Introduction

The dangers and risks involved in handling flammable and combustible liquids and gases call for extra vigilance in the processes of packaging and transporting these liquids and gases.

The fact that the harmful effects that can result from careless handling of these liquids are irreversible and long-term in nature, safety precautions are important when handling these liquids.

Firms that deal with these liquids have to apply some precautionary measures to ensure that the handling and use of these liquids is safe.

This attention is not only important in the way people use these gases but also most important from the production to packaging and transporting. Governments in response to these risks have put standards and measures to ensure safety in the whole process.

Firms on the other hand have put in place procedures that regulate and direct people who handle these gases.

This paper focuses on the process of storage, the facilities requires, the risks involved and some security measures that have been in place to reduce the occurrences of the disasters. The paper also will look at some of the standards regulatory bodies have put in place.

Definitions

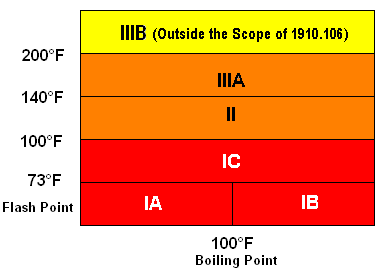

First, it is important to define some terms as used in this paper. Different classes easily identify flammable and combustible liquids, with each class posing different hazards, and therefore, there are different rules and regulatory requirements exist for each class. One basis for classification is the flash point.

This is the temperature at which, the amount of vapor generated, is enough to support combustion. Another basis for classification is the boiling point, which is the point where the saturated vapor pressure equals the atmospheric pressure.

Having defined the above terms, the definition of flammable liquids is more understandable. Flammable liquids are liquids containing more than one percent of a liquid whose flash point is below 100oF.

On the other hand, combustible liquids are liquids that have a flash point at or above 100oF (NFPA 2). Based on the above discussion, several classes of combustible and flammable liquids exist.

The following table offers a criterion for determining the class of a particular liquid given their flash point and boiling point. Classes 1a, 1b and 1c represent the flammable liquids while classes two and IIIa represent combustible liquids while those in IIIb are out of the scope meaning that they are neither combustible nor flammable.

It is important to note that each of these class attract different precaution measures. Besides these terms, other terms generally occur when dealing with combustible and inflammable liquids. For the purpose of this study, these definitions are critical.

The term liquid in this paper refers to any material that has fluidity greater than that of 300-penetration asphalt when tested which includes both flammable and combustible liquids.

An unstable liquid is one which in a pure state or when transported vigorously polymerize, decompose, condense, or will become self-reactive under conditions of shocks, pressure, or temperature.

A portable tank refers to a closed container having a carrying capacity over 60 gallons and its design does not intend for use in a fixed status.

A pressure vessel in this paper refers to storage tank or vessel whose design enable it to operate at pressures above 15 p.s.i.g. finally the term container will be used to stand for a container sealed by means of a lid or other device such that neither liquid nor vapor will escape at ordinary temperatures.

Storage facilities requirements

Flammable and combustible liquids are stored in tanks which may vary in size and design, the NFPA provide standards for the storage of these gases, there transportation and their use.

These standards as mentioned before aim at preventing the hazards that these liquids can cause. The N.C. Department of Labor provides the standards given below.

Storage tanks

The storage tanks should be made of steel or other approved nonflammable materials for underground storage. In cases where concrete tanks are used, they shall have special interior lining and must be designed using sound engineering practices.

In addition to these, operating pressures are not supposed to exceed that the design allows (NFPA 6). The metal tanks construction must incorporate several methods either singly or a combination of these: welding, bolting, riveting, and caulking.

The filler metal used in brazing must be a nonferrous metal or an alloy with a boiling point beyond 999oF and below that of the metal that it joins.

Underground tanks

In addition to the above acceptable standards, atmospheric tanks must not exceed 2500 gallons, if their original design was for underground but for some reason they were place above the surface.

Furthermore, it is important to avoid using them to store liquids above their boiling points (NFPA 12). For both low-pressure tanks and pressure vessels, the operating pressure must never exceed the design pressure.

Surface tanks

When storing tanks above the ground, the distance between any two tanks should not be less than three feet. In case of unstable liquid, the distance to maintain between tanks must be beyond half the sun of their diameters.

When storing liquefied petroleum gas with combustible or inflammable liquids, the distance between the LPG containers and the other liquid containers must exceed twenty feet (NFPA 15). In addition, above the ground tanks require normal and emergency venting to prevent rapture or vacuum.

To prevent accidental discharge of the liquid, the area surrounding the tank a provision of adequate drainage or dikes. In case dikes are preferred, the walls of the dikes should be earth, steel or concrete, which is liquid proof.

