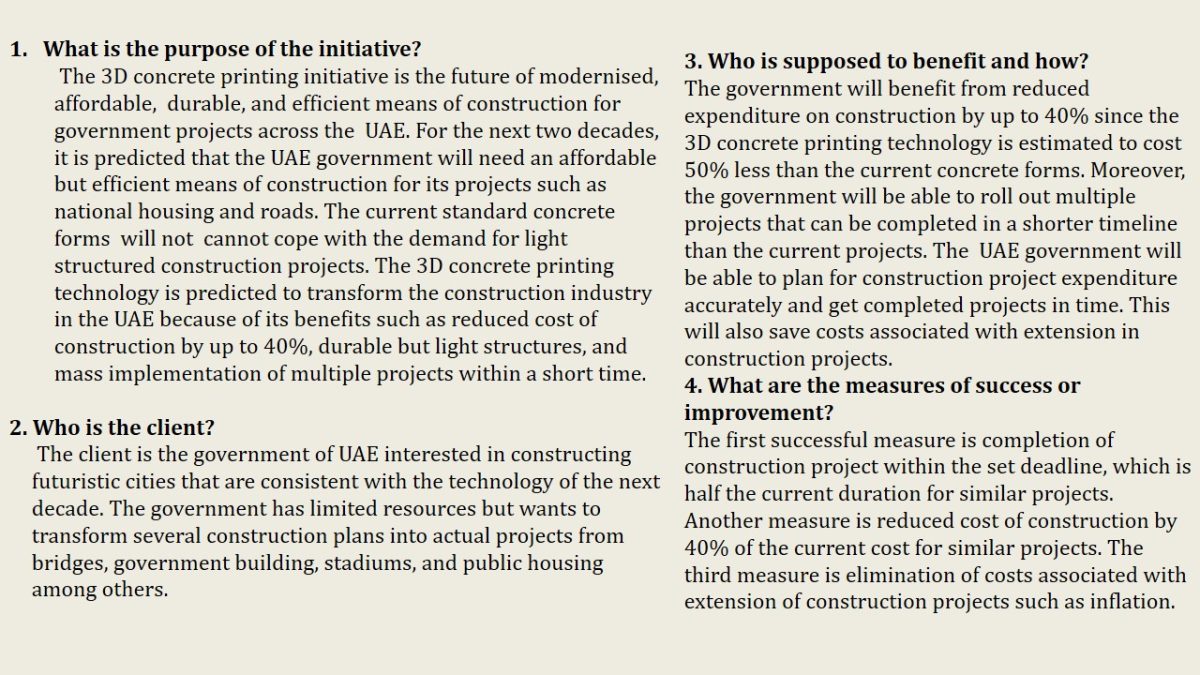

What is the purpose of the initiative?

The 3D concrete printing initiative is the future of modernised, affordable, durable, and efficient means of construction for government projects across the UAE. For the next two decades, it is predicted that the UAE government will need an affordable but efficient means of construction for its projects such as national housing and roads. The current standard concrete forms will not cannot cope with the demand for light structured construction projects. The 3D concrete printing technology is predicted to transform the construction industry in the UAE because of its benefits such as reduced cost of construction by up to 40%, durable but light structures, and mass implementation of multiple projects within a short time.

Who is the client?

The client is the government of UAE interested in constructing futuristic cities that are consistent with the technology of the next decade. The government has limited resources but wants to transform several construction plans into actual projects from bridges, government building, stadiums, and public housing among others.

Who is supposed to benefit and how?

The government will benefit from reduced expenditure on construction by up to 40% since the 3D concrete printing technology is estimated to cost 50% less than the current concrete forms. Moreover, the government will be able to roll out multiple projects that can be completed in a shorter timeline than the current projects. The UAE government will be able to plan for construction project expenditure accurately and get completed projects in time. This will also save costs associated with extension in construction projects.

What are the measures of success or improvement?

The first successful measure is completion of construction project within the set deadline, which is half the current duration for similar projects. Another measure is reduced cost of construction by 40% of the current cost for similar projects. The third measure is elimination of costs associated with extension of construction projects such as inflation.

What forms of knowledge and expertise will need to be consulted?

- The knowledge needed is the technology of printing concrete forms into viable slabs or blocks for building (Lester 34).

- The expertise needed include civil engineering knowledge, structural competency, land economics experts, and 3D printing information technology experts.

