Introduction

Transformers are an integral part of transmission systems at power plants. The challenge is to maintain transformers. As modern transformers have a higher tolerance, regular maintenance and testing ensure higher performance and dissipation of risk. Dubai Electricity and Water Authority (DEWA) is a utility company for supplying electricity and water. The power transmission system is an essential part of the company’s operations as it helps to transmit power from generation to distribution.

The transformer is the most important equipment in the transmission system. The transmission system carries electricity to the consumer units with the help of transformers. It assists the system to lower the voltage while transmitting electricity. This increases efficiency and reliability while reducing power loss. Therefore, the proper functioning of the transformers is an essential part to maintain the performance of the power distribution system. This paper asserts that preventive maintenance has a positive impact on the service of transformers.

Literature Review

Assessment of transformers for proper functioning is essential to reduce risk factors of transmitting and power loss. Various models and researches have suggested the best possible method of ascertaining transformer health and maintenance procedures to ensure proper functioning. This section deals with few such kinds of research.

Life Cycle Management

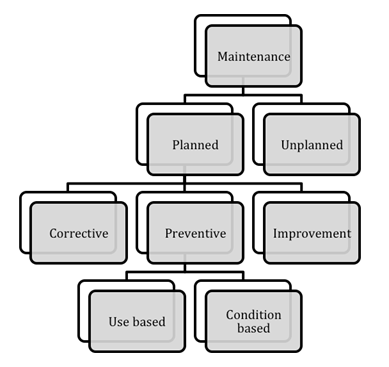

The literature studied can be segregated based on the type of maintenance suggested for transformers. They are as follows – corrective, preventive, and predictive maintenance. Corrective maintenance is done when the transformer breaks down, preventive maintenance is the process of preventive care that is done at regular intervals, and predictive maintenance is done depending on the condition of the transformer (see figure 1). Corrective maintenance essentially implies repair done for a faulty part. However, a transformer malfunction may cause serious damage to the power transmission system and incur huge losses.

Preventive maintenance procedures are usually outlined in the maintenance manual provided by manufacturers. For example, the manual provided by Siemens provides detailed guidelines of the preventive measures such as time-based system maintenance, oiling, greasing, etc. as the best method to prevent breakdown (Siemens 2014, p. 238). However, a better method would be a predictive method of maintenance, which would enable the company to predict the health of the machine and take preventive action accordingly. Hence, preventive and predictive maintenance are complementary measures.

Larson (2015, p. 17) points out that the best way to ensure a longer life-cycle of transformers is to begin a motor reliability program, improving the motor management system, tracking transformer performance, and testing and up-grading transformers. Further, the article also emphasizes the importance of real-time data collection regarding the health of the transformers. This is similar to the maintenance guideline presented by Siemens (2014, p. 238).

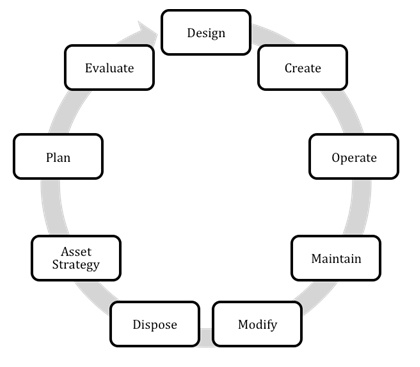

Dlamini (2012, p. 35) points out that to follow a maintenance cycle it is essential to follow two processes – strategic and operational process. The strategic process entails a plan that ensures that the strategic outlook of the company is safeguarded while the operational maintenance ensures that the assets function properly. Dlamini (2012, p. 37) points out that a structured interview of the employees and network users can also provide essential information regarding the life-cycle maintenance of transformers. He points out that the life-cycle maintenance process should be holistic and not partial. Based on the literature review, the life cycle assessment of transformers can be shown in the following diagram (see figure 2).

Bartley (2002, p. 6) points out that that the three main steps for life cycle transformer management are – risk assessment, condition assessment, and life cycle decisions. The life cycle decision assessment is a new point added to the already prevailing risk assessment and preventive measure. This entails understanding the condition of the transformer and if it should be retired, refurbished, replaced, or relocated. Further, Chacon, Taledo, Fritoli, and Ito (2015, p. 4) points out that online transformer monitoring can be a helpful solution for real-time assessment of asset health.

Power Company

Siemens uses in-built monitors in their transformers that provide valuable data regarding the health of the transformer. Such information includes gas-in-oil analysis, thermal parameters, and cooling performance (Siemens 2014, p. 235). Apart from the manufacturer guidelines, a vast body of academic literature has developed regarding the preventive and predictive maintenance of transformers. The following section deals with a few such research findings.

In order to understand the maintenance required by transformers, it is important to understand its different kinds of transformers. A transformer does not have any internal part that moves as it transfers electricity from one circuit to the other by electromagnetic induction (U.S. Department of the Interior Bureau of Reclamation 2005). Transformers are divided into two categories based on the change in voltage transmitted – power and distribution transformers.

Power transformers are larger, that is filled with oil for insulation and cooling (U.S. Department 2005). As these transformers are filled with a large quantity of oil, it is essential to monitor for leakages, spills, fires, and other environmental risks (U.S. Department 2005). It has already been established that predictive maintenance is complementary to predictive maintenance (Preventive and Predictive Maintenance 2017, p. 4).