Furthermore, the capacity of the dike must equal or exceed the capacity of the tank. Tanks located in flood zones have many requirements for them. Some of these requirements include the fact that the liquid level in the tank must never go below the established maximum flood line.

Other vessels

Storage tanks are not the only storage facilities for flammable and combustible liquids. This is obviously because of the efficiency in procurement, transport and usage, another contributing factor is the need for different quantities of these liquids by different users.

Owing to these factors, several other storage facilities exist. These include container and portable storage facilities (NFPA 11). As a security measure, only approved containers are used.

In addition, for each of the containers a provision of one or more devices installed in the top with sufficient emergency venting capacity enables it to limit internal pressure under fire exposure conditions.

Other storage devices include cabinets in which containers with these liquids are stored. Such a cabinet shall have a warning written in conspicuous writing.

Furthermore, such cabinets are made of fire resistant material and should contain less than sixty gallons of both class one or two liquids and less than double that amount of class three liquids.

Other storage facilities include storage rooms, which must meet the required resistivity rating in design and must have ventilation whether mechanical or gravity.

There are specific and stricter requirements especially if the rooms are for storing class one and two liquids (NFPA 18). More specifications and regulations exist for conditions inside these rooms; for example, containers with a capacity of thirty and above must not be stacked over each other and there must be a clear aisle of more than three feet in width.

Types of hazards and security measures

Having discussed the characteristics of the inflammable and combustible liquids, the primary hazards associated with these liquids are obvious i.e. possible fire outbreak and explosion.

Unlike other liquids, these liquids can explode of get ignited even at the normal working temperature and therefore, they ought to be treated with extra care.

An excellent plan for safety when using these liquids must feature some components, which include control of ignition sources, proper storage, fire control, and safe handling.

Under each of these components, several bodies have established standards to ensure that these standard safety measures are complied with.

Fire

This is a hazard that can be fatal when it occurs. The first and most important thing that one must do in proposing security measures to curb the instances of fire is to understand the causes.

With this in mind, it is important to acknowledge there are diverse possible sources of ignition that can start a fire when handling these liquids. In trying to understand these sources, this paper visits every one singly to unveil the details, which might be of use in this paper.

Static electricity

When the liquid flows in a pipe into a tank whether closed or open, the generation of static energy, which is a possible cause of sparking, is inevitable.

Given the flammable state of the liquid, this can be very dangerous as the tank can explode or a fire can start because of the electrostatic energy (UNL Environmental Health and Safety 20).

To prevent such from happening, it is important to prevent the static energy from producing sparks which are the most dangerous. This therefore requires that the containers containing these liquids bee grounded of bonded to prevent sparking.

Bonding is one of the techniques employed in connecting objects. It reduces the potential charge between the two objects that need to be connected. Safety regulations therefore require that one provide a bond wire between two containers during filling unless a metal path between them is present.

Open flames

Open flames are one of the most obvious sources of ignitions. The operating environment for these liquids should be free from the exposure of any open flames. As a matter of regulation, the areas are strictly nonsmoking zones.

This is because cigarette smoking is a source of ignition. Other sources of open flames are welding and metal workshops. Such activities, as per the regulations must be a safe distance away from the operating environment of these liquids.

Other sources of ignition include lightning and hot surfaces (UNL Environmental Health and Safety 32). By gaining understanding of these sources, one is able to minimize the chances of occurrence even when the regulation is not clear and therefore this is an important preventive measure.

Health hazards

In addition to the possible fire hazards posed by combustible and flammable liquids, they also pose a health hazard to users depending of the specific liquids and the mode of exposure.

Many of these liquids are corrosive and undergo multiple reactions if exposed to other chemical components like oxidizing agents or are stored improperly. To prevent this from happening, it is important to avoid physical contact with these liquids whenever possible.

People who handle these liquids and must be physically present should wear protective clothing (UNL Environmental Health and Safety 3).

In case there is contact with these hazardous liquids, first aid precautions are important to minimize the extent to which the effects affect the person involved.

When handling these liquids, it is of paramount importance to note that the vapors of these liquids are denser than air and therefore can flow into low areas displacing oxygen and therefore contaminating the general air. This means that in case of spillage or exposure, individuals must avoid low places like inside pits.

When inhaled, these liquids cause irritation of the respiratory passages resulting to headaches, muscle weakness, drowsiness, loss of coordination, disorientation, confusion, unconsciousness, and if not well attended death may result.

These liquids are also harmful. They affect several elements of the skin especially the skin oils a phenomenon, which results in irritation besides leaving the skin dry.

