, supply chain management is among the most challenging process in any business. This is attributed to internal and external risks that may actively disrupt this process. The figure below illustrates an emblematic supply chain.

Figure 1: Illustration of a simple supply chain

The figure above represents a simple supply chain in which raw materials are moved from their original source and supplied to the manufacturers. After processing the raw materials into usable goods or services, the manufacturer supplies the product or service to wholesalers, who in turn supply the same to consumers.

Supply Chain Management

After defining a supply chain, the next logical step would be to define supply chain management (SCM). According to Kersten and Blecker (2006), supply chain management refers to the process through which a business plans, implements and controls activities within the supply chain, in order to ensure that consumer needs are satisfactorily met.

The main objectives of supply chain management are to improve performance, versatility and reduce costs during the supply process for the organizational good, as well as the consumer’s benefit. Simply put, SCM seeks to ensure that a business provides the right product or service, at the right time, place and price to potential consumers. Finch (2004) further states that SCM enables supply managers to monitor and oversee materials, information and finances as they move through each link in a given supply chain.

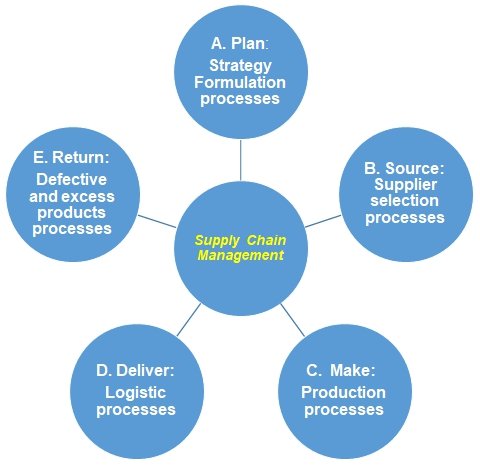

Similarly, Christopher and Lee (2004) assert that the concept of SCM is made up of five basic components. The figure below shows the components of SCM in chronological order.

Figure 2: Basic components of SCM

Plan

Refers to the strategies used to manage resources used to satisfy consumer needs. It involves coming up with metrics that help monitor the supply chain to ensure that it is efficient, cost effective and produces quality goods or services that add value to the end-consumer.

Source

This component of SCM focuses on the selection of suppliers of the materials needed to produce the goods and services. It enables managers to set prices, delivery and payment schedules and develop strategies to improve relations with these suppliers. At this stage, managers are better placed to develop inventory management systems and processes that facilitate efficient reception, verification, payment and transfer of shipments to manufacturers.

Make

This concentrates on the actual manufacturing of products. At this stage, supply chain managers are able to set up schedules relating to the production, testing, packaging and other necessary preparations before the products are delivered to consumers. This is the evaluation stage in the supply chain. This is mainly due to the fact that at this stage, business entities can test the manufactured product to ensure quality standards are met, measure the output capacity and evaluate workers performance.

Deliver

The main focus of this component is logistics. Businesses, coordinate order receipts from clients, make warehousing and transportation arrangements that will be used to deliver the end-product to consumers. Similarly, this component help companies develop and implement the invoicing system that will be used to collect payment.

Return

This is arguably the most challenging component in supply chain management. Companies have to develop versatile and responsive networks to cater for defective or excess products returned by clients and set up customer care departments, which offer solutions to consumers having problems with their products.

Supply Chain Risks

The definition of risk varies depending on the field of research. However, there is a general consensus that risks are best defined according to the volatility of expected results and lack of adequate information, which may lead to losses.

In this case, supply chain risks can be defined as the probability of damage occurrence, which results from an irregular event within a company’s supply chain or environment, leading to negative implications in the overall supply chain (Kersten & Blecker, 2006). This definition is most appropriate since it focuses on the origin and source of potential risks and considers the companies that are affected within the supply chain.

Supply Chain Risk Management

Research by Giunipero and Eltantawy (2004) indicate that most companies have over the past decades increased their interest in supply chain risk management. With due consideration to the above mentioned definition, SCRM can best be defined as a concept in supply chain management consisting of strategies, information, technology, companies and procedures, which are employed on a technical, personal and organizational level in order to identify, prevent or reduce potential supply chain risks (Kersten & Blecker , 2006).

Literature review

Throughout this discussion, it has been revealed that SCRM aims at reducing costs, improving information and resources flow, and enhancing customer satisfaction. However, it should be noted that the implementation of SCRM is not as easy at it sounds. According to Kersten and Blecker (2006), concepts such as lean management can lead to the emergence of risks within a supply chain.

For example, the authors assert that strong synchronized interfaces between companies lead to interdependency between partners seeking to reduce costs.