Establishing a system that adopts both the maintenance methods ensures a reduction in the total cost of maintenance, fewer emergency repair work, reduces the labor force for the maintenance work is pre-planned, and reduces preventable damage of the machine (Preventive and Predictive Maintenance 2017, p. 4). The predictive-preventive maintenance system can be established by first understanding the basic cost of maintenance of malfunctioning transformers, knowledge of equipment, and the conditions necessary to optimize output, safety, and yield (Preventive and Predictive Maintenance 2017, p. 7).

Cost Management

Karlsson (2007, p. 5) assess the cost of interruption of transmission service and the cost of equipment damage. Using game theory, the article develops a cost-effective maintenance plan that helps to restore the operational capability of the equipment. The paper does a cost-based analysis of the failure model and tests the reliability of the asset. Thus, the paper aims to understand machine reliability vis-à-vis maintenance costs.

Westman, Lorin, and Ammann (2011, p. 64) point out that the maintenance of transformers is essential as many of the transformers in use throughout the world are old. They point out that if the problems faced by the transformers are detected at an early stage, it helps in repair and reduce the cost of maintenance by 75 percent. The huge cost of repair for power transformers is the main incentive for power companies to take predictive and preventive measures of maintenance through the life cycle of the asset. The financial impact of transformer failure is so great that it becomes essential to enforce strict measures for its maintenance.

Transformer monitoring and data regarding its health are two essential resources necessary for maintaining a proper functioning asset (Westman, Lorin & Ammann 2011, p. 64). The monitoring system entails real-time data of the temperature of the transformer that is collected with the help of sensors measuring the dissolved gases, moisture in oil, and oil temperature (Westman, Lorin & Ammann 2011, p. 65). Agnostic tests are performed to assess the principal properties of the transformer that includes mechanical, thermal, and electrical status. This helps to determine the load level of the transformer and how these should be altered to improve its lifetime.

Annotated Bibliography

Aim

The aim is to understand the effectiveness of the article “Optimization of maintenance for power system equipment using a predictive health model” written by Bajracharya et al. (2013, p. 3) to address the issue of maintenance for power systems.

Summary

The article presents a model for predictive control based on the state of health of the power system. It presents a predictive model that shows the health of the equipment that is based on the usage and maintenance of the transformer. The article proposes the use of predictive maintenance in order to understand the effects of the outcome of the different maintenance procedures. The model uses a dynamic maintenance action model that is evaluated by a cost function.

It uses a cost function to optimize the maintenance of the equipment. The framework proposed by the model optimizes the loading transformers based on the dilapidation of the thermal insulation. Since the loading of the transformer affects machine temperature, it is considered as planned usage. The model helps to calculate the dynamic stress on the machine for a year. However, the article does not consider insulation degradation as a risk to the machine life cycle.

The authors argue that as insulation degradation causes negligible failure, it is not a necessary factor for change. However, the paper concludes that insulation degradation may affect the end of the operating life of the transformer. The article devices a linear cost function to show the optimum cost of aging equipment. The factors affecting cost are temperature with respect to a reference temperature. However, the cost could have been affected by other varying reasons, which the paper does not consider.

Evaluation

The model is a cost-based assessment of predictive health of power system equipment. The article shows that the model is applicable to most of the power system equipment. It assures that the model helps to predict the age of the equipment. This is expected to help the health of the equipment vis-à-vis loading of transformers. However, the model does not look at distribution optimization and problem-solving and hence, does not provide effective system-wide results. Further, the article does not consider insulation degradation as a plausible factor for the failure model as they believe its effect on the transformer failure is low.

Conclusion

The article presents a model to understand the health of equipment based on the optimization of the temperature. The aim of the article is to understand how temperature variation may affect the optimum operating life of a transformer. This is done using models on operating life, calculating a linear equation for cost, and optimum usage with minimum cost. This ideally presents the optimized operating life at minimum maintenance cost, but the model does not consider many of the vital factors that may affect the operation of the equipment such as insulation degradation.

Reference List

Bajracharya, G, Koltunowicz, T, Negenborn, RR, Papp, Z, Djairam, D, Schutter, BD & Smit, JJ 2013, ‘Optimization of maintenance for power system equipment using a predictive health mode’, Technical Report, Delft University of Technology.

Bartley, WH 2002, ‘Life Cycle Management of Utility Transformer Assets’, Breakthrough Asset Management for the Restructured Power Industry, Salt Lake City, Utah, pp.. 2-17.

Chacon, LBS, Toledo, MA, Fritoli, LP & Ito, HTB 2015, Predictive Technology in the Johnson&Johnson Power Transformer. Web.

Dlamini, MA 2012, ‘Transformer maintenance at Swaziland Electricity Company (SEC): a critical investigation’, Master Thesis, University of Pretoria, Pretoria.

Karlsson, S 2007, ‘A review of lifetime assessment of transformers and the use of Dissolved Gas Analysis’, Master Thesis, KTH School of Electrical Engineering, Stockholm.

Larson, A 2015, ‘Electric Motor and Transformer Maintenance Best Practices’, Power, 2015, p. 13.

Preventive and Predictive Maintenance. 2017. Web.

Siemens 2014, Power Engineering Guide – Siemens, Siemens. Web.

U.S. Department of the Interior Bureau of Reclamation 2005, Transformers: Basics, Maintenance, and Diagnostics, Books Express Publishing, Denver.

Westman, T, Lorin, P & Ammann, PA 2011, ‘Fit at 50 – Keeping Aging Transformers Healthy for Longer’, Asset Management & Maintenance Journal, vol. 24, no. 2, pp. 63-69.