Failure to administer first aid care may ultimately result to dermatitis. Eye contact with these liquids may result to a burning sensation, irritation and possibly eye damage (UNL Environmental Health and Safety 10).

Other hazards may lead to chronic hazards ranging from damage of lungs, liver and the heart to interference of the central nervous system and the causation of cancer.

Repeated exposures may result in target organ toxicity, which may ultimately result to the failure of those organs and ultimately death of the person

Environmental hazards

Moreover, it is important to note that flammable and combustible liquids are not eco friendly. Their spillage into the environment is a major pollutant that threatens the ecosystem if the quantities are high enough.

The exposure of these liquids to the aquatic ecosystem may result to acute toxicity whereby, they cause injury to aquatic organisms within a very short period of exposure.

They may also result in chronic toxicity whereby the cause adverse effects on aquatic life when expose in an aquatic ecosystem.

Various liquids will fall under different categories in this section (EPA 7). Improper disposal of these liquids or accidental spillages are causes of soil and air pollution.

General Use and Storage Considerations

In the above discussion, the discussion revolves around specialized use of the flammable and combustible liquids. However, it is of paramount importance to appreciate the fact that the handling of these liquids is not strictly restricted to specialized firms and individuals.

The aim of producing these liquids is for general use by the public and other unspecialized individuals and therefore, safety regulations need to consider this. In the following paragraphs, this discussion will focus on safety regulations for general use of these liquids.

One of the considerations that a person has to make is the available substitutes tot these liquids and how they can control their purchases of these liquids.

Whenever it is possible, consumers are encouraged to substitute product with high flash and boiling points with those with lower ones (UNL Environmental Health and Safety 22).

Furthermore, consumers are encouraged to maintain the smallest stock of these liquids possible. Given the just in time technology, consumers can obtain these products from the supplier just when needed and therefore they can maintain low inventories of the products.

Another regulation for the general user of these products is the available container sizes. The container sizes for combustible and inflammable liquids range from half a liter to twenty liters.

The setting of this limitation considers the class of the liquid, and in this sense, the consumer can only purchase a particular pack of these liquids at a particular time.

Besides, entrances to the rooms in which these liquids are stores must bear the appropriate warnings responders about the dangers in the room.

Distilling flammable or combustible liquids that are prone to formation of peroxide is a task that is discouraged. Furthermore, before conducting a distillation operation, one must ensure that the design of the apparatus allows for that purpose and that the glass equipment must be without crack, chips or any other defects.

Furthermore, protection from ignition sources is crucial during other important processes like extraction, centrifuging and grinding (UNL Environmental Health and Safety 16).

Ventilation for the rooms in which these processes take place is of paramount importance to prevent the saturation of these liquids vapor.

Other precautionary measures like the provision of fire extinguishers in the rooms in which these liquids are stored are important security measures.

There must be also physical separation between oxidizer and these liquids and one must ensure that these oxidizers are being kept away from gas flames or oil baths.

The use of automatic unattended systems is completely unacceptable when dealing with combustible and flammable liquids.

If necessary, engineering controls, in the form of override controls, automatic shutdown devices, over-temperature shutoff switches on electrically heated constant temperature baths, cooling fan and such like are required, then a specialist who in this case must be physically present in the venue must use them along with routine surveillance.

Conclusion

From the above discussion, it is clear that there are many regulations that have been proposed and put in place to regulate the use of this class of liquids.

Furthermore, it is important to note that this task of formulating the regulations has not been a concern for a single party but multiple bodies in various countries have come forward with regulatory guidelines that individuals and firms should follow when handling these liquids.

The inference that one can draw to these facts is that these liquids are delicate and dangerous to use and can be hazardous both to individuals and to the environment.

Even though some variances are eminent in the definitions of the terms and the regulations, one thing is common with all regulations; that they aim at providing safety measure when handling these very dangerous yet important liquids.

Having in mind the fact that the implementation of these regulations is an issue of safety, cooperation of the involved parties (i.e. both the regulator and the users of these liquids) is of great importance.

In view of this, it is the role of firms and individuals to cooperate in implementing these regulations as prescribed.

Though legislation has provided guidelines, there are finer details not encompassed in the legislature yet they can compromise the security and safe use of these liquids. This calls for commitment from firm mangers and individuals in implementing these regulations.

Works Cited

Environmental protection Agency (EPA). Release: 40 CFR 355.40, 302, 116.4 California Fire Code: Chapter 27. n.d. Web.

National Fire Protection Association (NFPA). Code 30. n.d. Web.

UNL Environmental Health and Safety · (402) 472-4925), 2000. Web.