- The is also a need for architectural expertise in the design to guarantee structural integrity of the projects at hand (Dykstra 19).

What resources will be needed to implement the initiative?

- 3D Printers.

- Concrete mixers.

- Cement, sand, gravel, and limestone.

- Technologically advanced factory.

- Investment of about $1 billion.

Who controls these resources?

- The 3D printers will be controlled by a trained IT expert with support from civil and architectural professionals (Ramos).

- The regulation of materials to use in 3D printing will be done by the civil engineer with assistance from the land economist (Lipson and Kurman 27).

- The approval of final concrete block will be done by the structural expert alongside the project manager.

- Allocation of funds will be done by the project accountant in consultation with the project manager.

- The experts in different fields will be part of the project supervisors.

What is the timeframe for planning, implementation and evaluation?

- The time frame is twelve months.

- First three months is planning.

- Second three months is for piloting.

- Last six months is for implementation and evaluation.

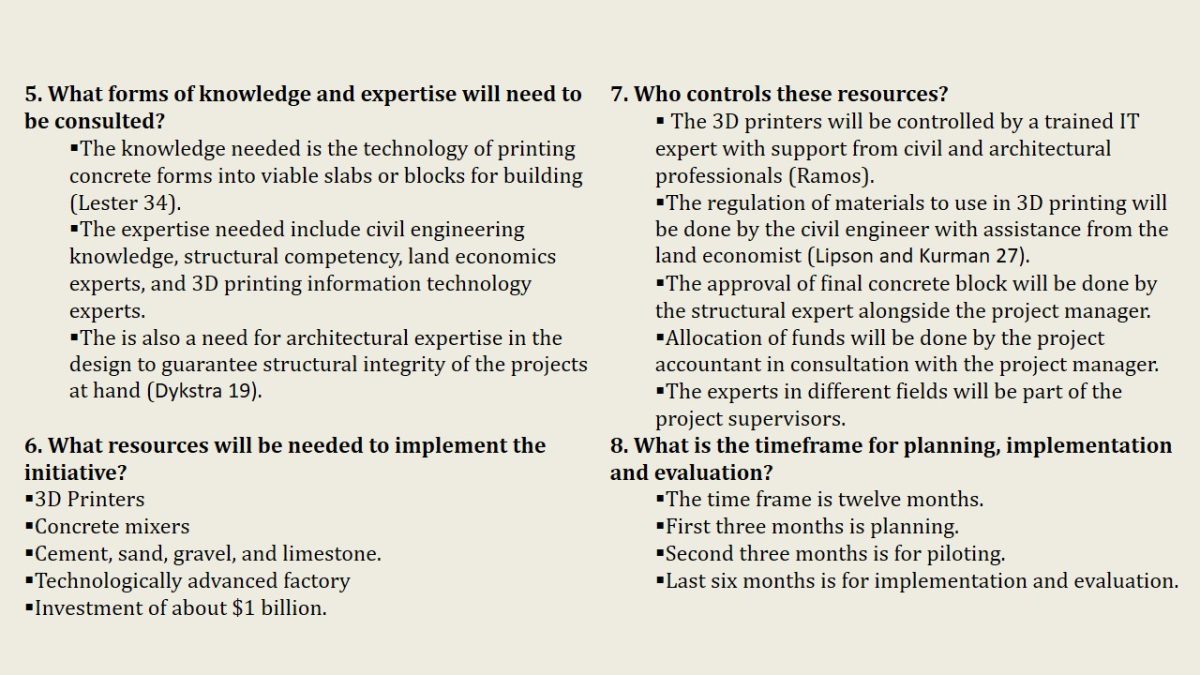

Research Futures Trends and Drivers

Trends occurring related to the UAE.