This dependency ultimately increases risks within the supply chain (Kersten et al, 2006). This is attributed to the fact that as more companies join a given supply chain, the division of labor, flow of information and inventory management becomes more complex. With increased complexities come increased risks.

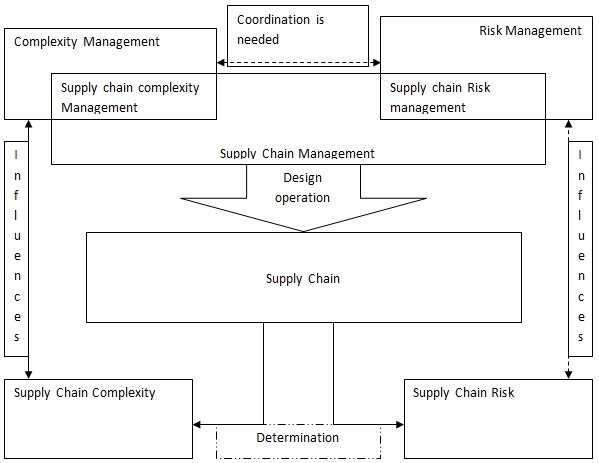

With this in mind, coordination between complexity management and risk management is required if SCRM is to be successful. This is mainly due to the fact that coordination between these two concepts enables a company to recognize, monitor and manage changes in risks or complexities more effectively (Shefi, 2005).

As has been revealed, the management of risks not only impacts the risk levels, but also the level of complexities within the supply chain. Similarly, the management of complexities affects both the level of complexities, as well as the level of risks (Faisal et al, 2006).

As such, the importance of this coordination goes beyond simple integration of these concepts because an increase in complexity may lead to the intensification of existing risks or the emergence of new risks. Similarly, a reduction in complexity levels decreases the risk levels within a given supply chain (Chris, 2008).

The figure below shows the importance of risk and complexity management within a supply chain.

Figure 3: management of supply risks and supply complexities

Source: Kersten and Blecker (2006).

This figure illustrates the relationship between supply complexities and supply risks and how they should be managed. It is clear that coordination between these two concepts is crucial in the determination of supply chain risks and complexities, thereby providing for efficient management of the same.

Guinipero and Eltantawy (2004), state that over the past few years, the number of risks compiled by most companies have changed significantly. The authors attribute this change to new market conditions that have seen companies formulate new methods of doing business (Guinipero & Eltantawy, 2004).

Traditionally, risks emanated from business practices carried out by each company. However, in today’s business environment, risks arise as a result of close cooperation between allied companies. Some of the acknowledged risk drivers affecting supply chains include but are not limited to: globalization, centralized production and distribution, outsourcing, reduction in supplier base and inventory holding among others.

According to Juttner (2005), a combination of any of these risk drivers leads to increased vulnerabilities within the supply chain. As such, the risk portfolio for each company within the supply chain increases. For example, globalization leads to geographical complexities, while outsourcing increases dependability within the supply chain.

Similarly, if a company concentrates on a small number of suppliers or even a single supplier, risks are bound to emerge in terms of reliability and consistence of the selected suppliers. Correspondingly, supply chain risks arising from one company are easily passed on to other companies within the supply chain, hence leading to an increased risk portfolio in other companies along the supply chain.

Kleindorfer and Saad (2005) state that the management of risks within a given supply chain is only effective if it is handled from the company level and the supply chain level.

The authors further assert that the process of managing risk is similar at both level and contains the following steps: Identification, analysis, assessment, solution and monitoring of risks. To guarantee efficiency, each company must follow these steps individually.

Then all companies along the supply chain should coordinate their activities before dealing with supply chain risks. Kleindorfer and Saad (2005) reiterate that there are numerous risks that could be transferred from one company to the other along the supply chain. This makes it difficult for individual companies to conclusively determine all the risks they are exposed to. As such, coordination at a company level enables companies to assess risks that may be transferred from partners along the supply chain.

Faisal et al (2006) emphasizes that in recent years, the application of SCRM strategies has gained prominence in the business world. The authors attribute this to the fact that companies have realized that ensuring the flexibility, efficiency and agility of supply chains while maintaining responsible supply chain practices is a great challenge in the dynamic and uncertain business environment today.

The authors argue that in order to mitigate risks, one must first identify the various sources that cause such risks. By mitigation, the authors refer to the strategies and measures employed to reduce, manage or avoid risks within the supply chain.

