Global versus local

Although operations strategy experience constant metamorphosis as a result of short term, midterm, and long term goal planning, no company can operate efficiently without quality system functioning. Quality operations strategy functioning encompasses “strong and systematic planning and actualization which functions simultaneously to cut down costs in operation modeling” (Powell 23). Thus, quality will quantify optimal functionality within a competitive advantage parameter. In order to achieve this, the existing forms of system monitoring are periodically upgraded to introduce multiple operating system models such as ratio analysis.

The Tag Heuer Boutique business has to deal with the imbalance between the global demands for quality products against the high taxation in the luxury watches sector in UAE. Specifically, the global demand for the Tag Heuer luxury watches cannot meet the supply. Despite a global demand of about 100,000 pieces, the company is operating below this capacity and is only able to produce about 80,000 pieces due to the high taxes and general cost of production. This imbalance has created a deficit in the market for the Tag Heuer watches (Ahmed Sediqqi and Sons, par. 4).

Center versus business unit

The business unit of the Tag Heuer Company is managed by a family. Despite having professionals in the production and other important department, the final decision on production strategies and improvements are based on the ideas of the family unit who acts as the directors. In summary, this aspect is a bottleneck for some of the decisions will be based on feelings and past experience rather than a quantifiable process of quality assurances and system sustainability (Powell 21).

Standard operations strategy system acts as the engine that supports implementers of business strategy in order to comprehensively verify rationale for supporting current, predicted, and actual results for every step upon introduction of a functionality (Powell 25). Therefore, the probability of success is far much better than that of failure when the system is properly designed. Success variables are achievable through value delivery, value addition, and creativity. Reflectively, these essential techniques and tools are managed by the family members of the Tag Heuer owner.

Function versus function

Since the Tag Heuer Company relies on raw materials that are shipped from outside the UAE, there are instances where the coordination between the production department and the supply chain has been compromised. In most cases, the company has to contend with the reschedules in shipment of the raw materials which increases the cost of production. Due to the pressure to produce more for the global market, the Tag Heuer has often resorted to do costing allocation on the need basis rather than the systematic total quality management within the short and long term plans. Though these actions are justified, their consequences are long term such the inability to predict market swings and possible improvements based on the feedback from customers (Escrig-Tena et al. 23).

Quality

The topological structure at the Tag Heuer has the elements of operations and communication system which facilitates optimal resource use and continuous performance efficiency. Based on what the Tag Heuer refers to as a credo emphasis, customer satisfaction informs the productive strategies such as customization of the watches and branding of other accessories which come with the watches such as the wrist band.

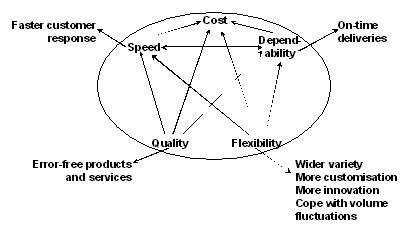

From previous experiences and active response of the customers, the management of the Tag Heuer has established a single contact between itself and customers across the globe. The skills required in supporting the Tag Heuer’s business strategic plan are found in operation management models which functions as an implementer and driver of business decisions which are to be translated into the actual process (Escrig-Tena et al. 23). This system tracks input and output ratio and measures the intrinsic efficiency of the employee and manager in line with a set target. Besides, the aspect of efficiency is introduced to ensure scarce resources are optimally exploited. Reflectively, when this ratio has a higher numerical value, it means that the company operates in a segment of high efficiency. Currently, the ratio is one of the highest among companies in the UAE who manufacture luxury watches. This is summarized in the figure below.

In the case of the Tag Heuer Company, the element of speed has ensured that the company is in a position to meet almost 80% of the market demand despite its small capacity. The company has been able to track the efficiency of its labor and cost of production. Besides, the company has been able to track internal and external variables through its approach of creating a sustainable, dependable, efficient, reliable, and affordable product (Ahmed Sediqqi and Sons, par. 7). In fact, the Tag Heuer’s watch is one of the most affordable globally despite its good quality.

Specifically, Tag Heuer has established a successful operation management model that simultaneously fuses the above aspects into a unit which operate independently but deliver results that are dependent on the success of each process. It is apparent that this company has efficient knowledge and experience in the uniqueness of its watch products in terms of their requirement in order to produce high quality products.

Productivity

Efficiency of the soft skills

The key part of the success puzzle for operations management strategy operates with efficiency of the soft skills involving a timeless vision of organizational principles, defining value of the business, determining requirements, clarifying the vision, building teams, mitigating task, resolving issues, and providing direction. A quality operations strategy system must incorporate these principles in the operations (Jacobs and Chase 19). Moreover, balancing act between having to perform optimally at minimal operation and overhead costs is a component of quality in system modeling. The Tag Heuer’s organizational culture incorporates continuous training and scientific management of the production process from raw materials to the final products.

Efficiency in the value maintenance

Reflectively, relaying information on the success of a production is dependent on operations strategy for value maintenance. In the process of balancing the act, a quality operations management system should be capable of applying the scientific skills in an artistic manner through informed and perfectly framed use of soft skills to address technical aspects of production management. Generally, the Tag Heuer’s quality operations strategy satisfies requirements within the budget and time schedule without disintegrating initial goal projections (Jacobs and Chase 22).

Balance between the short term and long term goals

The success and failure of a business entity are dependent on the effectiveness and quality of the operations management since it determines planned, integration, implementation, and control. In addition, this part should include control procedures and assessment (Jacobs and Chase 26). In order to come up with a viable operating system, the Tag Heuer‘s productivity initiative include quality control, communication with stakeholders, progress measurement, and flexibility in planning to accommodate any eventuality.

Works Cited

Ahmed Sediqqi and Sons: Tag Heuer boutique 2013. Web.

Escrig-Tena, Ana, Juan Bou-Llusar, Inmaculada Beltran & Vincente Roca-Puig. “Modeling the implications of quality management elements on strategic flexibility.” Advances in Decision Sciences, 1.1(2011): 1-27.

Jacobs, Roberts & R. Chase. Loose-leaf Operations and Supply Chain Management. 13th ed. 2010. London, UK: McGraw-Hill Education. Print.

Powell, Thomas. “Total quality management as competitive advantage: a review and empirical study.” Strategic Management Journal, 16.4(2006): 15–37.