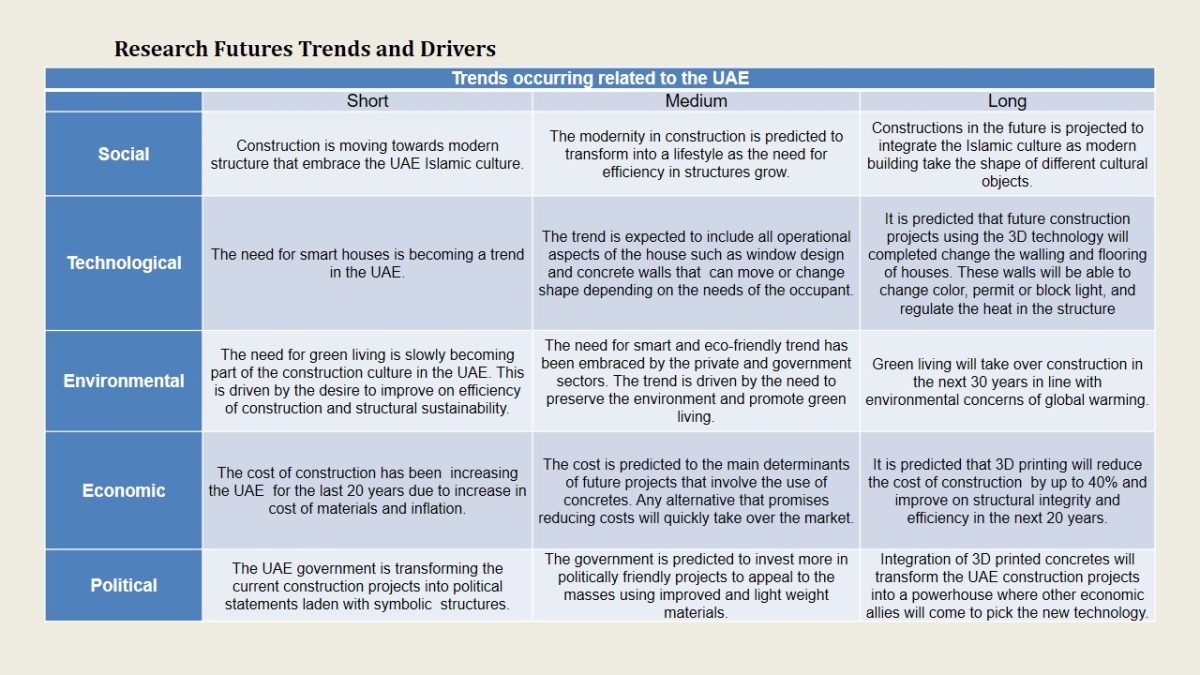

Trend Impact Analysis

Trend: Shift to 3D printed concrete in construction of government projects.

Impact Over 1-5 yrs:

- Reduced cost of construction by 20%.

- Increase in smart concrete structures by 5% as more project embrace the 3D technology.

- Improvement of green structures by 10%.

- Improved efficiency in construction by 10% as structures become light weight and stronger.

Impact Over 6-10 yrs:

- Reduced cost of construction by 35%.

- Increase in smart concrete structures by 15% as more project embrace the 3D technology.

- Improvement of green structures by 20%.

- Improved efficiency in construction by 15% as structures become light weight and stronger.

Impact Over 10+ yrs:

- Reduced cost of construction by 45-50% due to economies of scale

- Increase in smart concrete structures by 35% and above as more project embrace the 3D technology.

- Improvement of green structures by 35% and above.

- Improved efficiency in construction by 40% as structures become light.