Chris (2008) further states that due to uncertainties and complexities in the global economy, supply chain risks sources have been classified into the following three categories:

- Environmental sources (external)

These are external sources of supply chain risks. They include but are not limited to: market risks (shifts in market prices, exchange rates and interest rates among others), natural disasters, changes in demand and supply forces, competition, political stability, and public policies among others. - Organizational sources (internal)

These are sources of risks that are internal in nature (caused by factors within the company. They include but are not limited to: strikes, unskilled labor, technical breakdowns, ineffective systems and internal processes and poor management among others. - Supply chain sources

These include lack of ownership, inertia and chaos within the supply chain. According to Juttner et al (2003), lack of ownership within the supply chain leads to unclear responsibilities, which make it difficult to control the supply chain. Chaos refers to unwarranted reactions, false alarms and unwanted interventions within the supply line. Inertia can cause risks in the supply chain if companies are unwilling to conform or oblivious to changes in environmental and market conditions.

In regard to the importance of SCRM in today’s business environment, Waters (2007) sets out to explore this concept and its constituents. The author states that business entities are continually seeking for opportunities to improve the quality, consistency and safety of their products, all the while reducing operational costs, production time and enhancing business reputation and their product’s brand (Waters, 2007).

To achieve these objectives, businesses have to form strategic alliances with suppliers. SCRM provides an avenue through which attainment of these objectives can be guaranteed.

On the same note, Waters (2007) states that SCRM adds value to organizations by facilitating better knowledge of existing supply chains, greater control and management of suppliers, increased product quality and reliability, efficiency and reduced costs of production, good relationships between suppliers and manufactures and enhanced brand and organizational reputation.

In addition, the author further states that SCRM enables businesses to develop strategies, chain risk assessment and decision making measures, communication strategies and crisis management procedures, which help recognize, manage and monitor risks within the supply chain (Waters, 2007).

In a study to examine the level of risk exposure between large scale firms and small and medium size enterprises (SMEs), Finch (2004) observed that inter-organizational networking among large scale firms was the leading cause of increased risks among these firms. Similarly, the results indicated that large scale firms, which relied on SMEs for supplies were exposed to more risks.

On the other hand, SMEs that became supply chain partners increased their risk exposure levels and only a few SMEs had an exit strategy or a strategy to manage risks. Conclusively, the author revealed that it is important to evaluate the business continuity plan before joining a supply chain (Finch, 2004).

Shi et al (2004), highlight the models and methods that are often used for SCRM. While supply chain management methods have improved over the years, the development and implementation of models and methods that concisely consider and manage risks and uncertainties is still needed is businesses are to succeed in attaining their sales, financial and corporate objectives. Despite the direction, method or strategy used to mitigate risks, identification, assessment, management, control and monitoring of risks remain the core values of SCRM. With this in mind, Finch (2004) states that supply chain models can be categorized as illustrated in the table below:

Figure 4: Models and methods for supply chain risk management

The model applied depends on the needs of the company and the type of risks the company wishes to address. In most cases, a combination of these models can be applied to facilitate efficiency while identifying, managing and monitoring risks at a company or supply chain level. Analysis is done by observing the impact changes in inputs have on the model output.

Arguably, any discussion on models and methods for SCRM would not be effective if it fails to acknowledge Failure Mode and Effect Analysis (FMEA), which refers to a method used by most engineering experts to test the reliability of other methods and models.

According to Datta et al (2005), FMEA was developed in 1949 and was used for the purpose of identification of potential failures and analysis of the impacts such failure modes have on a system. The authors supports this method by stating that once risks are considered as failures, it becomes easier to evaluate how different methodologies and models can be applied efficiently in SCRM (Kleindorfer & Saad, 2005; Datta et al, 2005).

Case study analysis

This section will explore the application of SCRM in IBM Corporation. IBM Corporation is among the largest producer of computer hardware in the world. As such, it has a supply chain consisting of complex networks of suppliers, manufacturers and distributors (transportation) that covers many parts of the world.

This section will evaluate the end-to-end approach used by this corporation’s server X supply chain to manage risks. Probabilistic risk analysis shall be employed to develop a comprehensive overview on risk factors affecting the supply chain. Factors considered include but are not limited to: operational challenges, calamitous events, local delays and industry-wide occurrences.

Identification of supply chain risks

As mentioned earlier, identification of risks is the first step of SCRM. Efficiency in this step determines the success of the whole process. As such, a good model should be used to ensure that all variables are adequately considered. A systematic Approach was used to identify the risks that would impact the performance of IBM’s server X supply chain.

The first step involved identification of the risks. This was done by mapping essential business processes needed to facilitate the acquisition of the parts, assembly of the servers and delivery of the finished product to end-customers across the world. The second step was to identify and map the human, financial, and information resources needed by the identified processes in order to assess how they support the activities and decisions surrounding the production and delivery of the servers.

The third step focused on gathering information from managers and engineers regarding the root causes and effects of the identified risks. This was accomplished through a series of interviews. Having established the causes and sources of potential risks, which could affect the efficiency of the supply chain, the influencing factors were mapped and integrated into the business process in order to comprehensively identify the specific location and method the disruptions proliferate the supply chain.

Results indicated that people, infrastructure and logistic facilities located at the coast faced environmental risks such as hurricanes, which are prevalent at the Gulf of Mexico. In addition, it was discovered that some suppliers, which were owned by larger holding companies were at risk of financial insolvency.

Measuring the impact of Identified Supply Chain Risks

Bayesian network modeling was used to assess the impact the identified risks had on the server product supply chain performance. This model was used to analyze a set of variables and their probabilistic interdependencies. For example, major risks were associated with frequency of distribution, resources were associated with availability.

Time and cost distributions were associated with each activity carried out during the supply of the servers. The results were used to develop a template that was used to gather all the information needed to generate a model.

Data was collected from public domains, expert opinions and internal sources in order to provide the required data for the model. Finally, the combined illustration of all business processes formed the basis for the development of simulation model that would calculate the effects of disruptions and failures on server X’s chain of supply.

Figure 5: Typical Bayesian Networking Model

From this case study, it is evident that business processes modeling is important in the identification of resources needed to facilitate efficient supply chain performance. Similarly, identifying the human, capital and informational resources is pivotal if potential vulnerabilities are to be identified and mitigated. On the same note, understanding the prevailing environmental and market conditions may help a business understand and identify risks emanating from such sources.

Conclusion

Supply chains have become more global and complex over the past years, thereby leading to the emergence and increase of challenges and risks. Despite these hurdles, SCRM provides companies with an avenue through which they can attain their organizational goals, all the while meeting the needs of the clients optimally.

This is mainly because SCRM reduces costs, adds value to consumers and organization, ensures timely delivery and mitigates risks within the supply chain. This research set out to explore the concept of supply chain risk management. To this end, definitions and descriptions of terms used in this field of study have been offered.

A literature review highlighting other scholars’ thoughts on the subject has also been provided and a case study illustrating the application of SCRM has been included. Considering the hardships that cripple our business environments today, it would be a worthwhile endeavor to ensure that every business has SCRM strategies in place. Not only will this mitigate risks, but it will also add value to the business, thereby enhancing brand recognition and business reputation.

References

Chris, E. et al. (2008). Global Supply Chain Risks Management: A New Battleground for Gaining Competitive Advantage. Proceedings of ASBBS, 15(1), pp. 278 – 292.

Christopher, M., & Lee, H. (2004). Mitigating Supply Chain Risk through Improved Confidence. International Journal of Physical Distribution & Logistics Management, 34(5), pp. 388 – 396.

Cucchiella, F., & Gastaldi, M. (2006). Risk Management in Supply Chain: A Real Option Approach. Journal of Manufacturing Technology Management, 17(6), pp. 700 – 720.

Datta, S. et al. (2007). Management of supply chain: an alternative modeling technique for forecasting. Journal of the Operational Research Society, 58(11), pp. 1459 – 1469.

Faisal, M. et al. (2006). Supply Chain Risk Mitigation: Modeling the Enablers. Business Process Management Journal, 12(4), pp. 535 – 552.

Finch, P. (2004). The Supply Chain Risk Management. Supply Chain Management: An International Journal, 9(2), pp. 183 – 196.

Giunipero, L., & Eltantawy, R. (2004). Securing the Upstream Supply Chain: A Risk Management Approach. International Journal of Physical Distribution & Logistics Management, 34(9), pp. 698 – 713.

Juttner, U. (2006). Supply Chain Management: Understanding the Business Requirements from a Practitioner perspective. The International Journal of Logistics Management, 16(1), pp. 120 – 141.

Juttner, U. et al. (2003). Supply Chain Risk Management: Outlining an Agenda for Future Research. International Journal of Logistics: Research and Applications, 6(4), pp. 197 – 210.

Kersten, W., & Blecker, t. (2006). Managing Risks in Supply Chains: How to Build Reliable Collaboration in Logistics. Berlin: ESV Publishers.

Kleindorfer, P., & Saad, G. H. (2005). Managing Disruption Risks in Supply Chains. Production and Operations Management, 14(1), pp. 53 – 68.

Shefi, Y. (2005). The Resilient Enterprise: Overcoming Vulnerability for Competitive Advantage. Cambridge, MA: MIT Press.

Shi, D. et al. (2004). Managing Supply Chain Risks with Derivatives. IBM Research Report, pp. 1 – 27.

Waters, D. (2007). Supply Chain Risk Management. London, UK: Kogan Page.