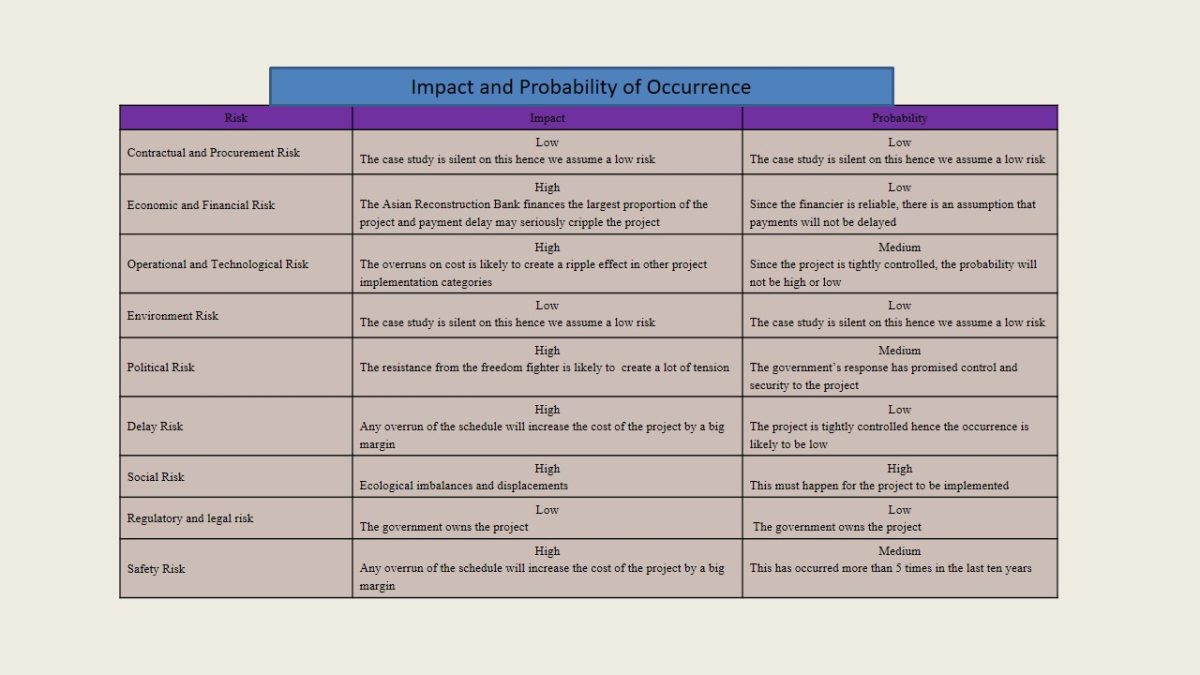

Impact and Probability of Occurrence

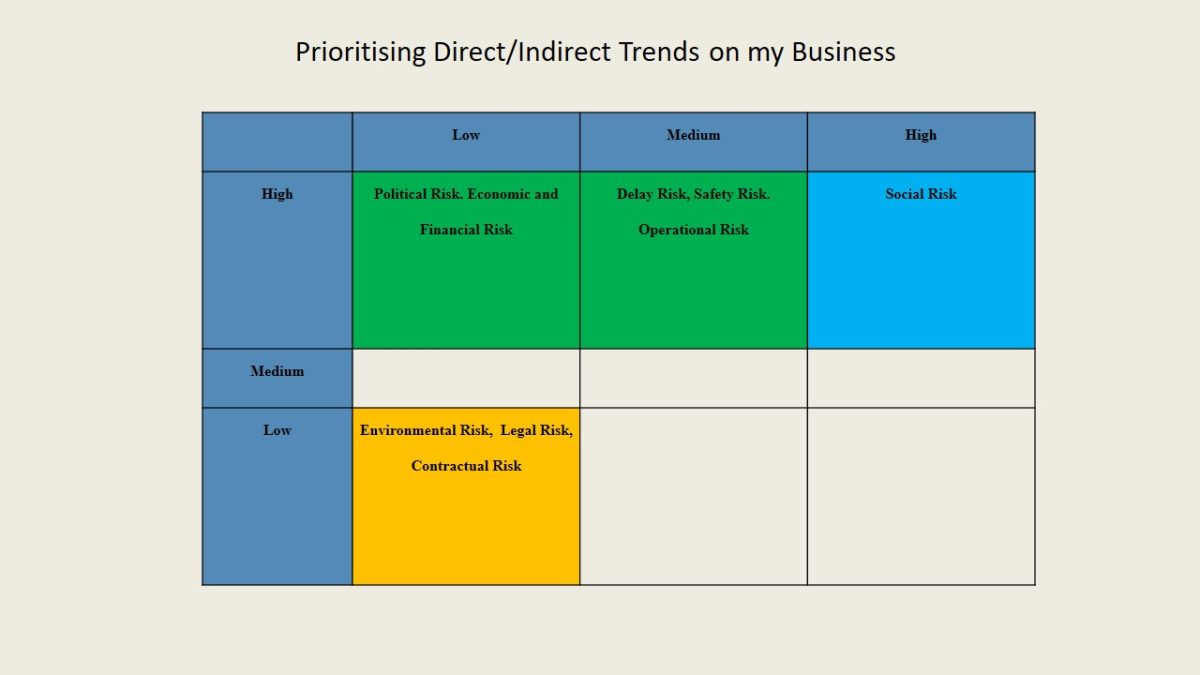

Prioritising Direct/Indirect Trends on my Business

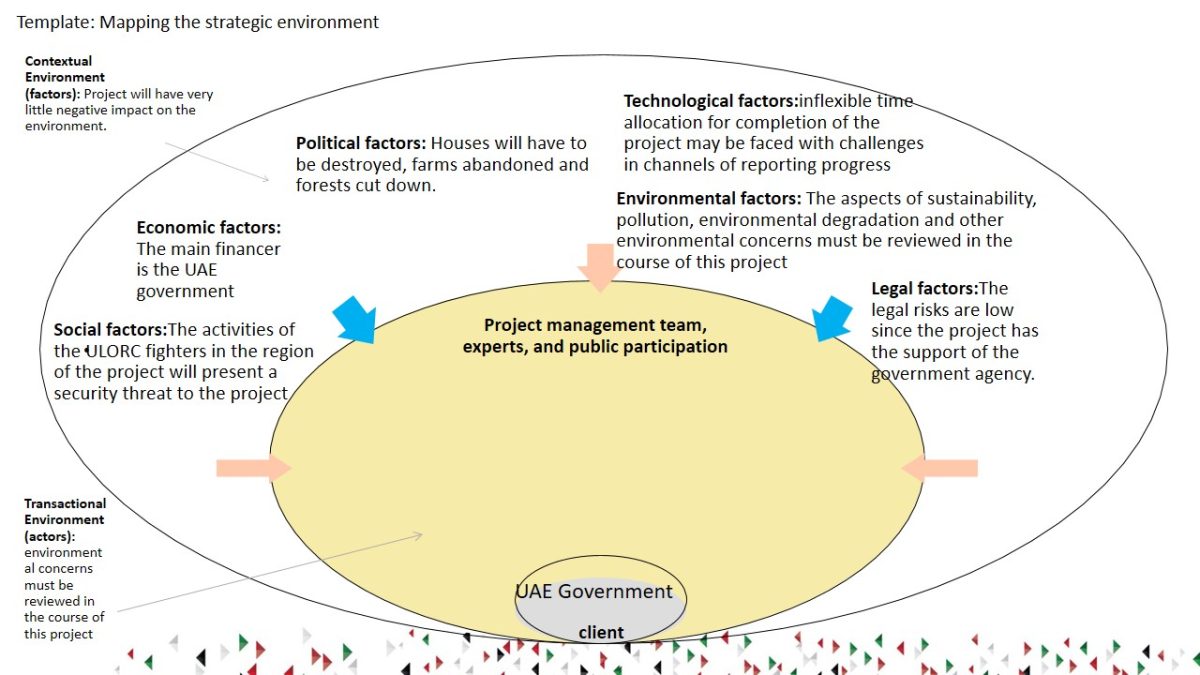

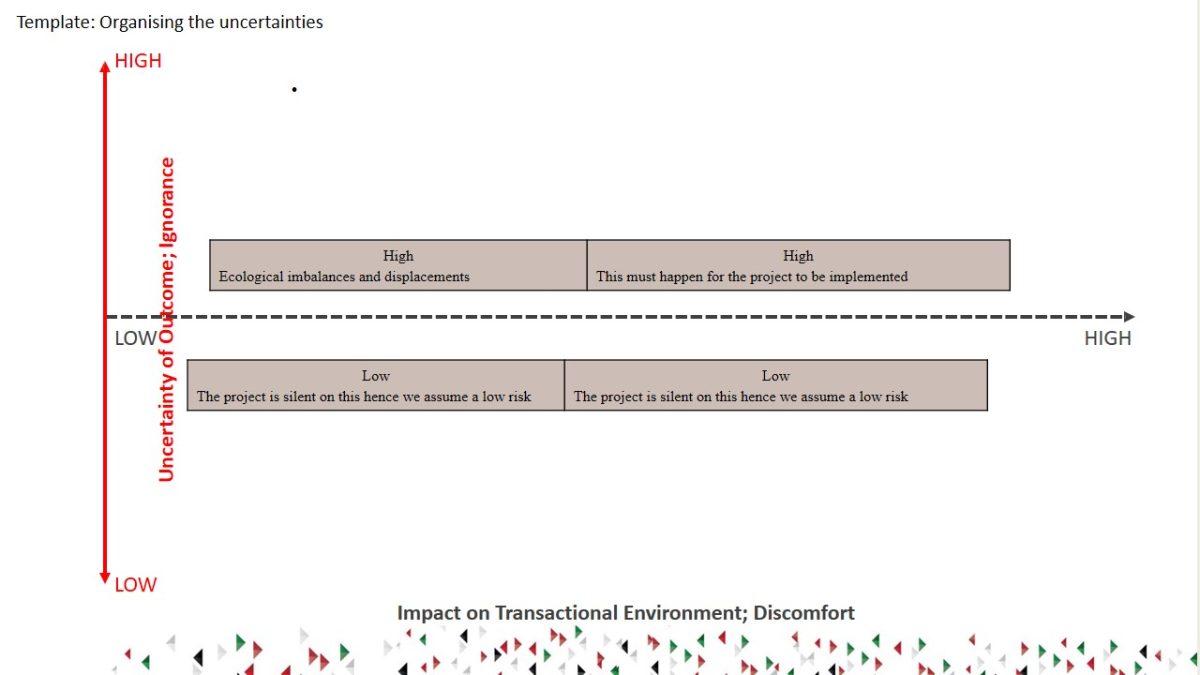

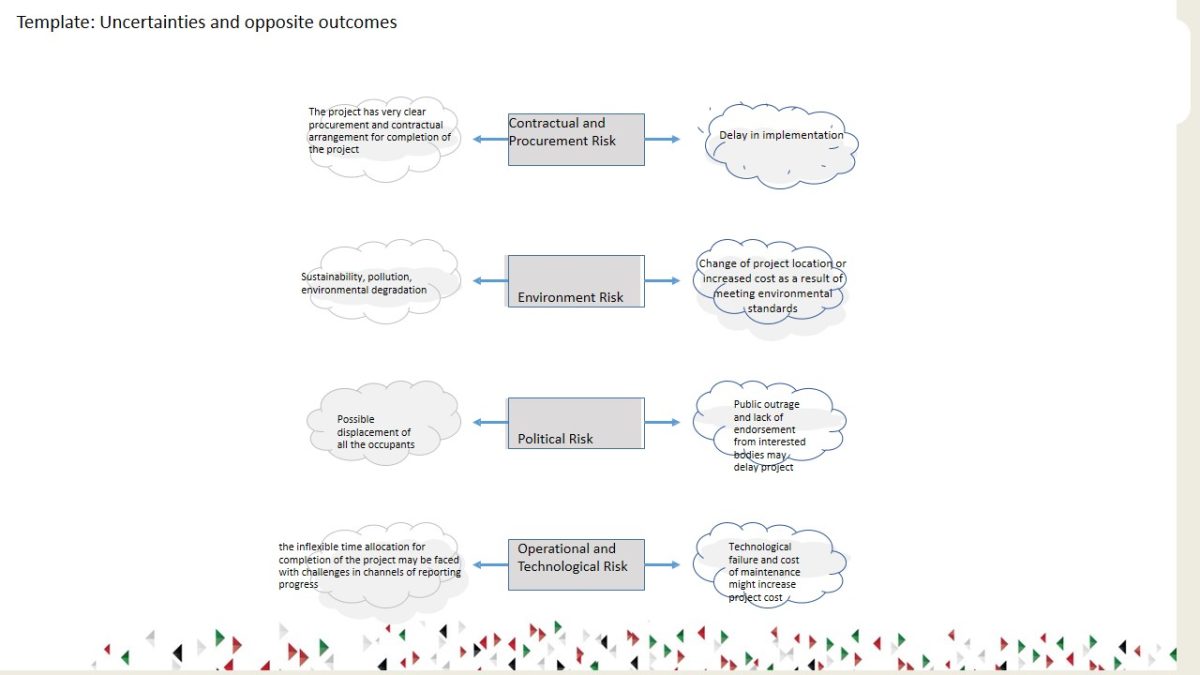

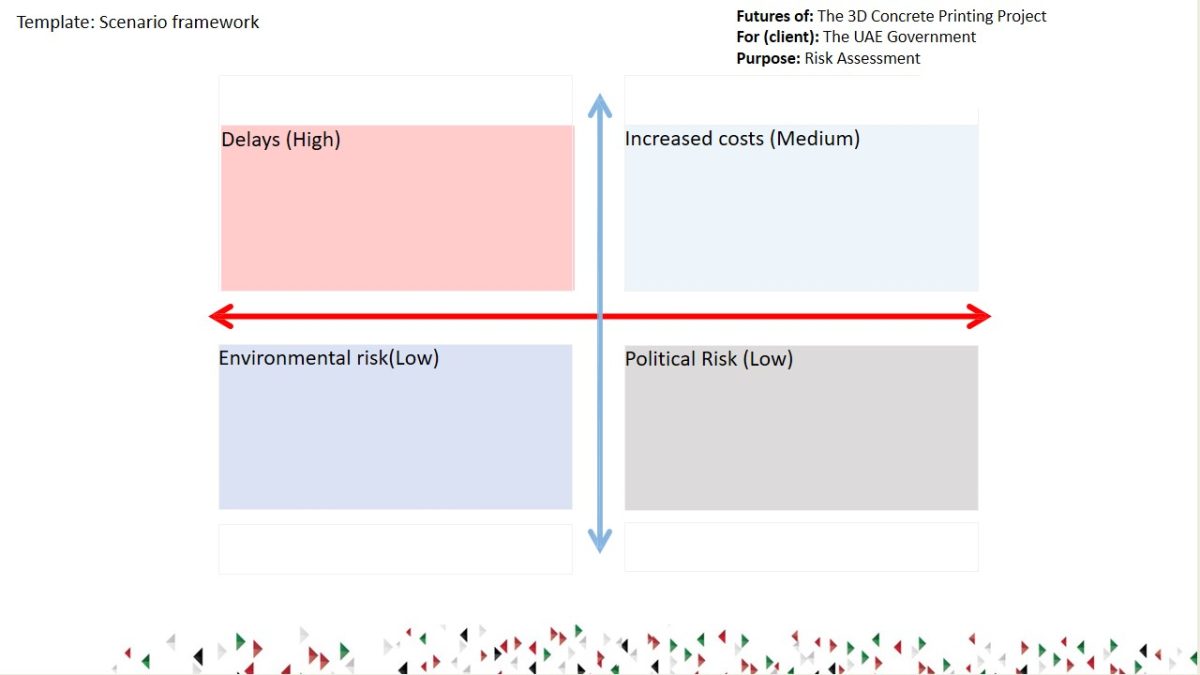

Template: Uncertainties and opposite outcomes

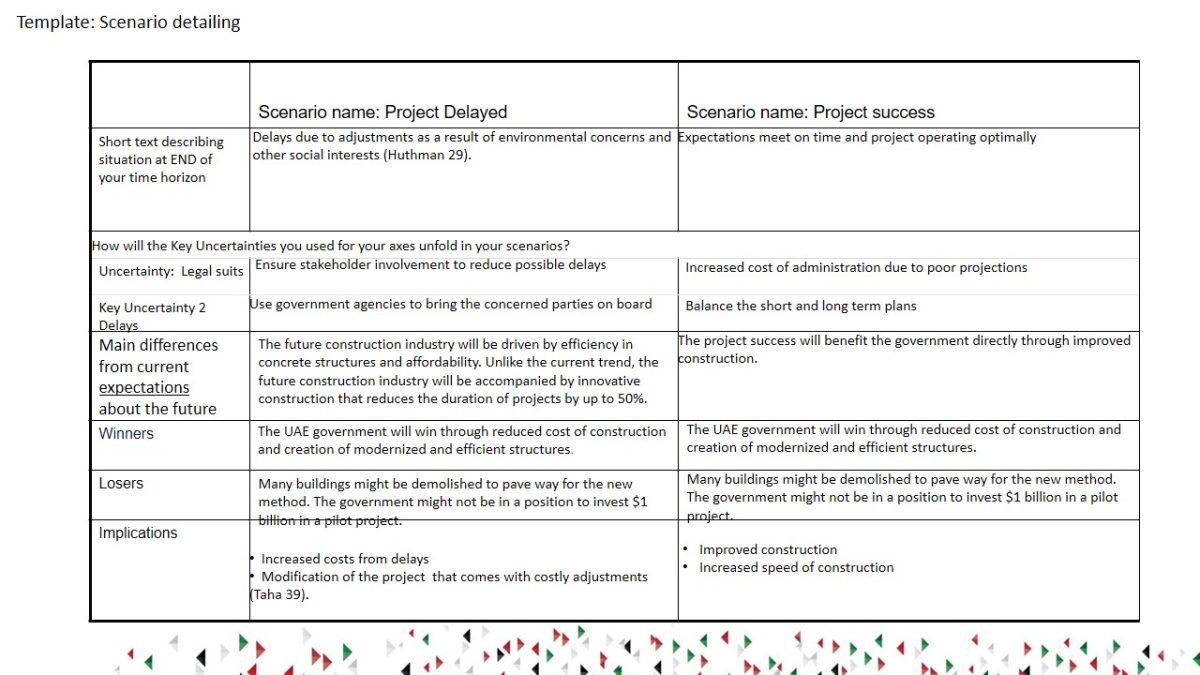

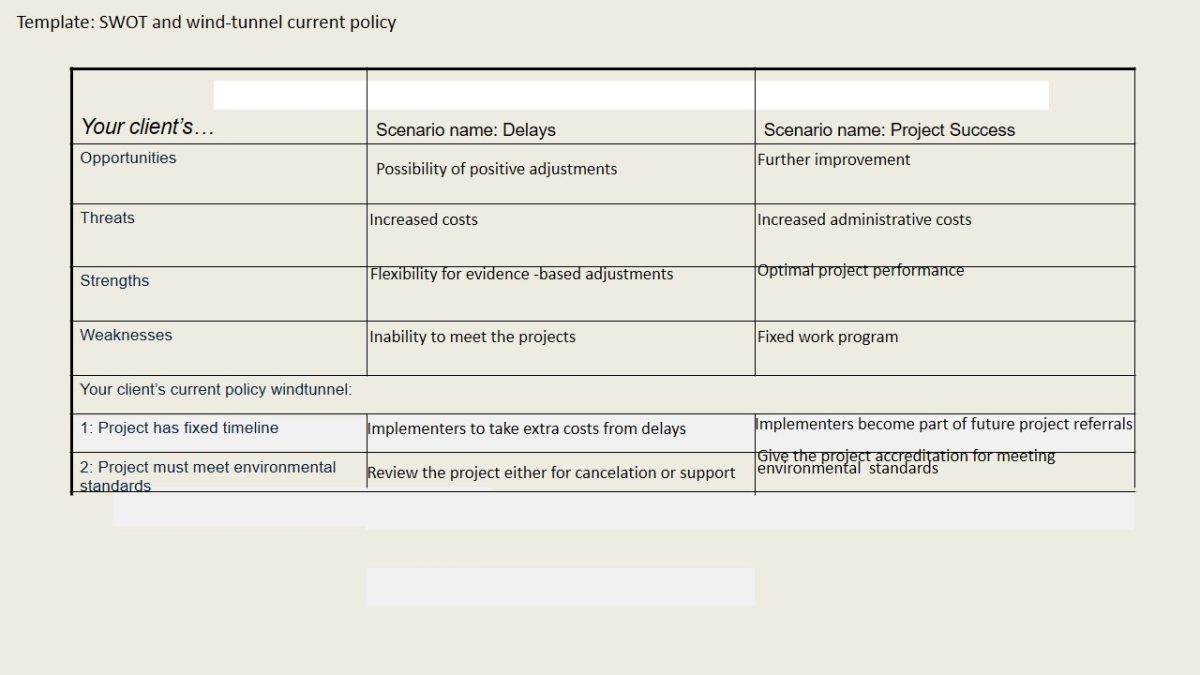

Contractual and Procurement Risk:

- The project has very clear procurement and contractual arrangement for completion of the project.

- Delay in implementation.

Environment Risk:

- Sustainability, pollution, environmental degradation.

- Change of project location or increased cost as a result of meeting environmental standards.

Political Risk:

- Possible displacement of all the occupants.

- Public outrage and lack of endorsement from interested bodies may delay project.

Operational and Technological Risk:

- the inflexible time allocation for completion of the project may be faced with challenges in channels of reporting progress.

- Technological failure and cost of maintenance might increase project cost.

Works Cited

Dykstra, Alison. Construction Project Management: A Complete Introduction. Kirshner Publishing Company, 2018.

Huthman, Ibrahim. 3D Printing for Prestressed Concrete. Ohio University, 2017.

Lester, Albert. Project Management, Planning and Control: Managing Engineering, Construction and Manufacturing Projects to PMI, APM and BSI Standards. 6th ed., Butterworth-Heinemann, 2013.

Lipson, Hod and Melba Kurman. Fabricated: The New World of 3D Printing. John Wiley & Sons, 2013.

Ramos, Jose. “Futures Action Model for Policy Wind Tunneling”. Action Foresight. 2017. Web.

Taha Mahmoud M. Reda, editor. International Congress on Polymers in Concrete (ICPIC 2018): Polymers for Resilient and Sustainable Concrete Infrastructure. Springer, 2018.